Patents

Literature

101results about How to "Heating effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

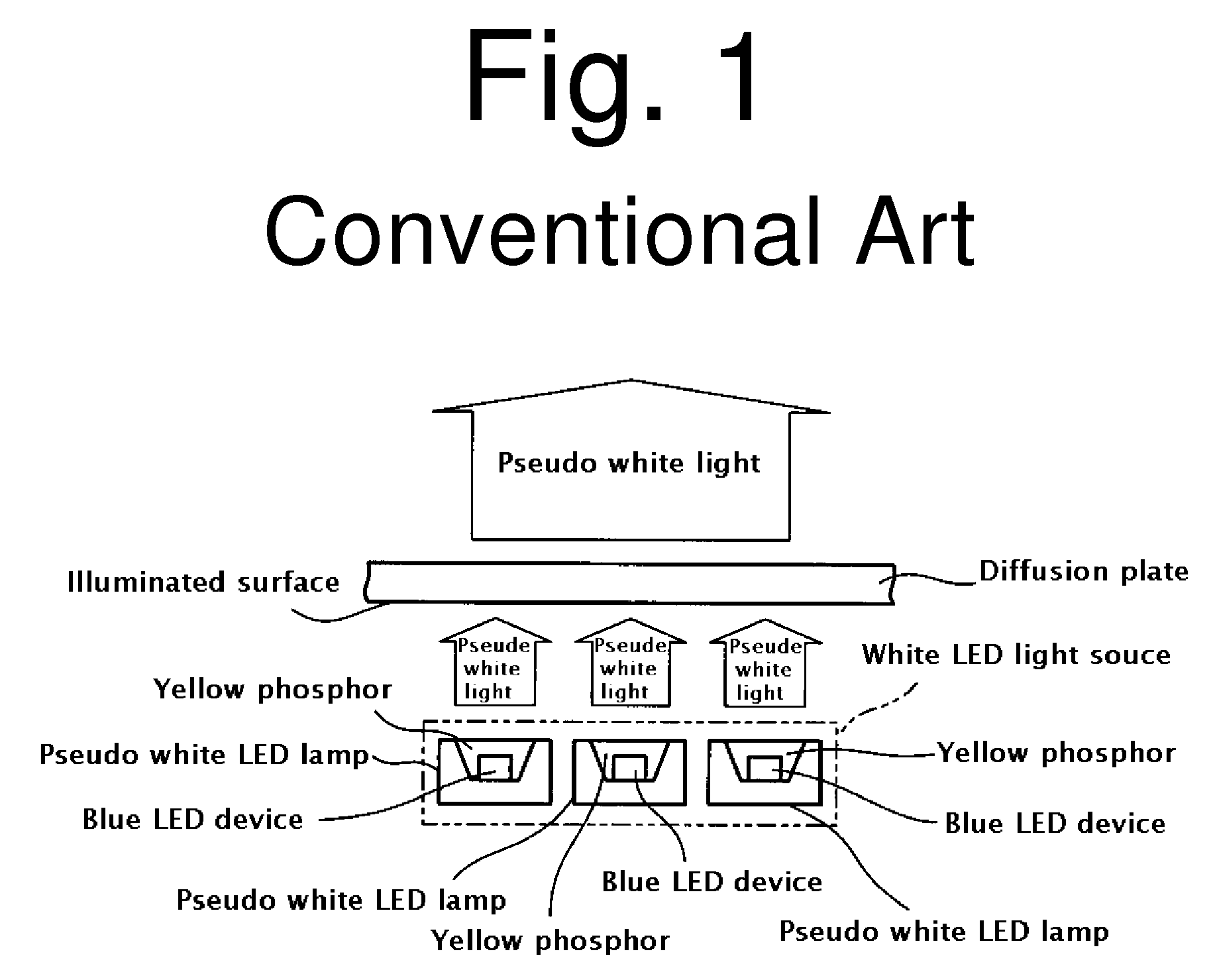

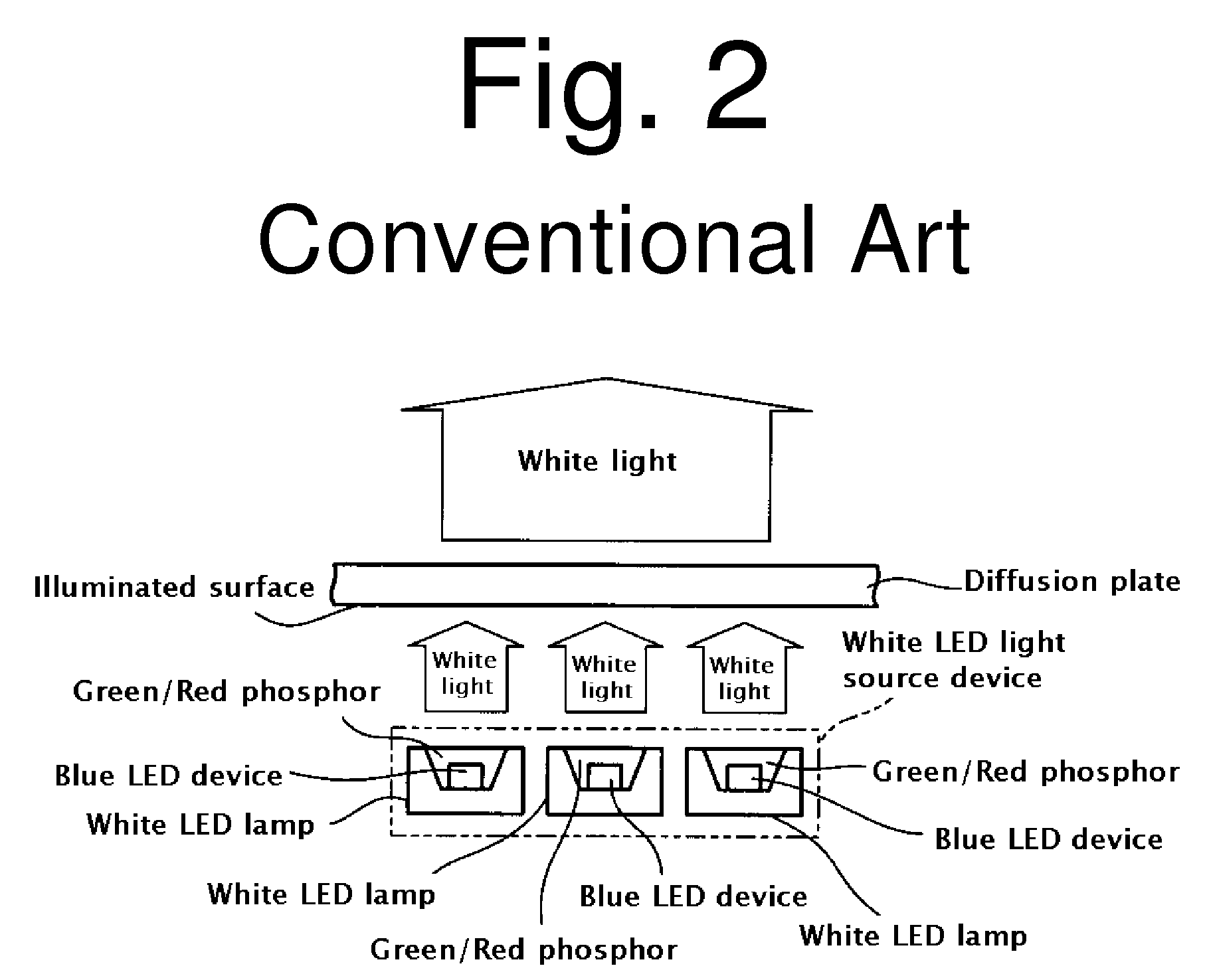

White LED Light Source Device and LED Backlight Using the Same

InactiveUS20080151527A1Improve utilization efficiencyWide range of colorsPoint-like light sourceGas discharge lamp usageLuminous intensityGreen-light

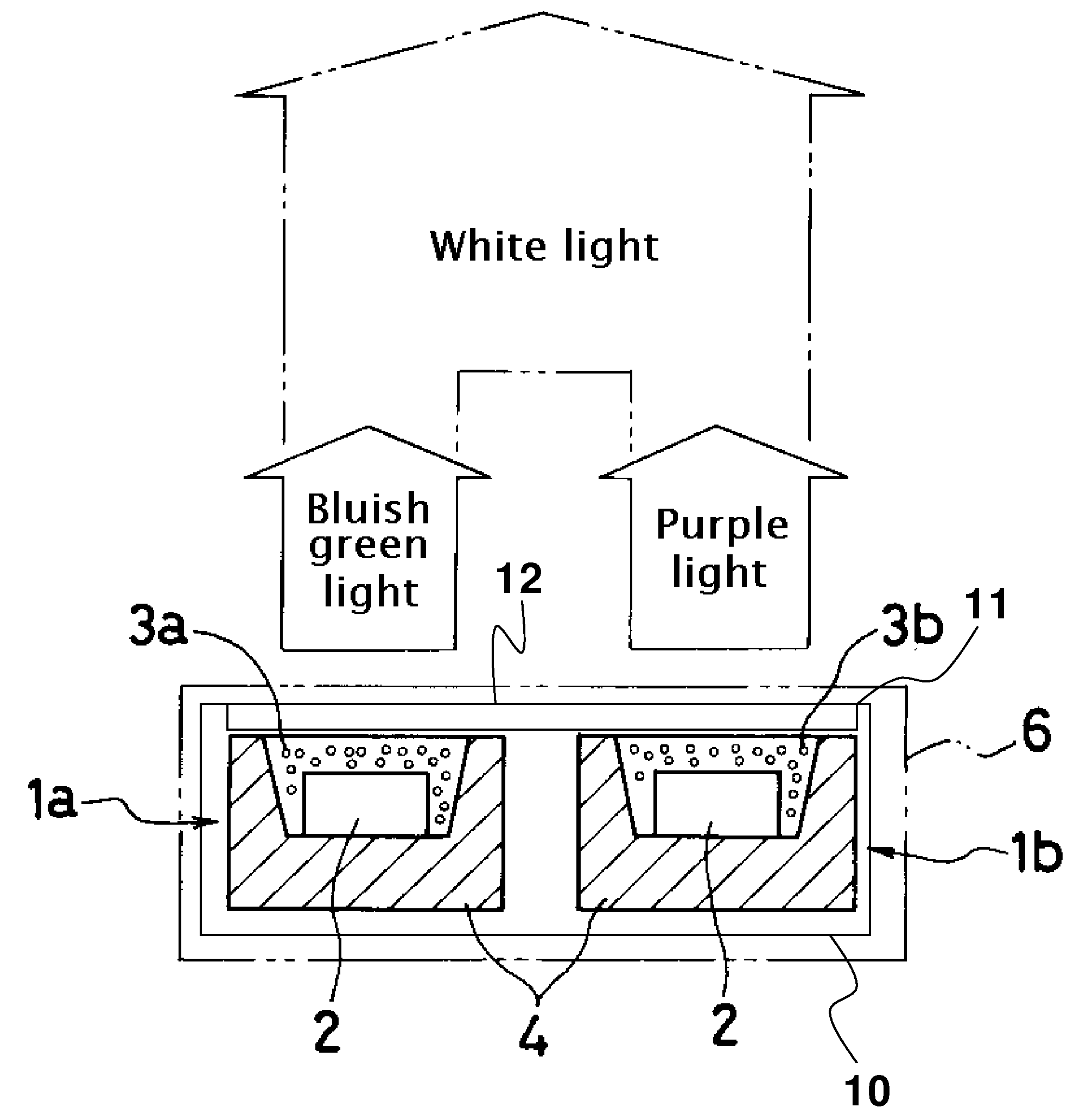

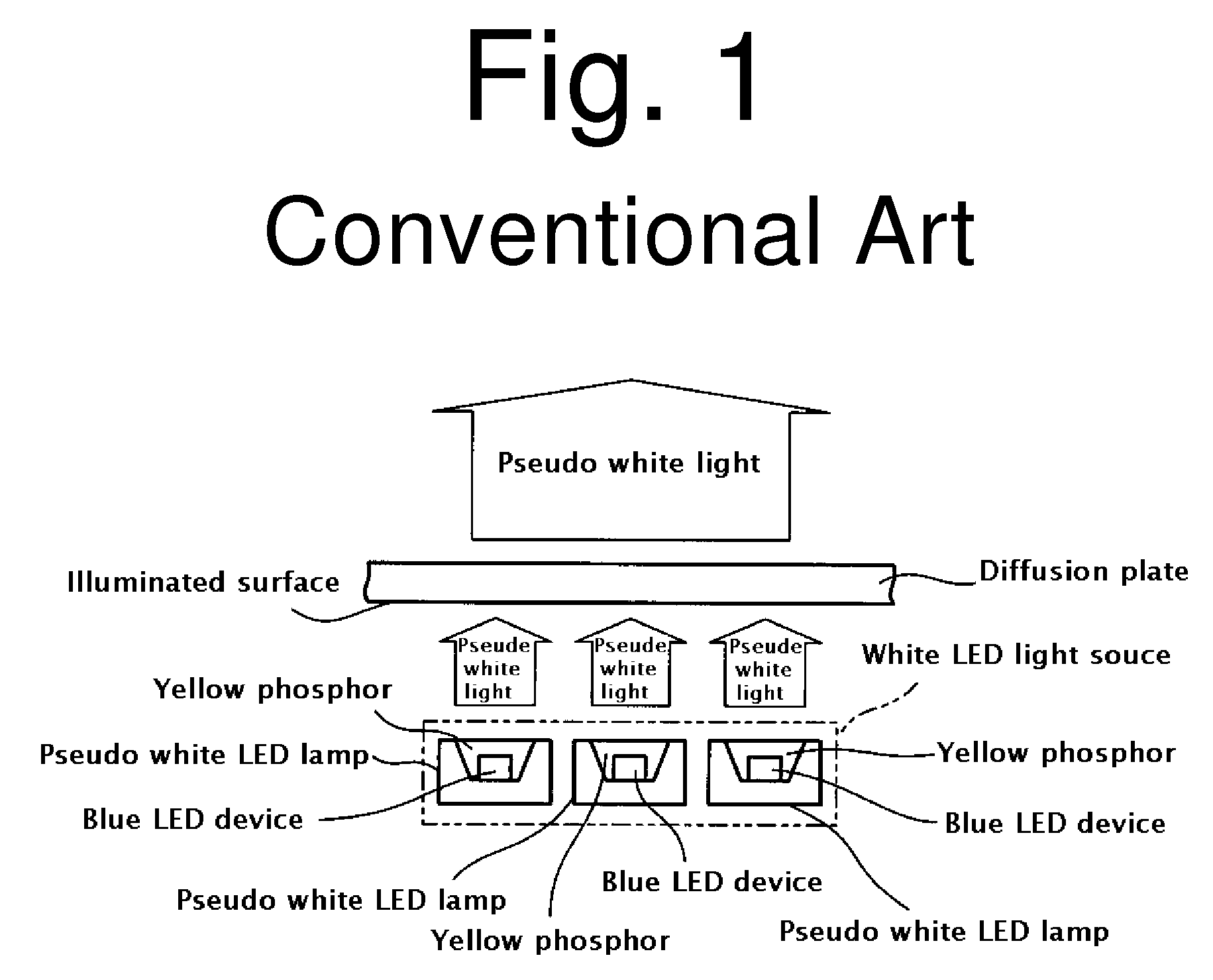

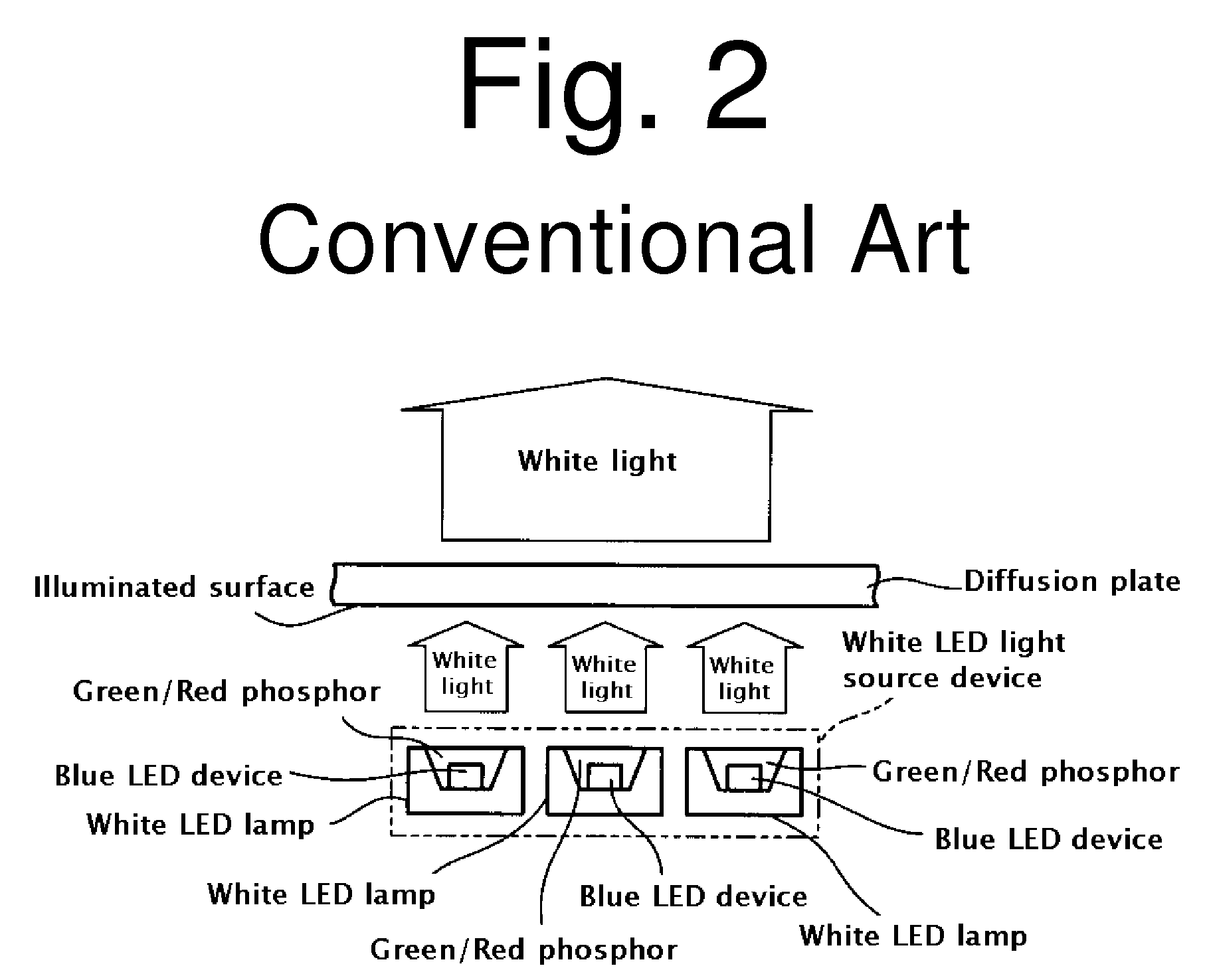

A white LED light source device and an LED backlight using the white LED light source can produce, among other features, white light with sufficient luminous intensity, uniform color tone, and high luminous utilization efficiency. A light path for producing white light with favorable color mixture can be shortened. The white LED light source device can be configured to include a bluish green LED lamp which can emit bluish green light by the combination of a blue LED device and a green phosphor material and a purple LED lamp which can emit purple light by the combination of a blue LED device and a red phosphor material. The bluish green light from the bluish green LED lamp and the purple light from the purple LED lamp are subjected to additive color mixture to produce white light with a spectrum containing three primary color wavelength components.

Owner:STANLEY ELECTRIC CO LTD

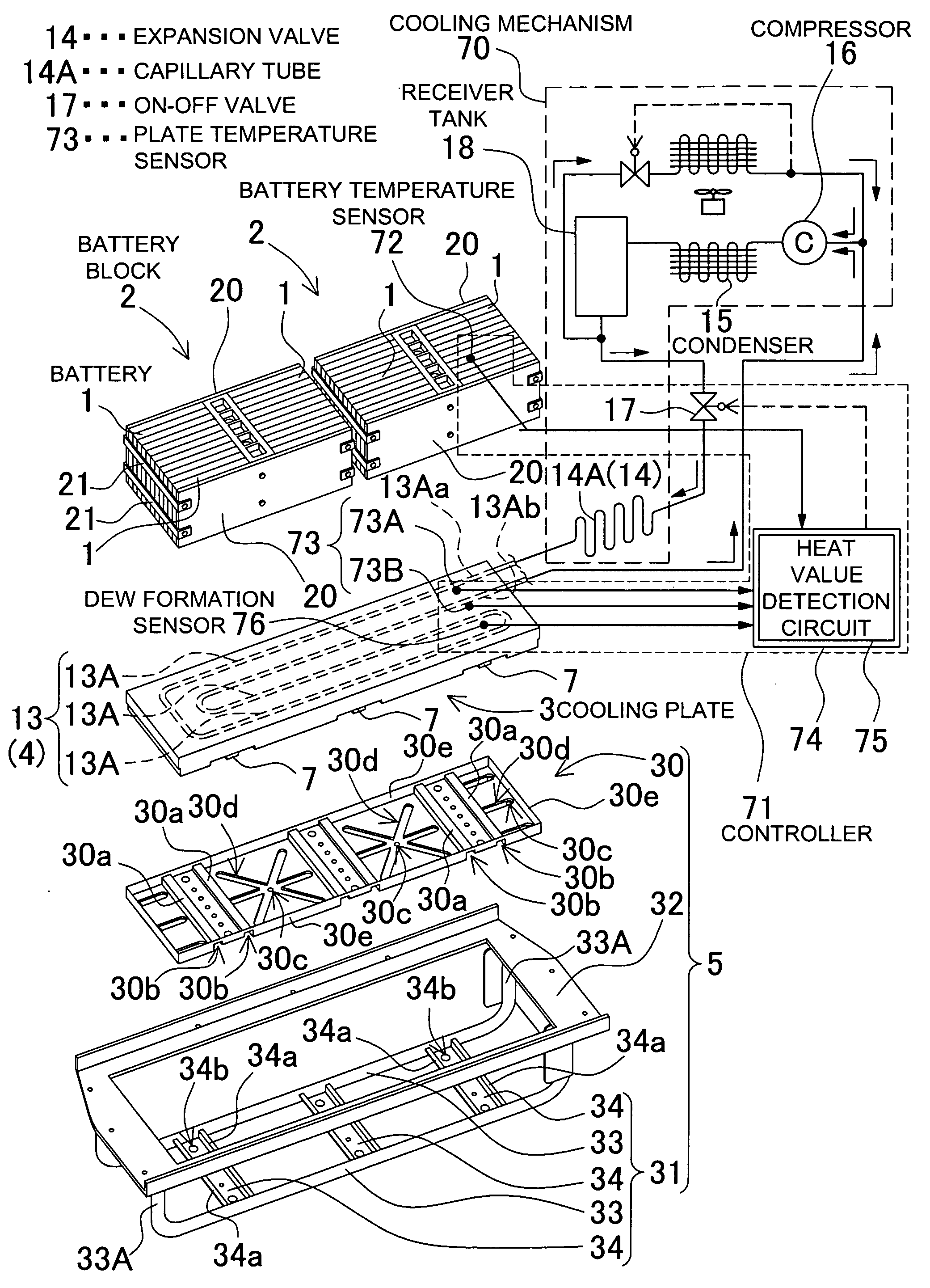

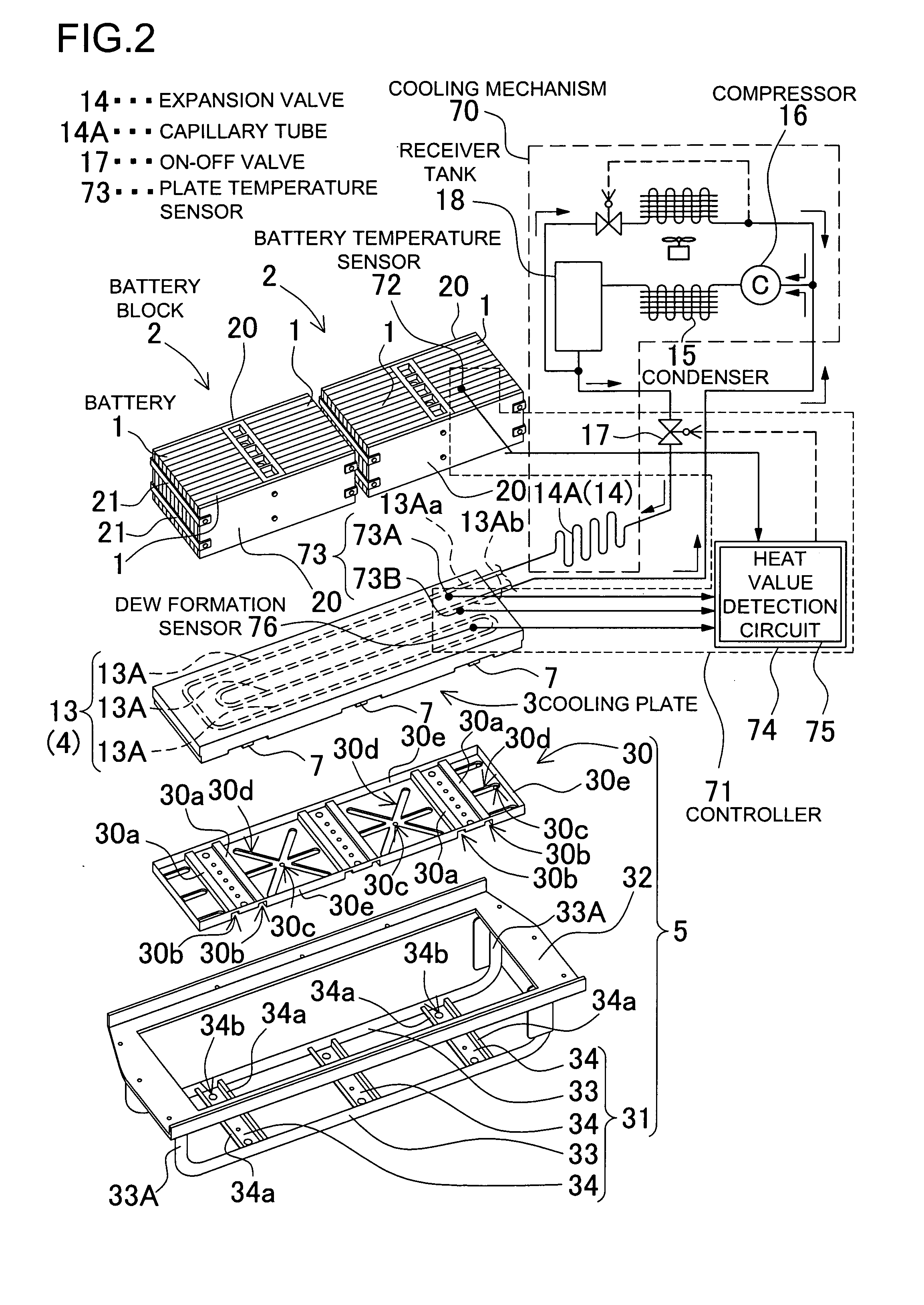

Electric power source used with vehicles

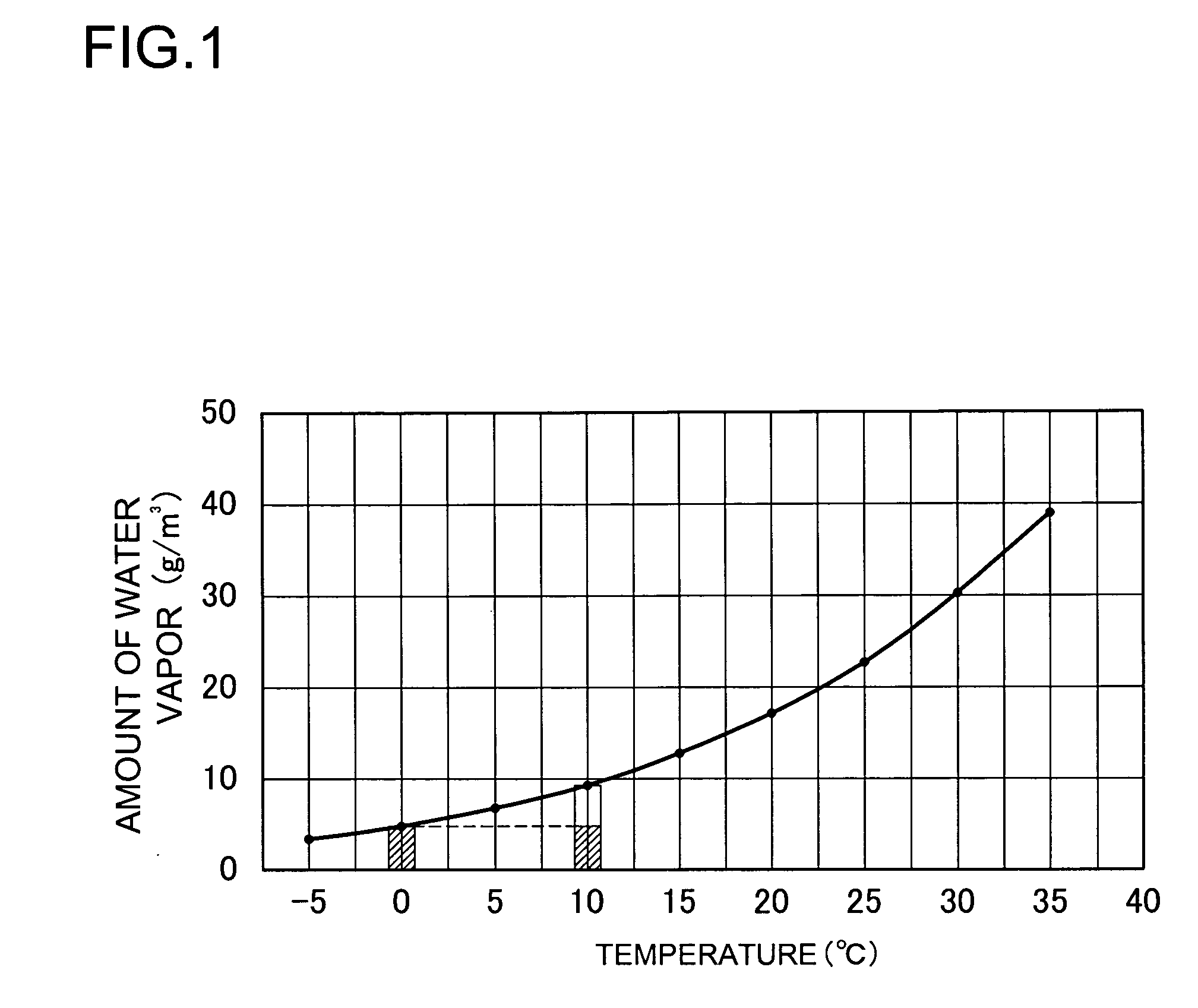

InactiveUS20090246606A1Temperature elevation can be reducedAvoid condensationCell temperature controlCell component detailsElectric power systemRechargeable cell

An electric power source used with a vehicle includes: a battery block composed of a rechargeable battery; a cooling plate thermally coupled with the battery block to cool the battery; a cooling mechanism for cooling the cooling plate; and a controller for controlling the cooling mechanism to switch the cooling plate into a cooled state and an uncooled state. The controller controls the cooling mechanism both in accordance with temperature of the battery block and temperature of the cooling plate, and switches the cooling plate into the cooled state and the uncooled state.

