Gold catalyst used for low-temperature catalytic oxidation of carbon monoxide and preparation method thereof

A gold catalyst, low-temperature catalysis technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. It can achieve the effect of good service life, high low temperature activity and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the above-mentioned gold catalyst for the low-temperature catalytic oxidation of carbon monoxide comprises the following steps:

[0020] (1) the first component is lactulose oligosaccharide or glucose, the second component is cerium nitrate and transition metal salt and the third component acrylamide or crotonamide are dissolved in water to obtain a mixed solution, and in the mixed solution, The molar concentration of the first component is 0.13mol / L, the molar concentration of the second component is 0.06mol / L, and the molar concentration of the third component is 0.06mol / L; In the described second component, cerium nitrate and The molar ratio of the transition metal salt is 1:0~0.11, wherein the transition metal salt is any one of lanthanum nitrate, yttrium nitrate, zirconium sulfate or tin sulfate;

[0021] (2) Adjust the pH value of the above-mentioned mixed solution to 8-12 with ammonia water or urea to obtain a colloid, stir for 3-7 hours...

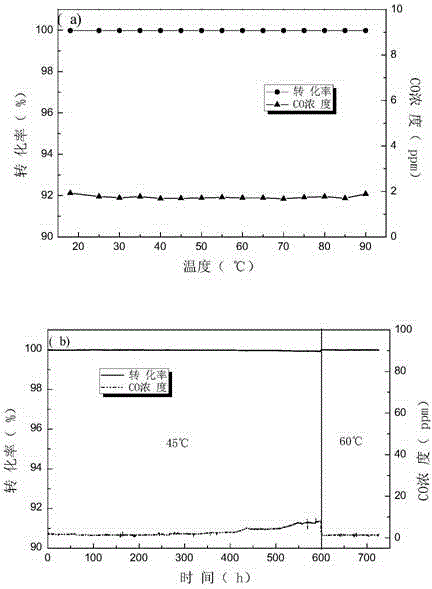

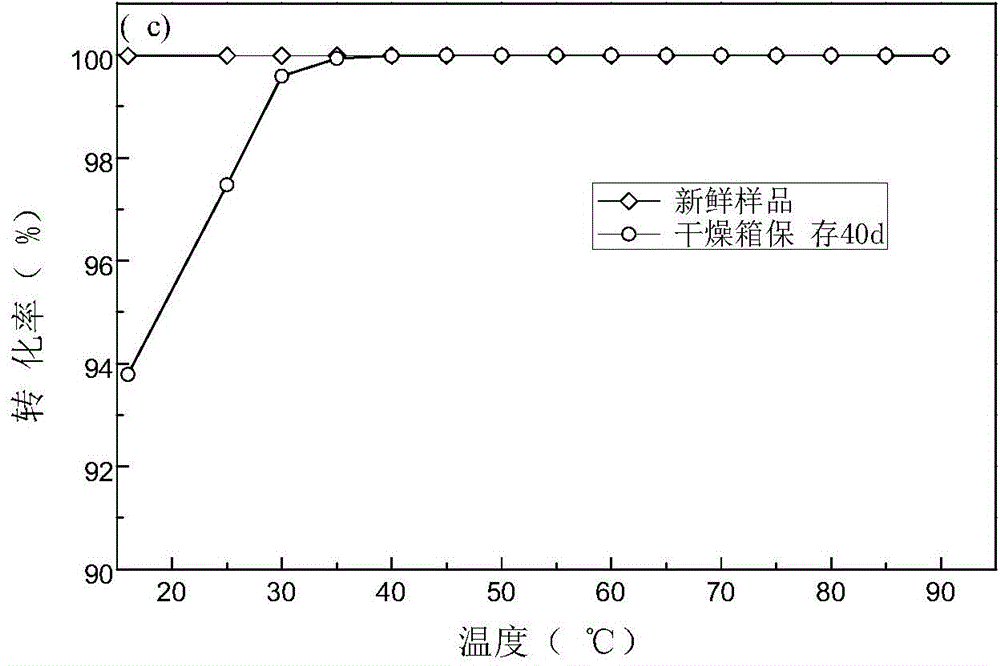

Embodiment 1

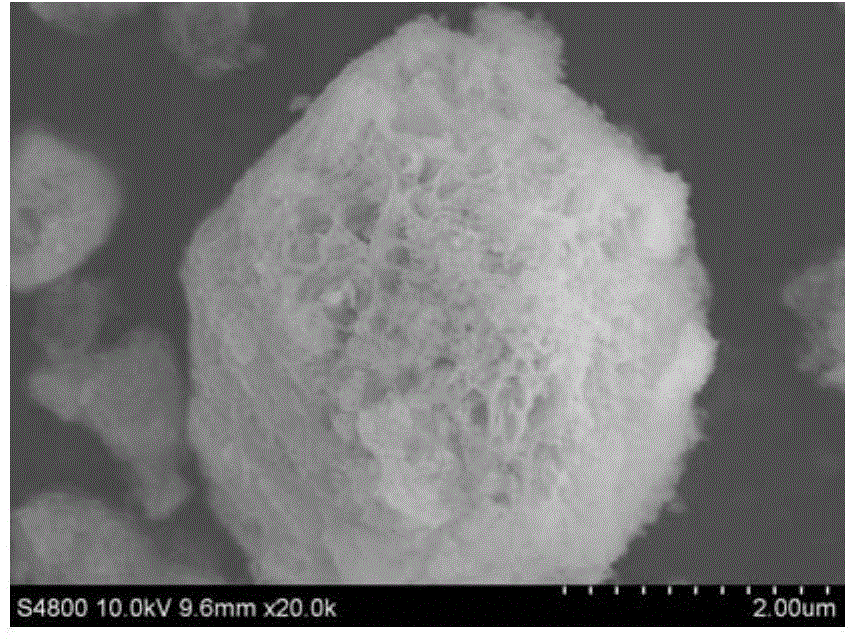

[0026] Glucose, cerium nitrate and acrylamide with molar concentrations (mol / L) of 0.13, 0.06 and 0.06 were dissolved in water to obtain a mixed solution, and the pH value of the mixed solution was adjusted to 10 with ammonia water to obtain a colloid, which was stirred for 4 hours, and then dissolved