Method for producing organic acid at high production rate through fermentation of intermittent backflow cells

A high-productivity, organic acid technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of low productivity and long fermentation cycle, achieve increased productivity, save tank washing and sterilization time , Good effect of industrial production application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

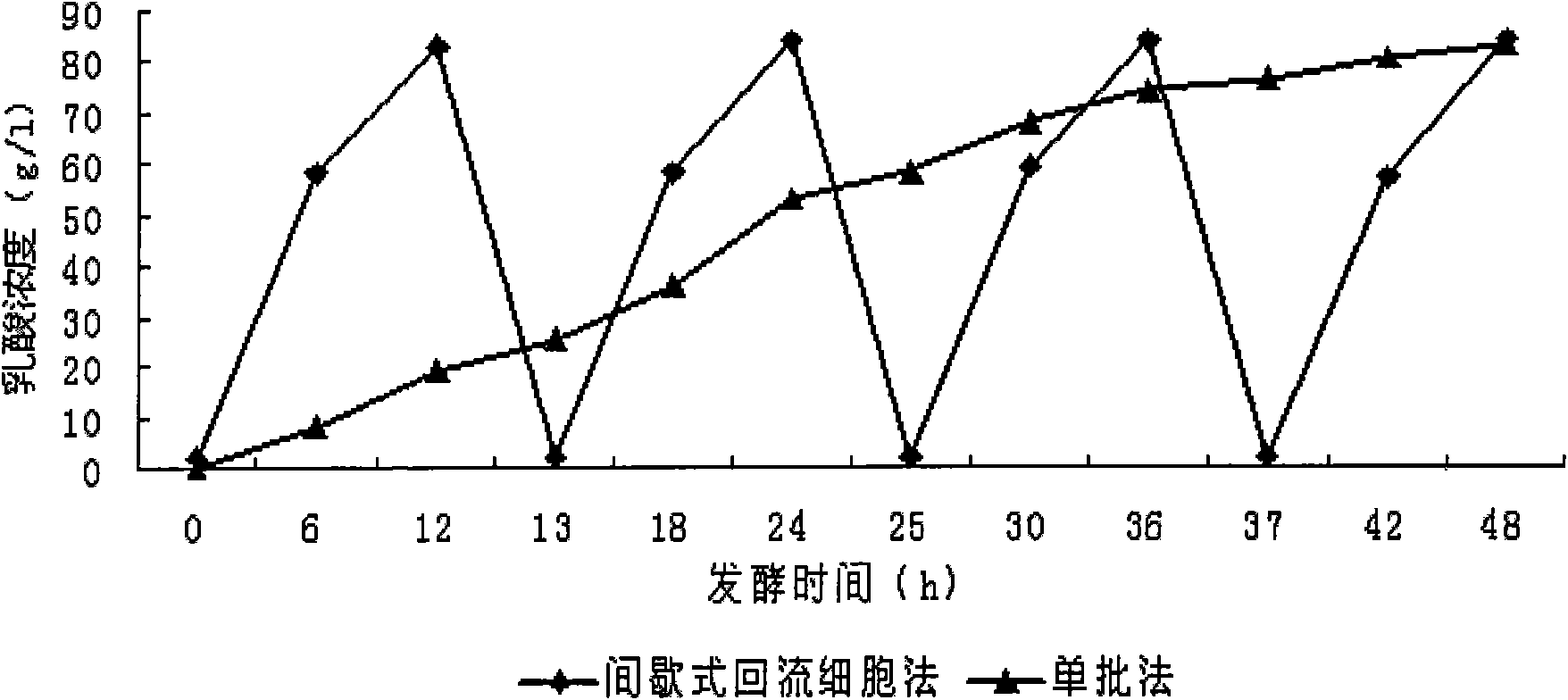

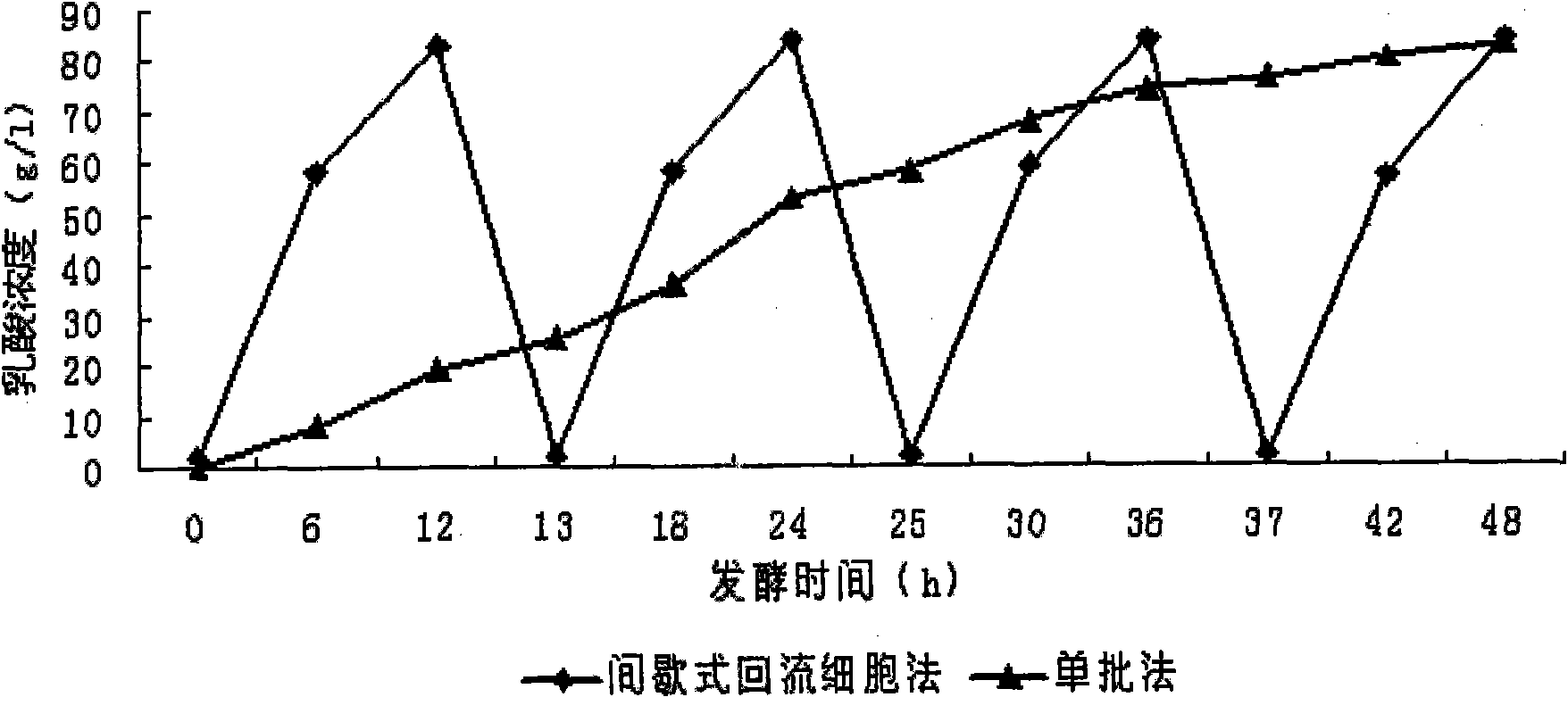

[0033] Fermentative production of lactic acid

[0034] Equipment: one set of 100L seed tank, one set of 100L fermenter, one set of seed medium microfiltration device with processing capacity of 100L / h (membrane pore size 0.22μm), one set of fermentation medium microfiltration device with processing capacity of 100L / h ( Membrane pore size 0.22μm), a set of fermentation broth microfiltration device with a processing capacity of 100L / h (membrane pore size 0.22μm), a set of 100L medium buffer storage tank, a set of fermentation broth buffer storage tank, and five pumps.

[0035] Species: Lactobacillus delbrueckii (L. delbrueckii HG 07).

[0036] Seed medium (g / L): Adjust the concentration of reducing sugar to 50% in corn saccharification solution, add 10% of bran hydrolysis filtrate, 3% of yeast powder, and 3% of beef extract, mix well, and adjust the pH to 7.0 with 10mol / L NaOH solution.

[0037] Fermentation medium (g / L): Adjust the reducing sugar concentration to 100 in the corn...

Embodiment 2

[0044] Fermentative production of lactic acid

