Catalyst for selective oxidation of CO and preparation method and application of catalyst

A catalyst and selective technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as difficult to meet industrial needs, narrow temperature window, etc., to achieve The steps are simple and are conducive to the effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

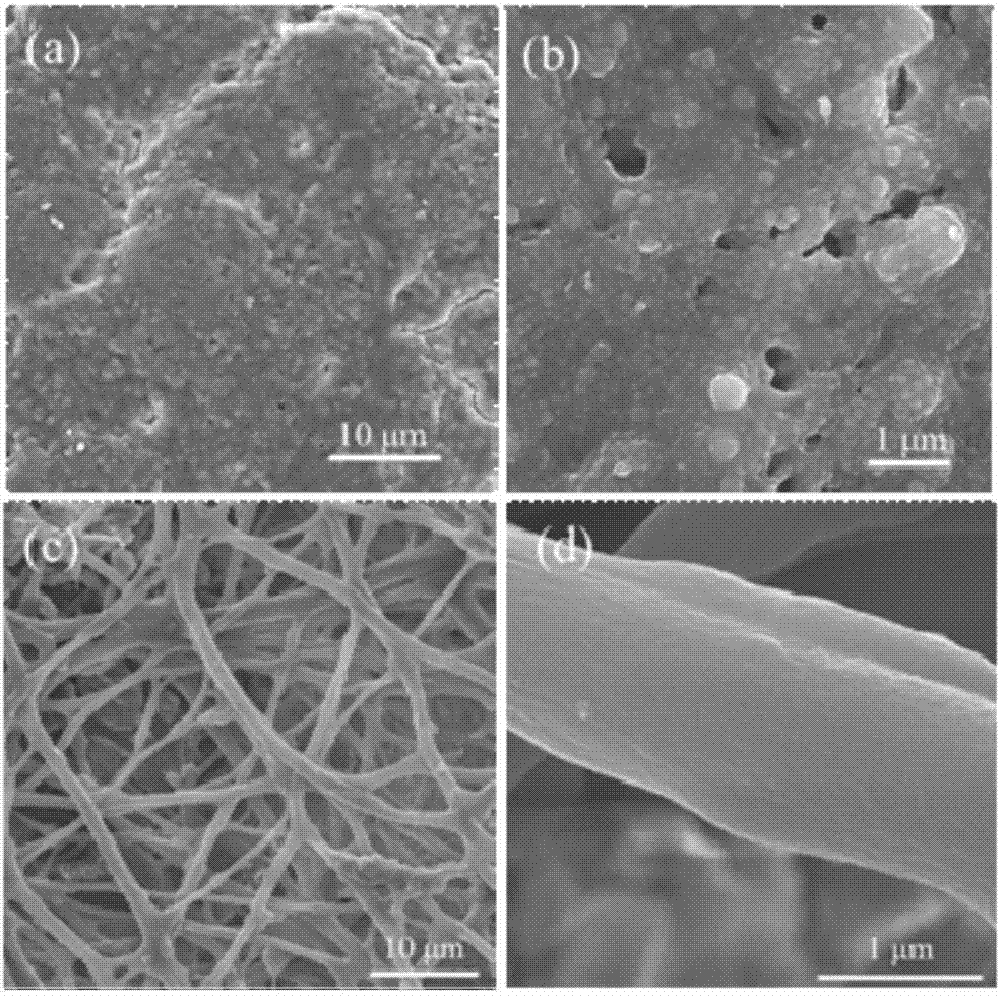

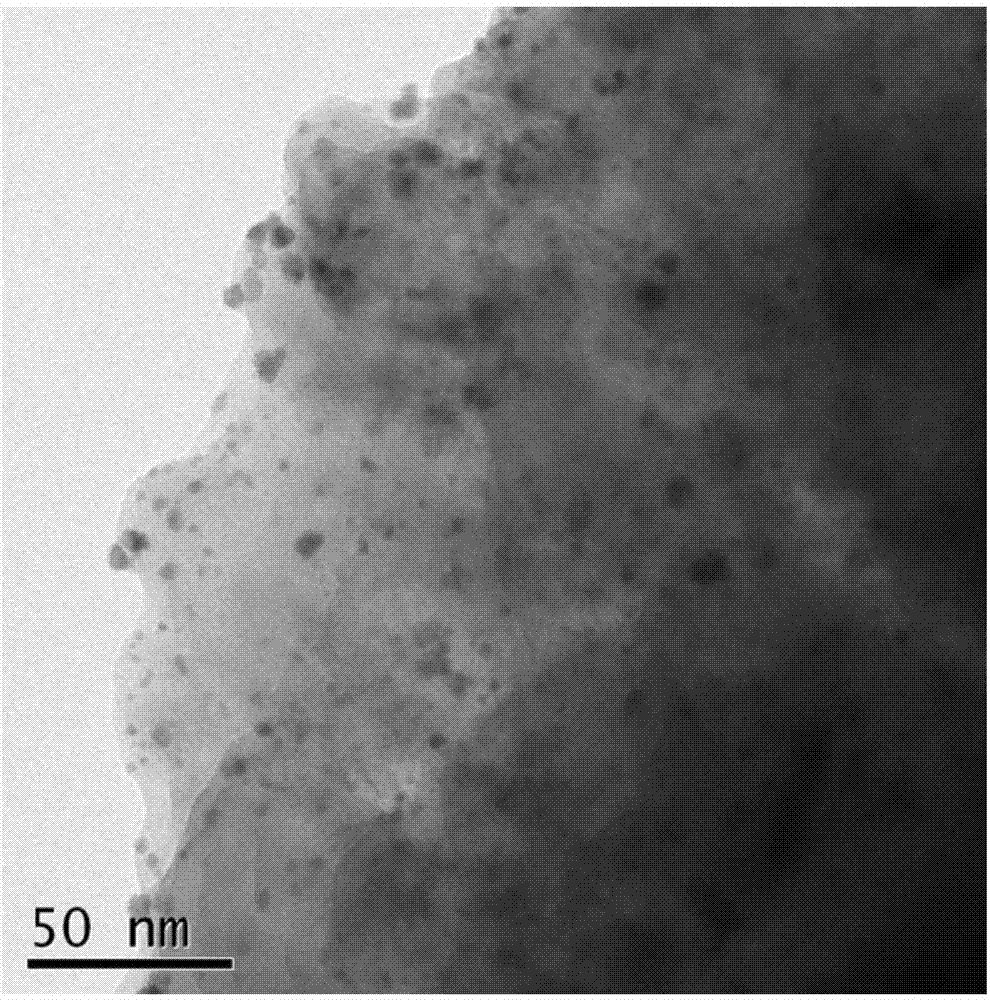

[0025] Dry and grind the eggshell, take 1g and disperse it in 100mL deionized water, add dropwise 10mL of H2O with a concentration of 3mg / mL 2 PtCl 6 The aqueous solution was added to the above suspension, stirred and adsorbed for 24 hours. Add 100 mg of sodium borohydride powder and continue to stir for 12 hours. The obtained precipitate is washed three times with deionization, filtered, and dried at 80° C. to obtain a Pt / eggshell powder sample, which is designated as Pt / ES.

Embodiment 2

[0027] Dry and grind the eggshell, take 1g and disperse it in 100mL deionized water, add dropwise 5mL of H at a concentration of 3mg / mL 2 PtCl 6 aqueous solution and 5 mL of RuCl at a concentration of 3 mg / mL 3 The aqueous solution was added to the above suspension, stirred and adsorbed for 24 hours. Add 100 mg of sodium borohydride