at 180 Keep at ℃ for 100 hours to obtain the reactant, filter the reactant to obtain a precipitate, wash the precipitate with water 8 times, wash with absolute ethanol 5 times, dry at 80°C for 20 hours, then calcinate at 550°C for 6 hours, Flower-like cerium oxide support CeO 2 . Dissolve chloroauric acid in deionized water to make a solution with a concentration of 0.0056mol / L, and the flower-shaped CeO 2 Add 100ml of deionized water to obtain a suspension with a mass percentage of 1% of the carrier, then add 16ml of chloroauric acid solution dropwise and stir for 2 hours, then use 0.5mol / L K 2 CO 3After adjusting the pH of the mixed solution to 9, react at 100°C for 24 hours...

Embodiment 2

[0028] The molar concentration (mol / L) is respectively 0.13, 0.06 and 0.06 lactulose-oligosaccharide, cerium nitrate and crotonamide to be dissolved in water and obtain mixed solution, adjust the pH value of mixed solution to 8 with ammonia water, obtain colloid, stir 3 Hours, kept at 160°C for 100 hours to obtain the reactant, filtered the reactant to obtain a precipitate, washed the precipitate 8 times with water, washed 5 times with absolute ethanol, dried at 120°C for 10 hours, and then dried at 450°C Calcined at lower temperature for 6 hours to obtain a spherical cerium oxide carrier. Dissolve chloroauric acid in deionized water to make a solution with a concentration of 0.0056mol / L, and the flower-like CeO 2 Add 100ml of deionized water to obtain a suspension with a mass percentage of 1.5% of the carrier, then add 16ml of chloroauric acid solution dropwise and stir for 2h, and use 0.5mol / LK 2 CO 3 After adjusting the pH of the mixed solution to 8, react at 80°C for 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com