Polymer carrier supported catalyst composite material, application and preparation method thereof

A polymer material, carrier-loaded technology, used in its application and preparation, carrier-loaded composite catalyst, powder catalyst field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

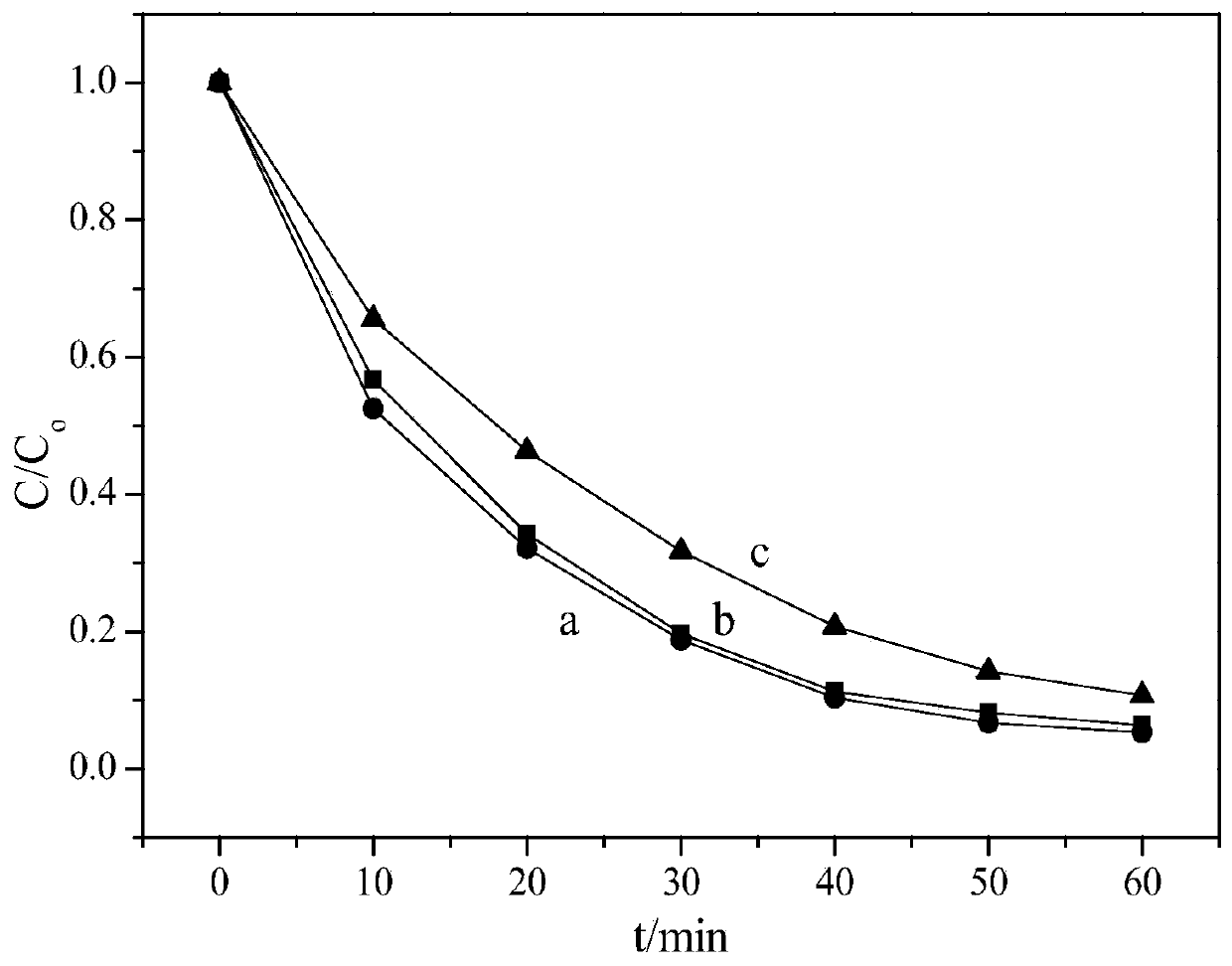

Embodiment 1

[0039] In this embodiment, a polymer carrier-supported catalyst composite material has a block shape, and the polymer block is used as a carrier matrix, and the catalyst particles are partially combined with the surface of the polymer block to distribute the catalyst particles on the surface of the polymer block. The surface of the polymer block forms a uniformly distributed array of catalytically active sites; the polymer block adopts a cavity block with a through-channel, so that the fluid can pass through the through-channel smoothly, and the outer surface of the polymer block, The inner surface of the penetrating channel forms the surface of the carrier matrix; the shape of the outer surface of the polymer block satisfies the following conditions: when the polymer carrier-loaded catalyst composite material is stacked in modules, any polymer carrier-loaded catalyst composite material block Openings at both ends of the through channel are kept open without being closed, so th...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, especially in that:

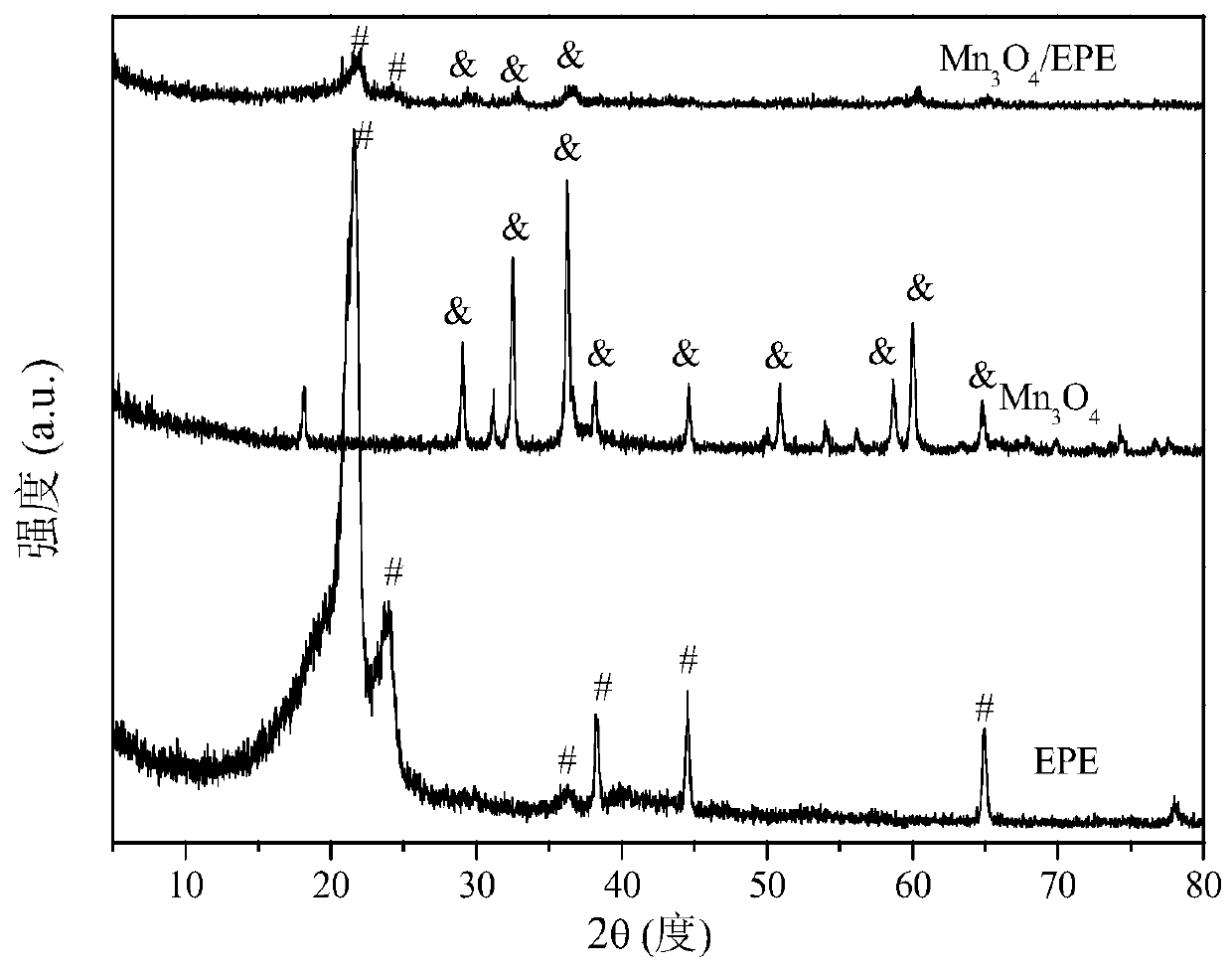

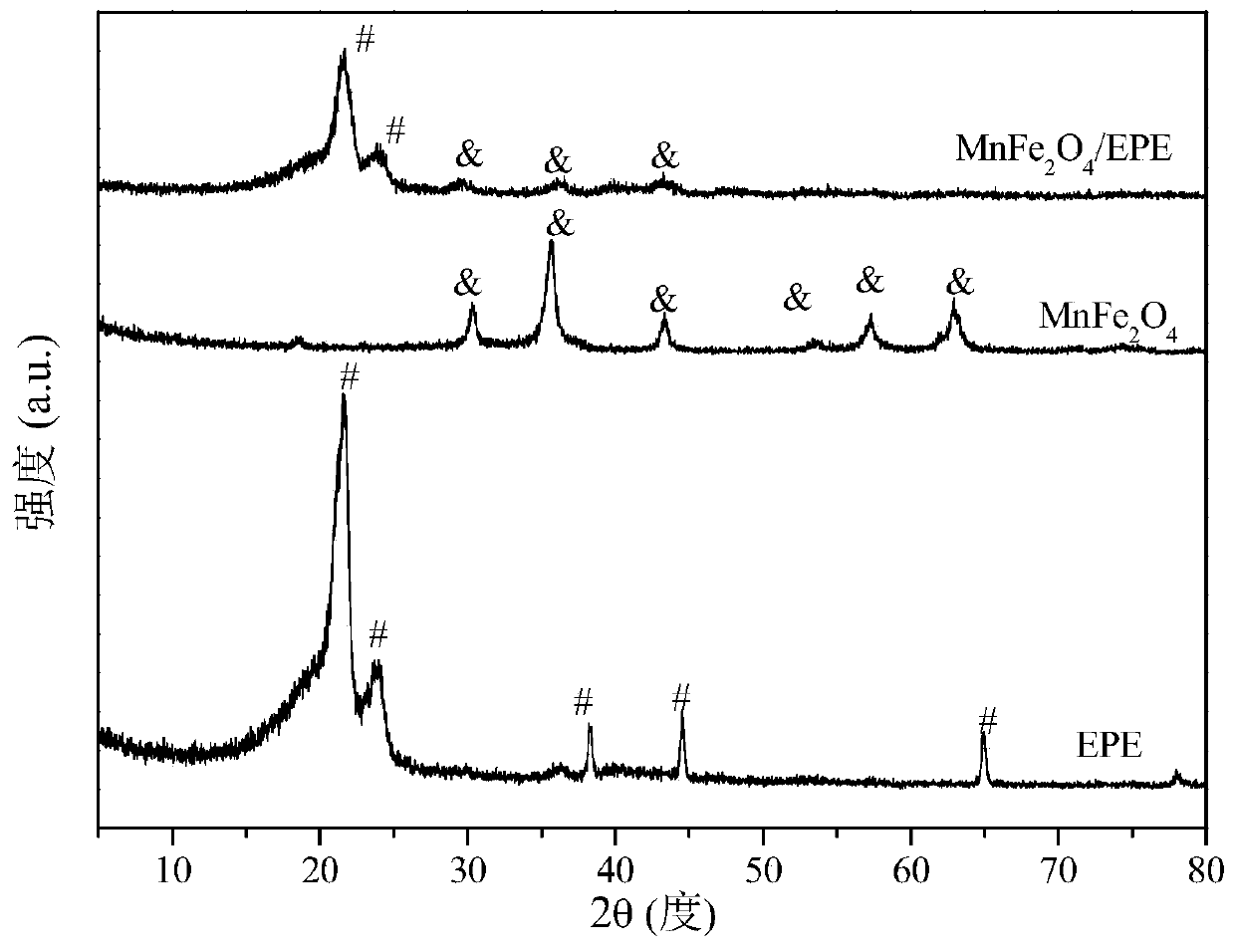

[0055] In this embodiment, a preparation method of powdered catalyst / polymer shaped catalyst is prepared by dipping-melting method into shaped catalyst Mn 3 o 4 / EPE, including the following steps:

[0056] Step 1: Mn 3 o 4 The preparation process of: this step is identical with embodiment one;

[0057] The second step: Mn 3 o 4 / EPE preparation process:

[0058] a. This step is the same as in Embodiment 1;

[0059] b. This step is the same as in Embodiment 1;

[0060] c. After completing the continuous multiple immersion-drying treatments in the above step b, use Mn 3 o 4 Fusion method of nanoparticles and polymers, the built-in powder catalyst Mn 3 o 4 / EPE polymer molding material precursor oven temperature is raised to 125 ° C, and at this temperature, the powder catalyst Mn 3 o 4 / EPE polymer molding material precursor is subjected to heat preservation and heat treatment for ...

Embodiment 3

[0066] This embodiment is basically the same as the previous embodiment, and the special features are:

[0067] In this embodiment, a preparation method of powdered catalyst / polymer shaped catalyst is prepared by dipping-melting method into shaped catalyst Mn 3 o 4 / EPE, including the following steps:

[0068] Step 1: Mn 3 o 4 The preparation process of: this step is identical with embodiment one;

[0069] The second step: Mn 3 o 4 / EPE preparation process:

[0070] a. This step is the same as in Embodiment 1;

[0071] b. This step is the same as in Embodiment 1;

[0072] c. After completing the continuous multiple immersion-drying treatments in the above step b, use Mn 3 o 4 Fusion method of nanoparticles and polymers, the built-in powder catalyst Mn 3 o 4 / EPE polymer molding material precursor oven temperature is raised to 155 ° C, and at this temperature, the powder catalyst Mn 3 o 4 / EPE polymer molding material precursor is subjected to heat preservation an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com