Photocatalytic degradation device for copper slag pollutants and using method thereof

A technology of pollutants and photocatalysis, applied in chemical instruments and methods, chemical/physical/physicochemical processes of energy application, chemical/physical/physicochemical processes, etc., can solve the problem of increasing catalytic time, reducing catalytic efficiency, and sealing performance Poor and other problems, to achieve the effect of fast mixing efficiency, ensure stability, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

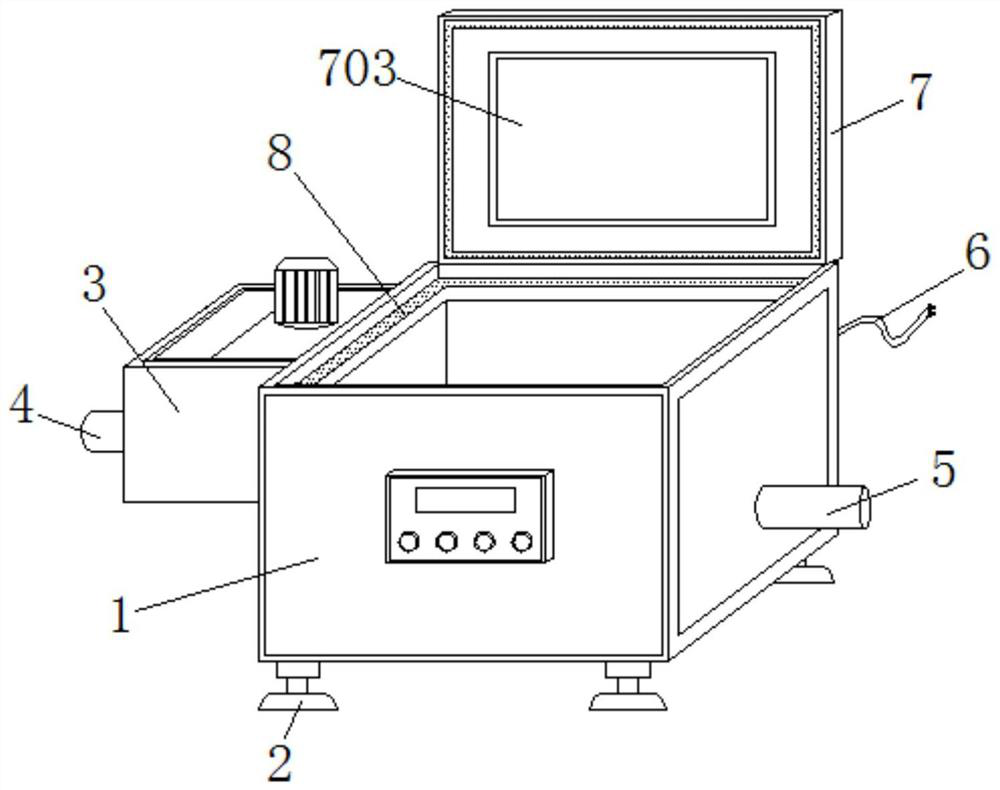

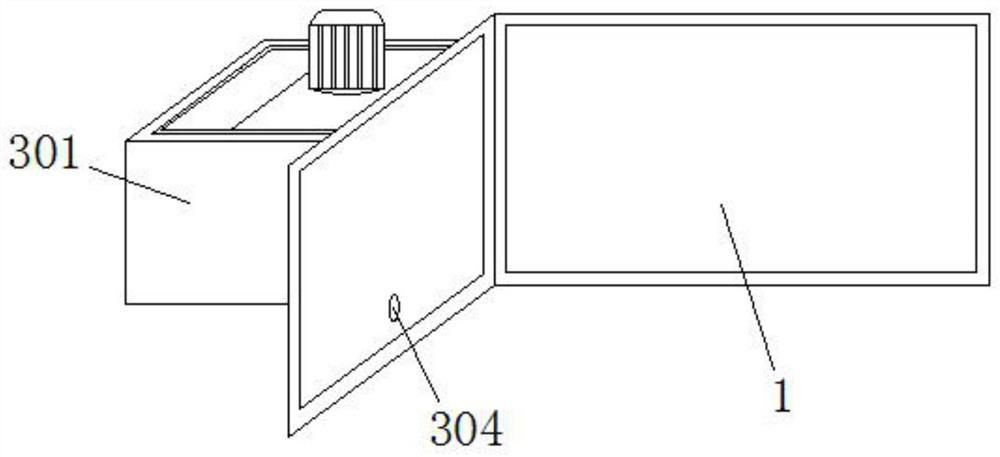

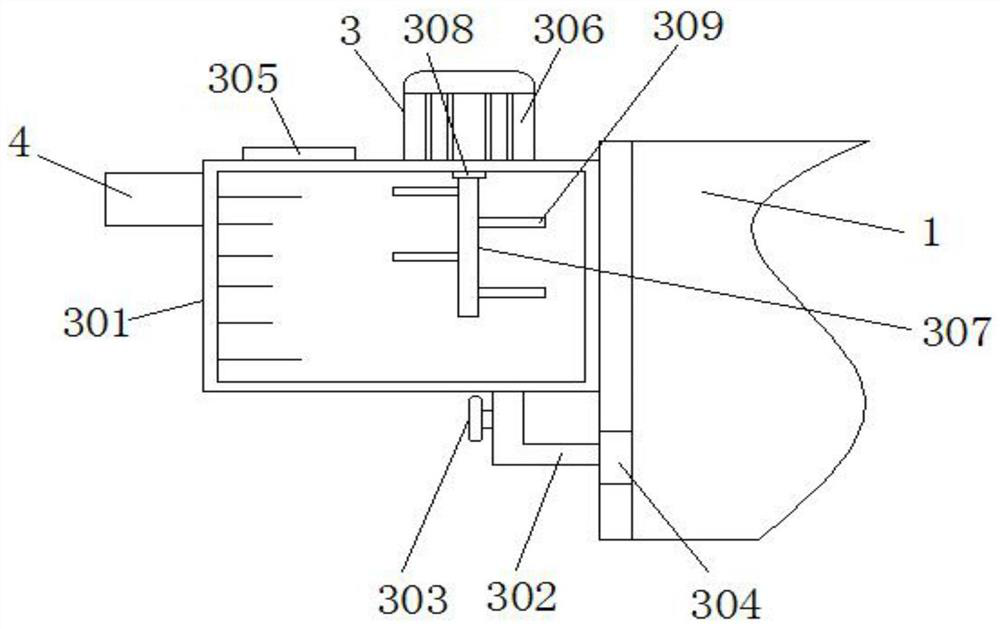

[0051] Please refer to Figure 1 to Figure 6 , a photocatalytic degradation device for copper slag pollutants, including a chassis 1, a stabilizing mechanism 2, a fixed block 201, a threaded column 202, a chassis 203, a first nut 204, a second nut 205, a drug mixing mechanism 3, Dispensing box 301, feeding pipe 302, feeding valve 303, feeding port 304, cover plate 305, motor 306, stirring rod 307, movable shaft 308, blade 309, water inlet 4, water outlet 5, external wiring 6, opening Catalytic mechanism 7, case cover 701, sealing layer 702, catalytic lamp 703, guide groove 704, push switch 705, guide block 706, return spring 707, movable block 708, positioning mechanism 8, place screen cloth 801, side frame 802, The positioning block 803 , the handle 804 , the side plate 805 , the positioning bolt 806 and the positioning groove 807 .

[0052] A stabilizing mechanism 2 is installed at the bottom of the cabinet 1 , and a positioning mechanism 8 is connected inside the cabinet 1...

Embodiment 2

[0064] The present invention also proposes a method for using a photocatalytic degradation device for copper slag pollutants, comprising the following steps:

[0065] Step 1: placing the photocatalytic degradation device and the placing surface after leveling;

[0066] Step 2: Pass the external raw water into the interior of the dispensing box, and then make the ratio according to the water volume;

[0067] Step 3: Put water into the inside of the chassis, and then put the screen with copper slag pollutants into the inside of the chassis for immersion;

[0068] Step 4: Put the lid on the box, turn on the photocatalytic degradation device, and make the catalytic lamp start to work, so as to photocatalytically degrade the copper slag pollutants.

[0069] Specifically, the specific operations of each step in the above method are as follows:

[0070] Step 1: When it is necessary to level the photocatalytic degradation device with the placement surface, the first nut 204 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com