powder and continue to stir for 12 hours. The obtained precipitate is washed three times with deionization, filtered, and dried at 80°C to obtain a Pt-Ru / eggshell powder sample, which is designated as Pt-Ru / ES.

Embodiment 3

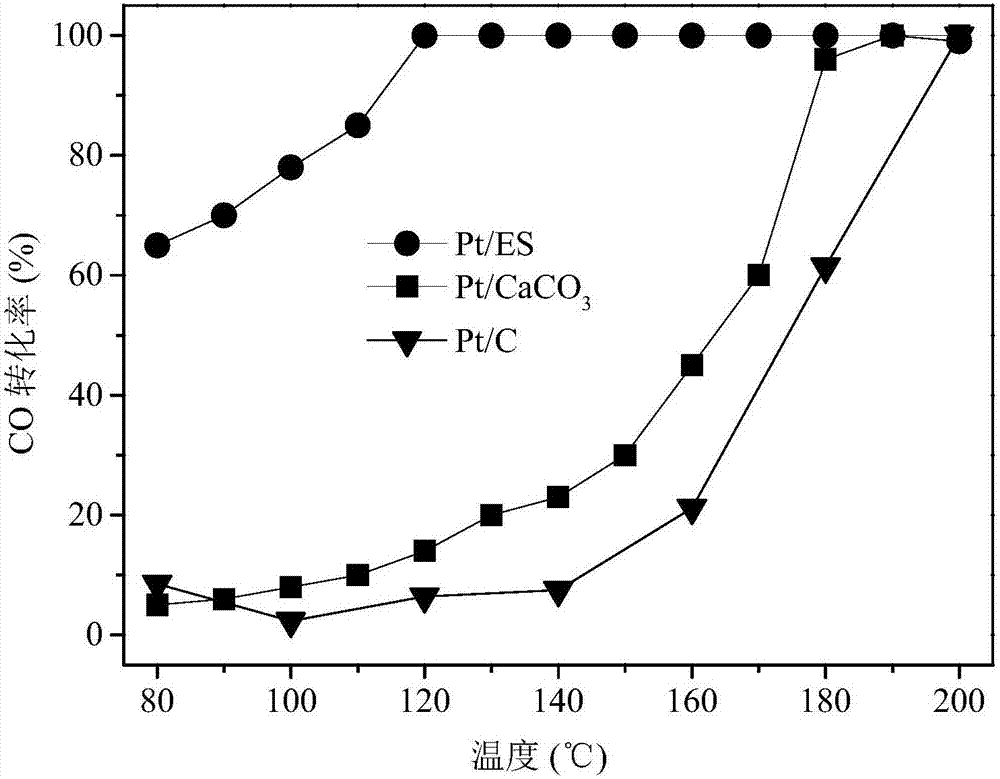

[0029] Take 0.1g sample Pt / ES as a catalyst and fill it into a quartz tube, and pass a hydrogen-rich mixed gas through the catalyst. The mixed gas composition is H 2 50%, CO 1%, O 2 1%, the rest is He, the reaction gas flow rate is 40ml / min, and the test temperature is 60℃~240℃. Commercial calcium carbonate supported Pt catalyst Pt / CaCO 3 And the commercial Pt / C catalyst was tested under the same conditions as a comparative example.

[0030] Depend on image 3 It can be seen that the Pt / ES catalyst provided by this application has excellent selective catalytic performance in the range of 120°C to 200°C, and realizes the selective catalytic oxidation of carbon monoxide in a wide window in a hydrogen-rich environment, and is especially suitable for hydrocarbons ( Such as methanol, natural gas, petroleum) through reforming reaction, water gas shift hydrogen production process system and hydrogen supply system of proton exchange membrane fuel cell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com