Exhaust corrugated fire retardance purifier of mining diesel engine

A technology for purification devices and diesel engines, which is applied in exhaust devices, mufflers, mechanical equipment, etc., can solve problems such as large exhaust resistance and exhaust gas pollution, and achieve low exhaust resistance, reduced CO concentration, and improved fuel economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

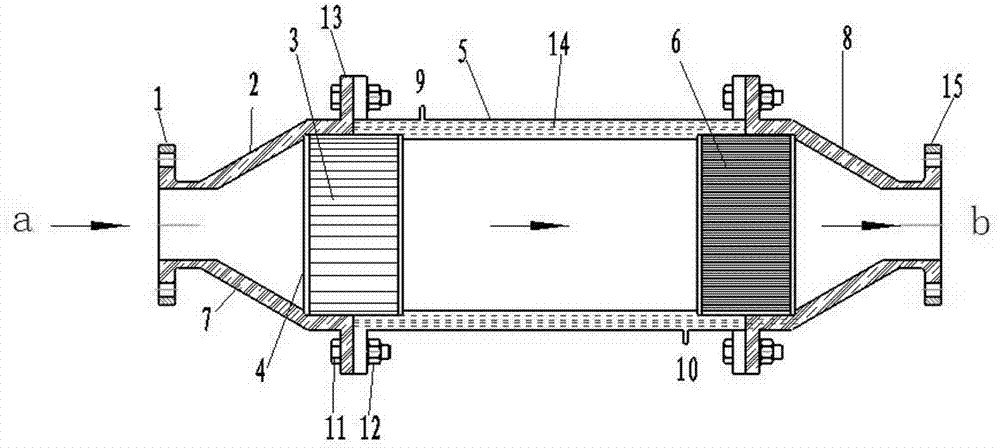

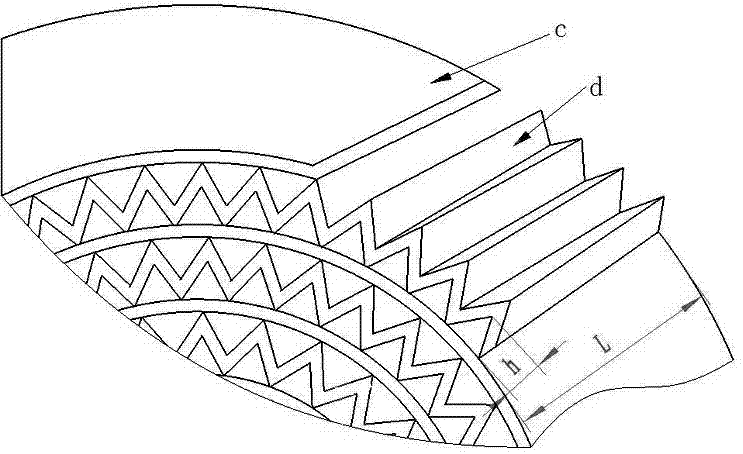

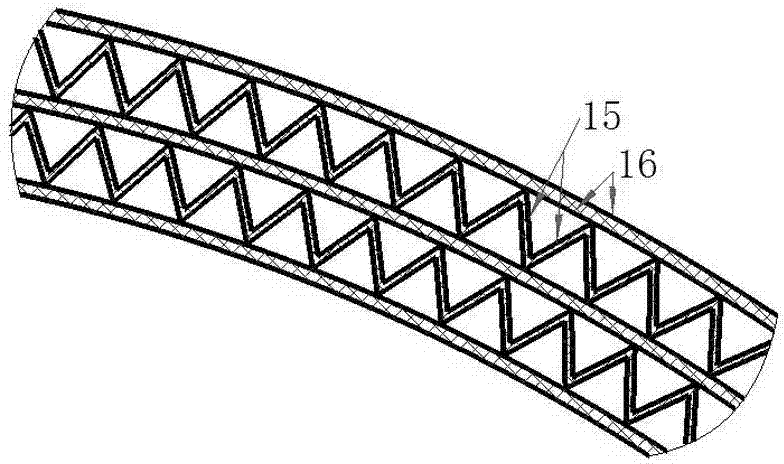

[0015] The exhaust corrugated fire arresting and purifying device for mining diesel engine includes: a pipe flange 1, a front housing 2, a middle housing 5, a rear housing 8, a corrugated catalytic purification layer 3, a corrugated fire arresting layer 6 and a gasket 4. The device of the present invention is connected behind the exhaust manifold of the mining explosion-proof diesel engine, and the pipe flange 1 is connected with the outlet flange of the exhaust manifold, and the pipe flange 1 and the front housing 2 are welded as one. The temperature is 400-500°C. In order to ensure that the outer surface temperature of the shell does not exceed 150°C and at the same time ensure the activity of the corrugated catalytic purification layer 3, the interlayer of the front shell 2 is equipped with heat-insulating aluminum silicate wool 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com