Owner:SANYO ELECTRIC CO LTD

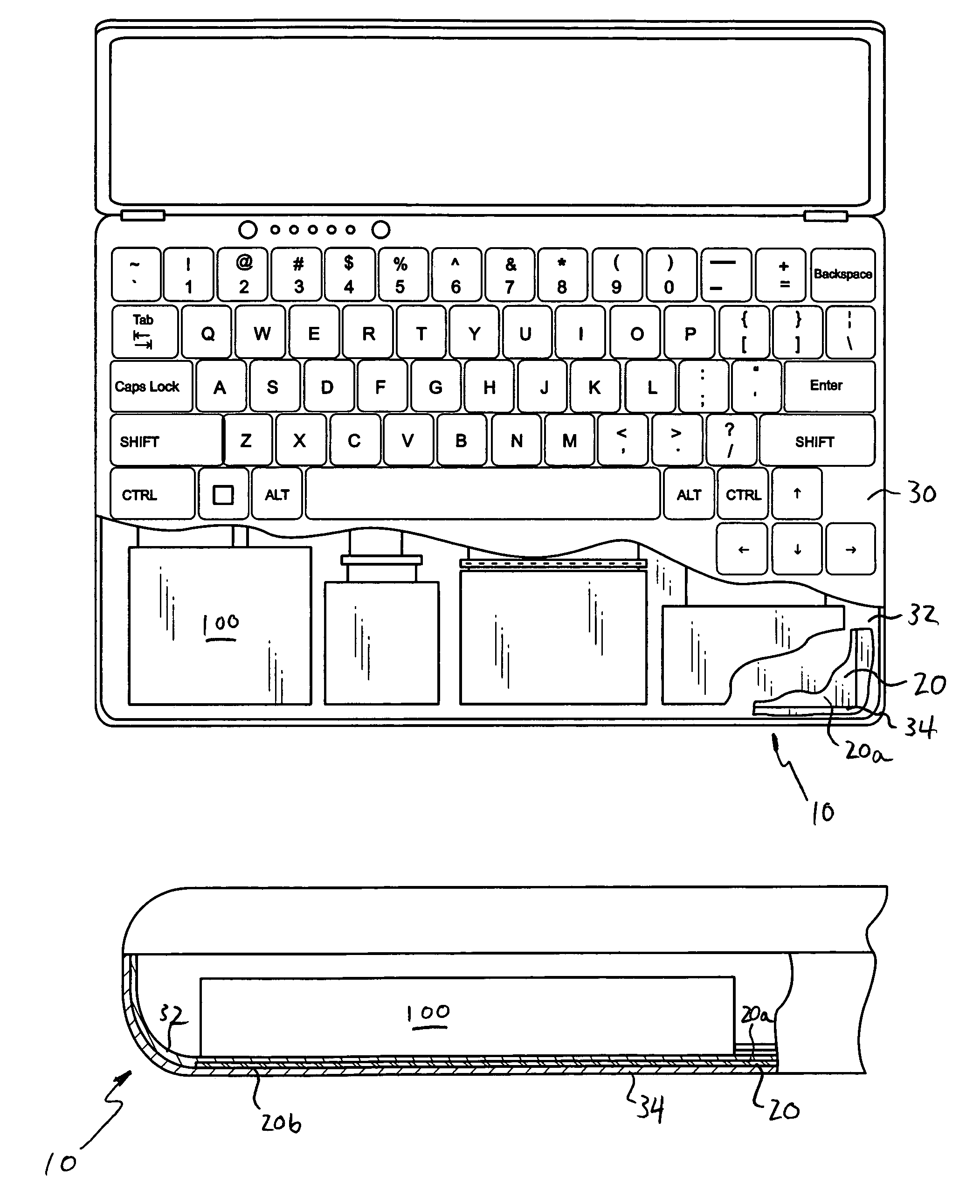

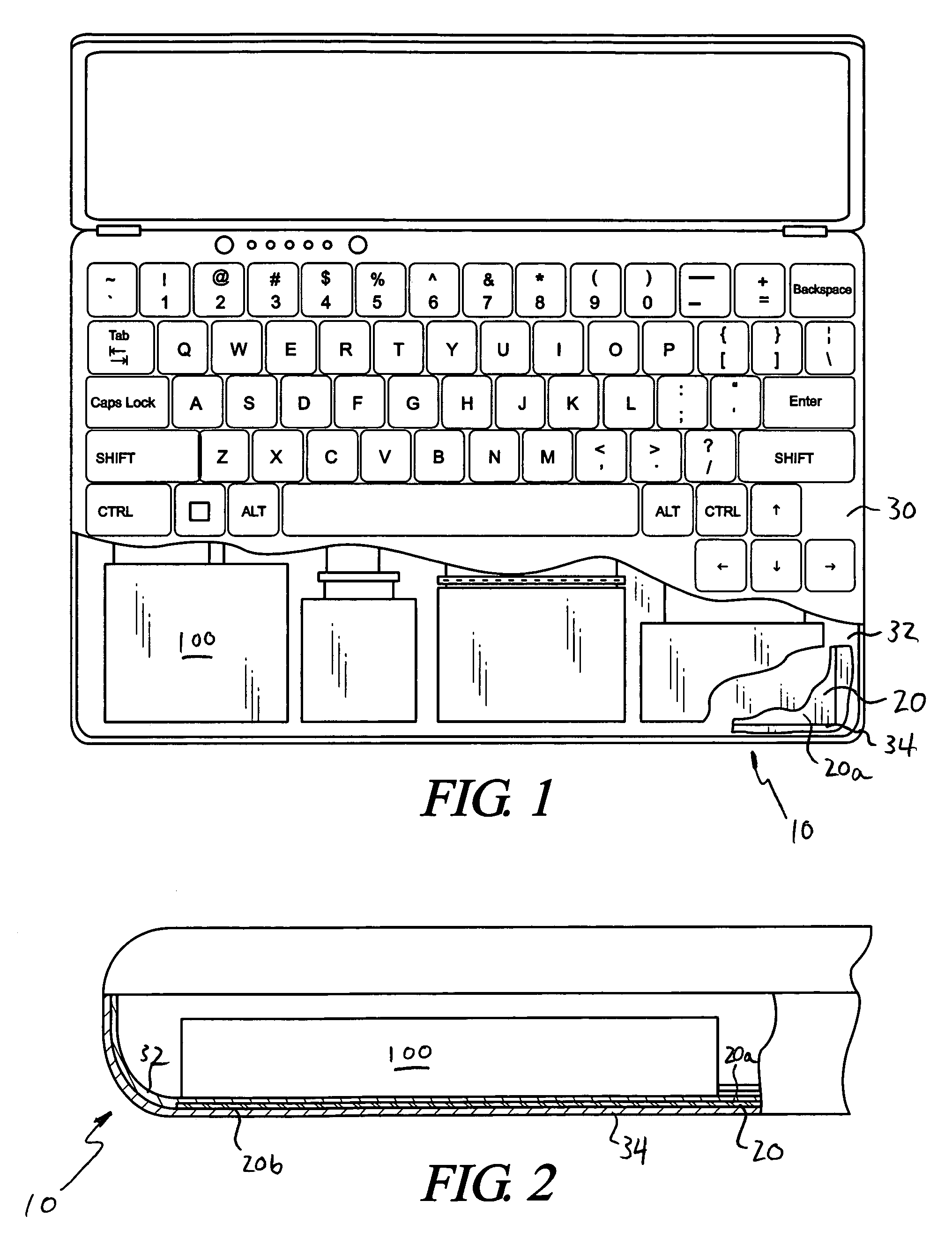

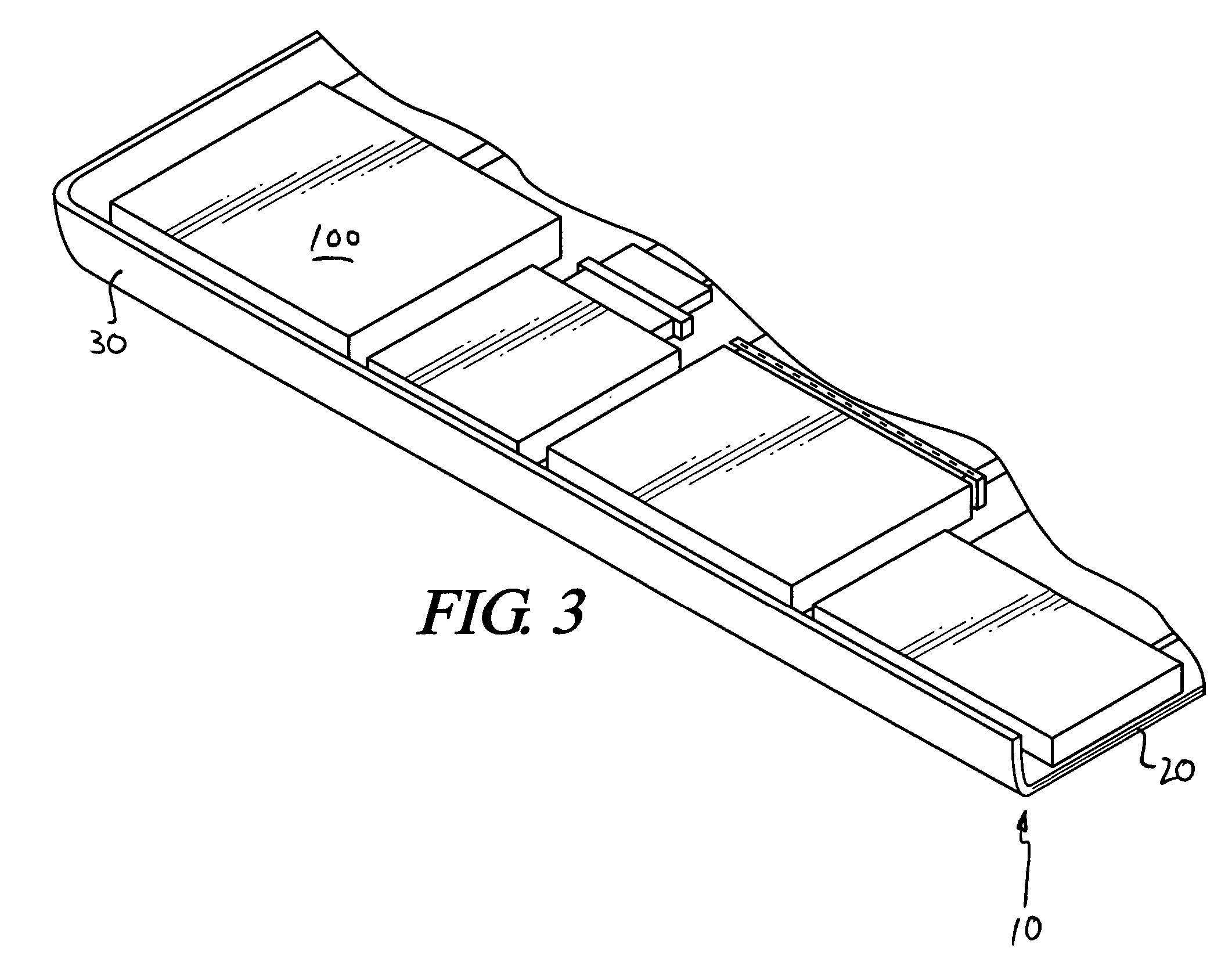

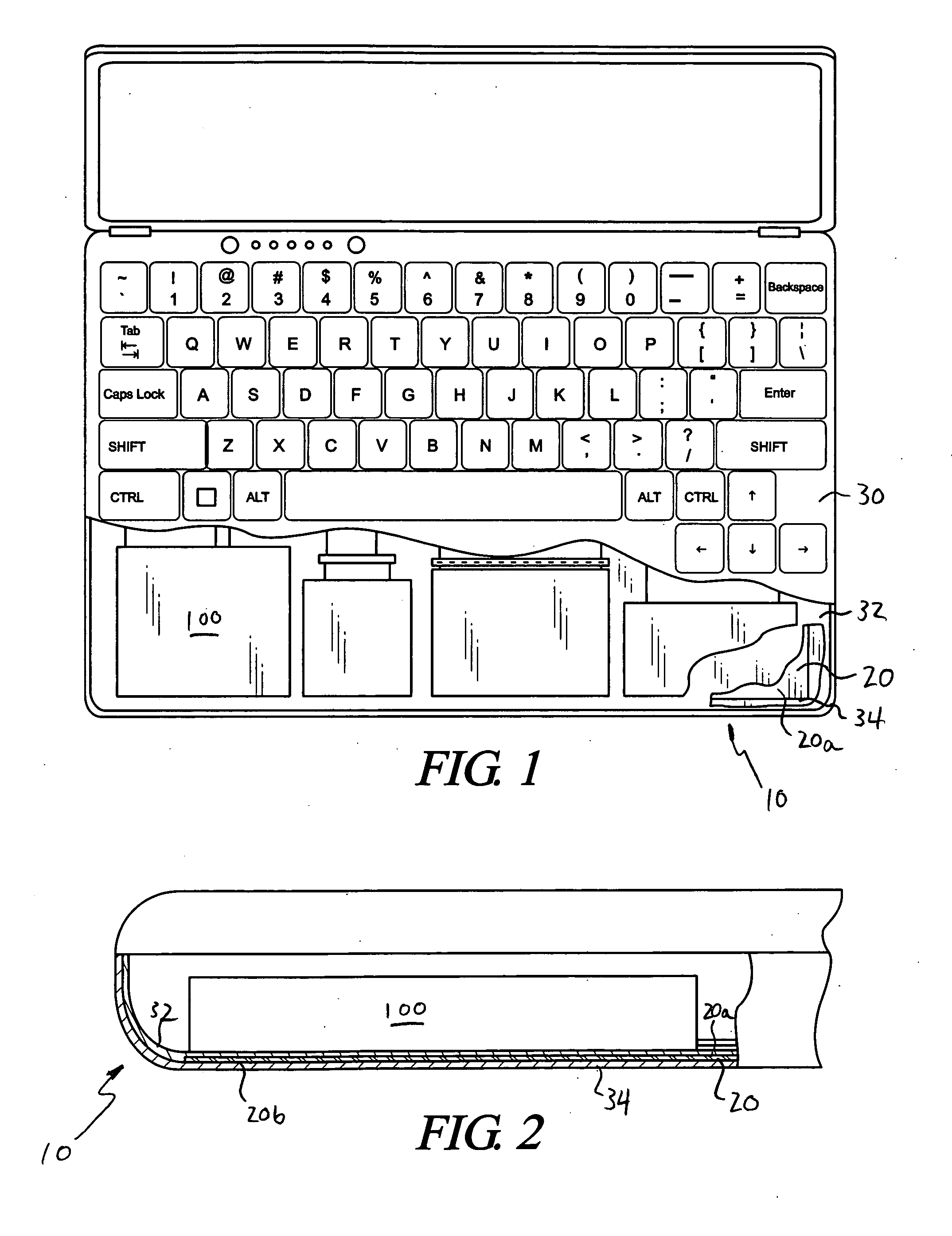

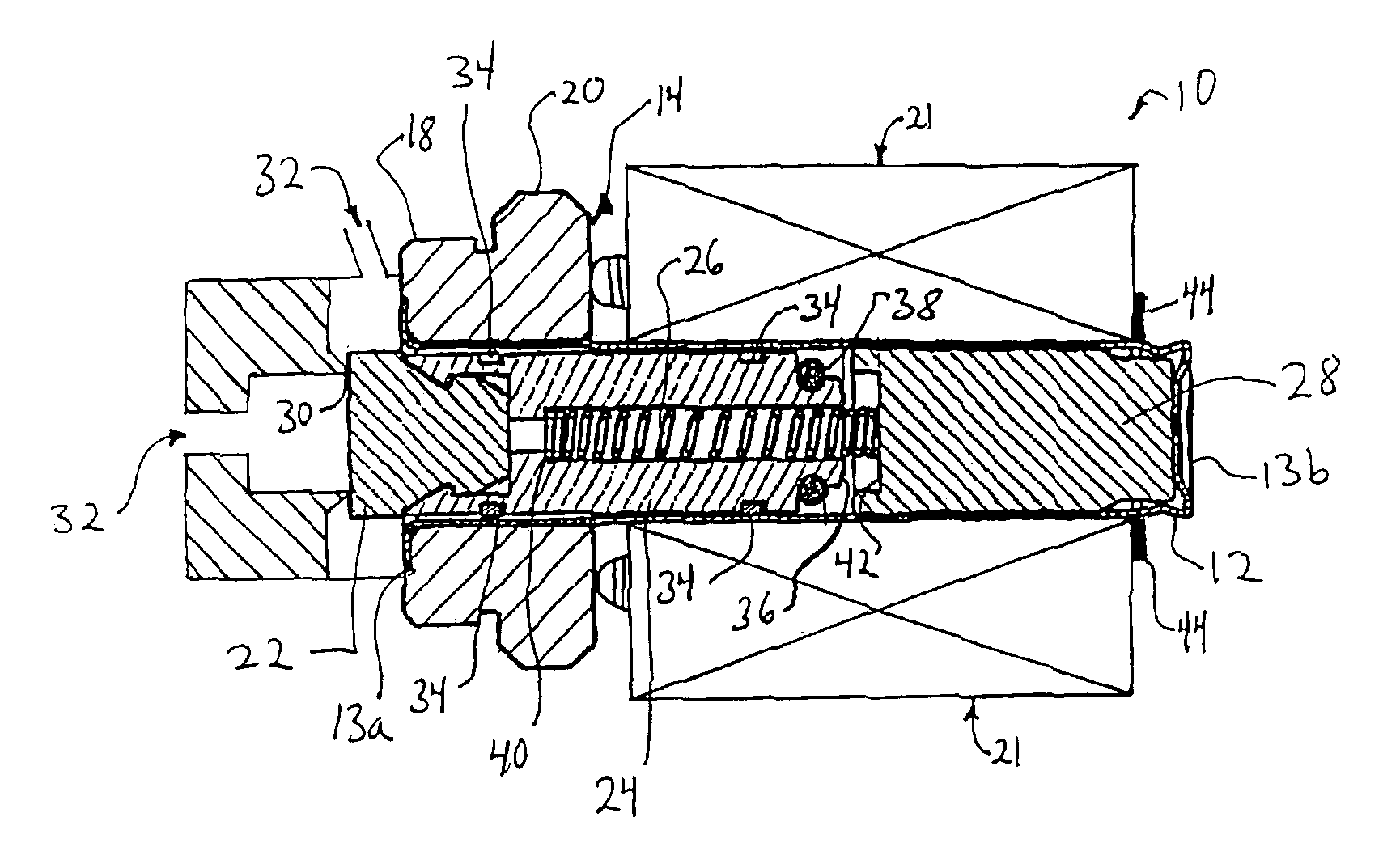

Integral heat spreader

ActiveUS7161809B2Heat dissipationReduce generationDigital data processing detailsSemiconductor/solid-state device detailsEngineeringThermal solution

A thermal solution for equipment containing a heat-generating component, which is positioned between the heat-generating component and an external surface of the equipment, where the thermal solution facilitates heat dissipation from the heat-generating component while shielding the external surface from the heat generated by the heat-generating component.

