Method and device for recycling W and V from waste flue gas denitration catalyst

A denitrification catalyst and waste flue gas technology, applied in the direction of improving process efficiency, etc., can solve problems such as unsuitable for industrial production, high energy consumption, waste of reagents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

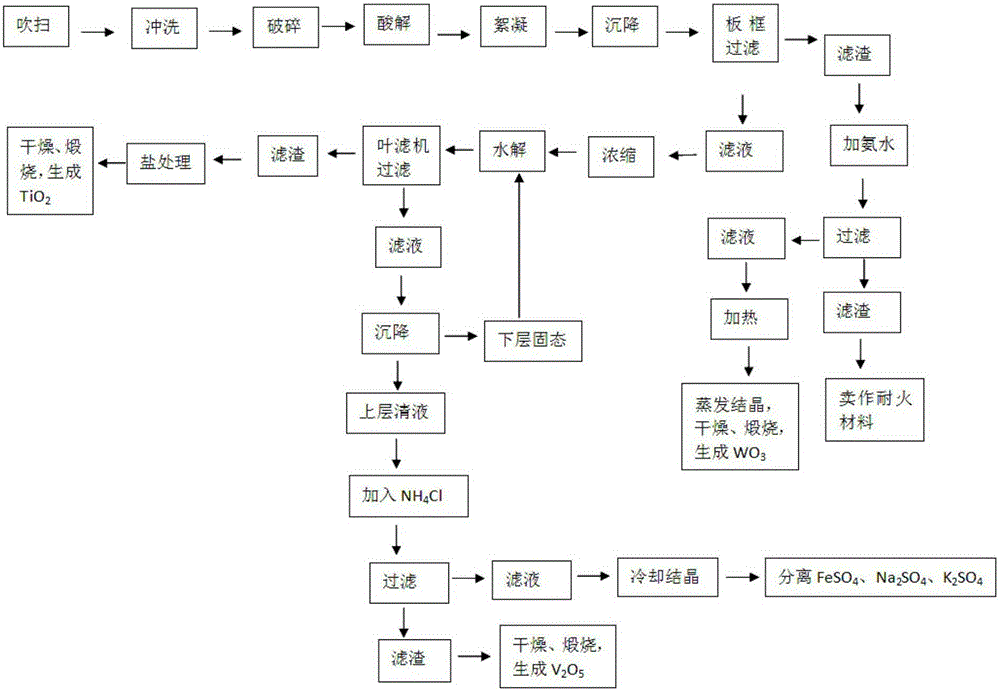

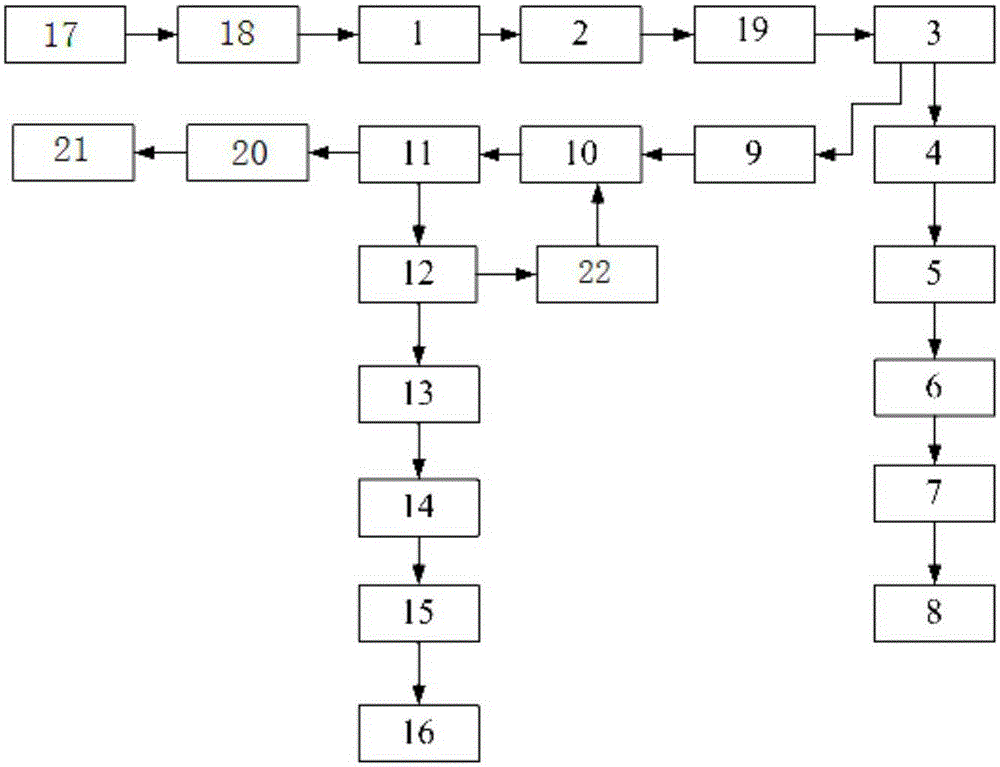

[0053] Embodiment 1 of the present invention: a method for recovering W and V from waste flue gas denitrification catalyst, such as figure 1 shown, including the following steps:

[0054] S01, blow the waste flue gas denitrification catalyst with compressed air for 20-23 minutes for each module to remove the dust in the channel;

[0055] S02, use a high-pressure water gun to flush the catalyst after dust removal, the flushing time of each module is 15-20min, and the pressure is 8-12Mpa, to further remove the dust in the channel;

[0056] S03, drying the washed catalyst;

[0057] S1, pulverizing the catalyst and adding concentrated sulfuric acid for acidolysis, adding water after acidolysis to obtain a titanyl sulfate solution; specifically including the following steps:

[0058] S11, crushing the catalyst into catalyst powder of 160-180 mesh;

[0059] S12, put the catalyst powder into the acid hydrolysis tank made of lead, add 88%-90% concentrated sulfuric acid according to t...

Embodiment 2

[0068] Embodiment 2: a kind of method that reclaims W and V from waste flue gas denitrification catalyst, such as figure 1 shown, including the following steps:

[0069] S01, blow the waste flue gas denitrification catalyst with compressed air, and blow each module for 15-20 minutes to remove the dust in the channel;

