Fuel cell power generation system for hydrogen production by methanol reforming of trace CO

A technology of reforming hydrogen production and fuel cells, which is applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problem of increasing the volume of system equipment and the complexity of system control, the inapplicability of fuel cell power generation systems, increasing Fuel cell power generation system cost and other issues, to achieve the effect of improving anti-carbon performance, improving activity and life, and improving surface characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

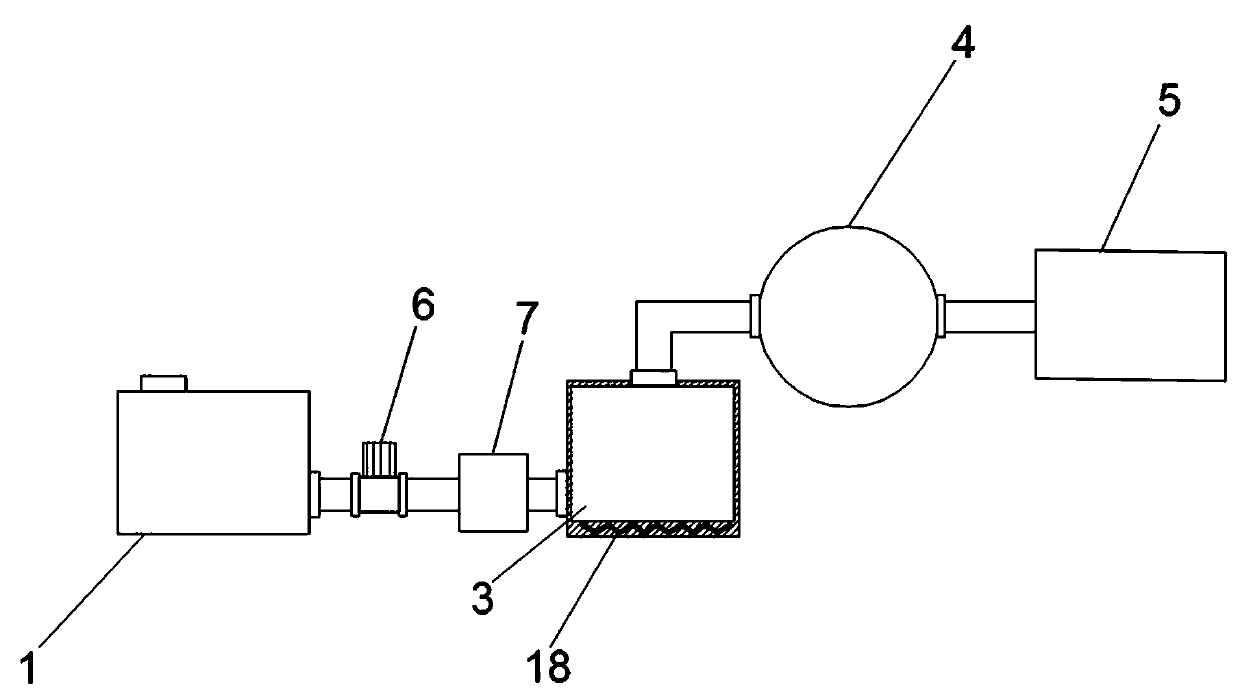

[0038] Such as figure 1 As shown, a fuel cell power generation system for methanol reforming hydrogen production with a trace amount of CO, which includes a control system and a liquid storage tank 1, a liquid outlet pump 6, a vaporizer 7, a reactor 3, a condenser 4 and a low temperature Proton exchange membrane fuel cell 5, the inside of described reactor 3 is equipped with methanol reforming hydrogen production catalyst; The inside of described reactor 3 is provided with electric heating wire 18, and also is provided with temperature sensor in described reactor 3 and a pressure sensor; a valve is provided at the outlet of each section of the pipeline, and a pressure gauge is provided at the outlet and the inlet of each section of the pipeline; the liquid storage bin 1, the liquid outlet pump 6, the vaporizer 7, the reactor 3, and the condenser 4 and the low-temperature proton exchange membrane fuel cell 5 are electrically connected to the control system, and the control syst...