Owner:NEOGRAF SOLUTIONS LLC

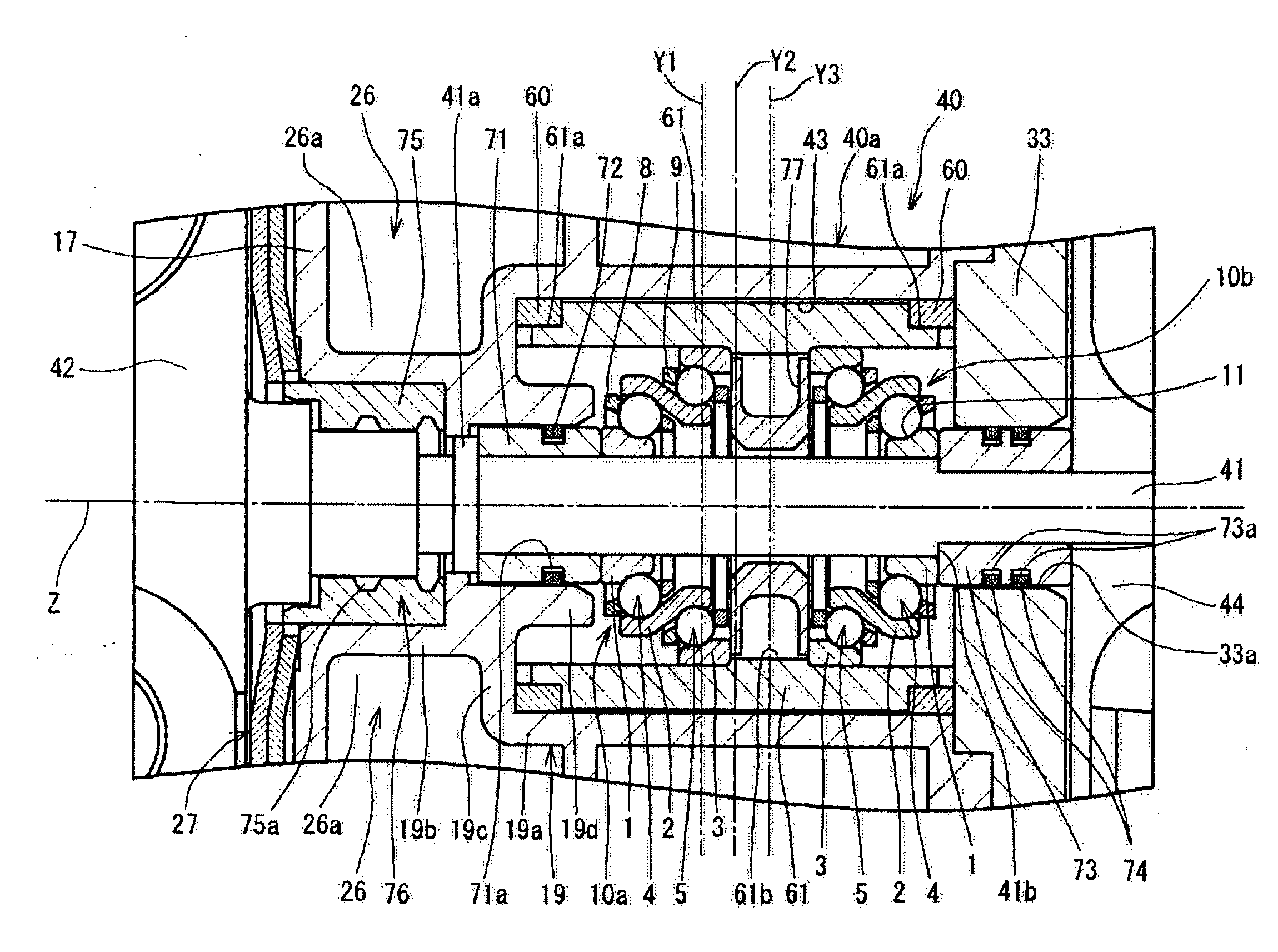

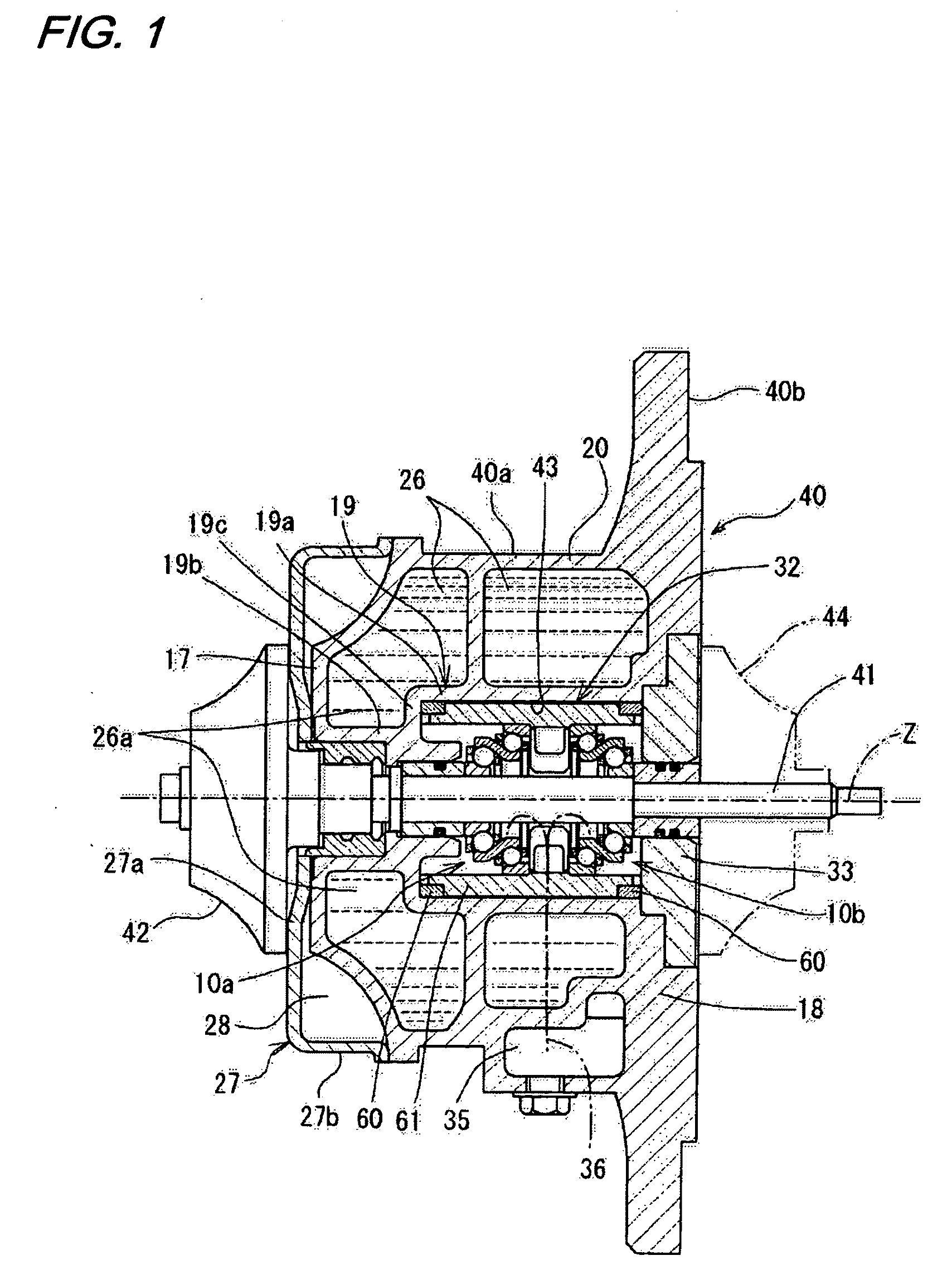

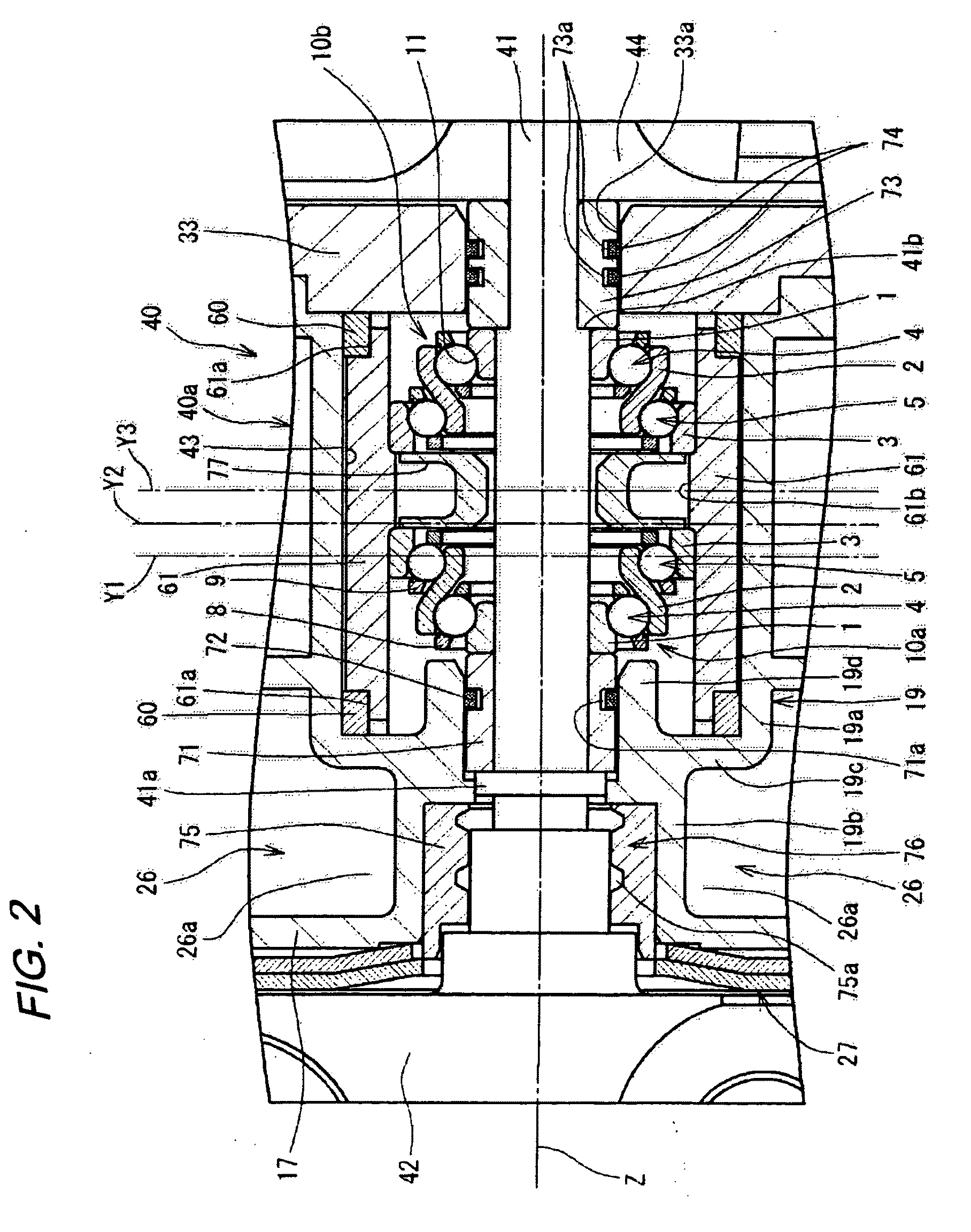

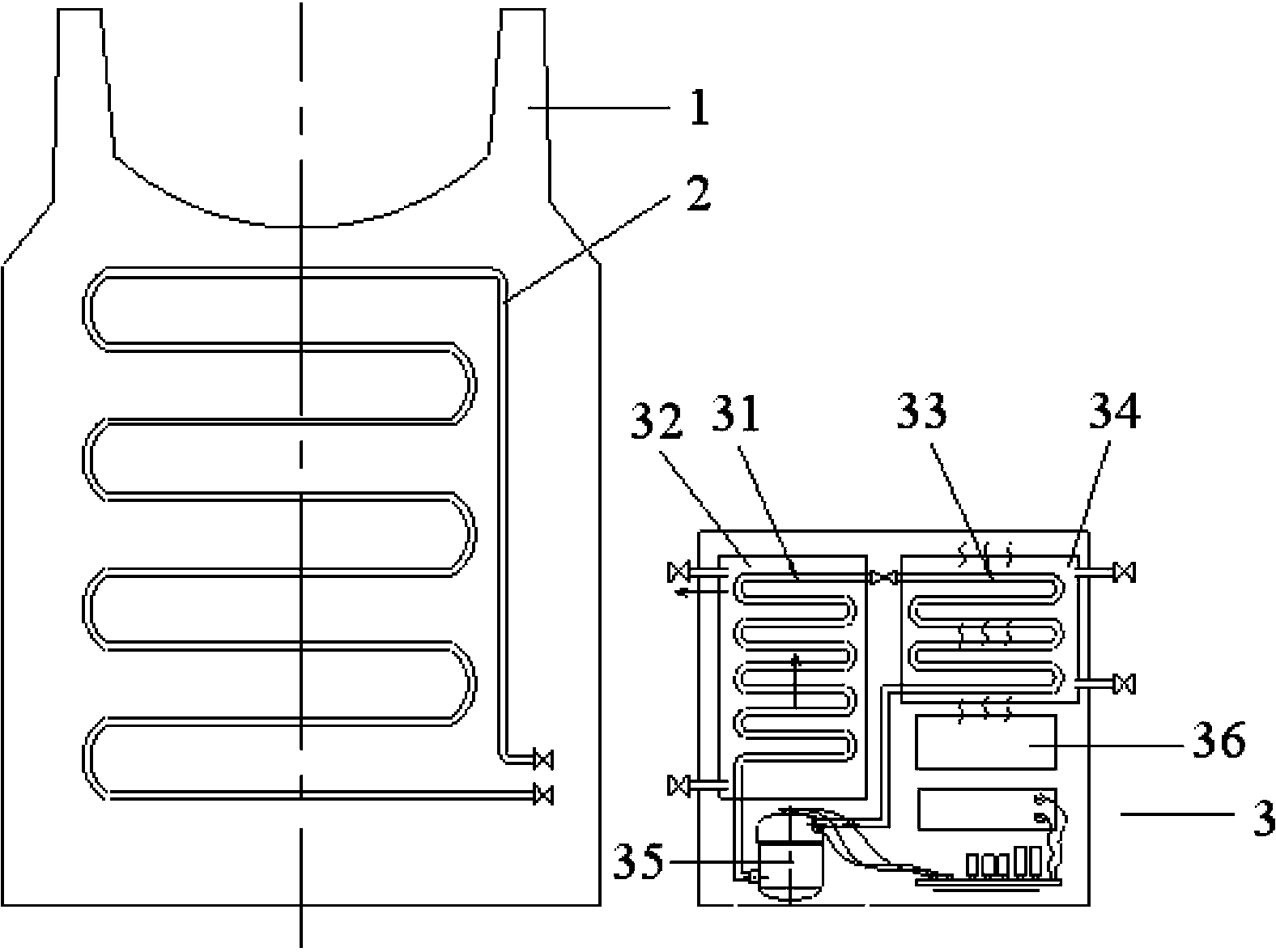

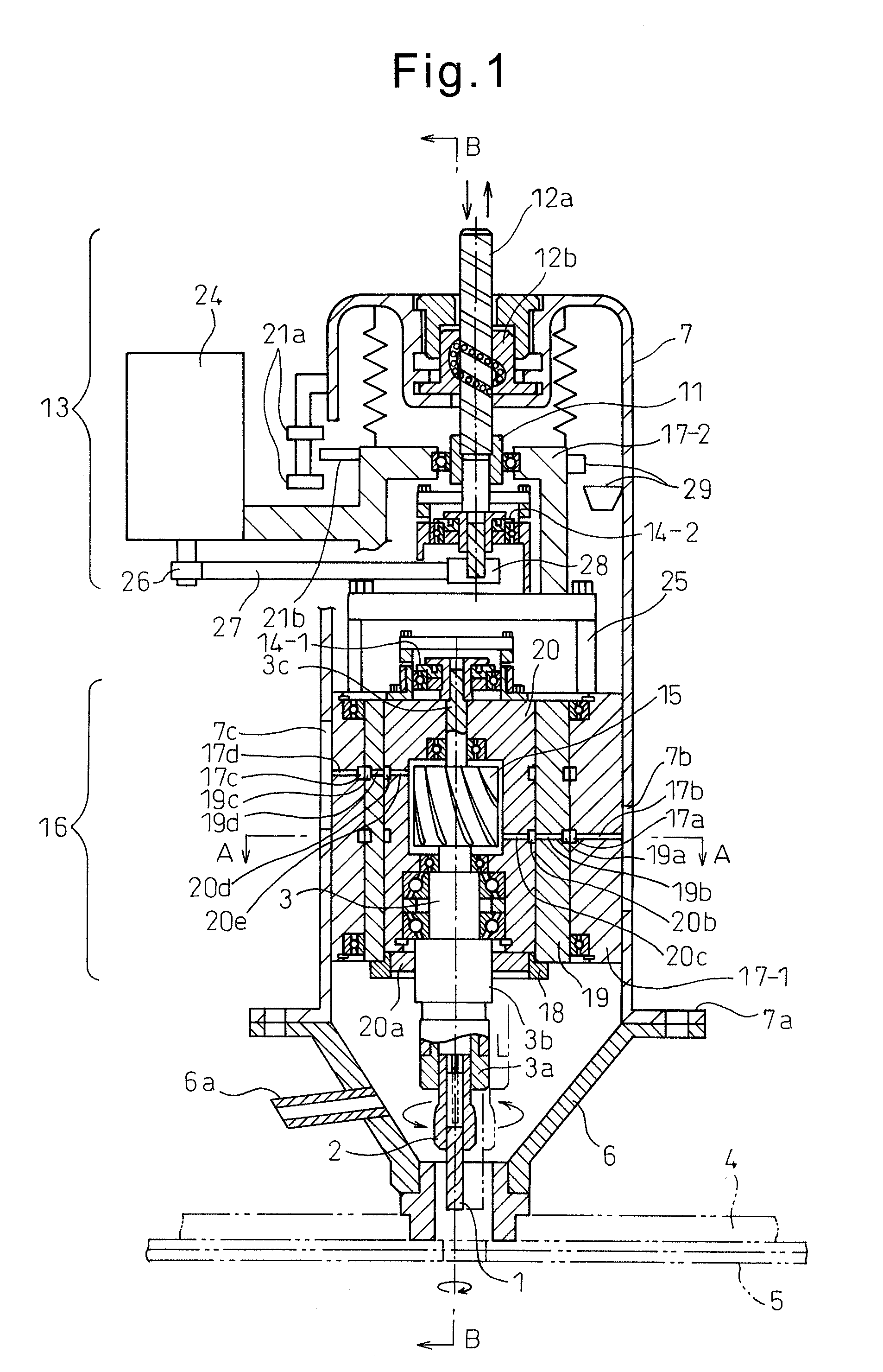

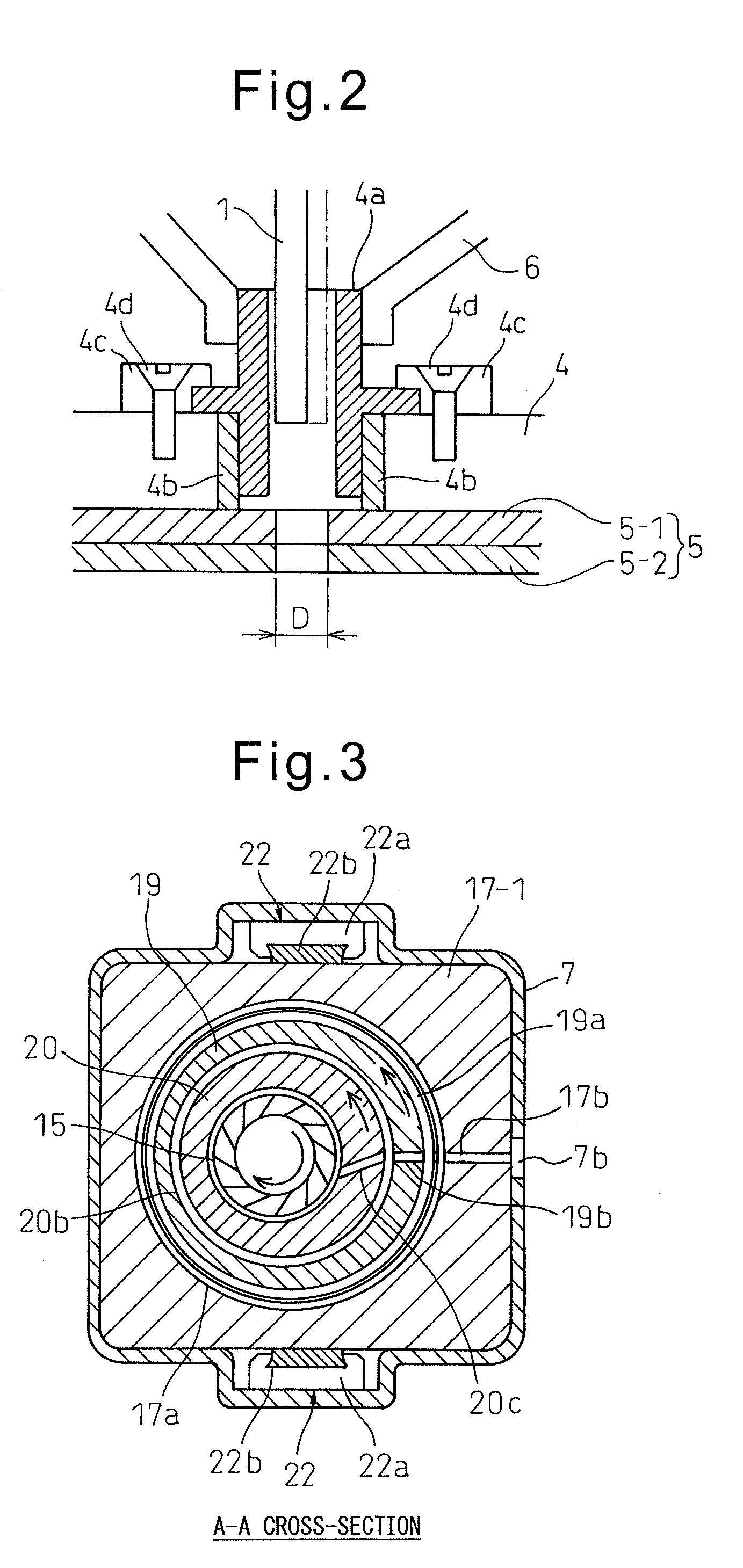

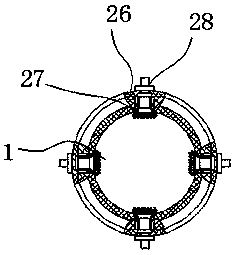

Rolling bearing device and turbocharger incorporating same

InactiveUS20090081040A1Heating effectReduce vibrationPump componentsShaftsRolling-element bearingTurbocharger

A rolling bearing device includes a bearing housing supported on a casing of a turbocharger, and a pair of rolling bearings mounted within the bearing housing and rotatably supporting a turbine shaft. A middle position between the pair of rolling bearings in an axial direction and a central portion of the bearing housing in the axial direction are offset from each other in the axial direction. Each of the rolling bearings includes an inner ring, an outer ring, an intermediate ring interposed between the inner and outer rings, a row of rolling elements rollably interposed between the inner ring and the intermediate ring, and a row of rolling elements rollably interposed between the intermediate ring and the outer ring. The intermediate ring has a damper function to be very slightly displaced or very slightly deformed elastically so as to damp vibration produced during rotation of the turbine shaft.

Owner:JTEKT CORP

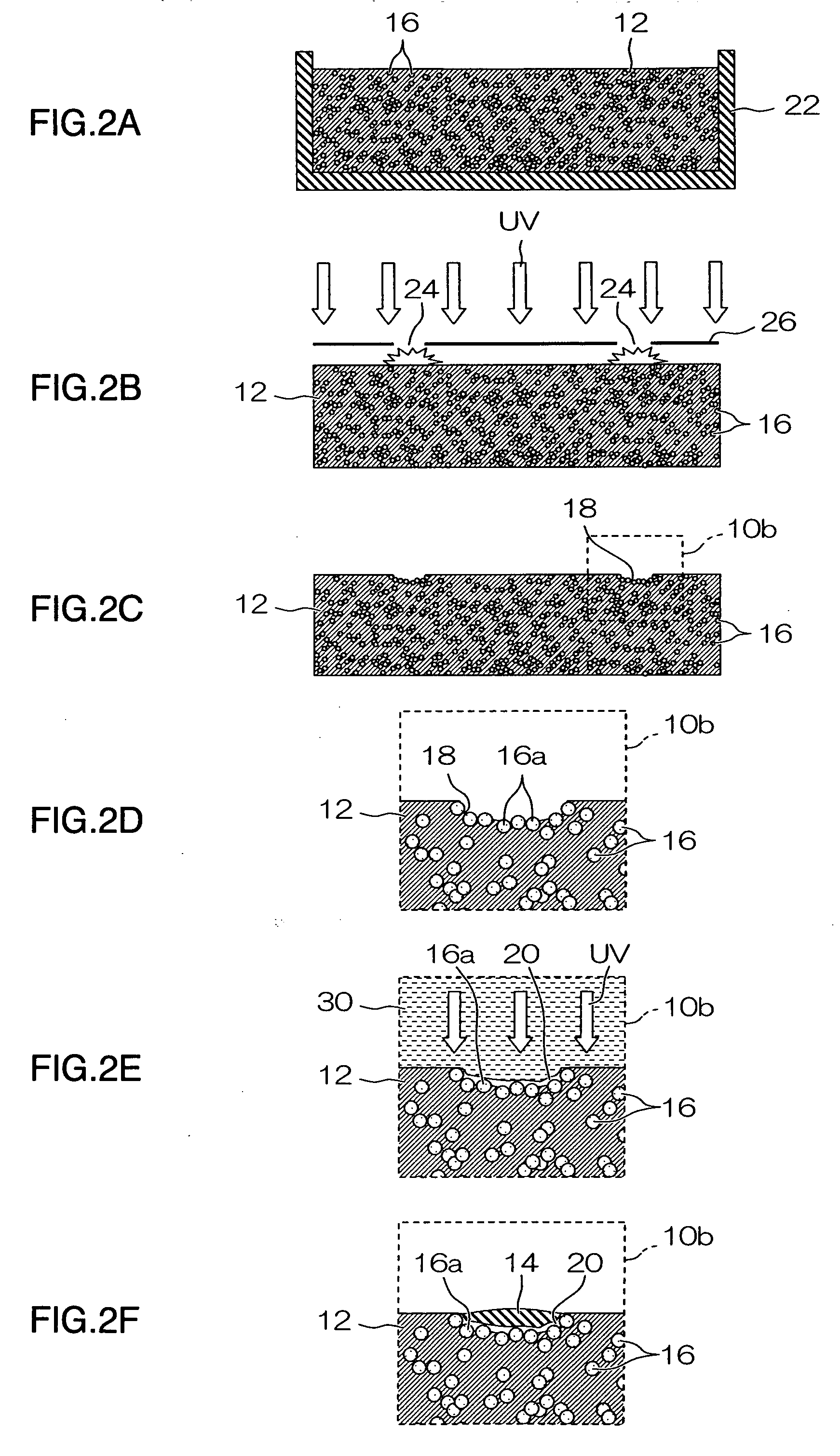

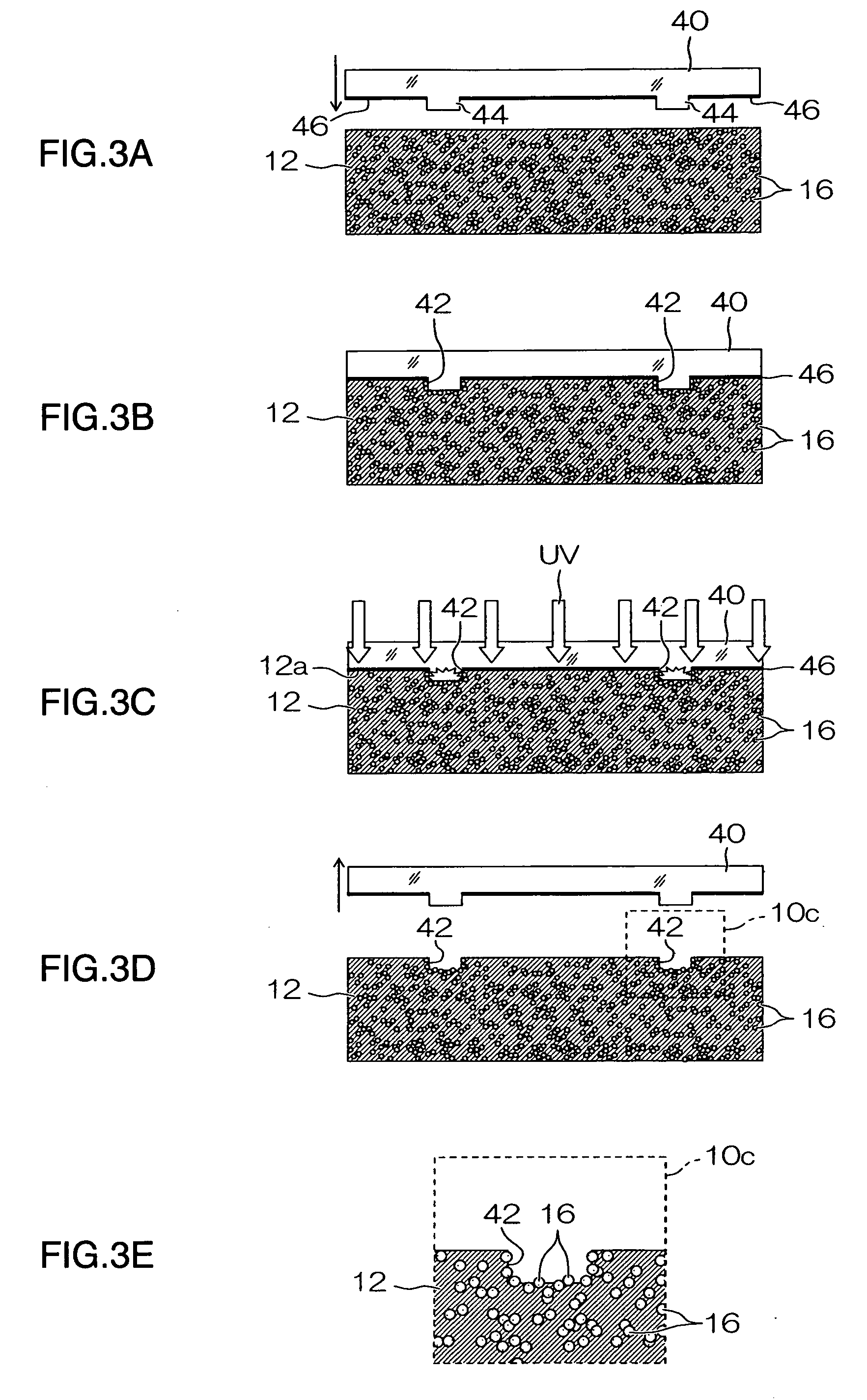

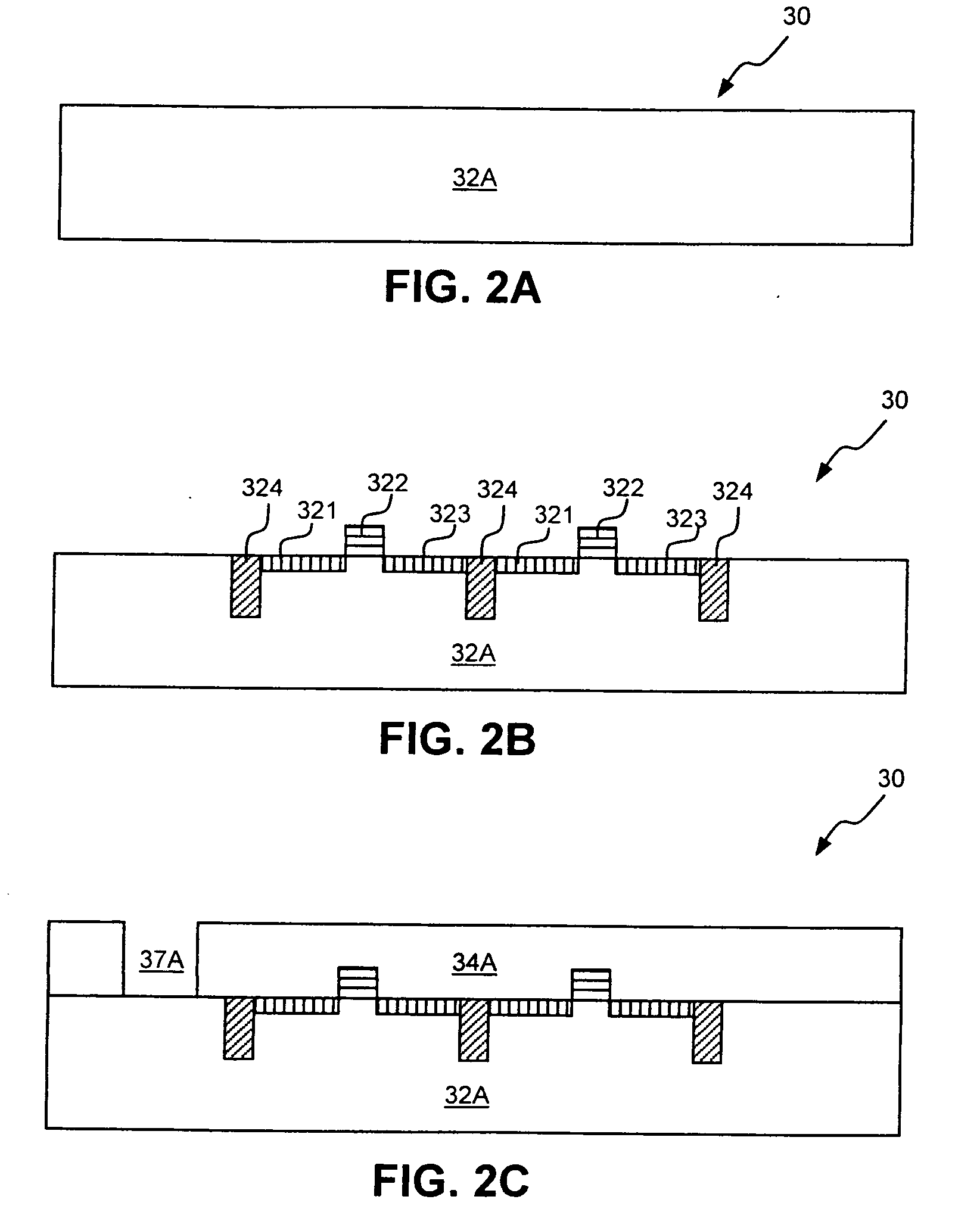

Method of manufacturing wiring substrate, and wiring substrate

InactiveUS20070014975A1Improve adhesionHigh bonding strengthPretreated surfacesTransparent dielectricsOptoelectronicsRadiation exposure

The method of manufacturing a wiring substrate comprises the steps of: performing a pattern exposure of a resin layer containing photocatalyst particles, in a shape of a desired wiring pattern so that the photocatalyst particles are exposed at a surface of the resin layer; performing irradiation of radiation to the resin layer having the exposed photocatalyst particles while the resin layer having the exposed photocatalyst particles is immersed in an aqueous solution of a metallic salt so that a photochemical reduction and precipitating of a metal film onto the exposed photocatalyst particles are performed; and forming a conducting layer on the metal film.

Owner:FUJIFILM CORP

Integral heat spreader

ActiveUS20060056157A1Heat dissipationReduce generationDigital data processing detailsSemiconductor/solid-state device detailsEngineeringThermal solution

A thermal solution for equipment containing a heat-generating component, which is positioned between the heat-generating component and an external surface of the equipment, where the thermal solution facilitates heat dissipation from the heat-generating component while shielding the external surface from the heat generated by the heat-generating component.

Owner:NEOGRAF SOLUTIONS LLC

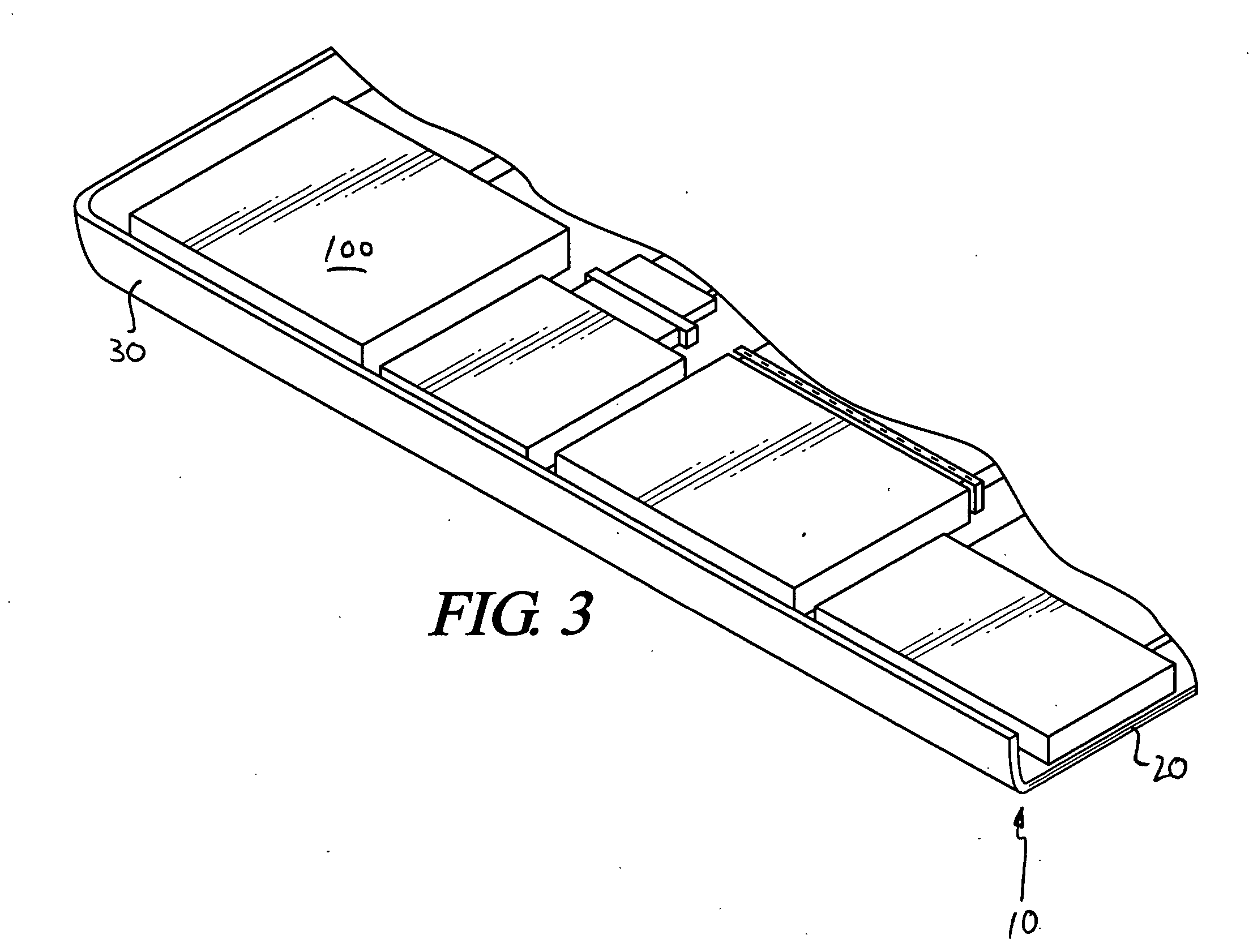

Detachable type refrigerating and heating air conditioner clothing

The invention relates to a detachable type refrigerating and heating air conditioner clothing. A pipeline is arranged in a fabric of the air conditioner clothing, an input and an outlet of the pipeline are connected with an external heat pump system, the heat pump system comprises a miniature pump, a pipeline at the evaporation side and a pipeline at the condensing side, the pipeline at the evaporation side and the pipeline at the condensing side are connected with the miniature pump, and a temperature lowering fan is arranged on the pipeline at the condensing side. Compared with the prior art, the air conditioner clothing has the advantages that the pipeline in the fabric is externally connected with different pipelines of the heat pump system, and is connected with a water tank at the evaporation side to exchange heat, so the heating effect is realized; the pipeline is connected with a water tank at the condensing side, the refrigerating effect is realized, and the all-time carrying of the external heat pump equipment is not needed; especially when the clothing is used in a short time, the clothing is connected with the system in advance, and the heat pump system is detached after the temperature is lowered or raised; in addition, a plurality of heat pump systems are arranged, and are placed at different locations, so the clothing can be used at any location.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

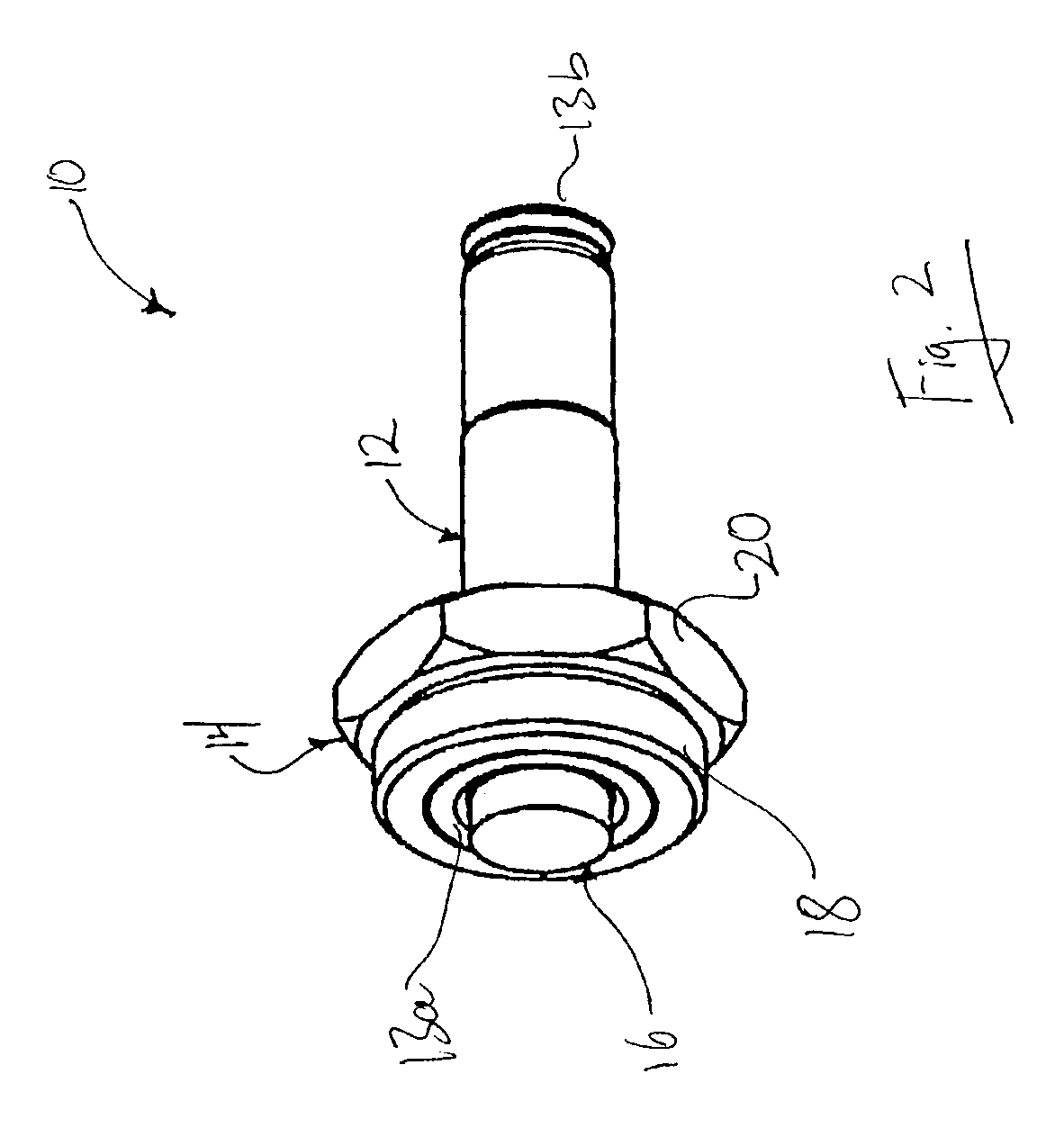

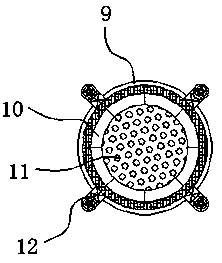

Hole making apparatus

InactiveUS20120294689A1Easy to operateGuaranteed to workWorkpiecesTurning toolsBall screwEngineering

An eccentric rotation drive mechanism which is rotatably contained in a first slide container is provided with an outer cylinder, an internal cylinder which is housed at eccentric position thereof and a first air motor contained therein. One end of a rotation shaft portion, that is, a shaft of the first air motor is fastened to a hole making tool, the other end of which is coupled to the end surface of the outer cylinder through a first reduction device. The rotation of the air motor makes the hole making tool rotate and revolve and simultaneously the rotation of a second air motor mounted outside of a casing is transmitted to a ball screw through a rotation transmission device inside of a second slide container to advance and retreat a feed drive mechanism so as to machine a hole in a workpiece.

Owner:YAGASITA HUKUZO +1

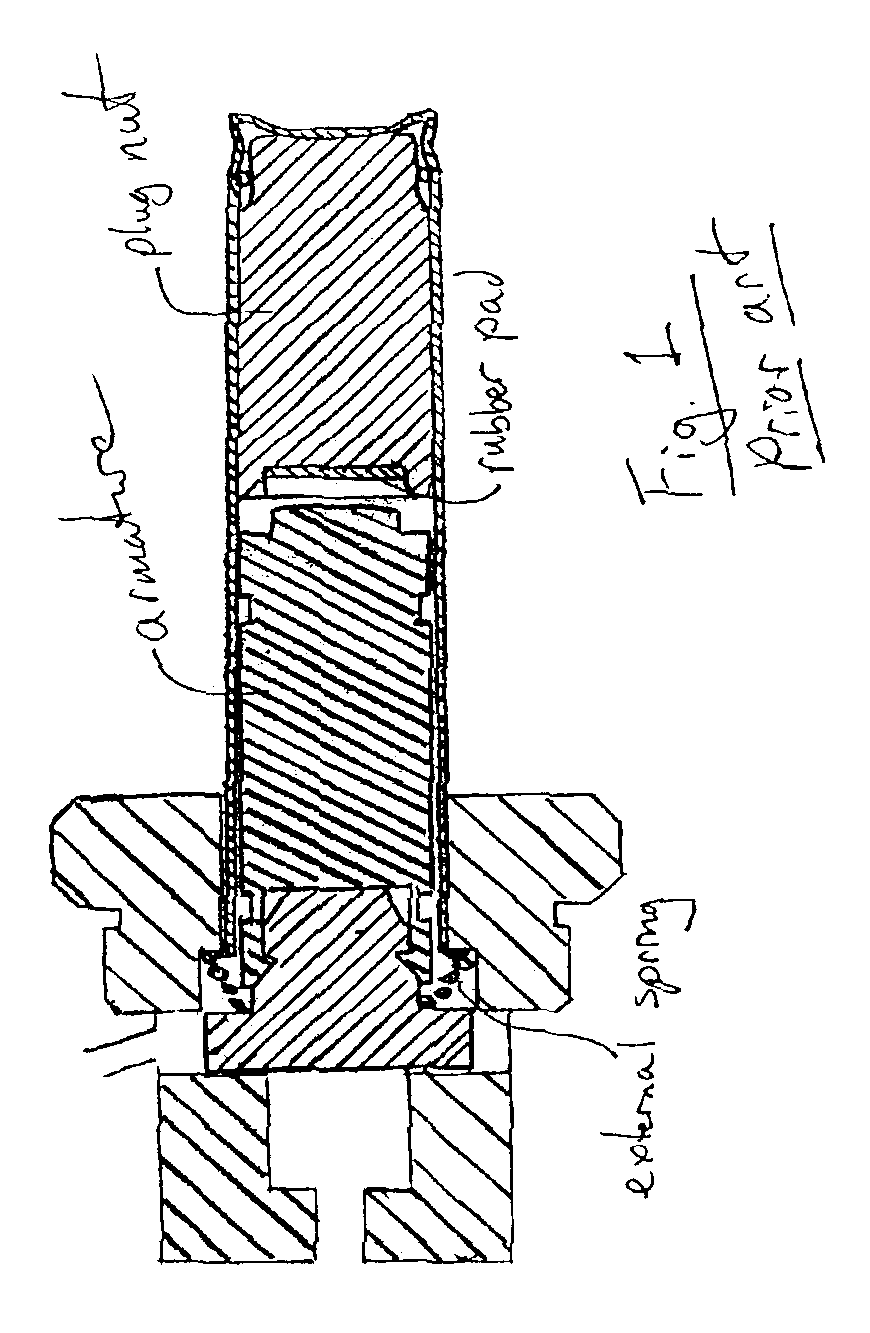

Solenoid valve

InactiveUS6935612B2Easily replaceable interfaceUniform pressureOperating means/releasing devices for valvesMagnetic materialsSolenoid valveEngineering

The solenoid valve of the present invention includes an armature with a protrusion and a plug nut with a recess for receiving the protrusion. The protrusion includes a polymer o-ring. The protrusion is configured such that it slides freely within the recess. The o-ring contacts the plug nut to prevent further motion of the armature toward the plug nut after the protrusion has entered the recess.