[0070] S02, use a high-pressure water gun to flush the catalyst after dust removal, the flushing time of each module is 20-25min, and the pressure is 5-8Mpa, to further remove the dust in the channel;

[0071] S03, drying the washed catalyst;

[0072] S1, pulverizing the catalyst and adding concentrated sulfuric acid for acidolysis, adding water after acidolysis to obtain a titanyl sulfate solution; specifically including the following steps:

[0073] S11, crushing the catalyst into 180-200 mesh catalyst powder;

[0074] S12, put the catalyst powder into a lead-made acidolysis tank, add 85% to 88% concentrated sulfuric acid according to the weight ratio of ca...

Embodiment 3

[0083] Embodiment 3: a kind of method that reclaims W and V from waste flue gas denitrification catalyst, such as figure 1 shown, including the following steps:

[0084] S01, blow the waste flue gas denitrification catalyst with compressed air for 23 to 30 minutes for each module to remove the dust in the tunnel;

[0085] S02, use a high-pressure water gun to flush the catalyst after dust removal, the flushing time of each module is 25-30min, and the pressure is 7-10Mpa, to further remove the dust in the channel;

[0086] S03, drying the washed catalyst;

[0087] S1, pulverizing the catalyst and adding concentrated sulfuric acid for acidolysis, adding water after acidolysis to obtain a titanyl sulfate solution; specifically including the following steps:

[0088] S11, pulverizing the catalyst into 190 mesh catalyst powder;

[0089] S12, put the catalyst powder into a lead-made acidolysis tank, add 90% to 92% concentrated sulfuric acid according to the weight ratio of cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com