Active lactobacillus casei beverage and preparation method thereof

A technology of Lactobacillus casei and beverages, which is applied in the field of active Lactobacillus casei beverages and its preparation, can solve the problems of long fermentation period, slow fermentation acid production, discount of prebiotic function, etc., and achieve reduced risk of fermentation failure, rapid pH value drop, Effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] (1) Skimmed milk powder was reduced and hydrated at 12.0%, 400g / bottle was divided into 500mL Erlenmeyer flasks, sterilized in a water bath at 96°C for 120min, cooled to 37°C for later use.

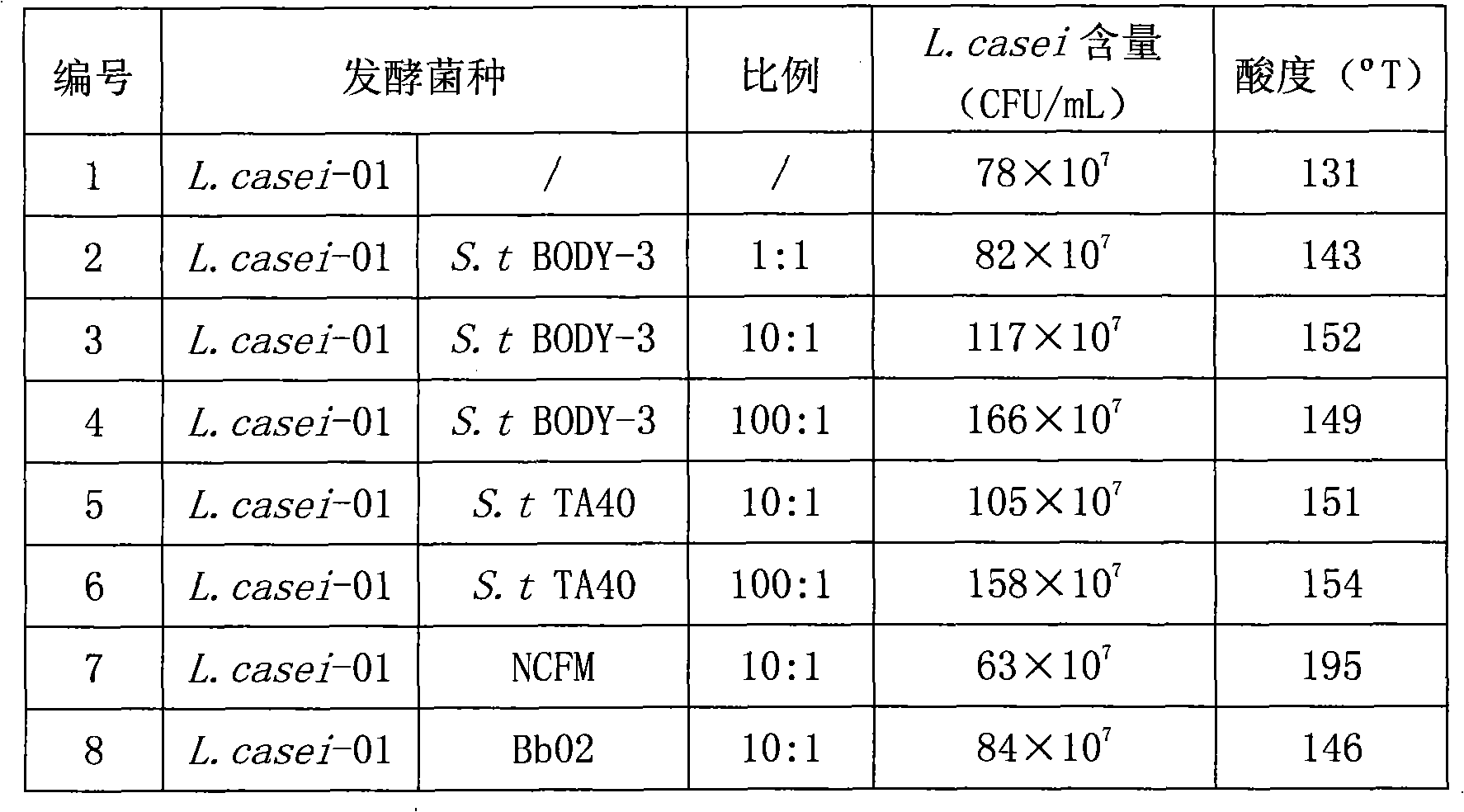

[0077] (2) Under aseptic conditions, according to the total inoculation amount of 0.04‰ and the ratio shown in Table 1, insert different strains into each Erlenmeyer flask, mix evenly, and ferment at 37°C for 36 hours, then measure the acidity and cheese milk of the fermentation system The number of live bacilli was shown in Table 1.

[0078] Table 1 The combination of different strains and their effects on fermentation

[0079]

[0080] 9

[0081] The results showed that when Lactobacillus casei L.casei-01 was matched with Streptococcus thermophilus BODY-3 and TA40 at a ratio of 1:1 to 100:1, it had a good synergistic fermentation effect, and the acidity increased rapidly, and L. The number of live bacteria in casei reached the highest. When Lactobacillus casei and...

Embodiment 2

[0083] (1) Skim milk powder is reduced and hydrated at 12.0%, and 400g / bottle is divided into 500mL conical flasks, and carbon sources and metal ions of different types and concentrations are added to different conical flasks as shown in Table 2, and stirred evenly and fully Dissolve and sterilize in a water bath at 96°C for 120 minutes, then cool to 37°C for later use.

[0084] Table 2 Addition amount of different carbon sources and inorganic salts

[0085] Numbering

[0086] (2) According to the total amount of inoculation of 0.04‰, the ratio of L.casei-01:S.t BODY-3=10:1, insert the starter, ferment for 36 hours at 37°C, measure the acidity and the content of Lactobacillus casei after the fermentation ends, The results are shown in Table 3.

[0087] Table 3 Effects of different carbon sources and inorganic salt additions on the fermentation of L.casei

[0088] Numbering

[0089] Adding carbon sources and metal ions to the fermentation system can both p...

Embodiment 3

[0091] (1) Skim milk powder is reduced and hydrated at 12.0%, 400g / bottle is divided into 500mL triangular flasks, and active polypeptides of different types and concentrations are added to different triangular flasks as shown in Table 4, stirred evenly, and sterilized in a 96°C water bath After 120 minutes, cool down to 37°C for later use.

[0092] (2) According to the total inoculum size of 0.04‰, the ratio of BD-II: TA40=50: 1 was inserted into the starter, and after 36 hours of fermentation at 37°C, the acidity of the fermentation system and the content of Lactobacillus casei were measured. The results are shown in Table 4.

[0093] Table 4 Effect of adding different active polypeptides on fermentation

[0094] Numbering

[0095] Active polypeptides can significantly promote the proliferation of Lactobacillus casei, and soybean polypeptides are slightly superior. About 2‰ soybean polypeptides or fish collagen peptides can promote the increase of fermented lactic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com