Owner:CAIRE

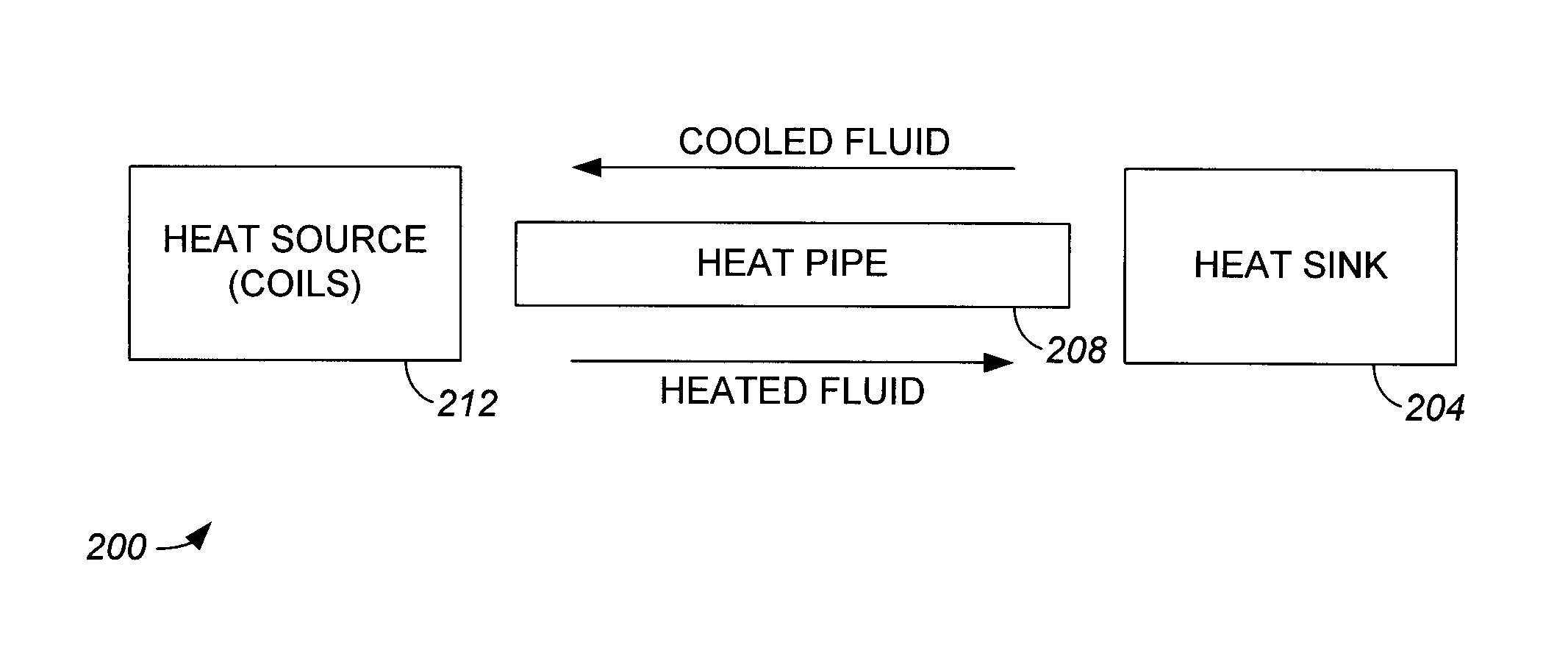

Detachable heat sink

InactiveUS7164466B2Reduce heatHeating effectSemiconductor/solid-state device manufacturingHeat exchange apparatusHeat spreaderWaste management

Owner:NIKON CORP

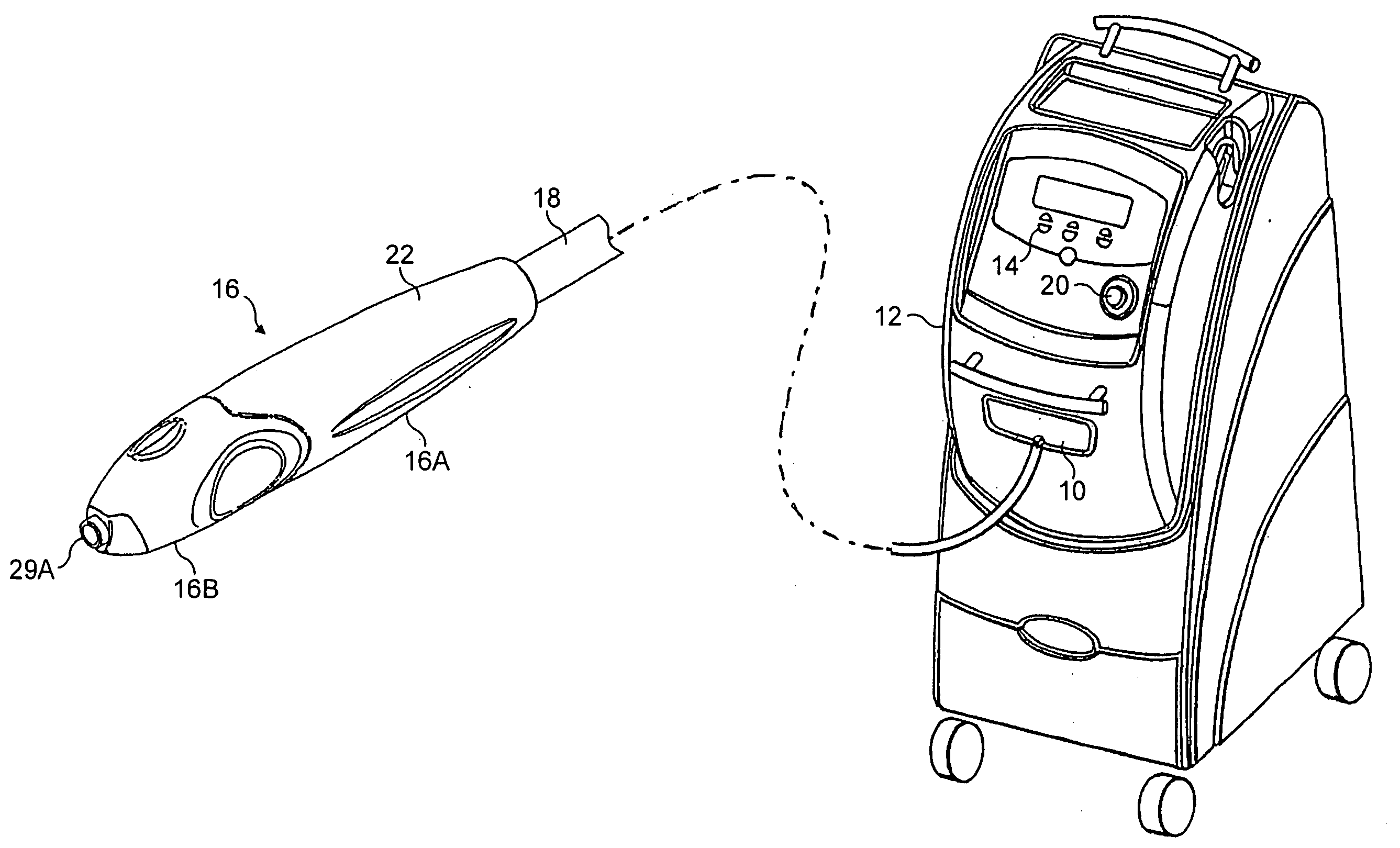

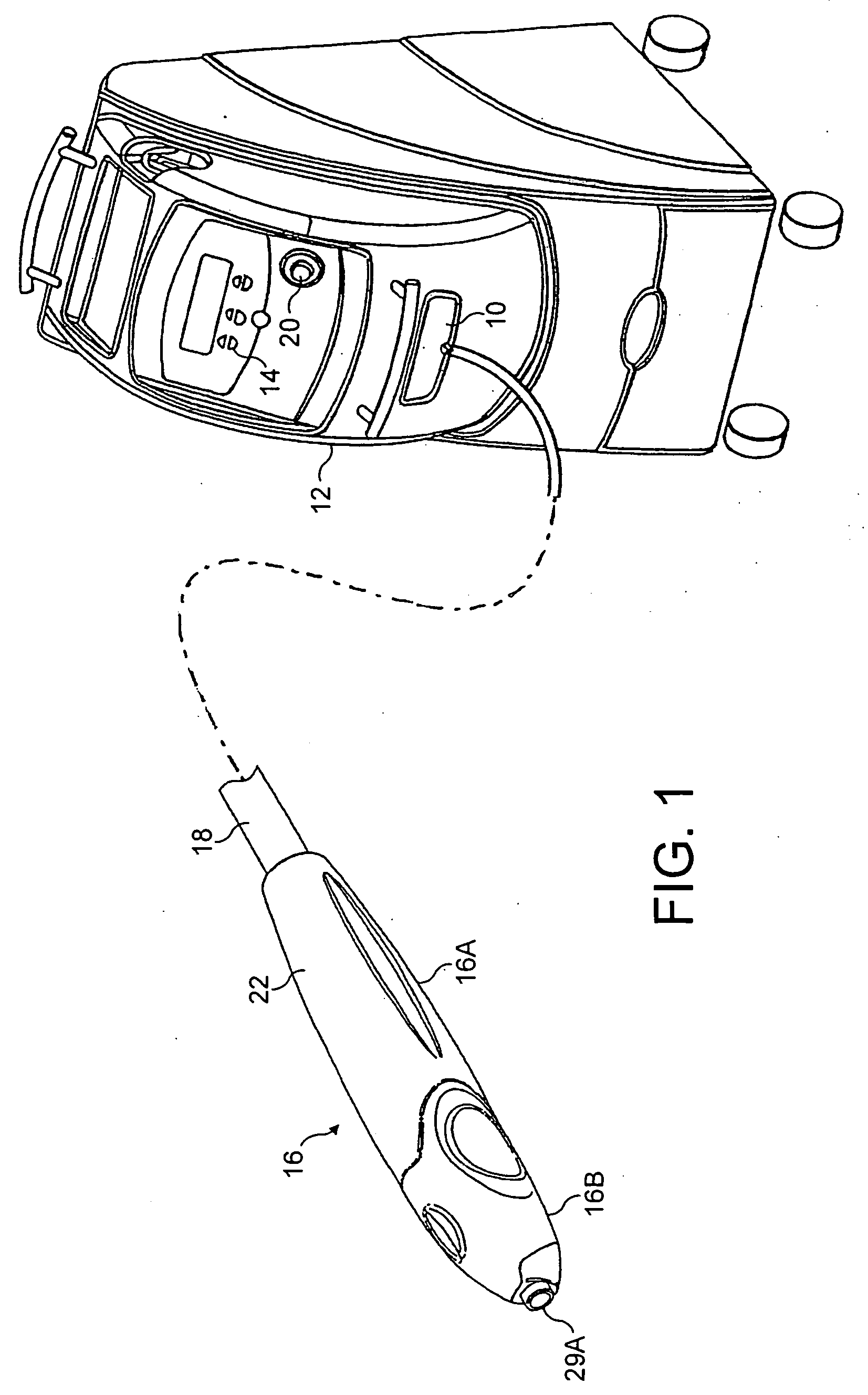

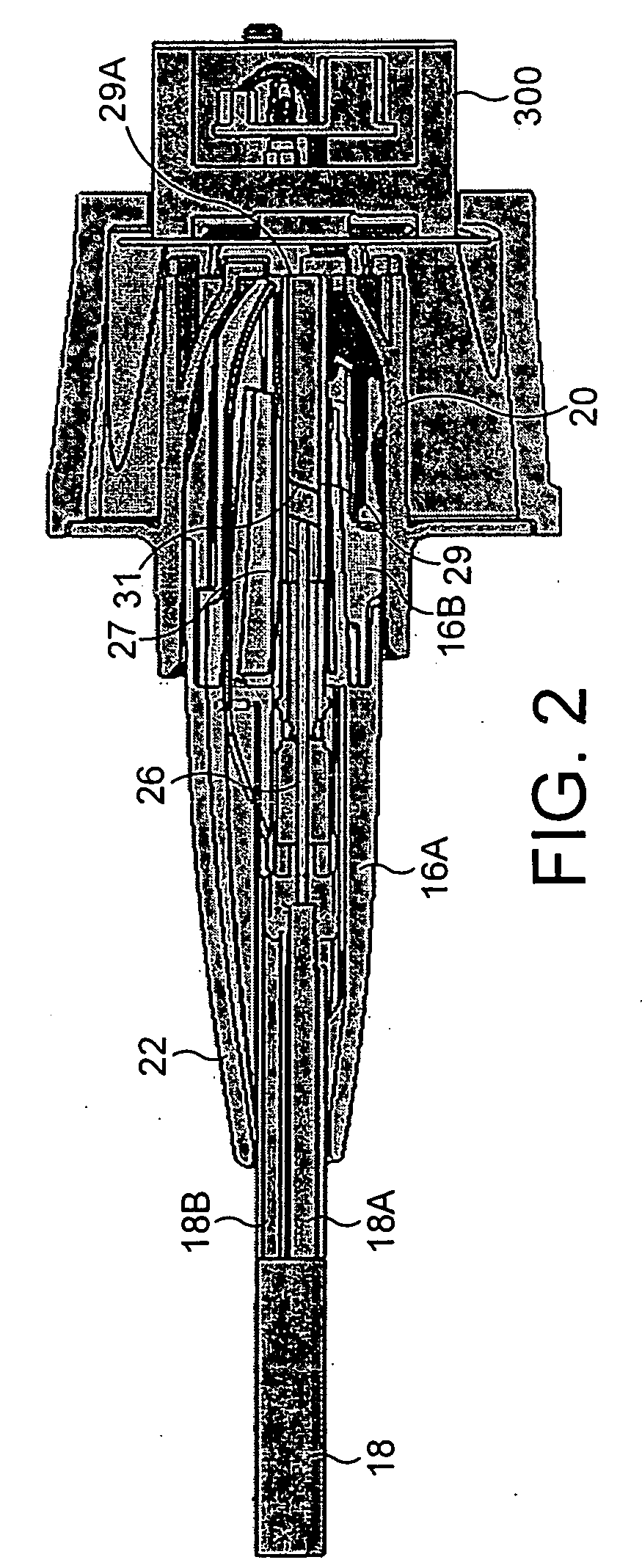

Tissue treatment system

InactiveUS20060189974A1Heating effectHeating fastSurgical instruments for heatingThermal energyRadio frequency energy

A tissue treatment system has a radio frequency generator and a handheld treatment instrument that generates a gas plasma jet for delivering thermal energy to a tissue surface to be treated. Incorporated in the housing for the generator is a calibration device for adjusting the energy output of the generator, if necessary, at the beginning of a treatment session. The calibration device has a target element with a target surface, a transducer for sensing changes in temperature of the target element with respect to the temperature of a reference element, and an energy output adjuster for adjusting the radio frequency energy output of the generator in response to a calibration signal generated by the transducer. The generator housing has a receptacle for locating the nozzle of the handheld instrument in juxtaposition with the target element so that when a plasma burst is generated as part of a calibration sequence it is incident on the target surface. The generator output is automatically adjusted to compensate for any deviation of a calibration value, produced from the calibration signal, from a reference value. Also disclosed is a method of regenerating the reticular architecture of tissue, the method including calibrating the energy delivery of a tissue treatment system.

Owner:ENERGIST

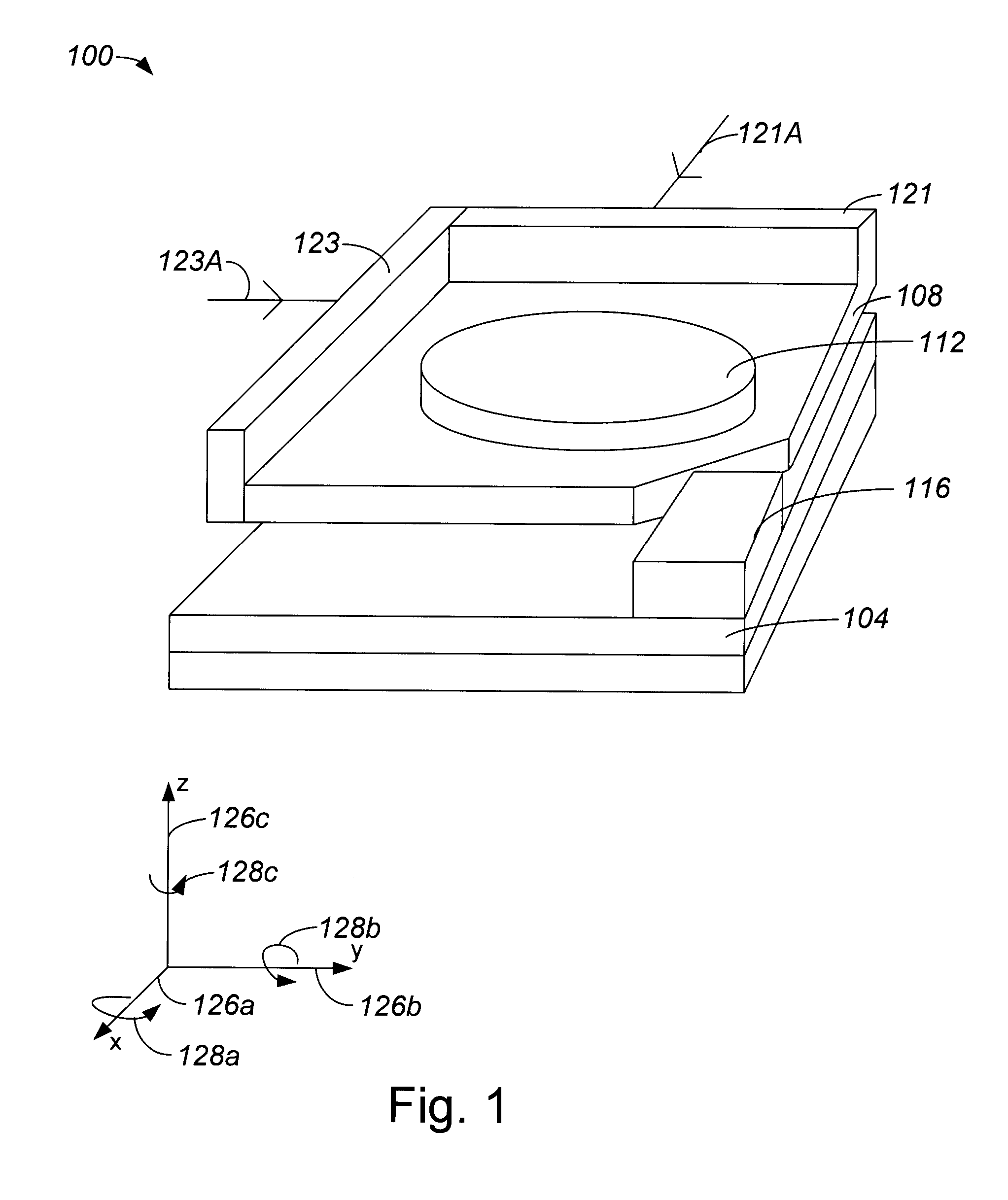

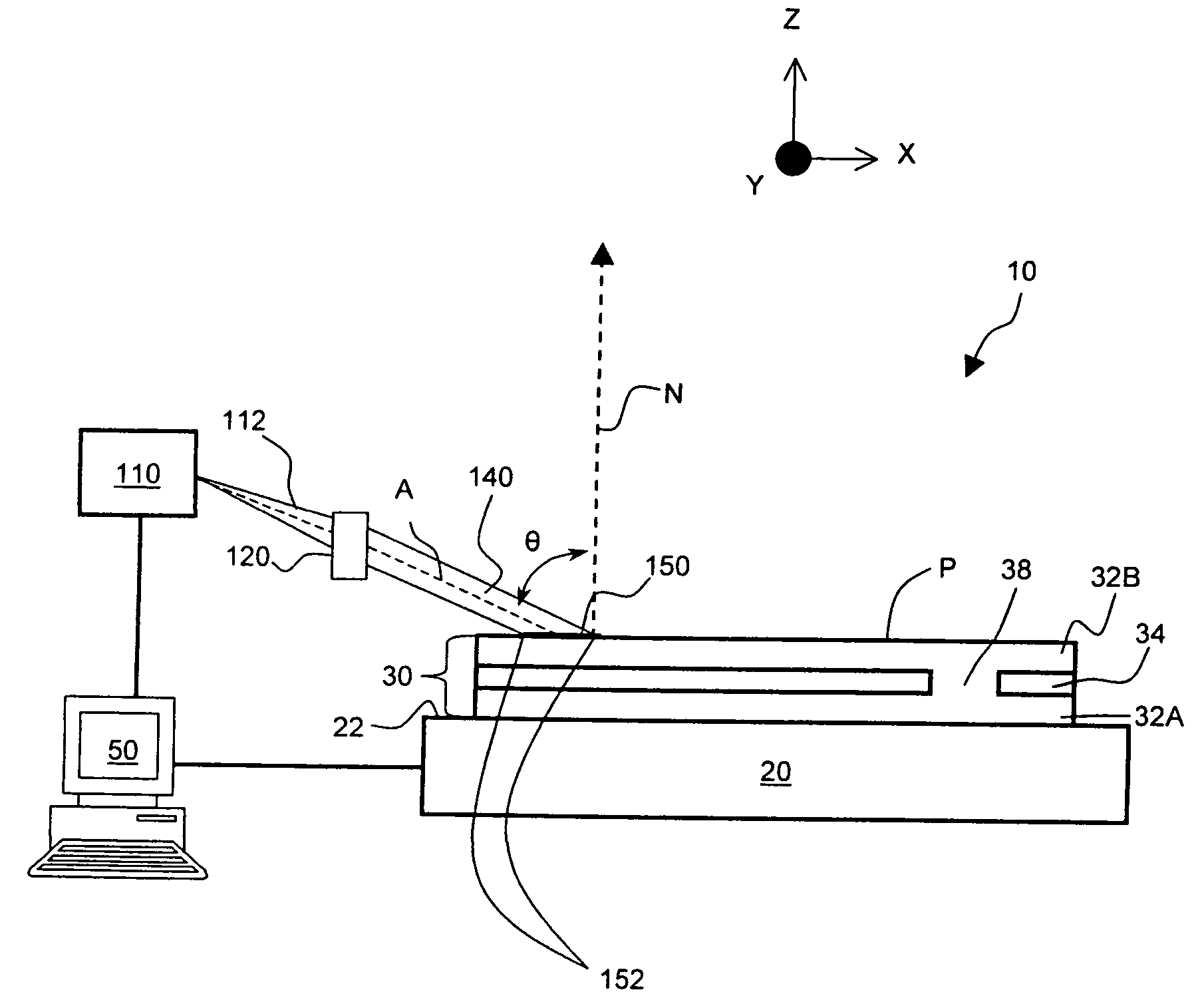

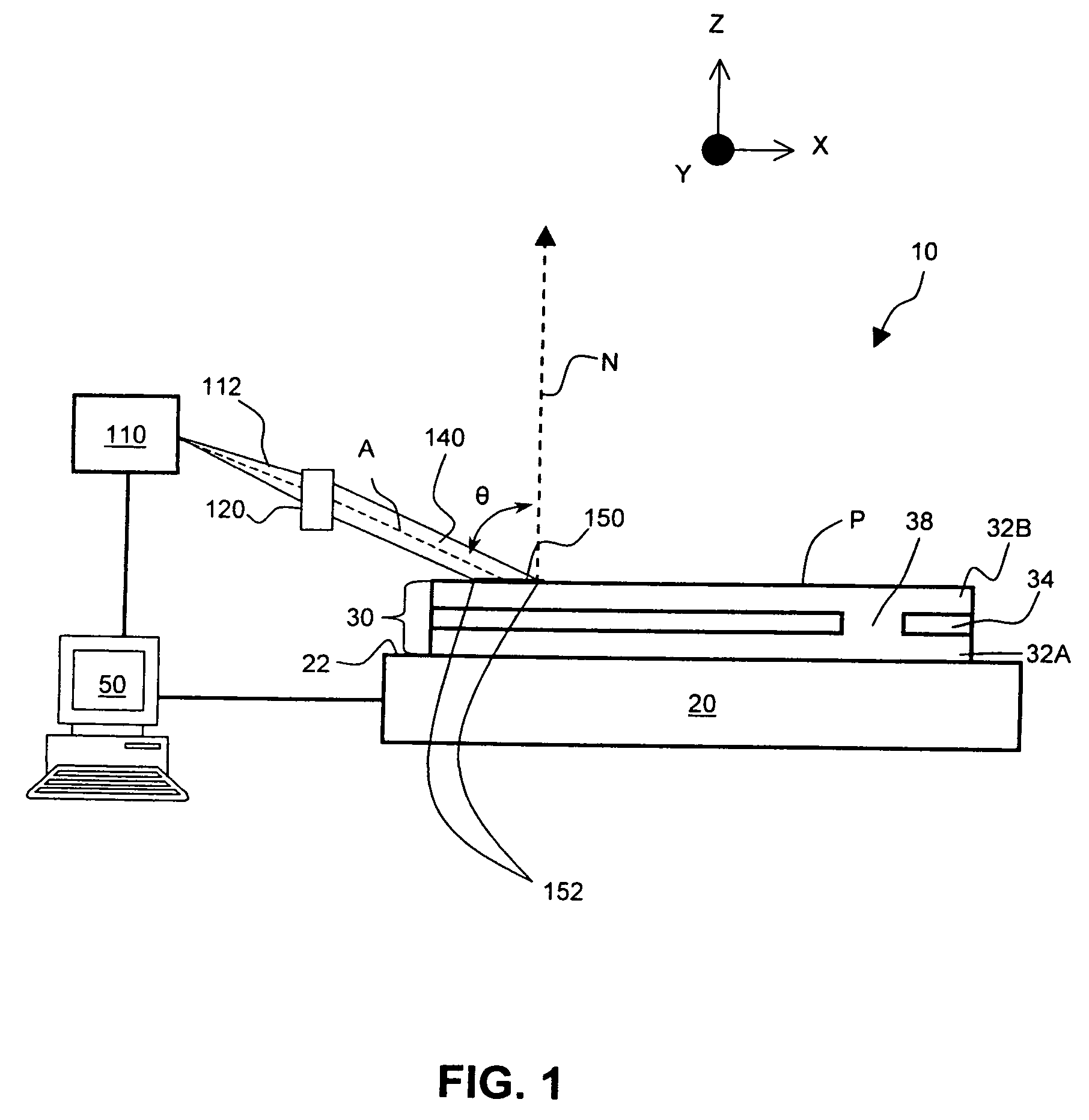

Systems and processes for forming three-dimensional circuits

InactiveUS20100140768A1Heating effectSemiconductor/solid-state device detailsSolid-state devicesElectronic propertiesHeat treated

Provided are systems and processes for forming a three-dimensional circuit on a substrate. A radiation source produces a beam that is directed at a substrate having an isolating layer interposed between circuit layers. The circuit layers communicate with reach other via a seed region exhibiting a crystalline surface. At least one circuit layer has an initial microstructure that exhibits electronic properties unsuitable for forming circuit features therein. After being controllably heat treated, the initial microstructure of the circuit layer having unsuitable properties is transformed into one that exhibits electronic properties suitable for forming circuit feature therein. Also provided are three-dimensional circuit structures optionally formed by the inventive systems and / or processes.

