Device and method for preparation of liquid smoke and co-production of activated carbon by pyrolysis of Chinese hawthorn seeds

A technology of activated carbon and smoke liquid, applied in the field of biomass resource utilization, can solve the problems of lack of technology and system for comprehensive utilization of pyrolysis products polygeneration, achieve significant economic benefits, high medical value, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

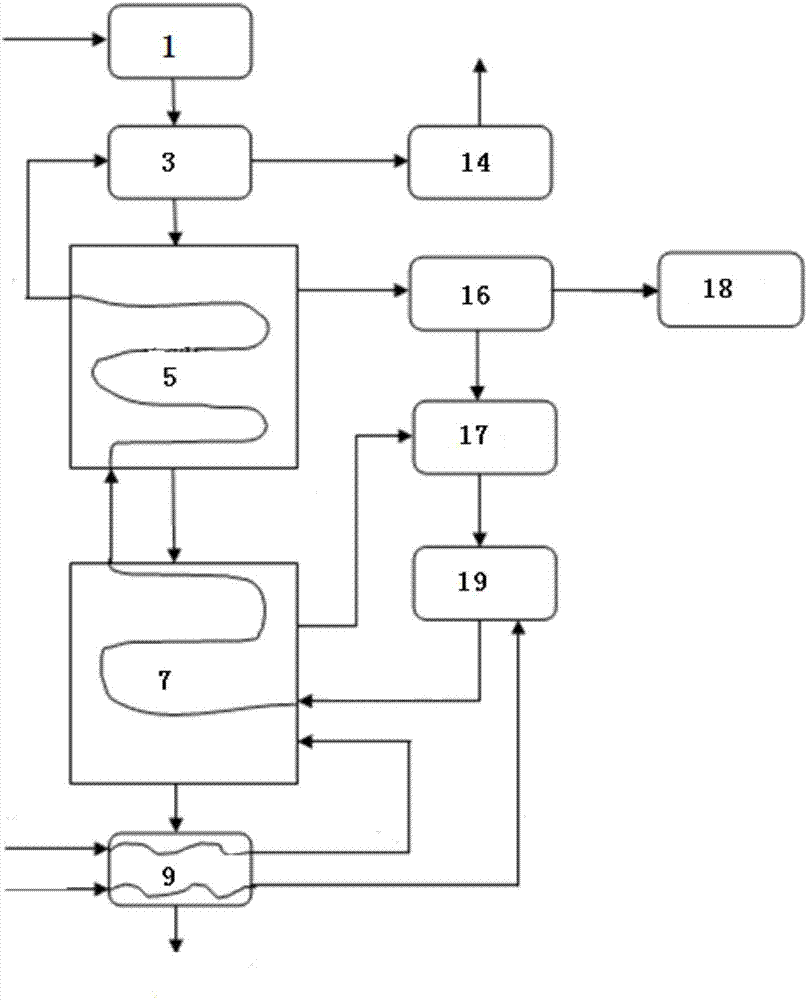

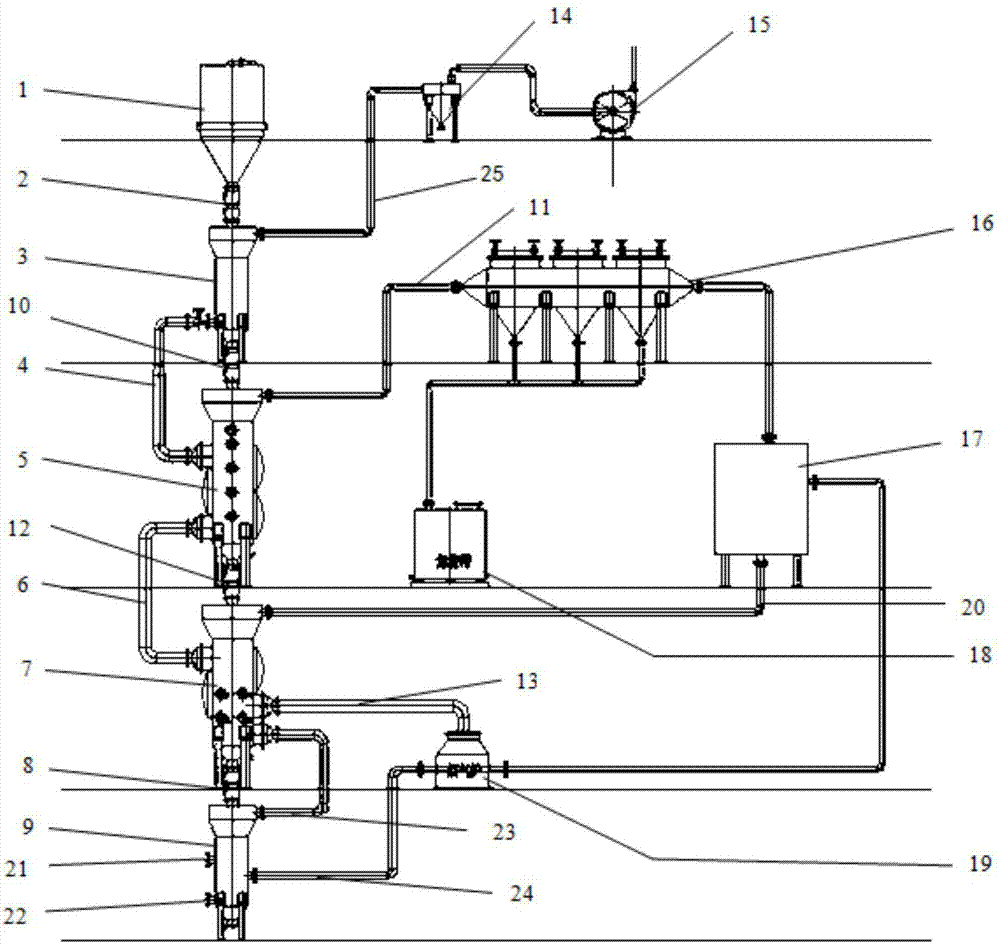

[0052] The present invention is described in detail as follows in conjunction with accompanying drawing:

[0053] Such as figure 2 As shown, the biomass pyrolysis device of the present invention for preparing smoked liquid and co-producing activated carbon comprises a feed hopper 1, a drying chamber 3, a pyrolysis furnace 5, an activation furnace 7, a discharge sealing tank 9, a 14, exhaust fan 15, three-stage condenser 16, gas cabinet 17, liquid collector 18, burner 19, low temperature flue gas pipeline 4, high temperature flue gas pipeline 6, pyrolysis gas pipeline 11, flue gas channel 13, activation Gas pipeline 20, normal temperature water cooling pipeline 21, normal temperature air cooling pipeline 22, high temperature water vapor pipeline 23, high temperature air pipeline 24, flue gas outlet pipeline 25, the feed hopper 1 passes through the material inlet of the drying chamber 3 and the pyrolysis furnace 5 The semi-coke outlet of the lower part of the pyrolysis furnace...

Embodiment 2

[0060] The device described in Example 1 was used to realize biomass pyrolysis polygeneration.

[0061] Step 1, the hawthorn core (moisture content is 15%) is sent into the pyrolysis reaction furnace 3 through the hopper 1, and the feed rate is 500kg / h;

[0062] Step 2. Control the reaction temperature of the drying furnace to be 200° C., the solid phase residence time to be 20 minutes, and the dry material to fall vertically into the pyrolysis furnace, and the feed rate is about 400 kg / h (moisture content is 5%);

[0063] Step 3. Control the pyrolysis reaction temperature to 500°C. The high-temperature pyrolysis gas phase product is passed into a three-stage condenser, and after condensation, a liquid product and a non-condensable combustible gas are obtained. The yields are 160kg / h and 80kg / h respectively, and the combustible gas The flow rate entering the burner is 80kg / h, and the combustible gas of 80kg / h is burned in the burner under the working condition of excess air co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com