[0045] Equipment: one set of 100L seed tank, one set of 100L fermenter, one set of seed medium microfiltration device with processing capacity of 100L / h (membrane pore size 0.22μm), one set of fermentation medium microfiltration device with processing capacity of 100L / h ( Membrane pore size 0.22μm), a set of fermentation broth ultrafiltration device with a processing capacity of 100L / h (molecular weight cut-off 1000 Daltons), a set of 100L medium buffer storage tank, a set of fermentation broth buffer storage tank, and five pumps.

[0046] Strain: Lactobacillus rhamnosus (L. rhamnosus HG 08).

[0047] Seed medium (g / L): Adjust the reducing sugar concentration to 10 in the rice saccharification solution, add bran hydrolysis filtrate 3, yeast powder 1, and beef extract 1, mix well, and adjust the pH to 7.0 with 8mol / L KOH solution.

[0048] Fermentation medium (g / L): Adjust the reducing sugar concentration to 100 in the rice sacch...

Embodiment 3

[0055] Fermentative production of lactic acid

[0056] Equipment: one set of 100L seed tank, one set of 100L fermenter, one set of seed medium microfiltration device with processing capacity of 100L / h (membrane pore size 0.22μm), one set of fermentation medium microfiltration device with processing capacity of 100L / h ( Membrane pore size 0.22μm), a set of fermentation broth microfiltration device with a processing capacity of 100L / h (membrane pore size 0.22μm), a set of 100L medium buffer storage tank, a set of fermentation broth buffer storage tank, and five pumps.

[0057] Strains: Lactobacillus casei (L. casei LZD12).

[0058] Seed medium (g / L): Adjust the concentration of reducing sugar to 50% in corn saccharification solution, add 10% of bran hydrolysis filtrate, 3% of yeast powder, and 3% of beef extract, mix well, and adjust the pH to 7.0 with 10mol / L NaOH solution.

[0059] Fermentation medium (g / L): Adjust the reducing sugar concentration to 100 in the corn saccharif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com