Owner:ULTRATECH INT INC

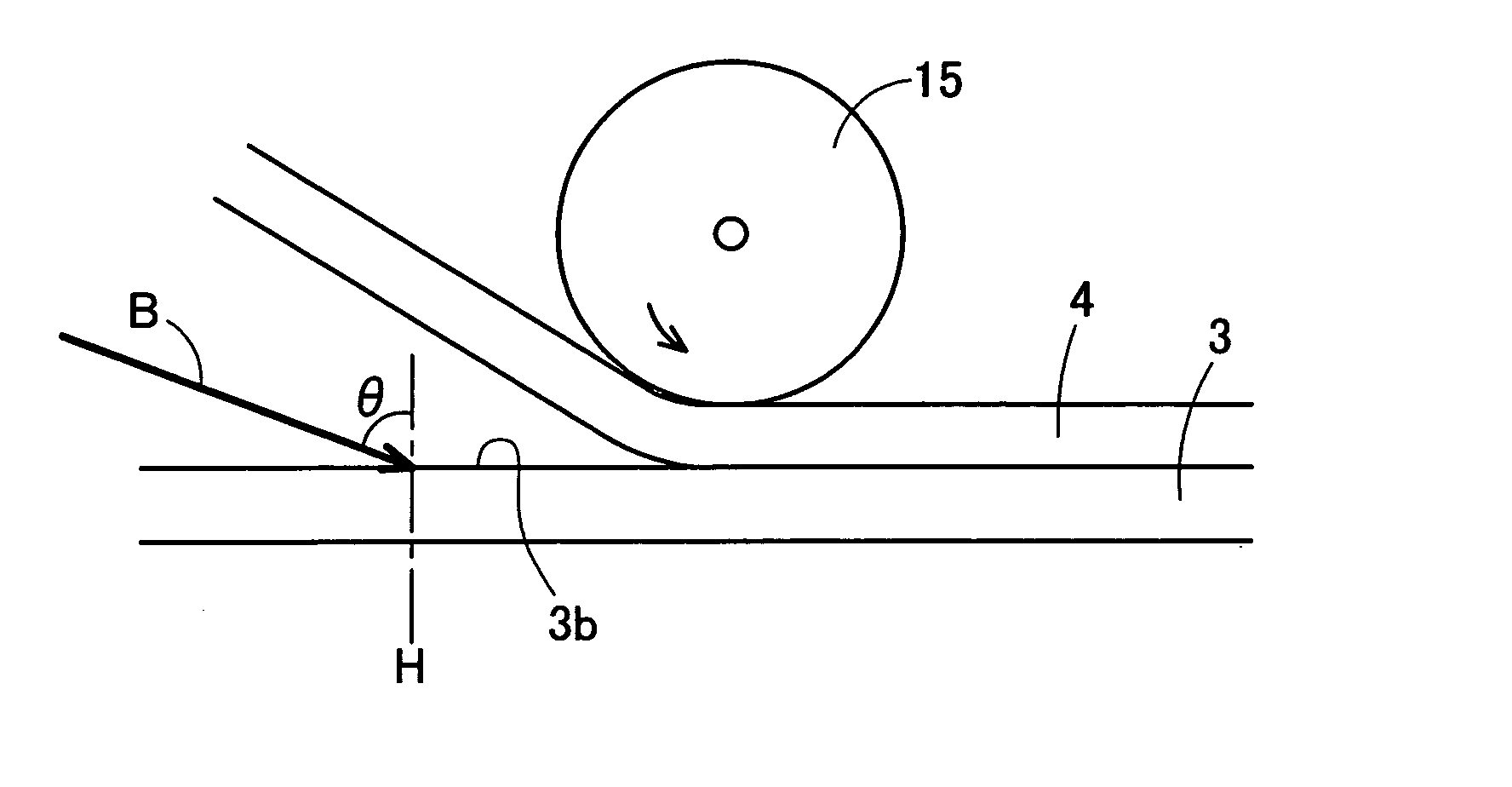

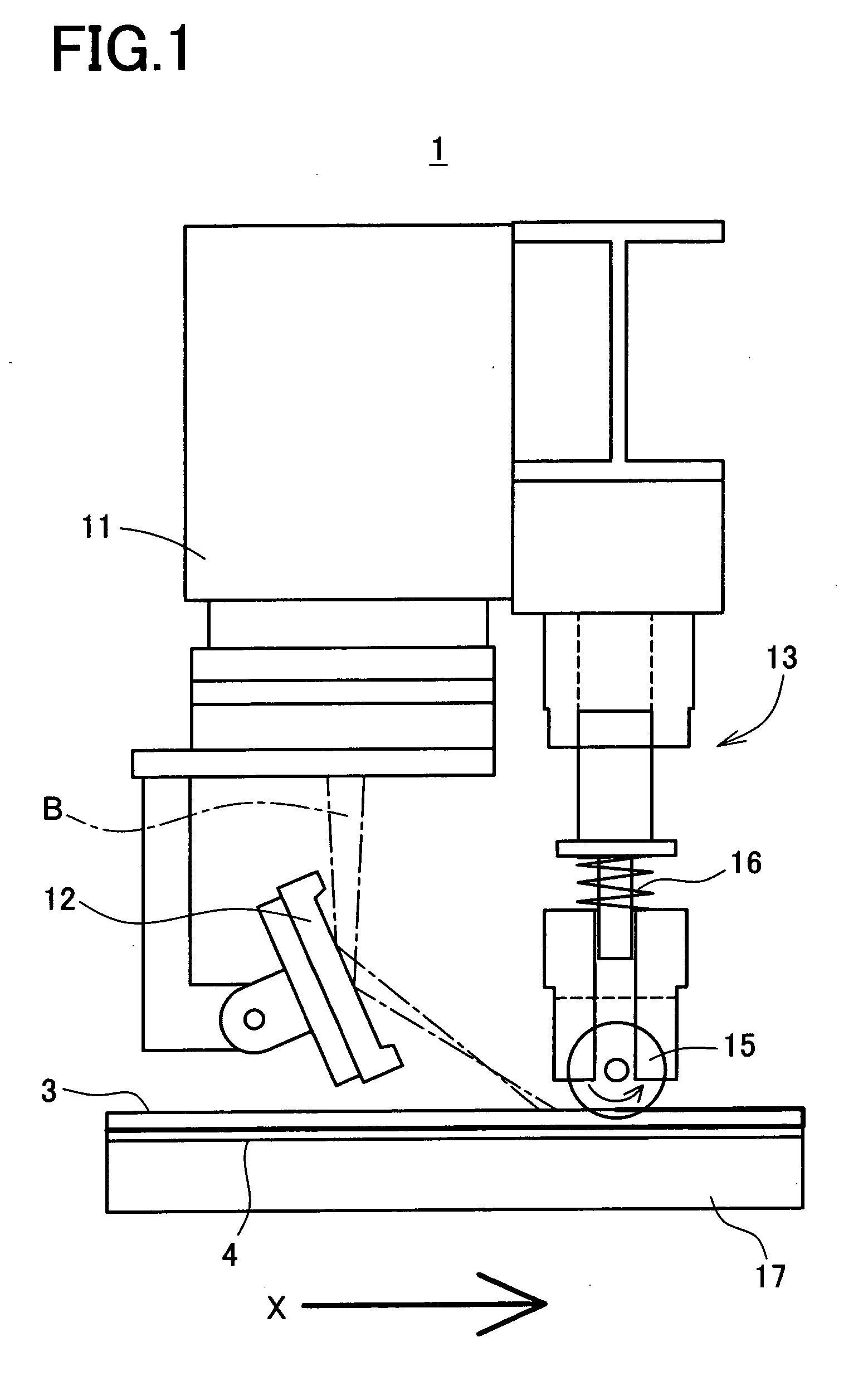

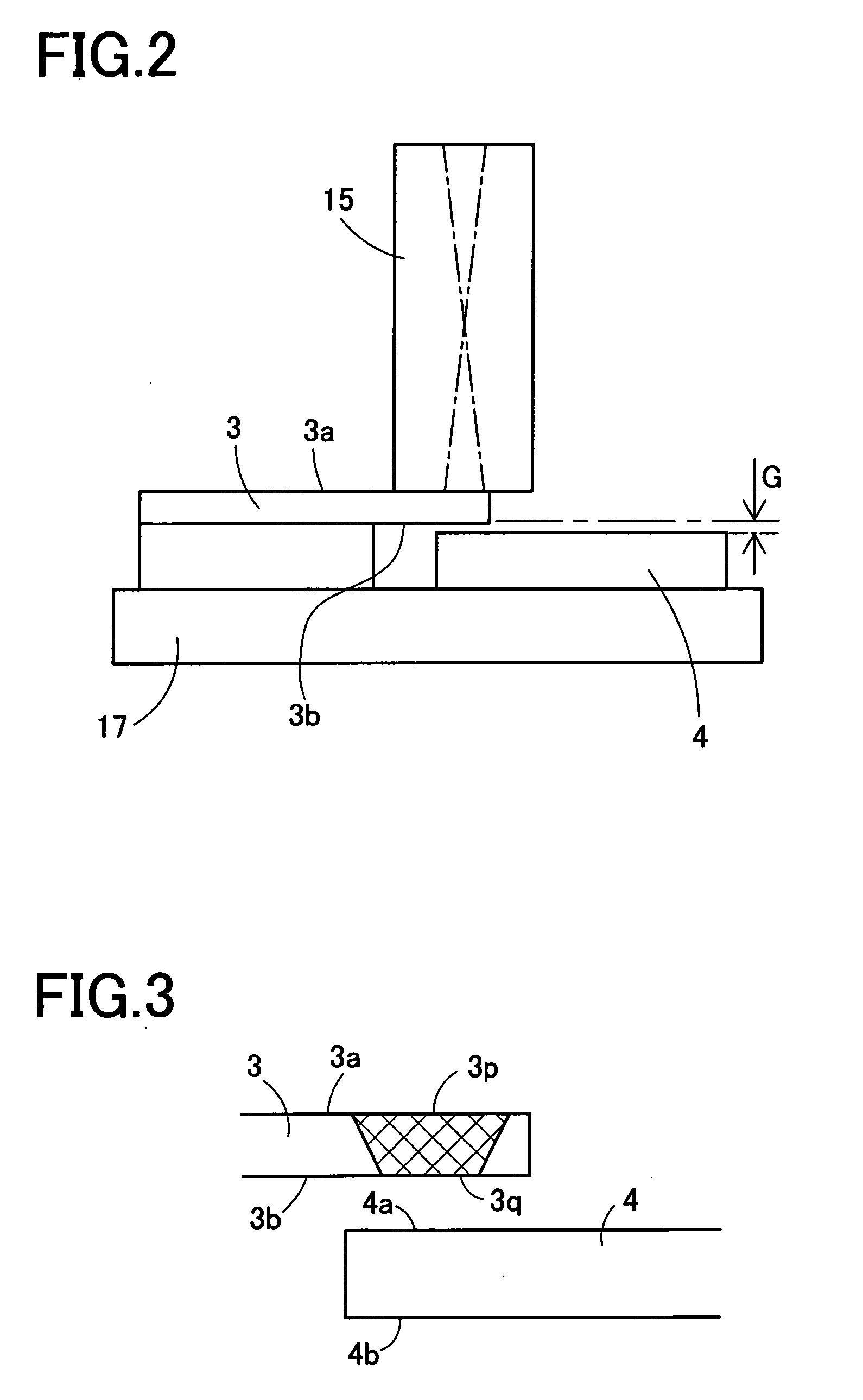

Laser roll joining method for dissimilar metals and laser roll joining apparatus

InactiveUS20050230371A1Reduce heat inputHeating effectWelding/soldering/cutting articlesLaser beam welding apparatusDuctilityDissimilar metal

An object is to provide a laser roll joining process for dissimilar metals capable of improving the joining strength of a joint by increasing the amount of generation of ductile intermetallic compound and a laser roll joining equipment. A laser roll joining process for dissimilar metals for joining a first metal sheet 3 and a second metal sheet 4 of different materials held in non-contact state by after only the first metal sheet 3 is heated by laser irradiation, pressing a heated portion of the first metal sheet 3 against the second metal sheet 4 with a pressure welding roller 15 so that they are brought into a firm contact with each other and subjected to plastic deformation, wherein a joining portion between the first metal sheet 3 and the second metal sheet 4 is cooled.

Owner:KUTSUNA MUNEHARU +1

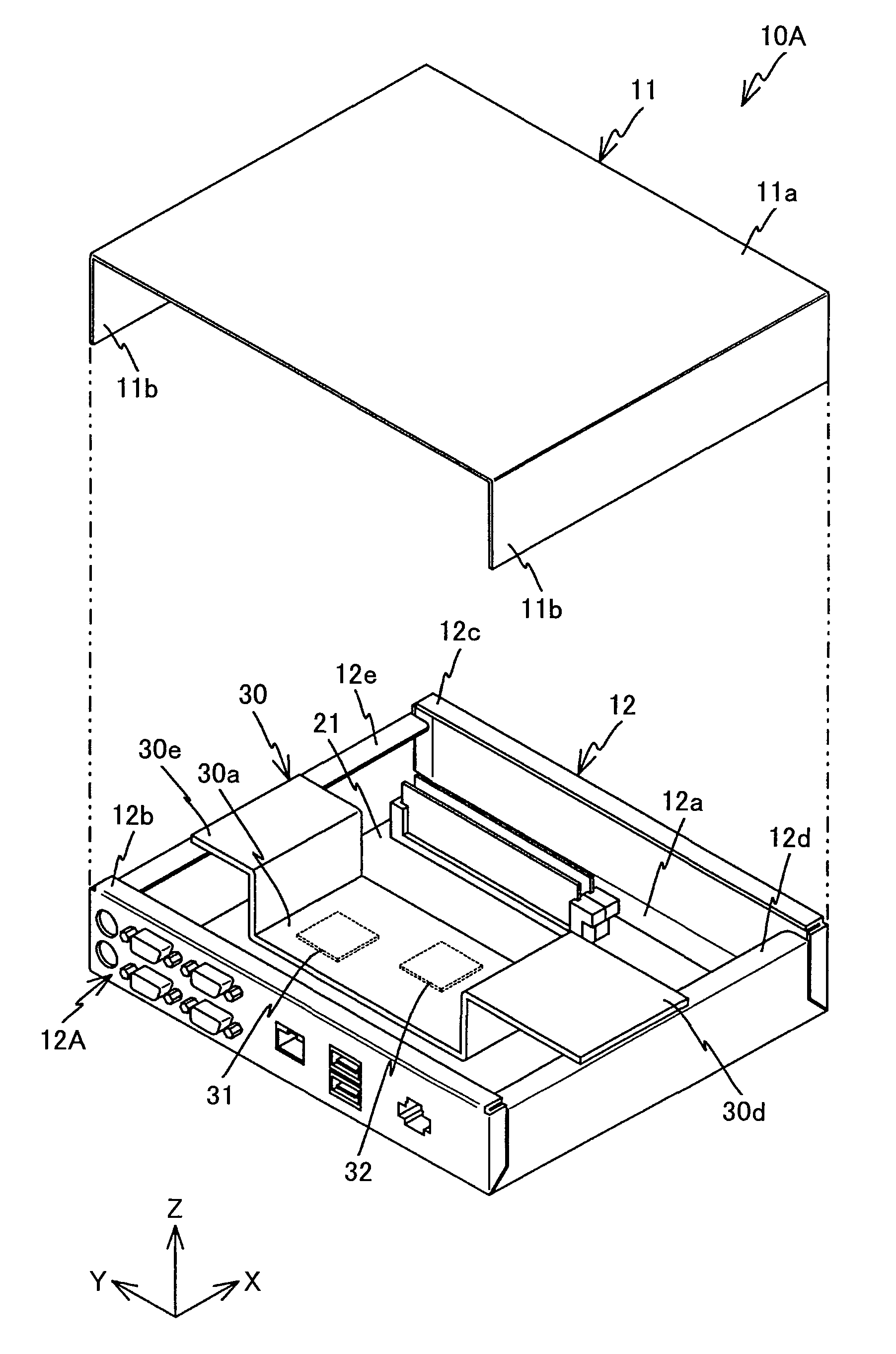

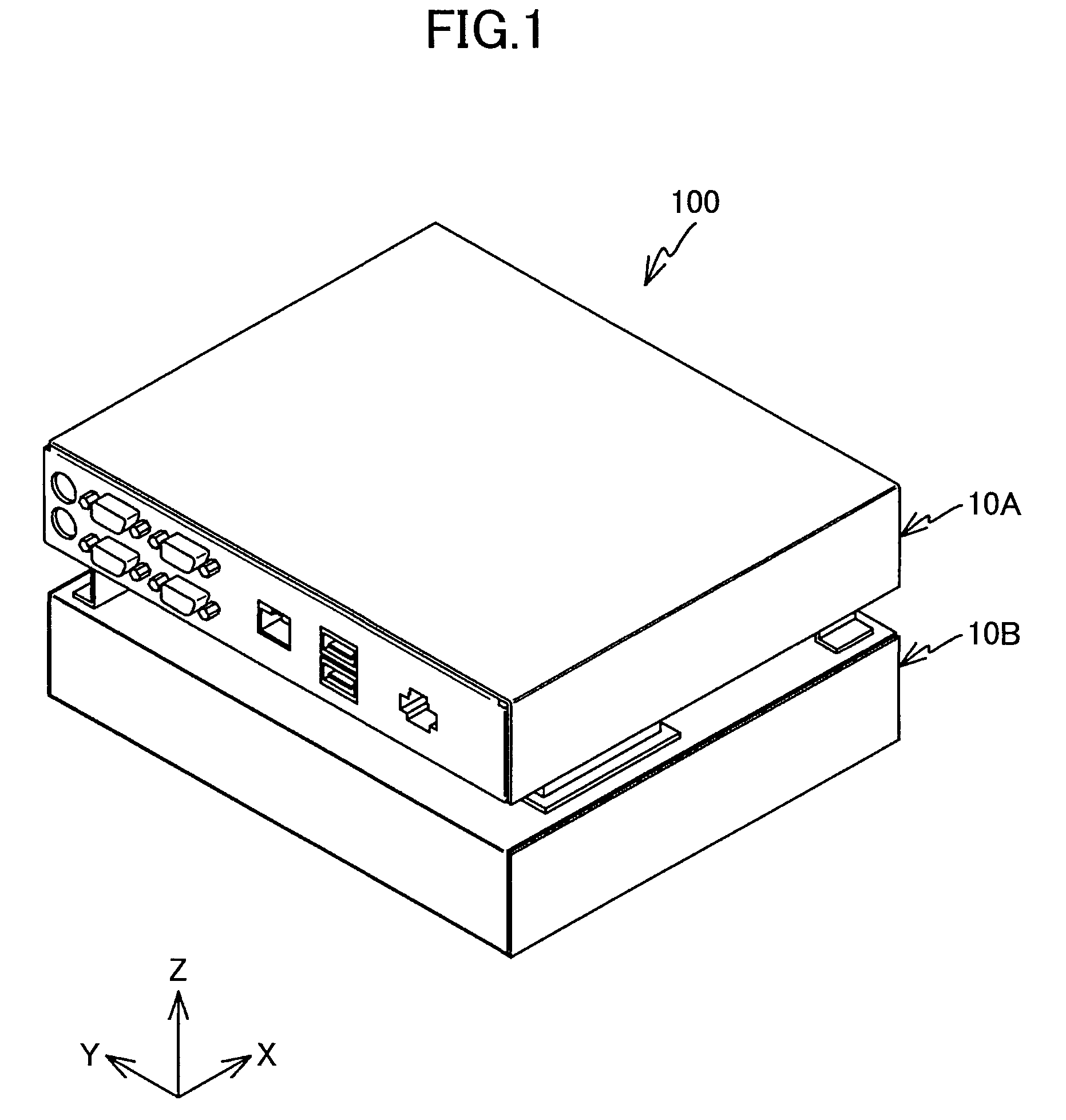

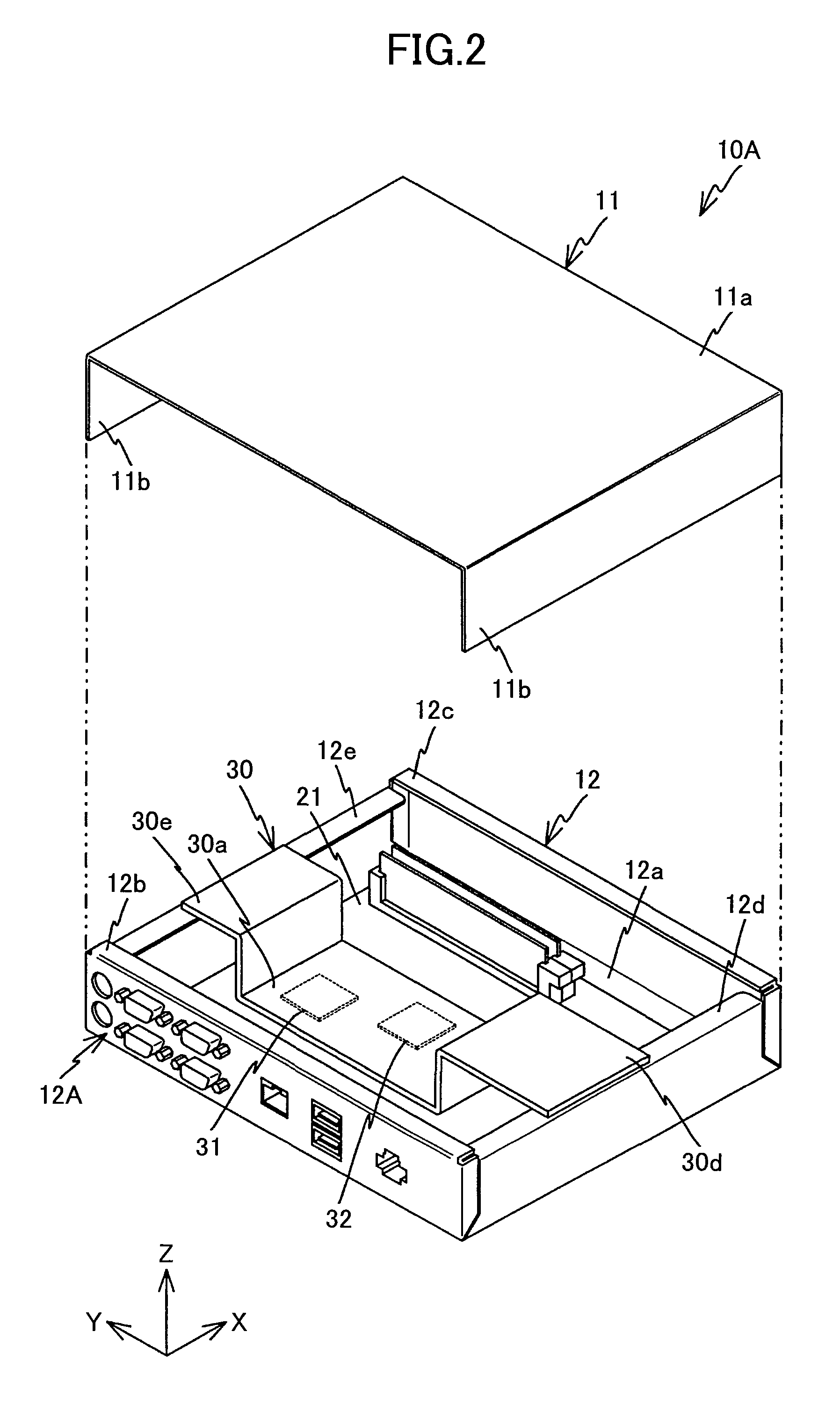

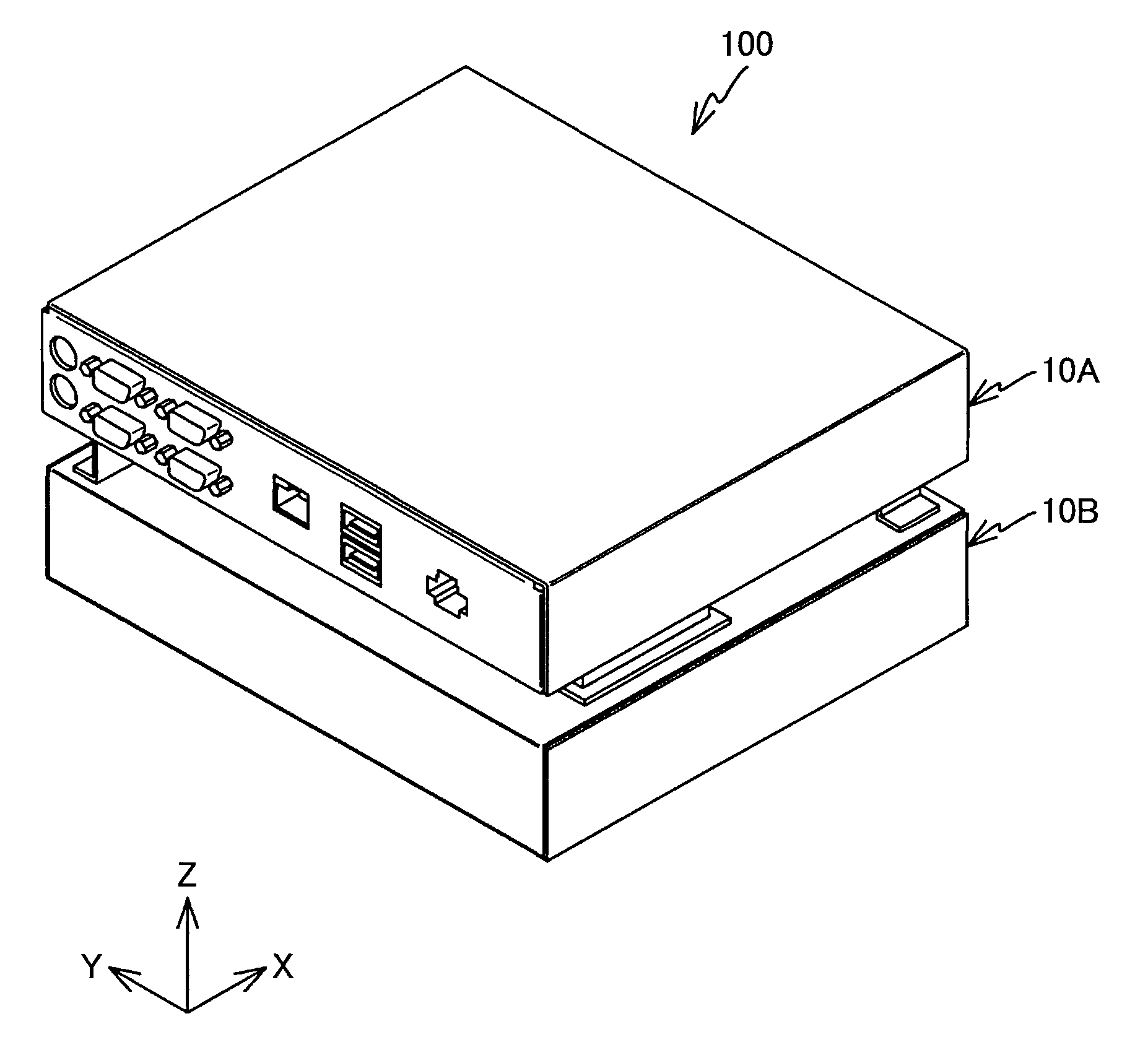

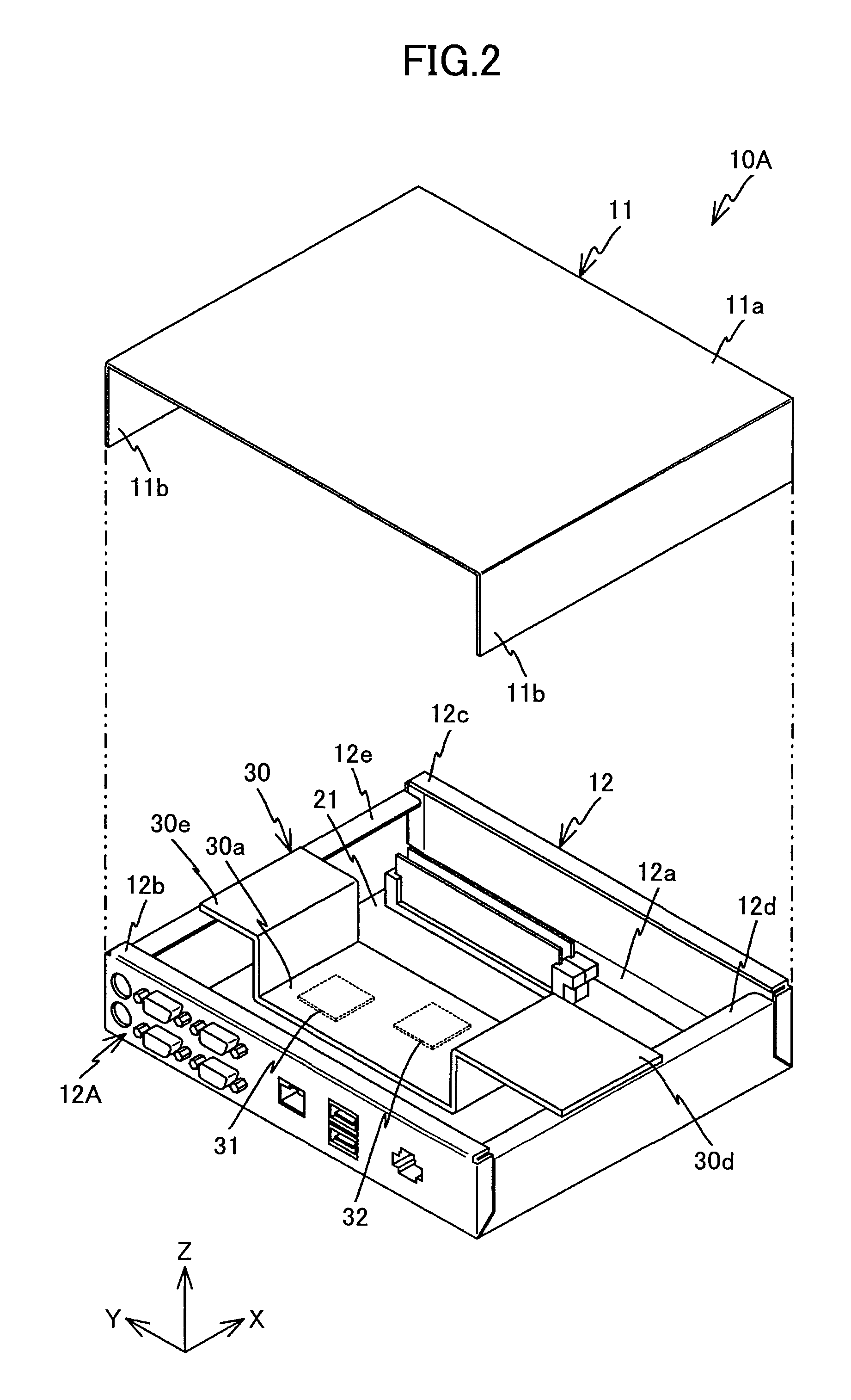

Information processing apparatus with heat dissipating structure

InactiveUS7961471B2Improve cooling efficiencyPartly effectiveDigital data processing detailsSemiconductor/solid-state device detailsInformation processingHeat resistance

An information processing apparatus having improved cooling efficiency is disclosed. The information processing apparatus includes a first chassis and a second chassis separated from each other at a prescribed distance, the first chassis accommodating a substrate on which high heat generating parts such as a CPU and a chipset are mounted, and the second chassis accommodating low heat generating and low heat resistance parts. Because of this structure, the first chassis and the second chassis are thermally isolated, and the surface area of the apparatus is increased, thereby improving the cooling efficiency of the apparatus.

Owner:RICOH KK

Encapsulated Active Ingredients, Methods of Preparation and Their Use

InactiveUS20080206325A1Improve stabilityEffective oxygen barrierGranular deliveryFood shapingAdditive ingredientHydrolysate

The present invention relates to particles that include an active ingredient that is encapsulated first by coacervation, and then by a glassy matrix. The glassy matrix includes 3-50 wt % of a hydrophobically modified starch, and 50-97 wt % of a starch hydrolysate. The particles are useful for encapsulating active ingredients intended for oral ingestion and may be added to food products.

