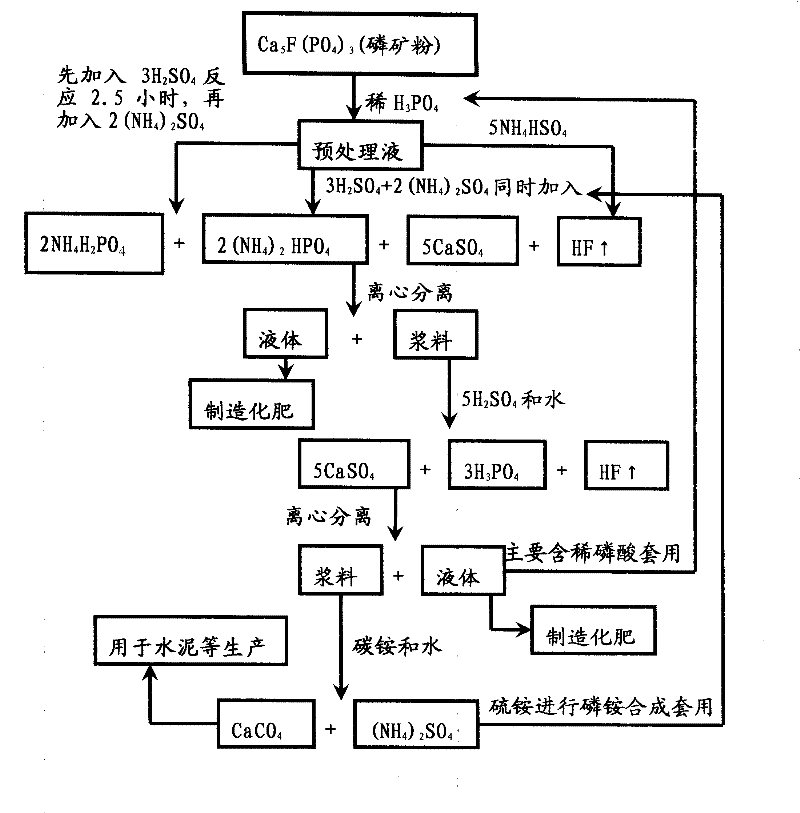

Novel process for cleanly producing phosphate ammoniate fertilizer in the processing of phosphate rock powder

A technology of phosphate rock powder and ammonium phosphate salt, which is applied in the direction of ammonium orthophosphate fertilizer, phosphate fertilizer, ammonium sulfate, etc., and can solve the problems of land occupation and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A. Pretreatment of phosphate rock powder: firstly, the finely ground P 2 o 5 Mix 26g of phosphate rock powder with a content of 21.33% and 60g of water, add 6-10g of dilute phosphoric acid with a concentration of 20% for pretreatment, heat at the same time, and stir for 10 minutes to obtain pretreated pulp, which is to be acidolyzed.

[0039] B. One-time acid hydrolysis treatment: 13g of concentrated sulfuric acid with a concentration of 98% was added dropwise in 10 minutes with the above pulp under stirring, and then 11.7g of ammonium sulfate solid was added in a one-time feeding method, and the temperature was raised to keep the reaction in a slightly boiling state The reaction was carried out for 5 hours, the condensing tube kept the liquid reflux, and the generated HF gas was treated with lye for tail gas absorption. The reaction slurry was sampled and centrifuged to analyze the P in the supernatant and solid waste residue. 2 o 5 content. The reaction phosphorus...

Embodiment 2

[0045] A, phosphate rock powder pretreatment: with embodiment one.

[0046] B, one-time acid hydrolysis treatment: with the above-mentioned ore pulp in a stirring state, 13g of concentrated sulfuric acid with a concentration of 98% was added dropwise in 10 minutes, reacted for 3 hours in a slightly boiling state, then added 11.7g of ammonium sulfate solid, and then React in boiling state for 2 hours, keep the liquid reflux in the condenser tube, and the generated HF gas is treated with lye for tail gas absorption. The reaction slurry was sampled and centrifuged to analyze the P in the supernatant and solid waste residue. 2 o 5 content. The reaction phosphorus release rate can reach 40-50%.

[0047] C, centrifugal treatment: with embodiment one.

[0048] D, secondary acid hydrolysis treatment: with embodiment one.

[0049] E, slurry filtration: with embodiment one.

[0050] F, the extraction of sulfate radical and the synthesis of calcium carbonate: with embodiment one. ...

Embodiment 3

[0052] A, phosphate rock powder pretreatment: with embodiment one.

[0053] B. Primary acid hydrolysis treatment: Add 30 g of ammonium bisulfate solid to the above-mentioned ore pulp under stirring, and react for 5 hours in a slightly boiling state. The condensing tube keeps the liquid reflux, and the generated HF gas is treated with lye for tail gas absorption. The reaction slurry was sampled and centrifuged to analyze the P in the supernatant and solid waste residue. 2 o 5 content. The reaction phosphorus release rate can reach 29-35%.

[0054] C, centrifugal treatment: with embodiment one.

[0055] D, secondary acid hydrolysis treatment: with embodiment one.

[0056] E, slurry filtration: with embodiment one.

[0057] F, the extraction of sulfate radical and the synthesis of calcium carbonate: with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com