Embodiment 2

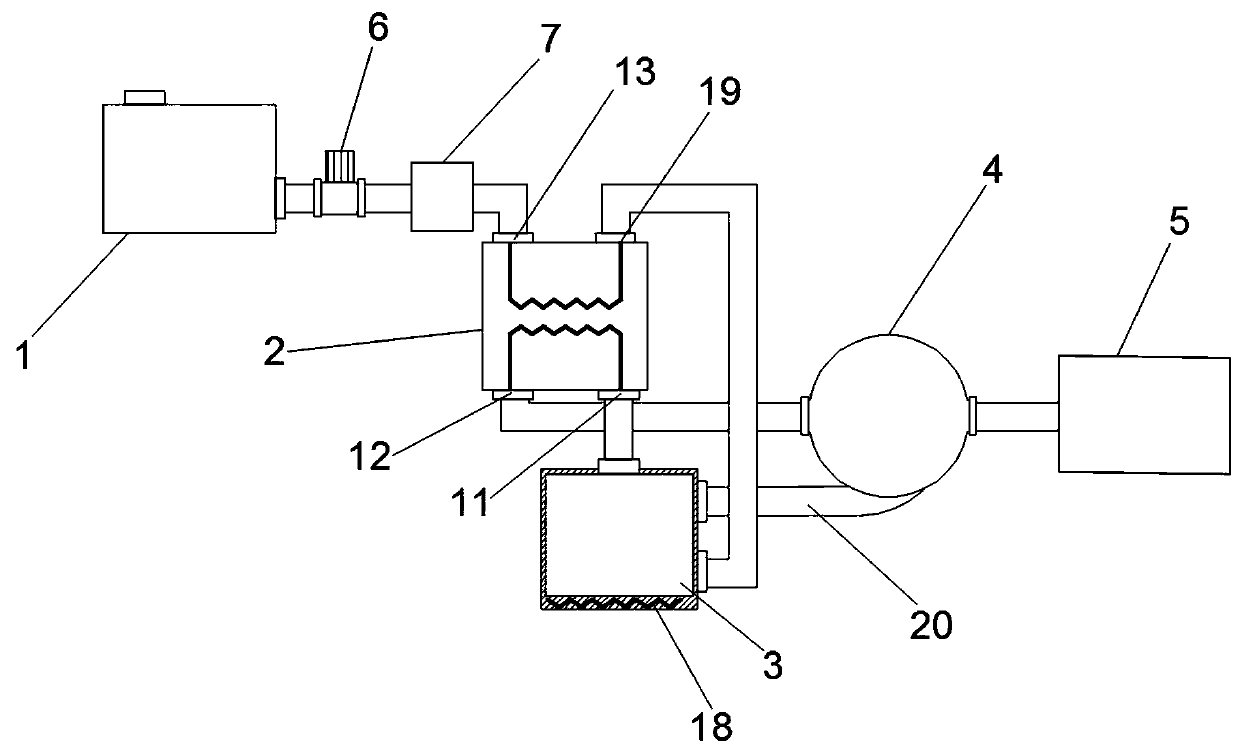

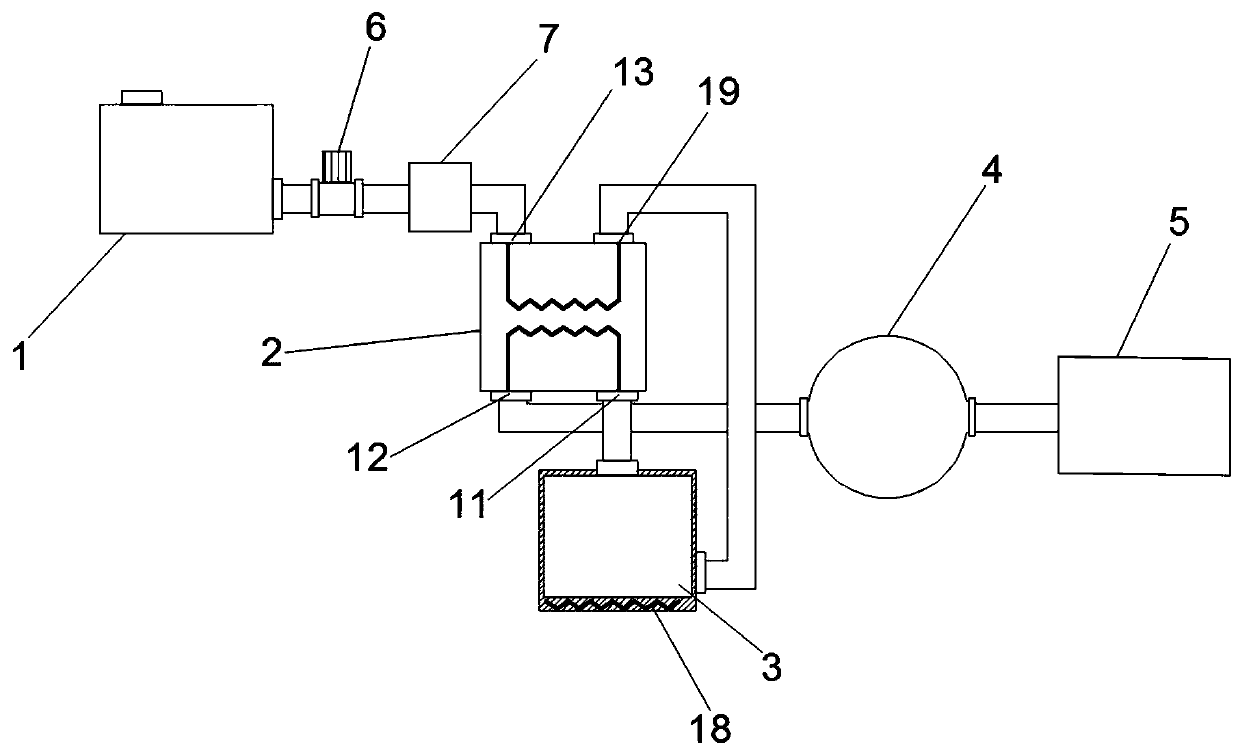

[0047] Such as figure 2 As shown, a fuel cell power generation system for methanol reforming hydrogen production with a trace amount of CO, which includes a control system and a liquid storage tank 1, a liquid outlet pump 6, a vaporizer 7, a reactor 3, a condenser 4 and a low temperature Proton exchange membrane fuel cell 5, the inside of described reactor 3 is equipped with methanol reforming hydrogen production catalyst; The inside of described reactor 3 is provided with electric heating wire 18, and also is provided with temperature sensor in described reactor 3 and a pressure sensor; a valve is provided at the outlet of each section of the pipeline, and a pressure gauge is provided at the outlet and the inlet of each section of the pipeline; the liquid storage bin 1, the liquid outlet pump 6, the vaporizer 7, the reactor 3, and the condenser 4 and the low-temperature proton exchange membrane fuel cell 5 are electrically connected to the control system, and the control sys...

Embodiment 3

[0056] Such as figure 2 As shown, a fuel cell power generation system for methanol reforming hydrogen production with a trace amount of CO, which includes a control system and a liquid storage tank 1, a liquid outlet pump 6, a vaporizer 7, a reactor 3, a condenser 4 and a low temperature Proton exchange membrane fuel cell 5, the inside of described reactor 3 is equipped with methanol reforming hydrogen production catalyst; The inside of described reactor 3 is provided with electric heating wire 18, and also is provided with temperature sensor in described reactor 3 and a pressure sensor; a valve is provided at the outlet of each section of the pipeline, and a pressure gauge is provided at the outlet and the inlet of each section of the pipeline; the liquid storage bin 1, the liquid outlet pump 6, the vaporizer 7, the reactor 3, and the condenser 4 and the low-temperature proton exchange membrane fuel cell 5 are electrically connected to the control system, and the control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com