Owner:FIRMENICH SA

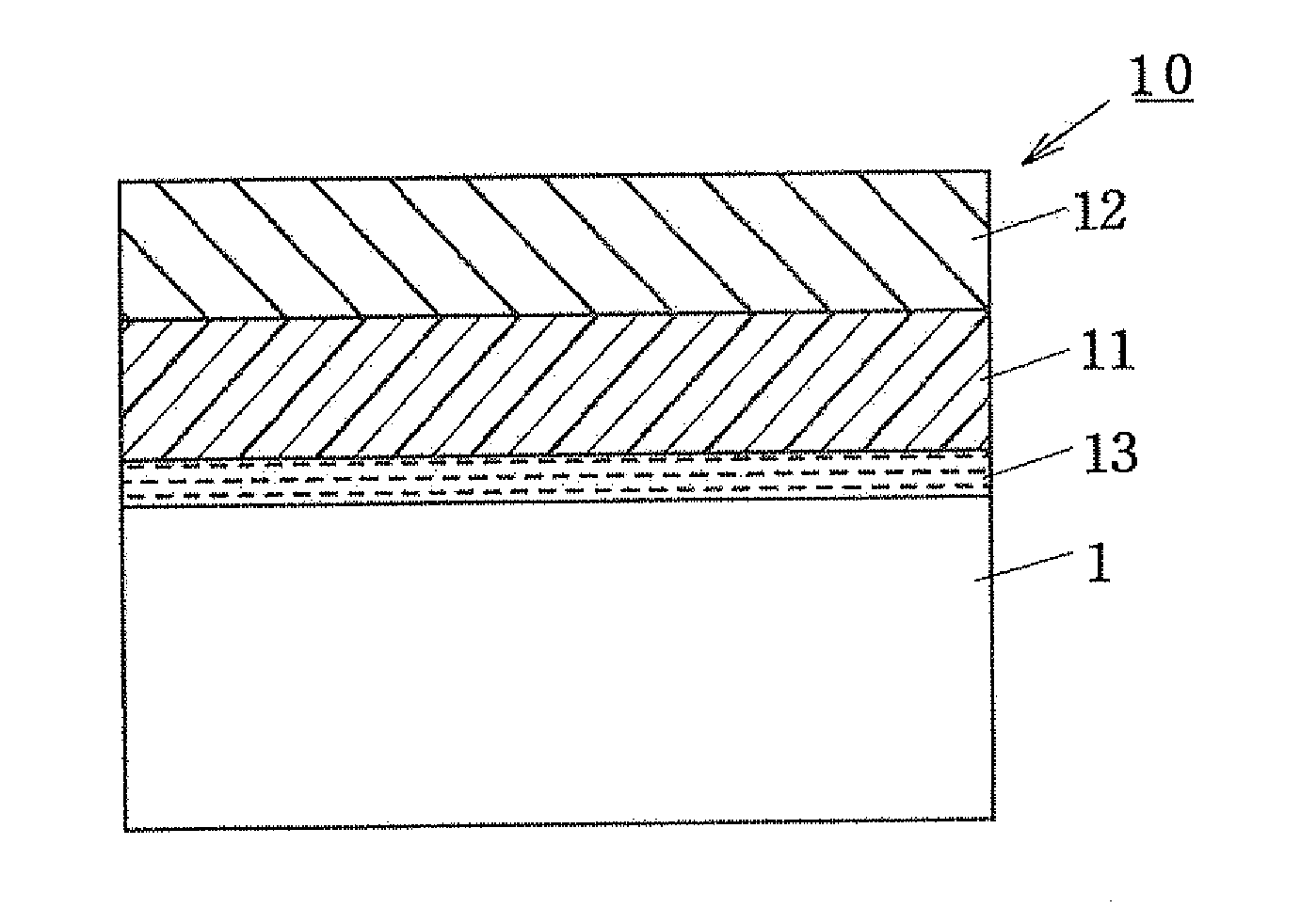

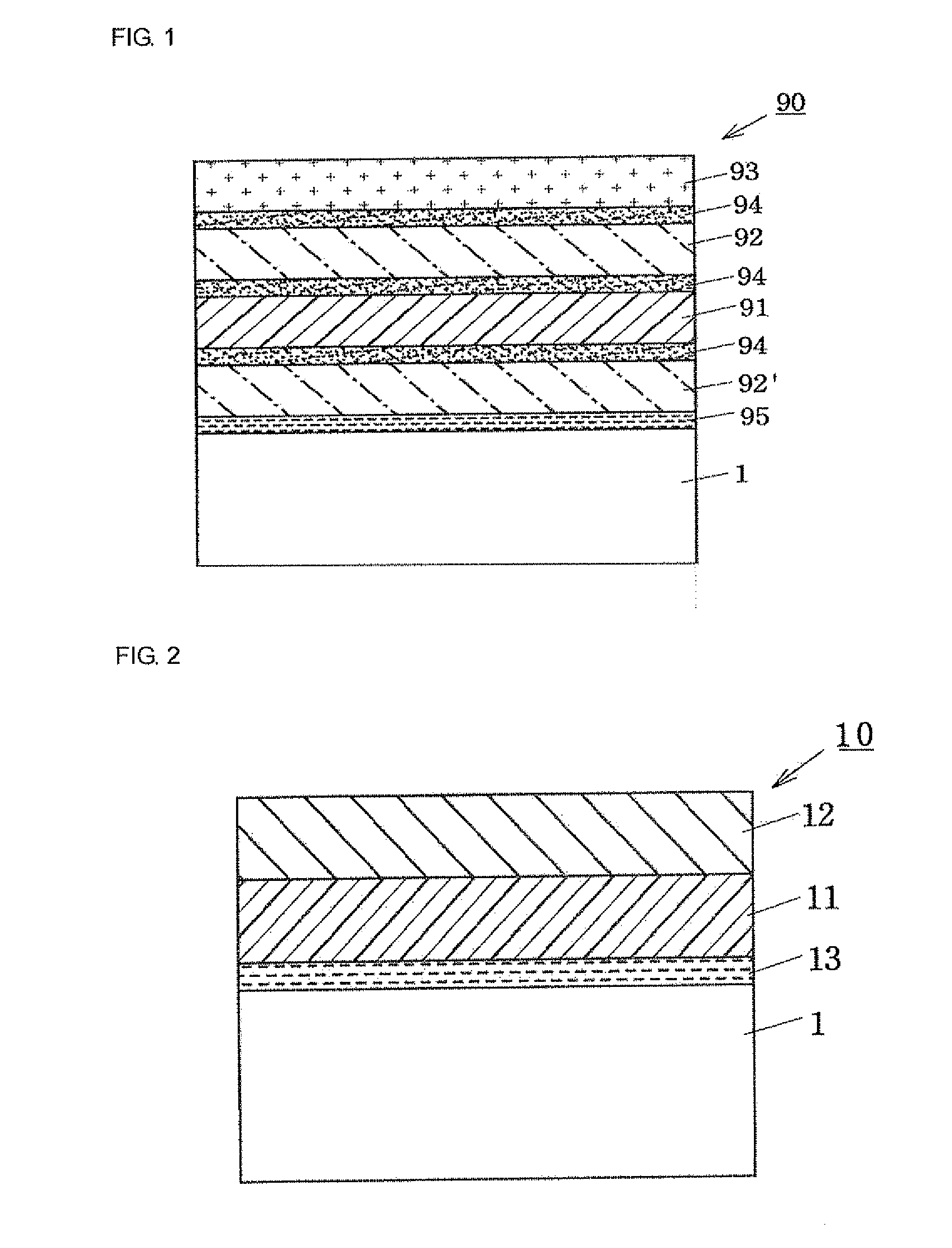

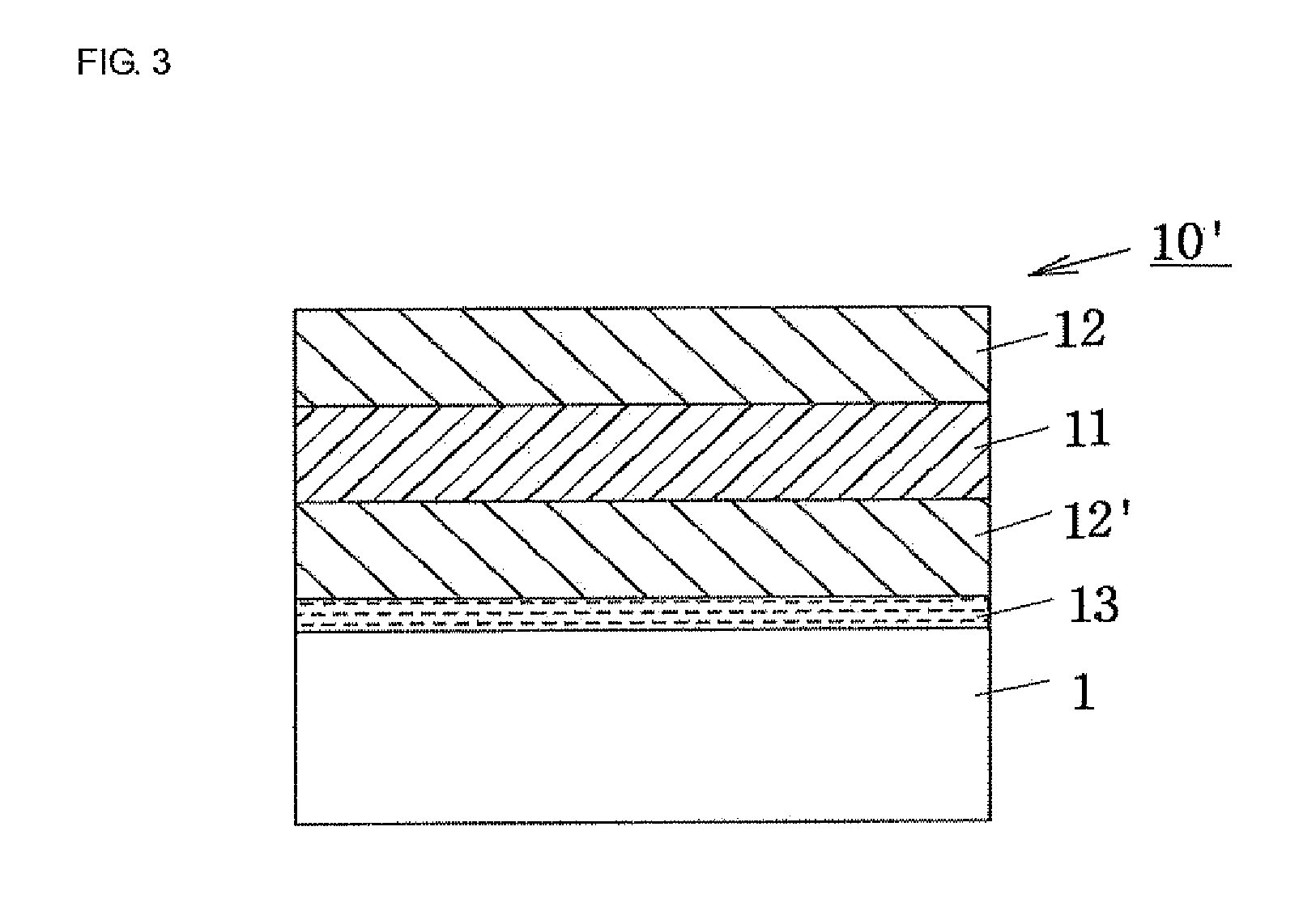

Heat-dissipation sheet assembly manufactured by using electrochemical method

InactiveUS20140370222A1Easy to separateAvoid damageSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrochemistry

There is provided a heat-dissipation sheet assembly comprising a heat-dissipation sheet layer having good heat conductivity and a protection layer(s) electrodeposited on one or both sides of the heat-dissipation sheet layer. When the heat-dissipation sheet layer is immersed in an aqueous solution for electrodeposition added with a material for electrodeposition and electric current is permitted to flow in the aqueous solution, the protection layer(s) is electrodeposited on the one or both sides of the heat-dissipation sheet layer. The heat-dissipation sheet assembly can be attached to a heat-generating unit by applying an adhesion layer to an underside of the heat-dissipation sheet assembly.

Owner:A TECH SOLUTION

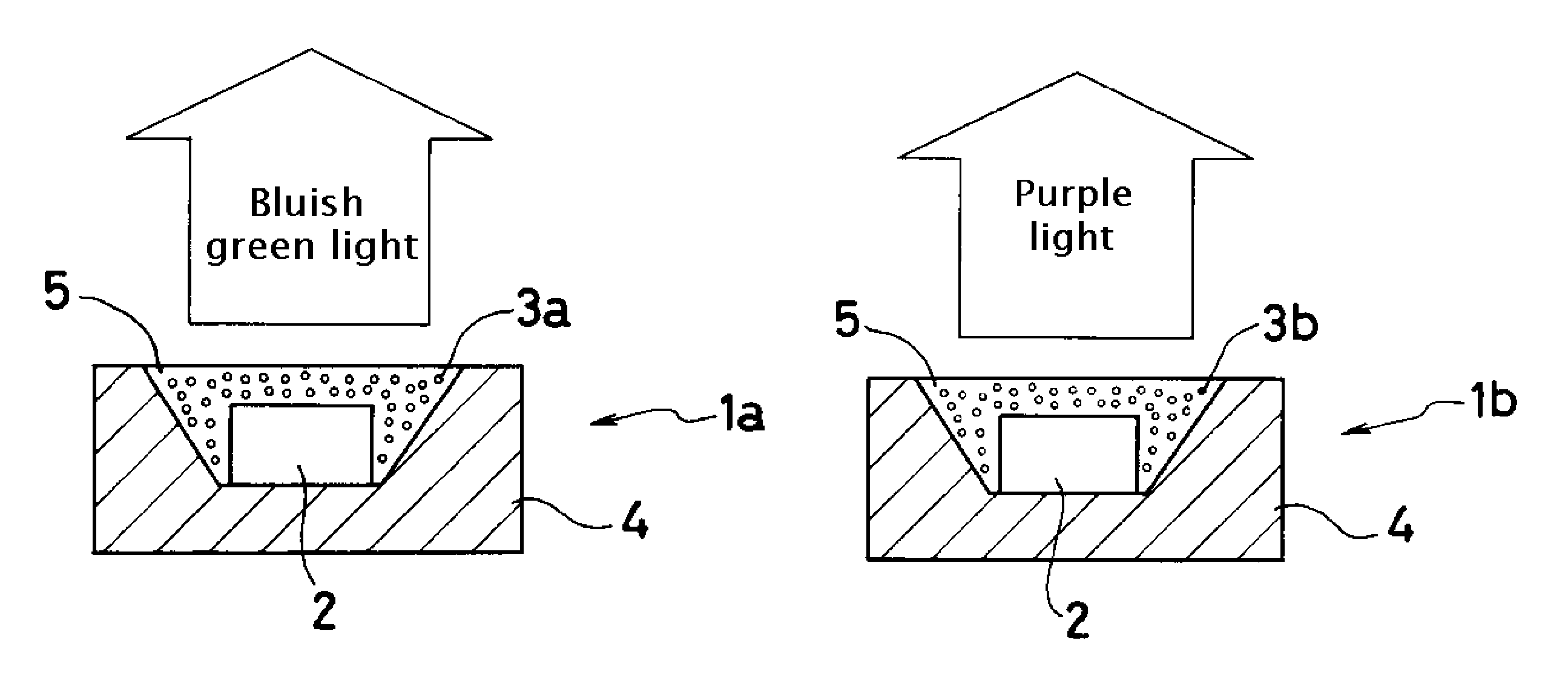

White LED light source device and LED backlight using the same

InactiveUS7810947B2Improve efficiencyFavorable color mixturePoint-like light sourceGas discharge lamp usageLuminous intensityPhosphor

A white LED light source device and an LED backlight using the white LED light source can produce, among other features, white light with sufficient luminous intensity, uniform color tone, and high luminous utilization efficiency. A light path for producing white light with favorable color mixture can be shortened. The white LED light source device can be configured to include a bluish green LED lamp which can emit bluish green light by the combination of a blue LED device and a green phosphor material and a purple LED lamp which can emit purple light by the combination of a blue LED device and a red phosphor material. The bluish green light from the bluish green LED lamp and the purple light from the purple LED lamp are subjected to additive color mixture to produce white light with a spectrum containing three primary color wavelength components.

Owner:STANLEY ELECTRIC CO LTD

Information processing apparatus

InactiveUS20080285224A1Cool efficiency be increaseIncrease surface areaDigital data processing detailsSemiconductor/solid-state device detailsChipsetEngineering

An information processing apparatus having improved cooling efficiency is disclosed. The information processing apparatus includes a first chassis and a second chassis separated from each other at a prescribed distance, the first chassis accommodating a substrate on which high heat generating parts such as a CPU and a chipset are mounted, and the second chassis accommodating low heat generating and low heat resistance parts. Because of this structure, the first chassis and the second chassis are thermally isolated, and the surface area of the apparatus is increased, thereby improving the cooling efficiency of the apparatus.

Owner:RICOH KK

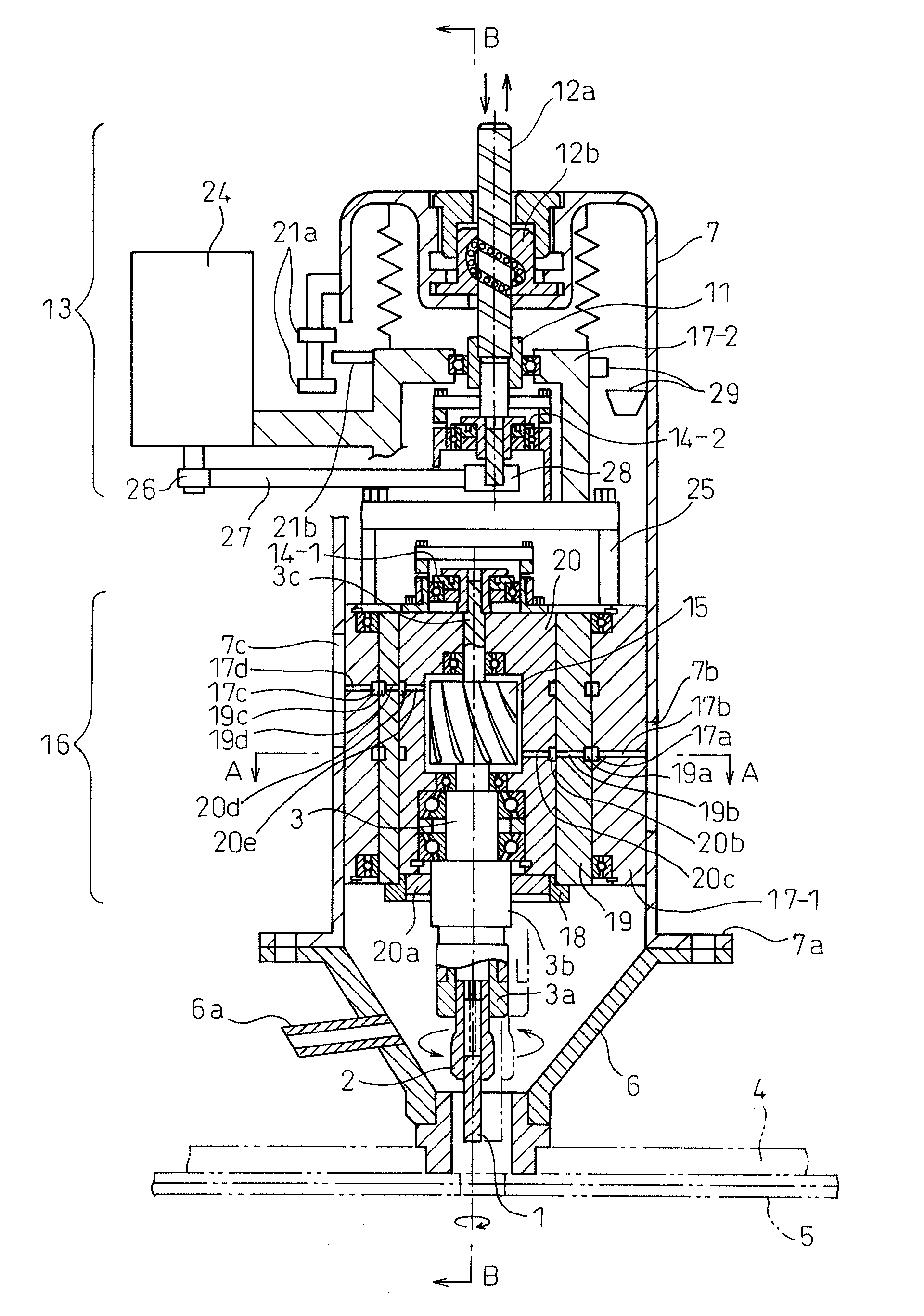

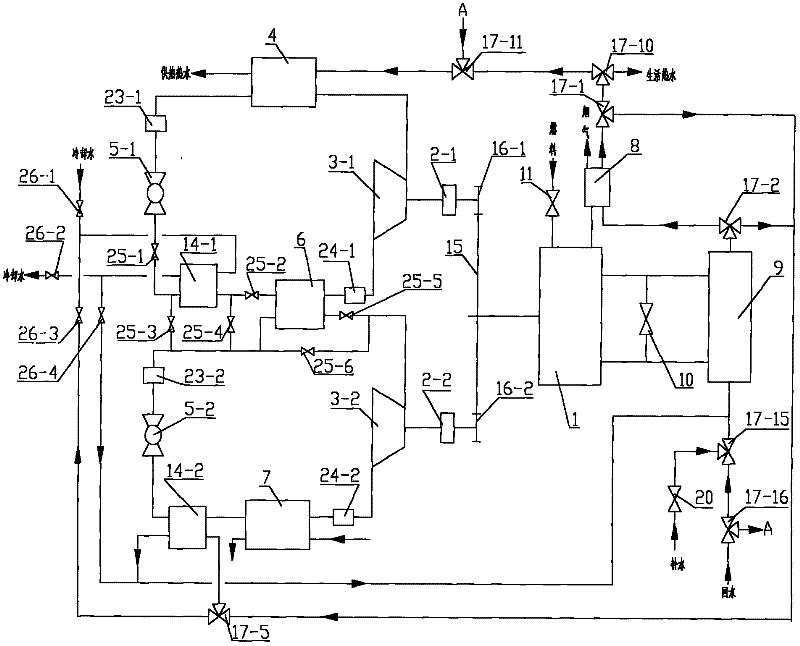

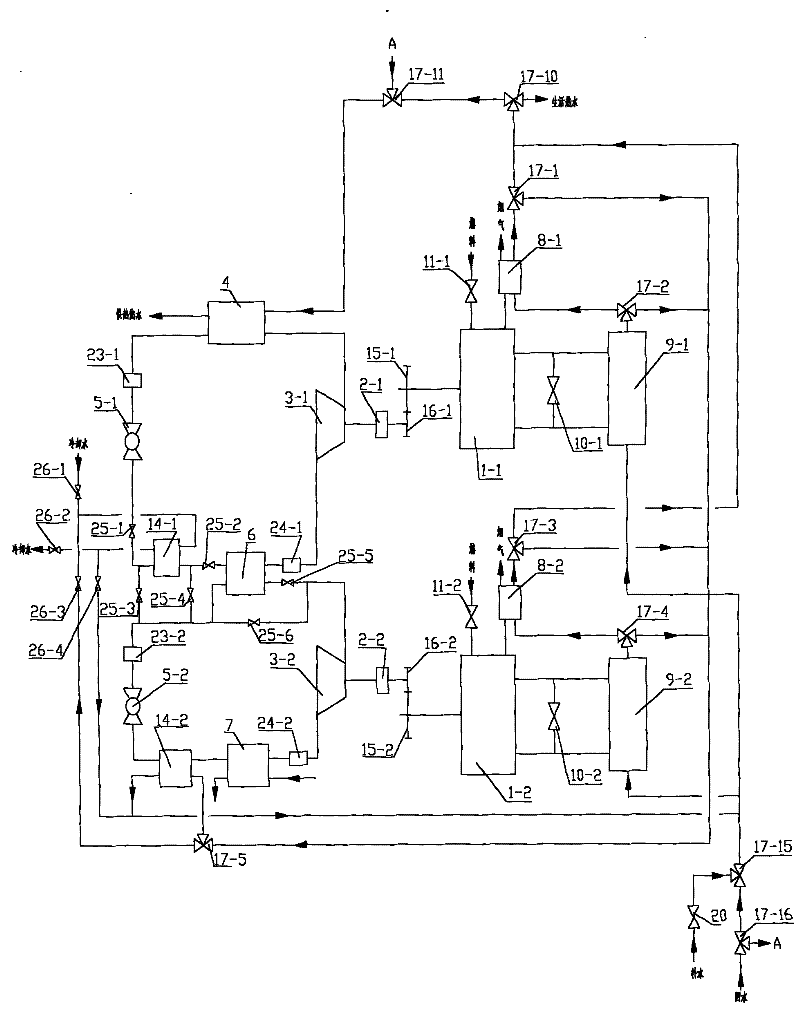

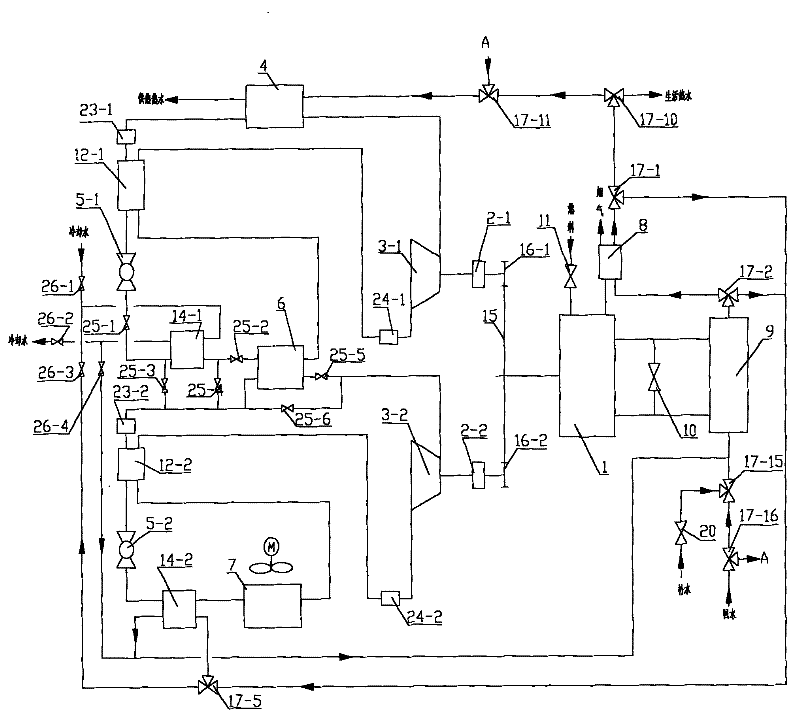

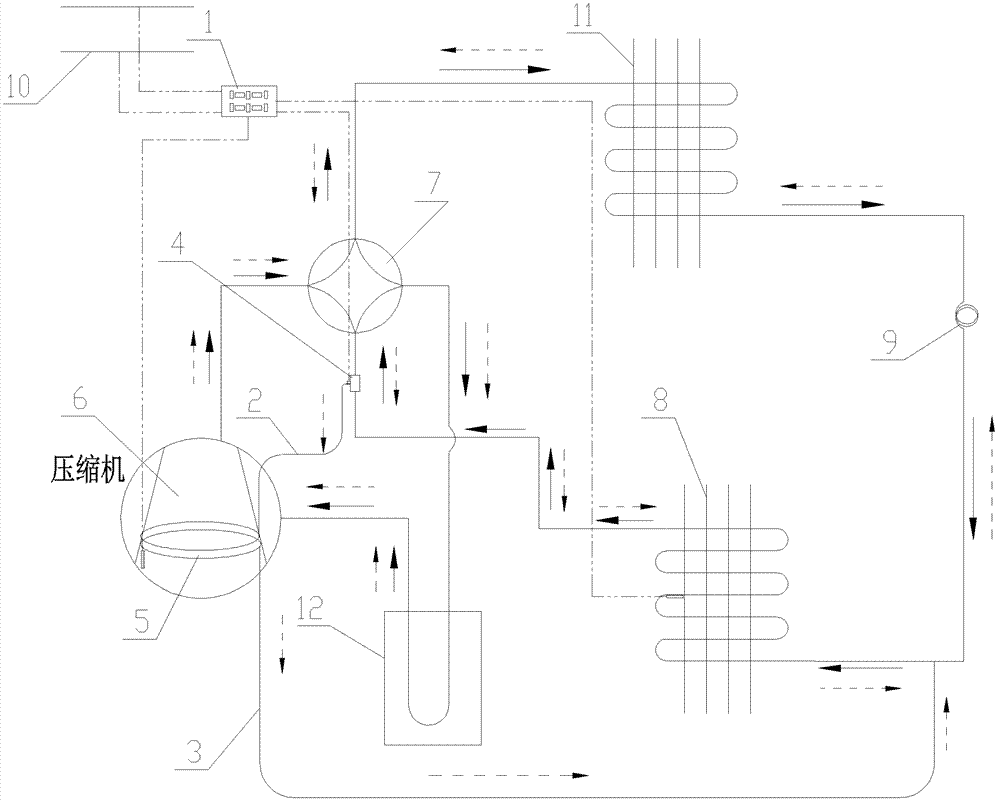

Engine-driven cascade heat pump device

InactiveCN102226596ARaise the heating temperature valueOvercome the disadvantages of low efficiencyCompression machines with cascade operationSuperheatersVapor–liquid separatorEngineering

The invention discloses an engine-driven cascade heat pump device which is characterized by comprising a cascade heat pump system, at least an engine system and a water loop, wherein the cascade heat pump system comprises a high-temperature circulating system and a low-temperature circulating system; a high-temperature compressor, a condenser, a high-temperature reservoir, a high-temperature throttling valve, a high-temperature refrigerant heater, a condensation evaporator, a high-temperature air-liquid separator and a refrigerant side valve form a high-temperature refrigerant circulating system; a low-temperature compressor, a condensation evaporator, a low-temperature reservoir, a low-temperature throttling valve, a low-temperature refrigerant heater, an evaporator, a low-temperature air-liquid separator and a refrigerant side valve form a low-temperature refrigerant circulating system; and the engine system comprises an engine, an engine cooling heat exchanger, a smoke heat exchanger, a cooling water bypass valve and a fuel regulating valve. The engine-driven cascade heat pump device disclosed by the invention can improve the utilization efficiency of fuel, realize high-efficiency utilization of energy sources, reducing pollution, and realizing multiple functions of refrigerating in summer, heating in winter, preparing domestic hot water and the like with the same unit.

Owner:YANTAI UNIV

Control method of oil temperature of compressor

ActiveCN103075324AHeating up fastEasy to controlPositive displacement pump componentsPump controlEngineeringFunctional specification

The invention discloses a control method of oil temperature of a compressor, which has the advantages of no waiting time for starting and energy saving, and a good oil temperature range can be guaranteed when the compressor is operated at low temperature. During starting or operation of the compressor, if the difference between delta T and a specified value is less than 0, a high-temperature refrigerant in a pipeline which is used for conveying the high-temperature refrigerant when an air conditioner is operated in a heating mode is led to the compressor, so as to heat the bottom of a housing of the compressor; in the process that the bottom of the housing of the compressor is heated by the high-temperature refrigerant, if the difference between the delta T and the specified value is greater than or equal to 0 and continues for at least two minutes, the high-temperature refrigerant which is led to the compressor is disconnected, and otherwise, the high-temperature refrigerant continues heating the bottom of the housing of the compressor; and the delta T is the difference between the lubricating oil temperature of the compressor and the steam temperature or the difference between the temperature of the bottom of the housing of the compressor and the saturation temperature corresponding to the discharge pressure, and the specified value is a minimum value which is required in a functional specification of the compressor and is at least equal to or greater than the difference between the temperature of the bottom of the housing of the compressor 6 and the saturation temperature corresponding to the discharge pressure.

Owner:NINGBO AUX ELECTRIC

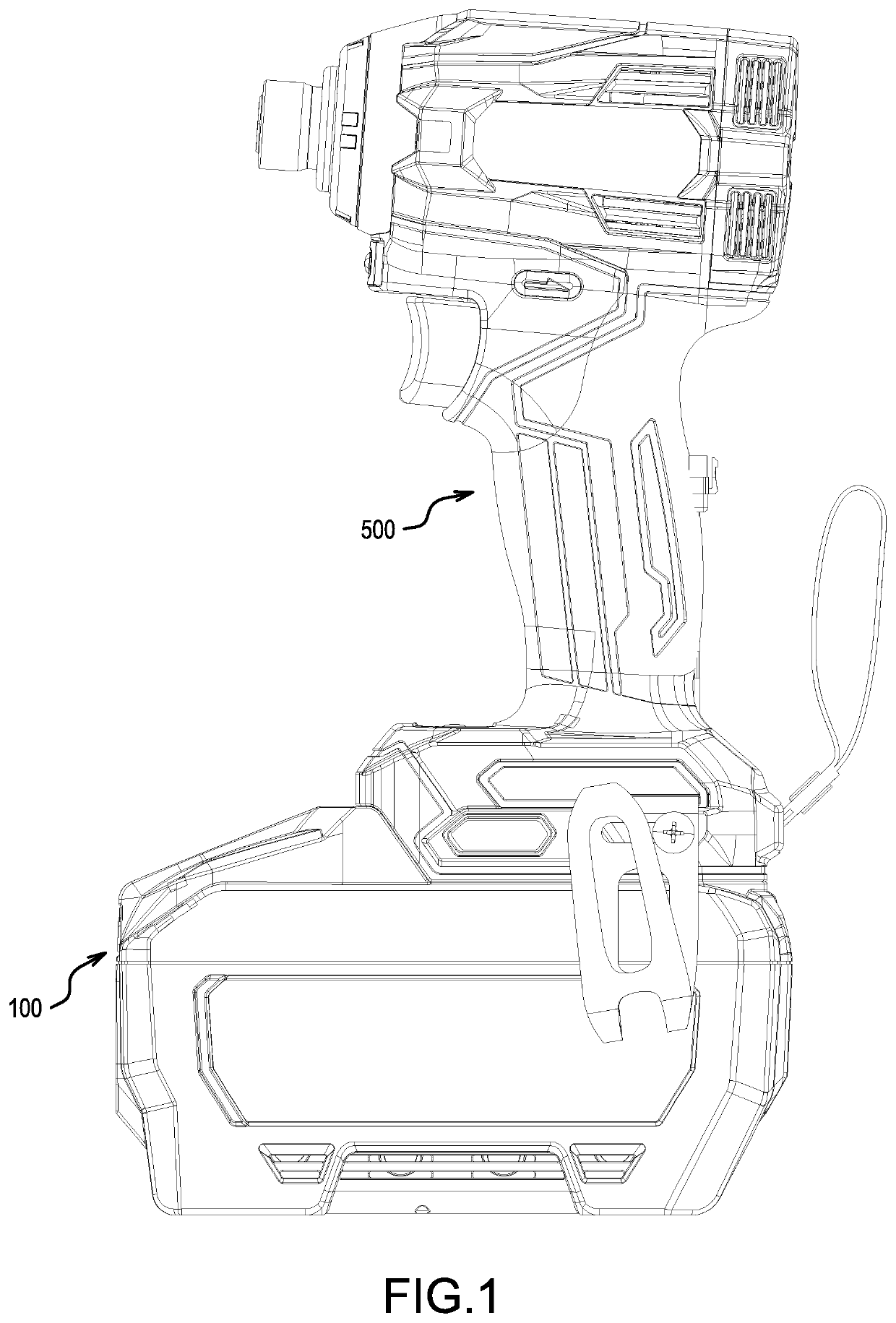

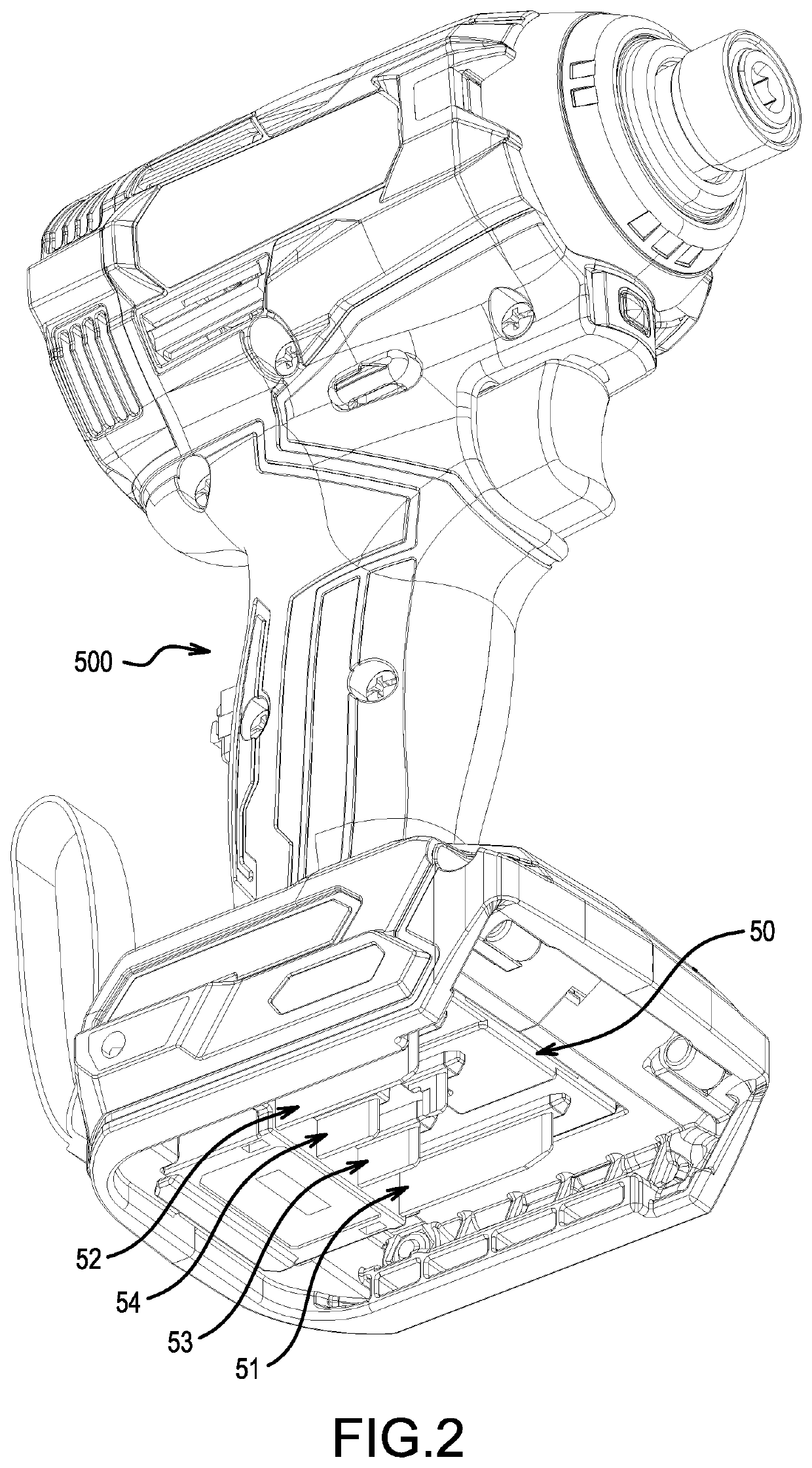

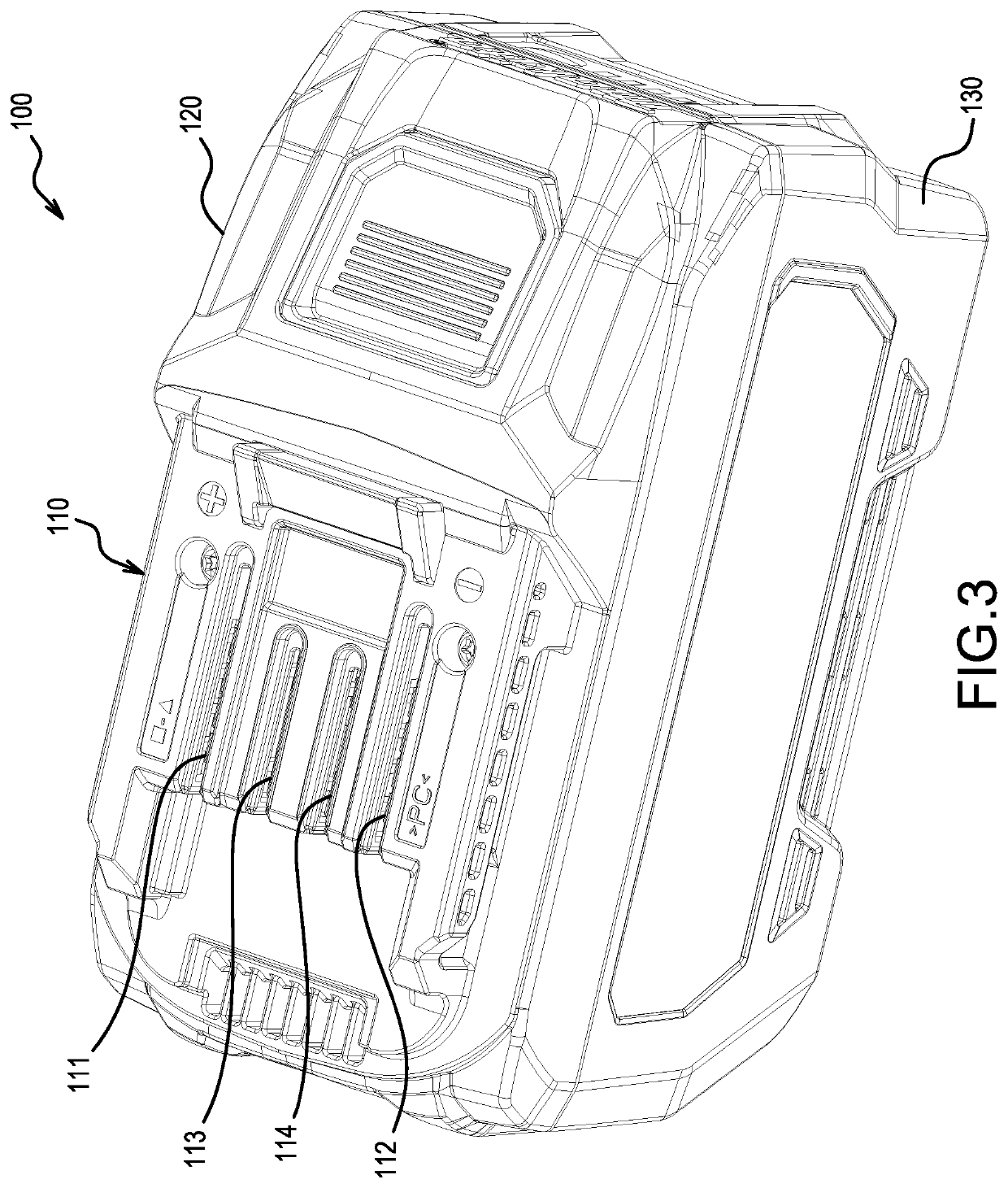

Battery pack

ActiveUS20210305661A1Reduce the number of partsSmall sizeCharge equalisation circuitCircuit monitoring/indicationBusbarEngineering

