Lactobacillus fermentum LG1 and application thereof

A technology for fermenting Lactobacillus and fermented dough, which is applied to bacteria, pre-baked dough treatment, microorganisms, etc., can solve the problems of easy contamination and corruption of dough, long fermentation period, etc. Effects of Ingredient Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

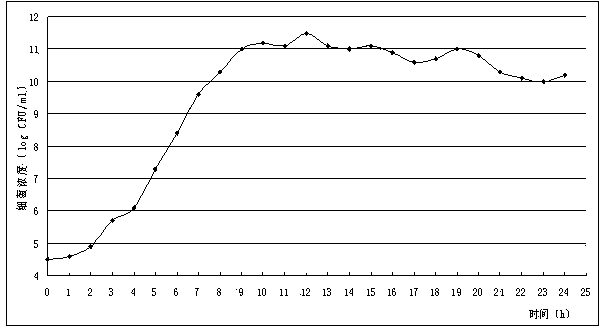

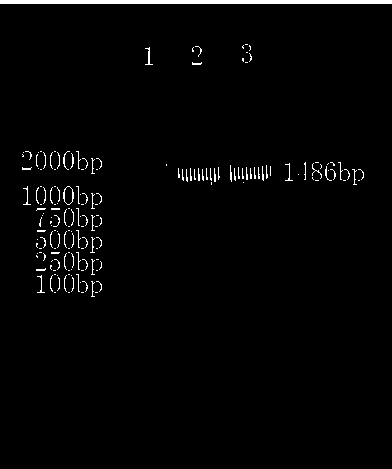

[0044] Example 1: Isolation, purification, identification and preservation of Lactobacillus fermentum LG1

[0045] 1. Source of bacteria

[0046] The experimental strains were all isolated from the collected yellow rice fermented dough samples collected by farmers in this area.

[0047] 2. Strain isolation and purification culture

[0048] 2.1 Strain isolation

[0049]Weigh 1 g of the homemade yellow rice fermented dough sample, place it in 10 ml of 0.8% sterile saline, and shake to dissolve. Take an appropriate amount of suspension solution for 10-fold gradient dilution, and the specific dilution factor is 10 -1 , 10 -2 , 10 -3 , 10 -4 , 10 -5 , 10 -6 , 10 -7 , 10 -8 , 10 -9 , respectively take 100ul of the diluted solution to coat the MRS agar plate, place in a 37°C incubator, and incubate for 24h. Plates with 50-150 single colonies were selected for subsequent experiments. Three parallel experiments were performed for each sample.

[0050] 2.2 Strain purific...

Embodiment 2

[0082] Embodiment 2: the application of Lactobacillus fermentum LG1 in making yellow rice corn fermented dough

[0083] 1. The production of yellow rice corn fermented dough by Lactobacillus fermentum LG1 can be realized through the following steps:

[0084] (1) Lactobacillus fermentum LG1 was activated and cultivated in MRS liquid medium for two generations, and the culture medium was inoculated into flour according to 2% of the total mass of flour, mixed well, and an appropriate amount of water at 30°C was added for kneading;

[0085] (2) The main ingredient of kneading flour is yellow rice flour, the auxiliary material is corn flour, and the mass ratio of main material and auxiliary material is 3:1;

[0086] (3) The reconciled dough was fermented for 6 hours at 37°C and 80% humidity.

[0087] 2. The yellow rice corn fermented dough made by Lactobacillus fermentum LG1 will undergo the following changes before and after fermentation:

[0088] (1) The number of Lactobacill...

Embodiment 3

[0095] Embodiment 3: the application of Lactobacillus fermentum LG1 in making yellow rice millet fermented dough

[0096] 1. The production of yellow rice and millet fermented dough by Lactobacillus fermentum LG1 can be realized through the following steps:

[0097] (1) Lactobacillus fermentum LG1 was activated and cultivated in MRS liquid medium for two generations, and the culture medium was inoculated into flour according to 3% of the total mass of flour, mixed well, and an appropriate amount of water at 30°C was added for kneading;

[0098] (2) The main ingredient of kneading flour is yellow rice flour, the auxiliary material is millet flour, and the mass ratio of main material and auxiliary material is 2:1;

[0099] (3) The reconciled dough was fermented for 7 hours at 35°C and 75% humidity.

[0100] 2. The yellow rice and millet fermented dough made by Lactobacillus fermentum LG1 will undergo the following changes before and after fermentation:

[0101] (1) The numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com