A battery pack may include a battery (60), a board (10), a first connection terminal (12), a second connection terminal (11), a control circuit (620), and a busbar (18). The first connection terminal is provided on the board and is configured to be connected to an electric work machine (500). The second connection terminal is provided on the board and is connected to the battery. The control circuit is provided on the board and is configured to control discharging of the battery. The busbar is provided on the board in a current discharge path between the first connection terminal and the second connection terminal.

Owner:MAKITA CORP

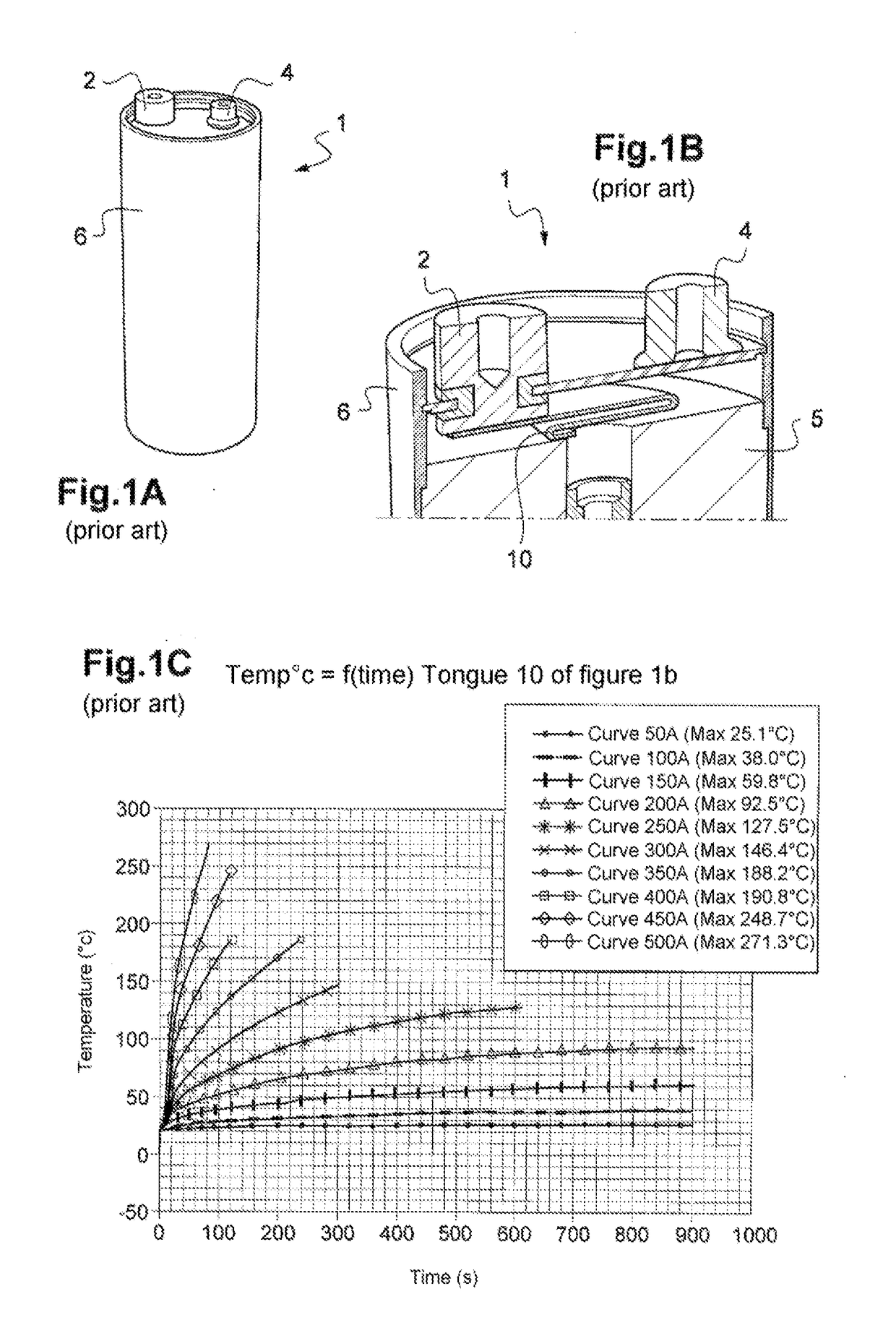

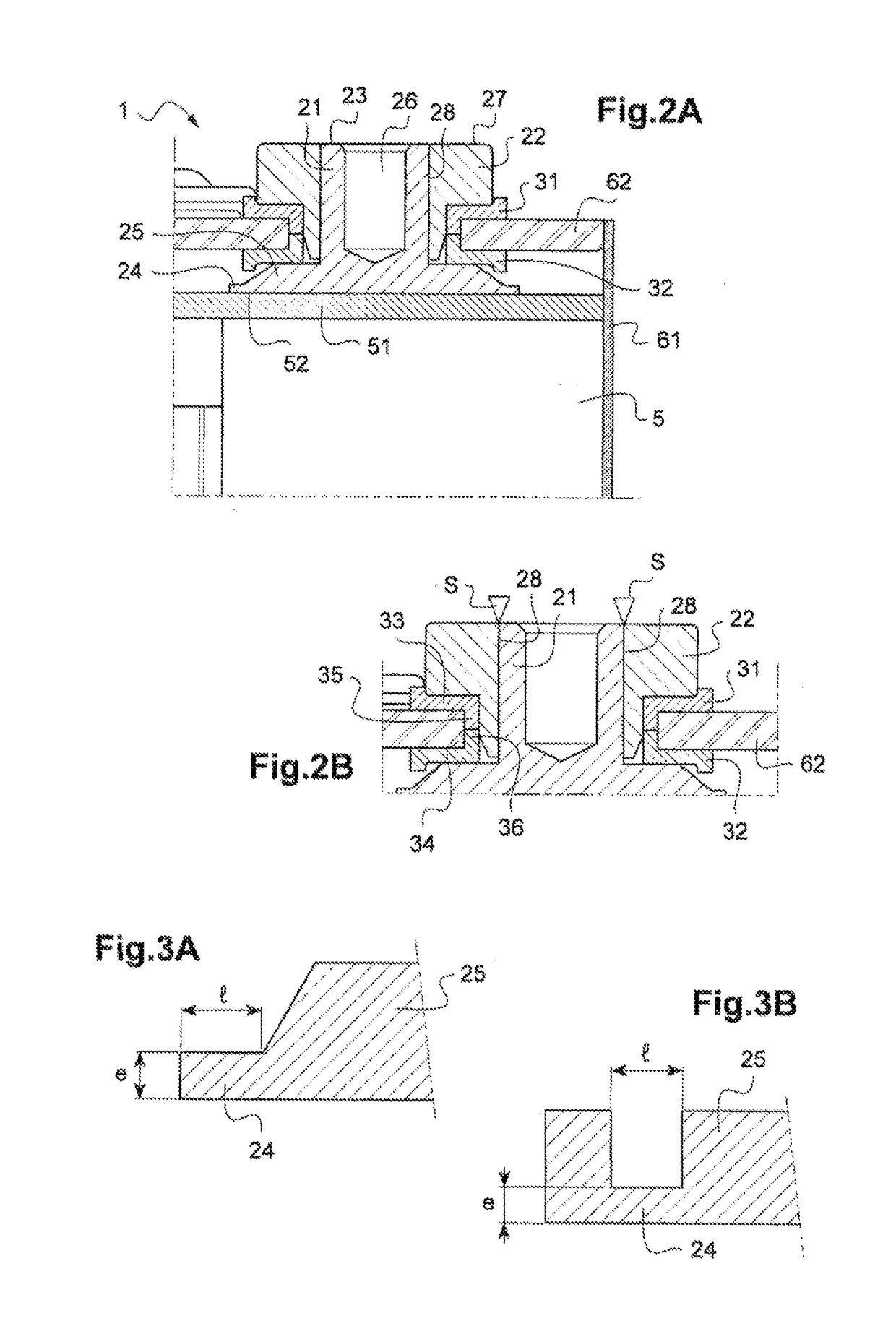

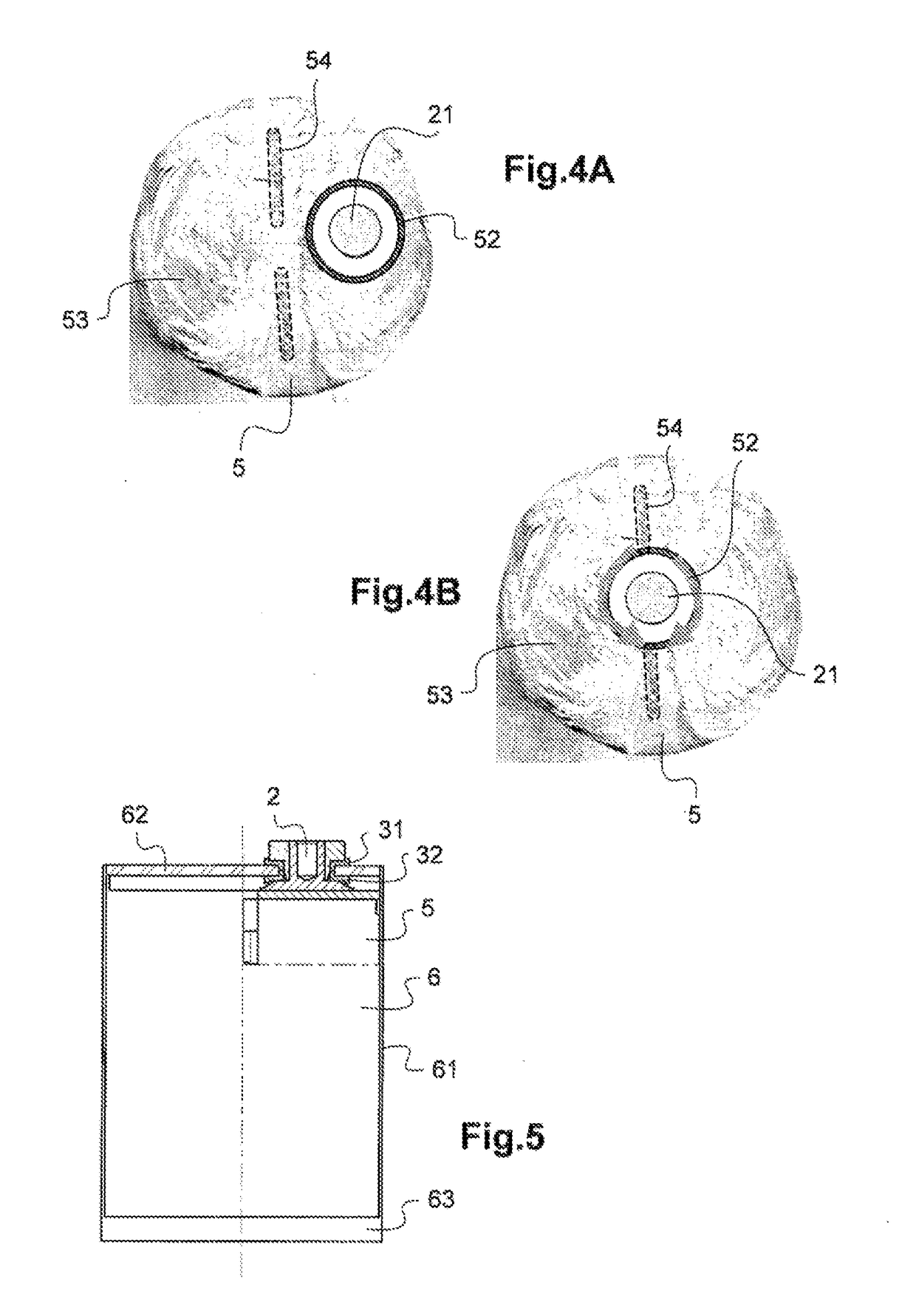

Lithium electrochemical accumulator having a terminal directly connected to the electrochemical assembly and associated production methods

ActiveUS20170117575A1Reliable electrical connectionIncrease energy densityFinal product manufactureSmall-sized cells cases/jacketsLithiumEngineering

The present invention relates to a lithium-ion electrochemical accumulator comprising an electrode assembly, a casing arranged to sealably contain the electrode assembly, two current output terminals each connected to one or other of the anode(s) and cathode(s) of the assembly, one of the terminals, called the first terminal, passing through a wall of the casing and being electrically insulated therefrom. According to the invention, the first terminal comprises a first conductive part passing through the casing and comprising a portion at least one region of which is welded directly to the bottom.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

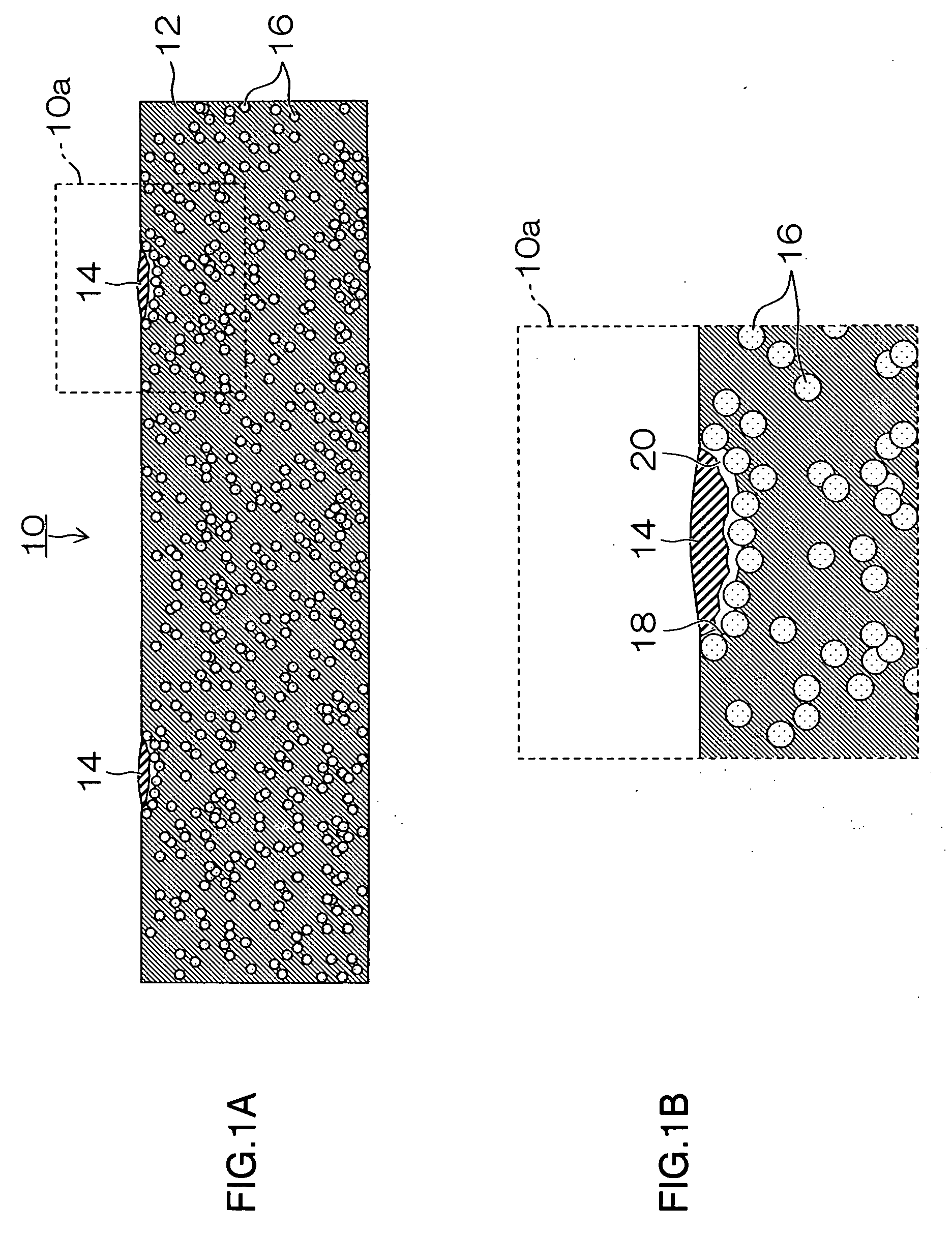

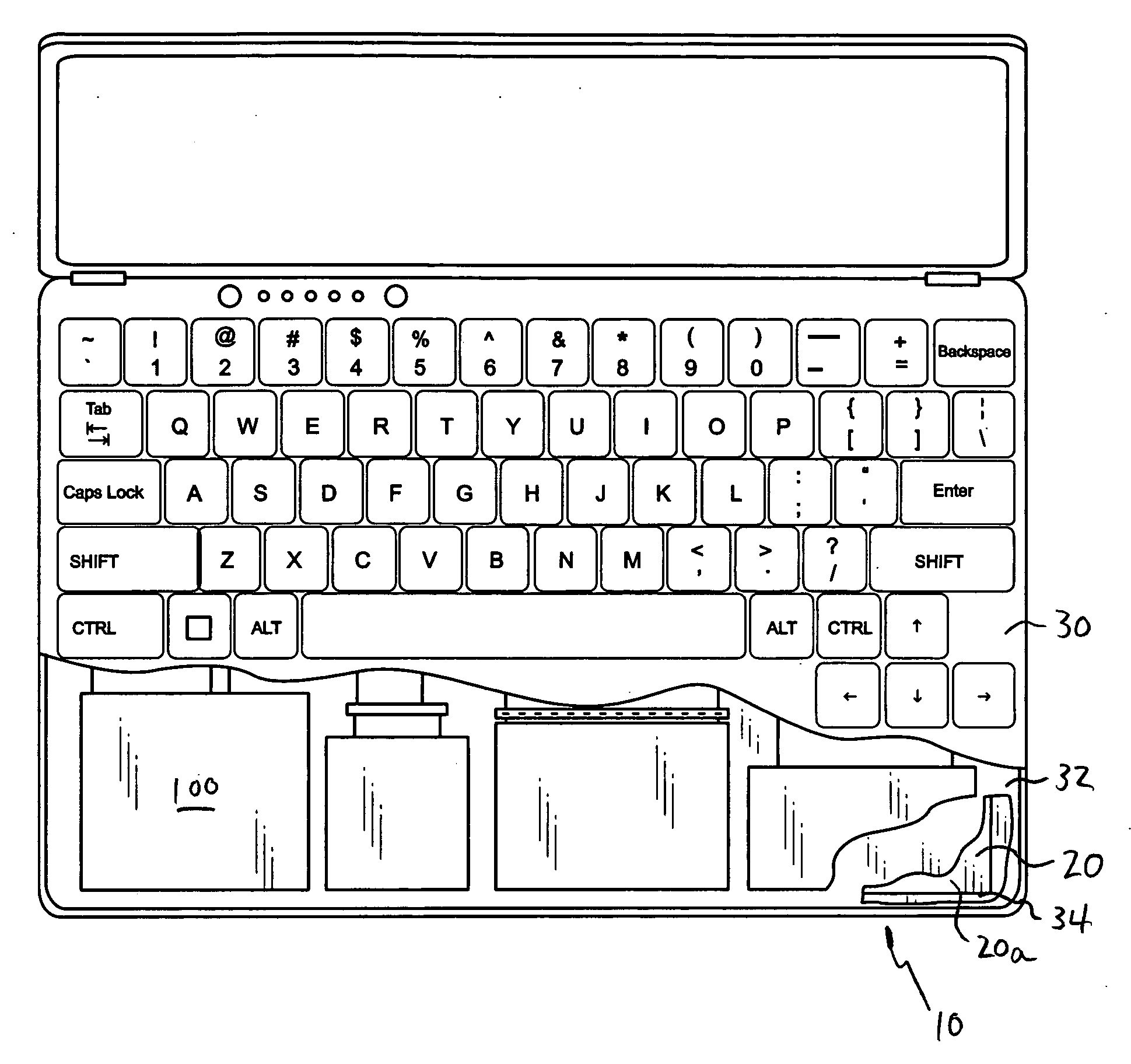

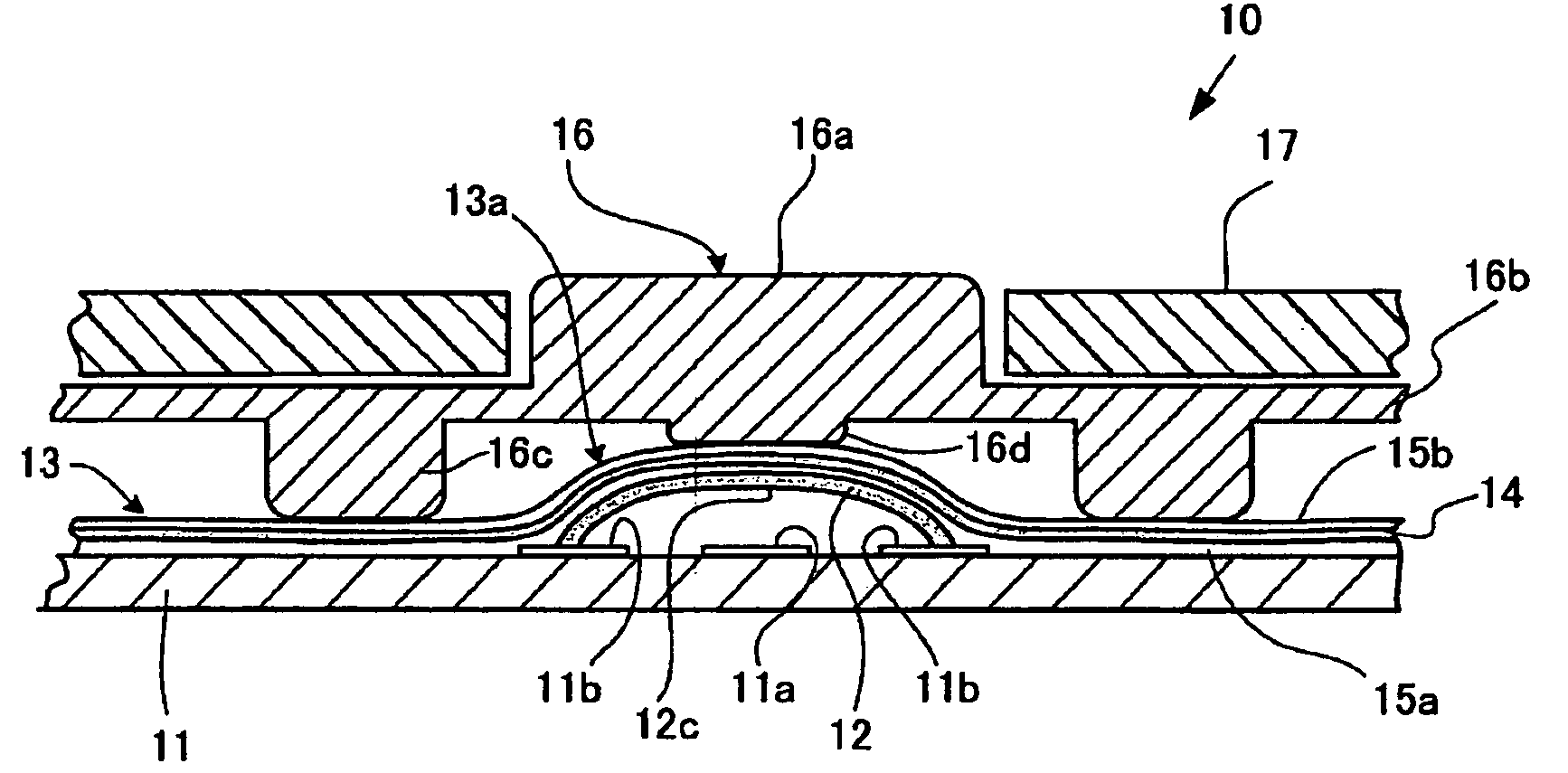

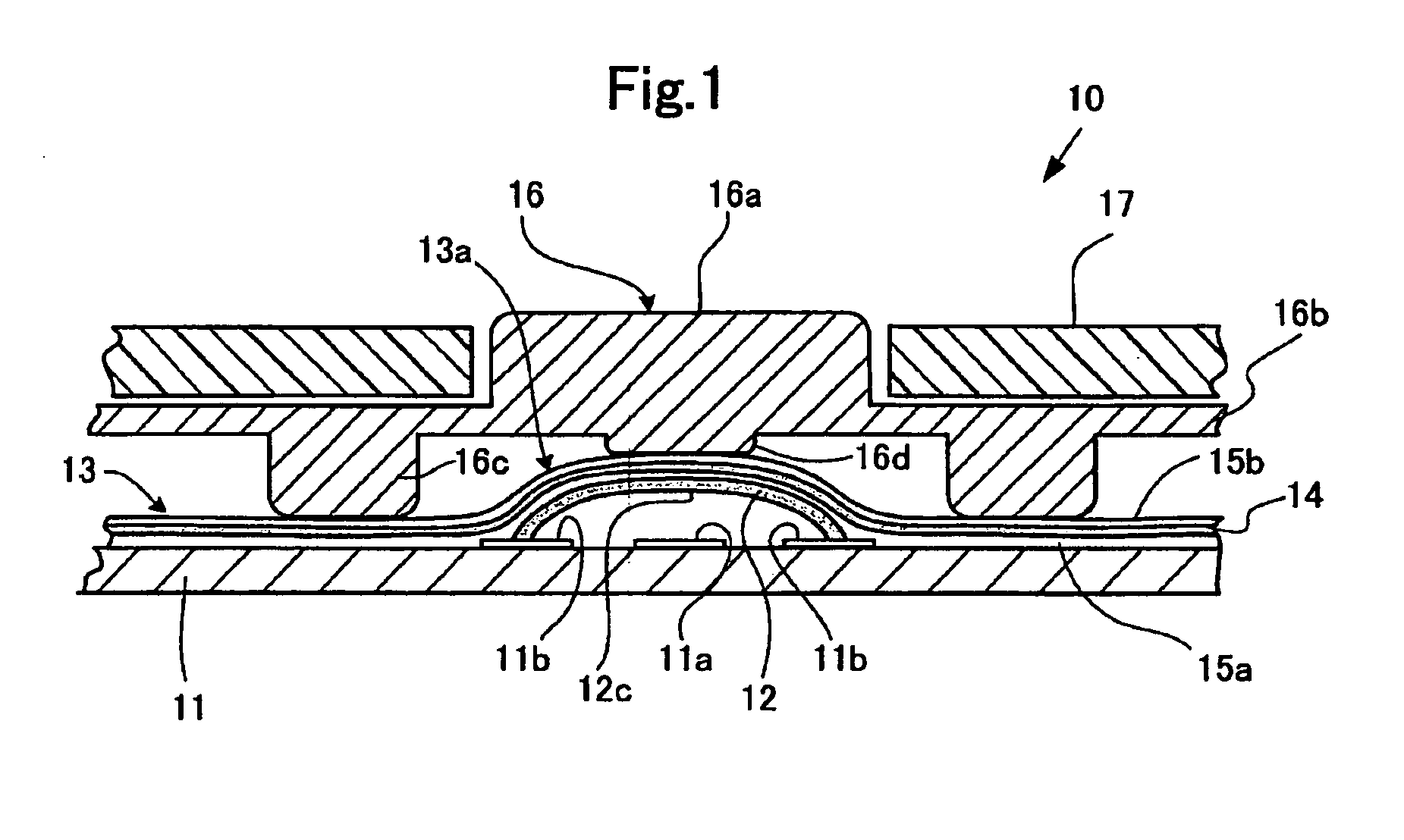

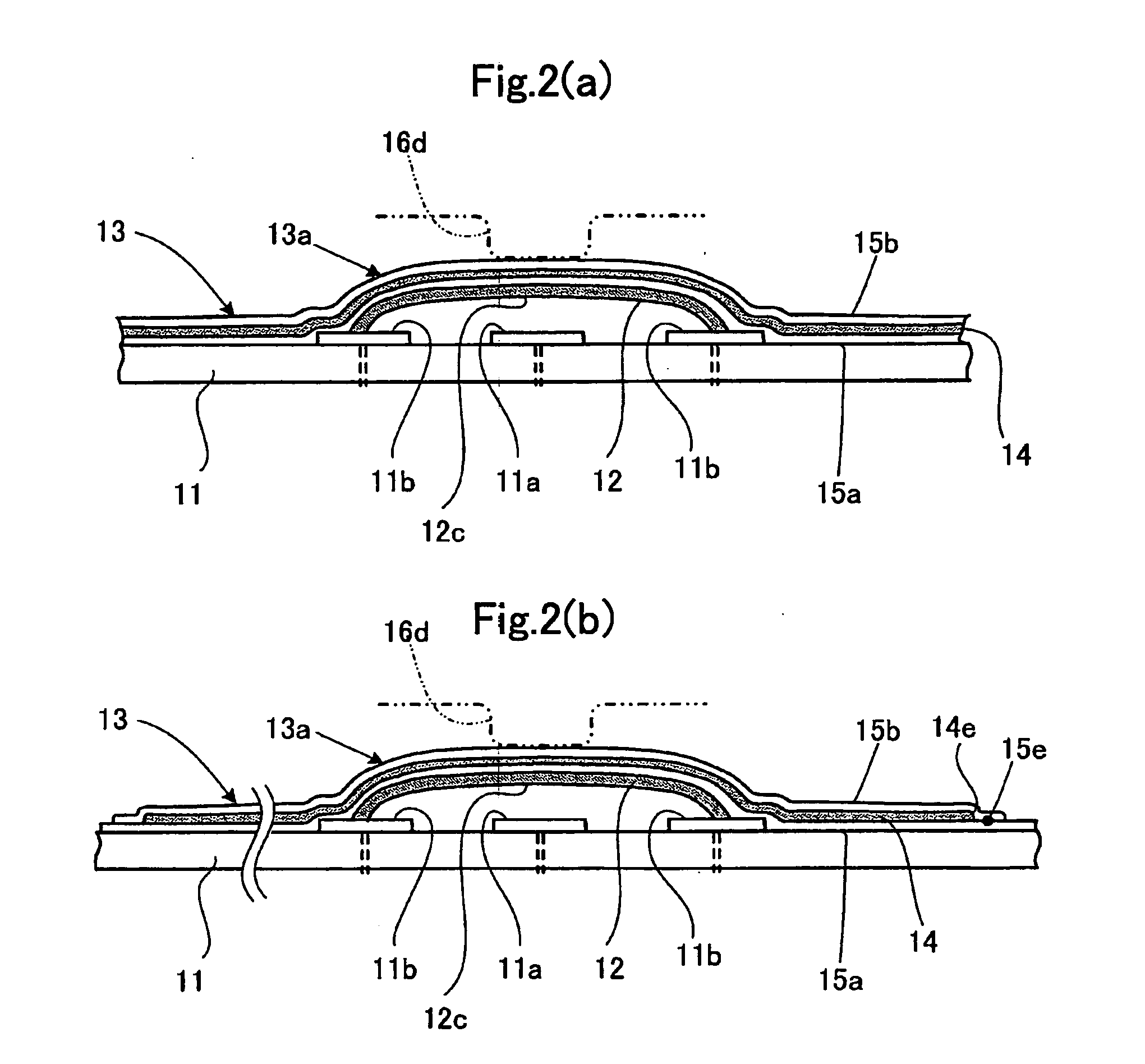

Push-button switch and electronic apparatus having the same

InactiveUS20090090607A1Improve the heating effectHeating effectEmergency actuatorsContact surface shape/structurePush switchHeat conducting

To prevent the local heating of an electronic apparatus chassis, there is provided a push button switch (10), which comprises a substrate (11) having a first contacting part (11a) and a second contacting part (11b) operable to be brought into electrical conduction with the first contacting part (11a), and a flexible electrically insulating sheet (13) covering the substrate (11) and having a click portion (13a) on the inside of which the first and second contacting parts are disposed to be brought into and out of electrical conduction therebetween in response to depression of the click portion. The electrically insulating sheet (13) includes a heat conducting layer (14) extending along the substrate (11).

Owner:PANASONIC CORP

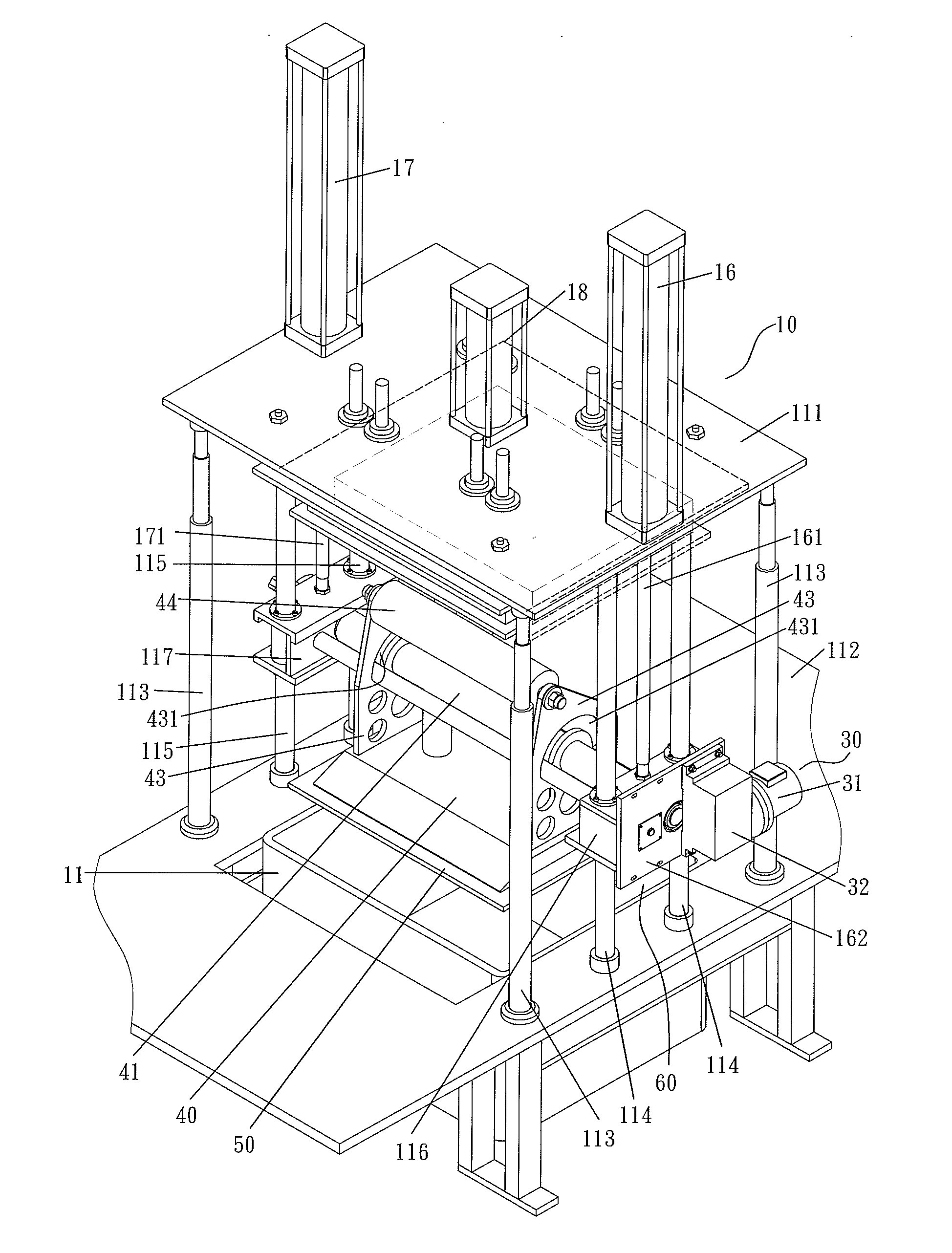

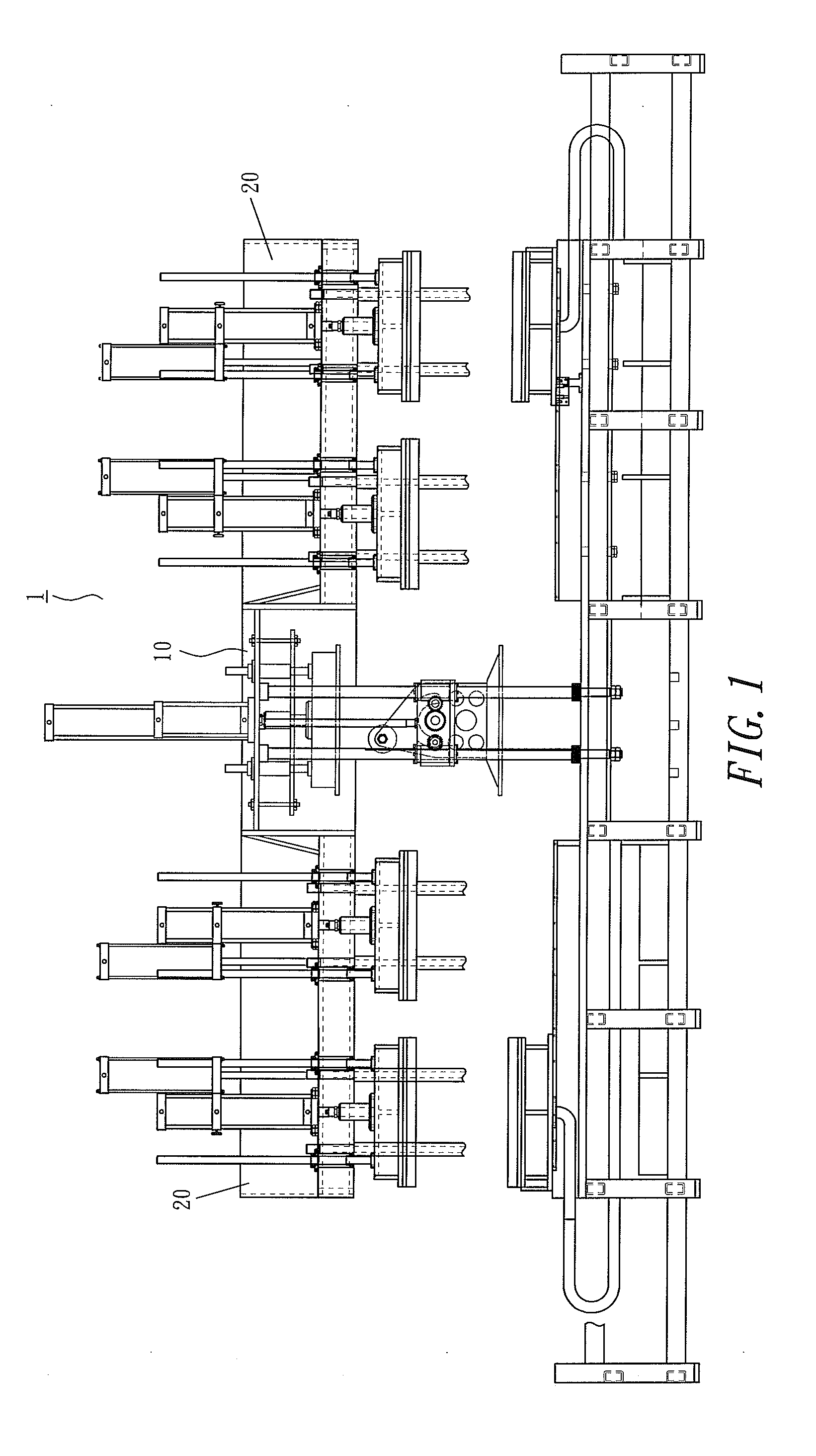

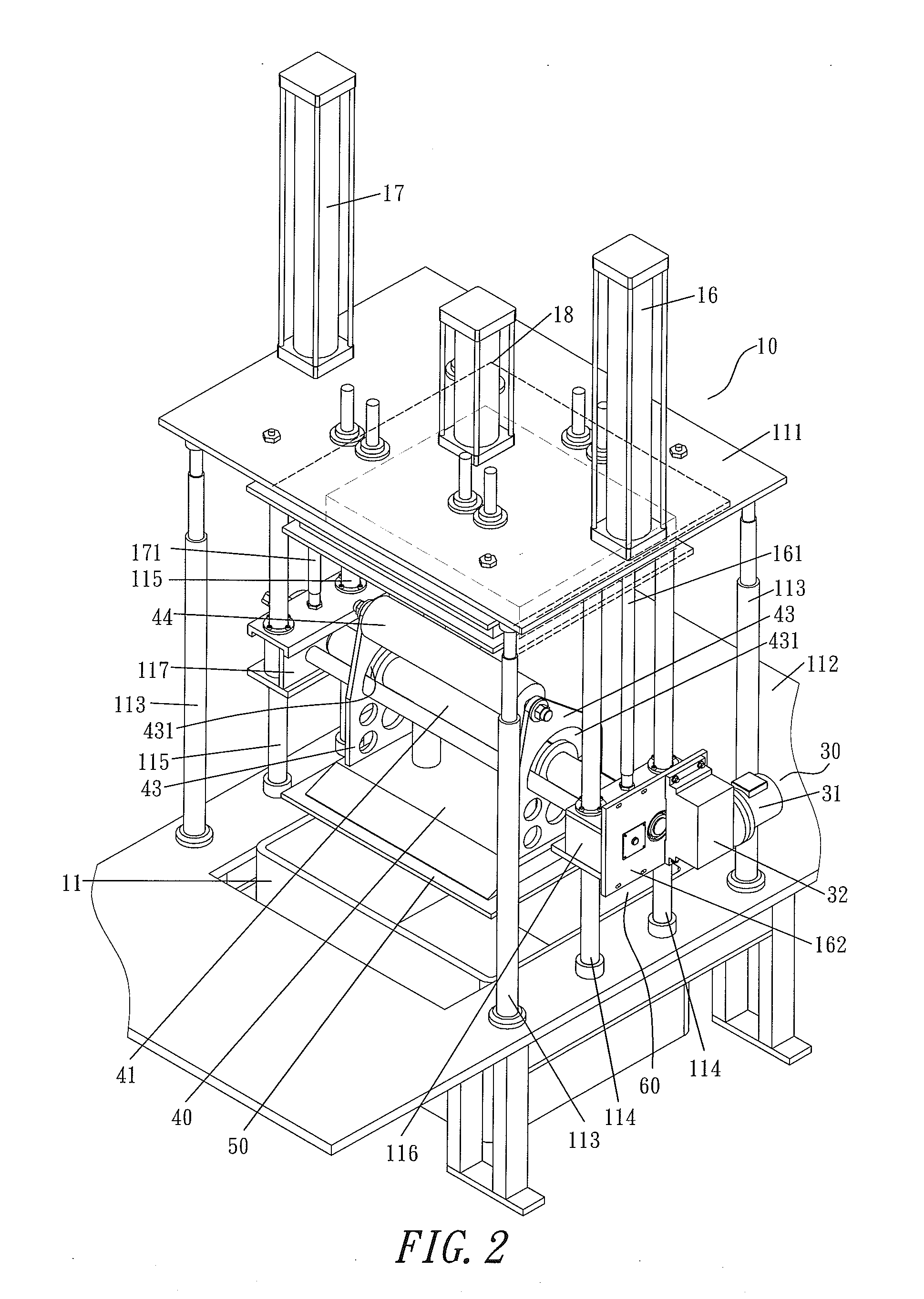

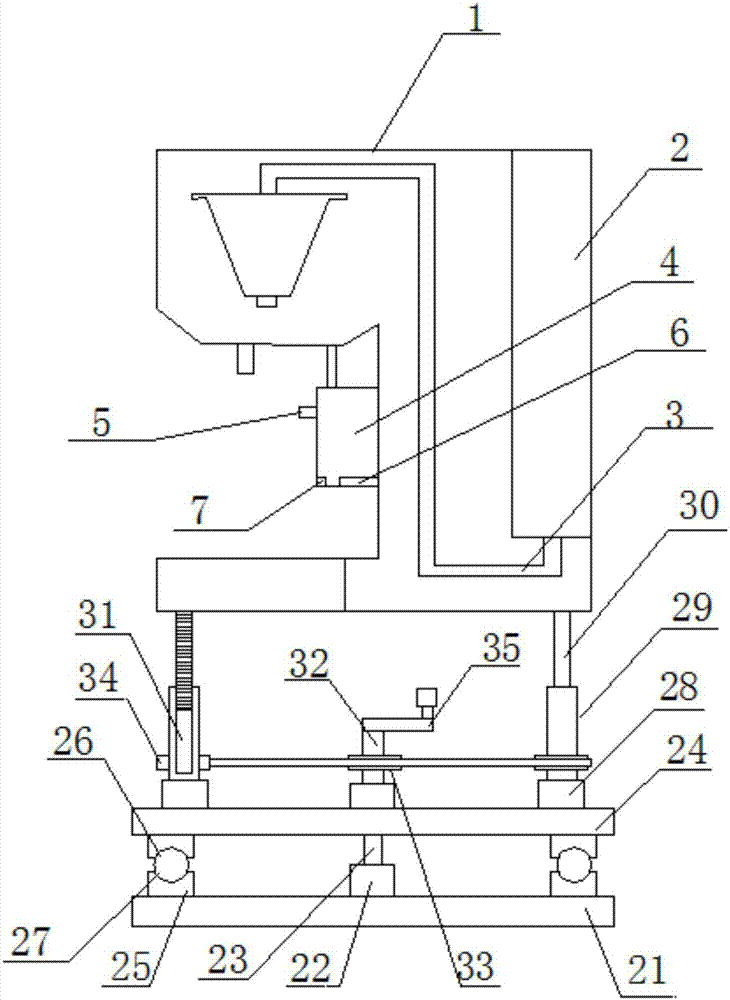

Automated Molding Machine for Ultra Small Draft Angle Slurry Molding Products

ActiveUS20150267353A1Heating effectMove preciselyEnvelopes/bags making machineryPaper-makingMechanical engineeringExtrusion

In an automated molding machine for ultra small draft angle slurry molding products, a righting gear of a righting mechanism drives a turning mechanism to perform a turnover action to assist righting an ascending or descending action along a righting rack of a righting shaft synchronously. When a slurry suction die is moved up and down and / or turned over, the slurry suction die can be ascended to a designated position through the righting provided by the righting gear and righting rack to achieve a precise closing molding when the slurry suction film is carried, ascended and closed with an extrusion die or descended and closed with a moving mold. Meanwhile, the extrusion die is controlled by a power cylinder to perform a descending stroke and close mold with the slurry suction die.

Owner:CHANGZHOU CHENGXIN ENVIRONMENTAL PROTECTION TECH CO LTD

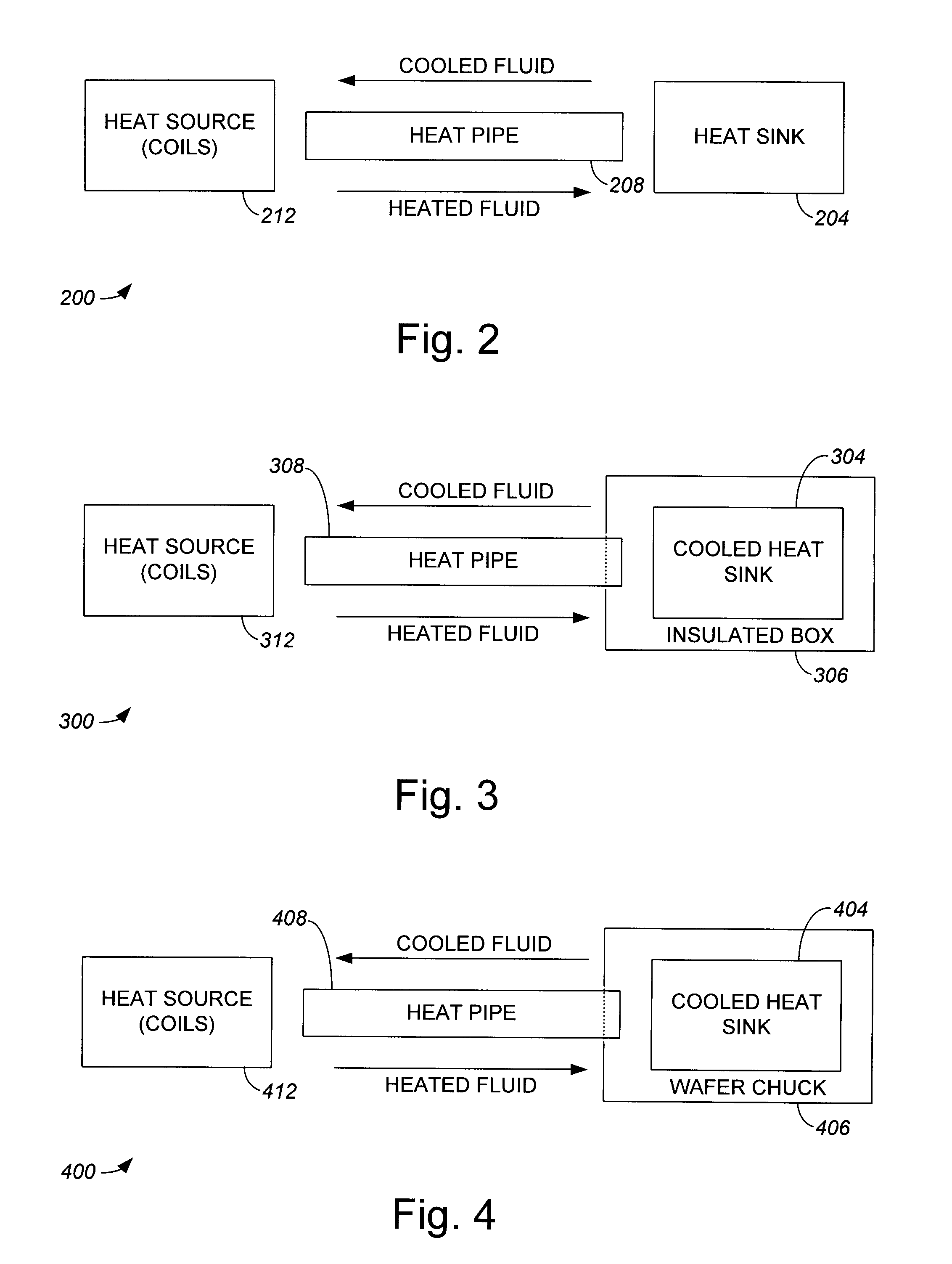

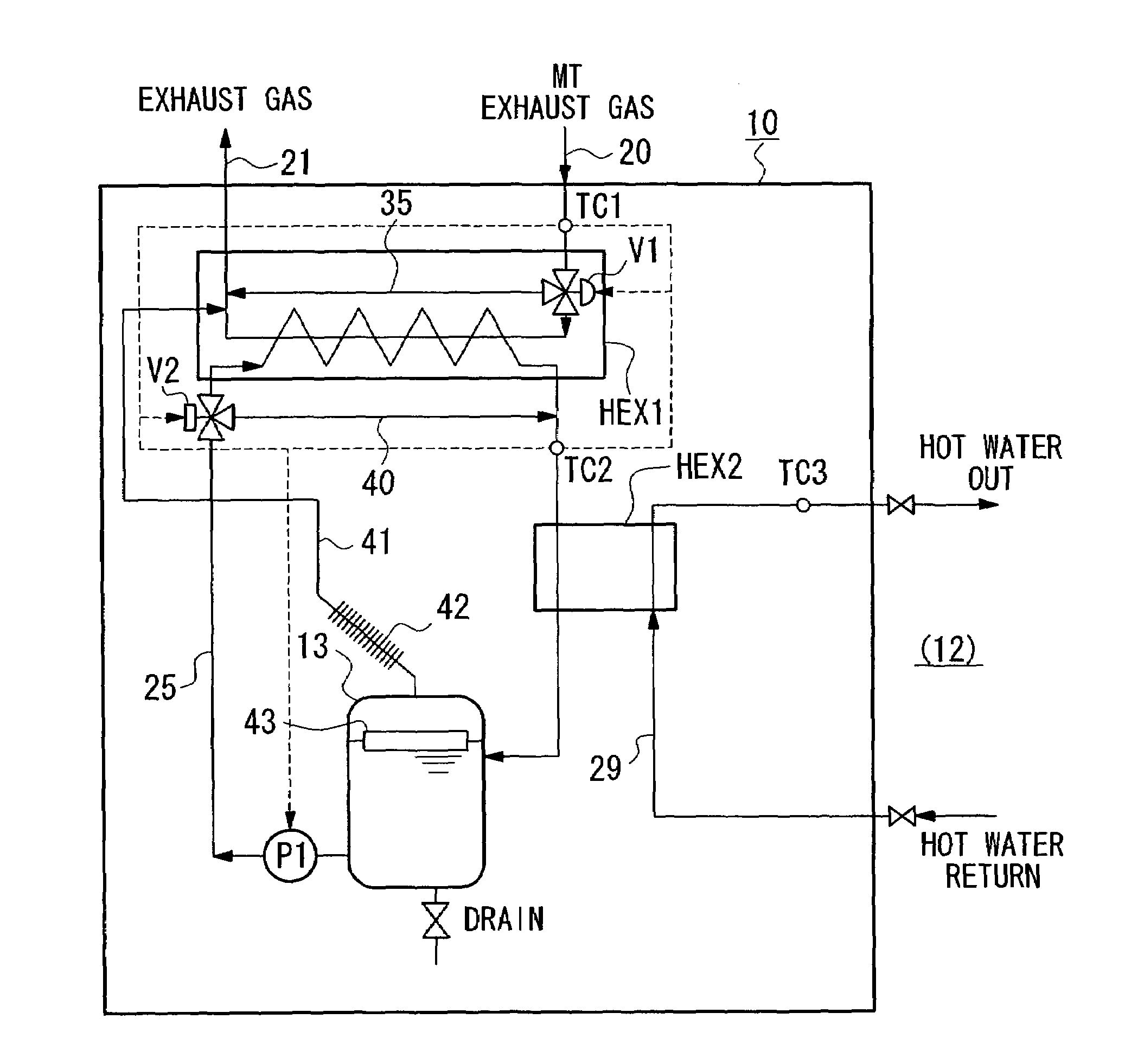

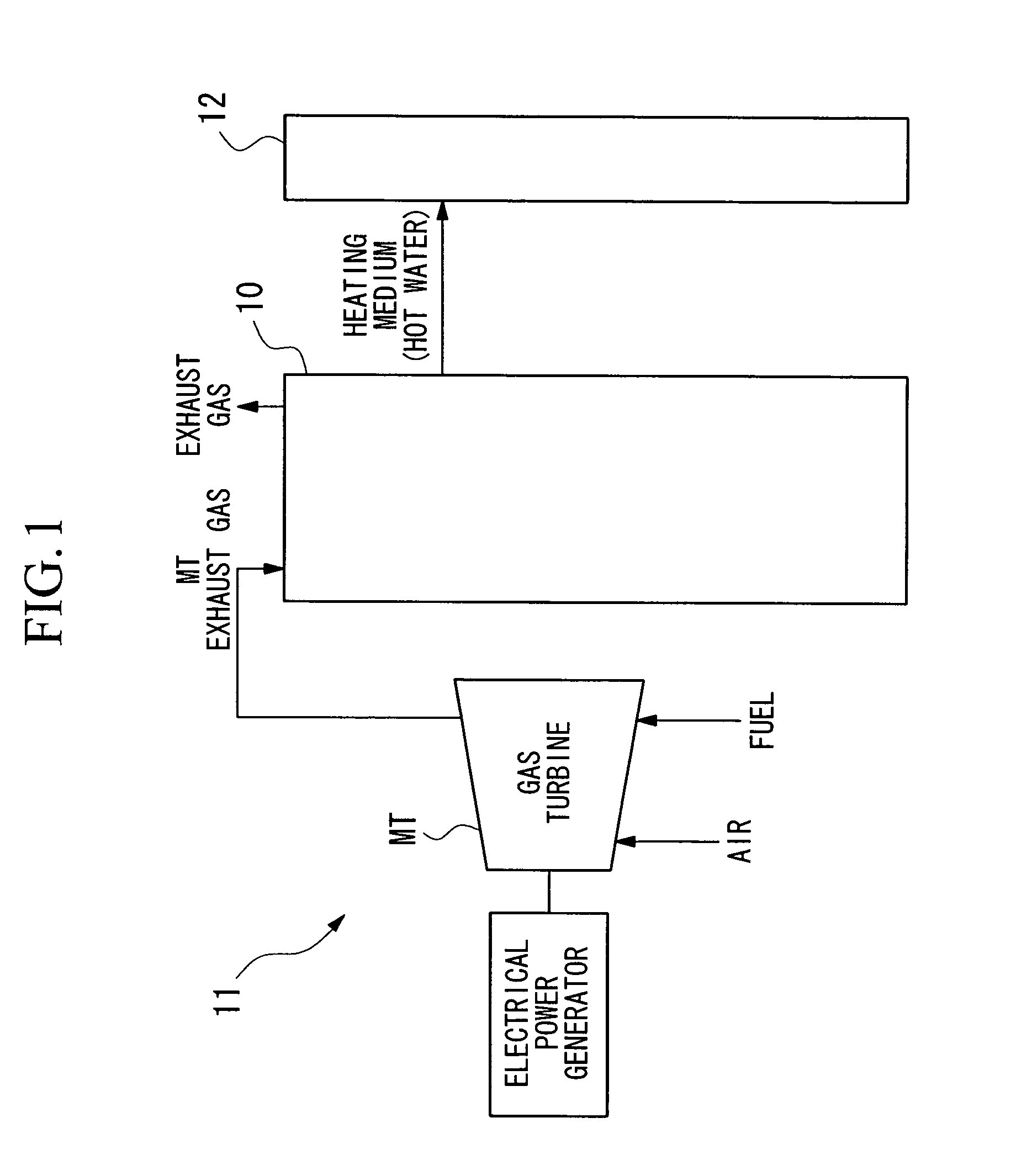

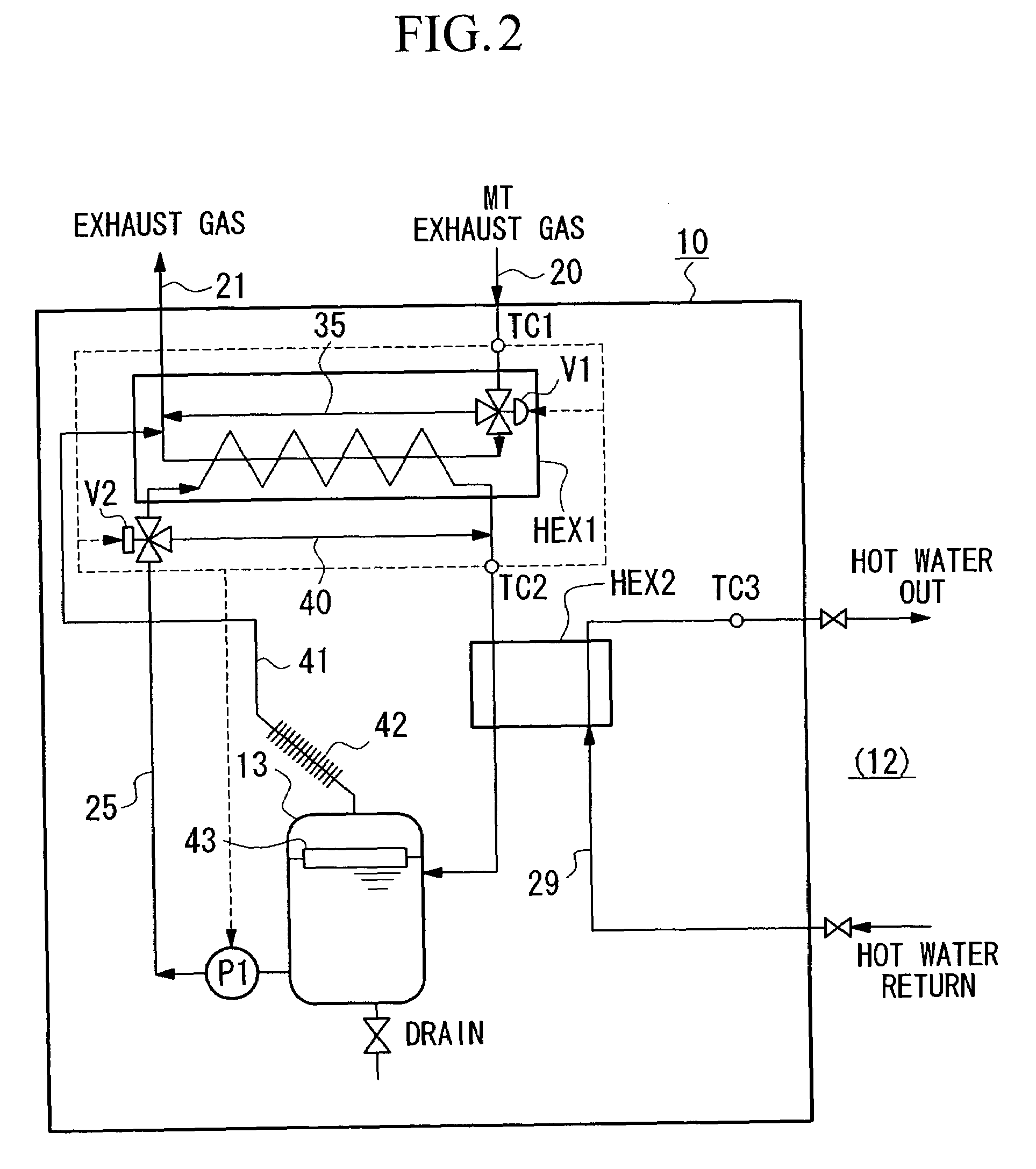

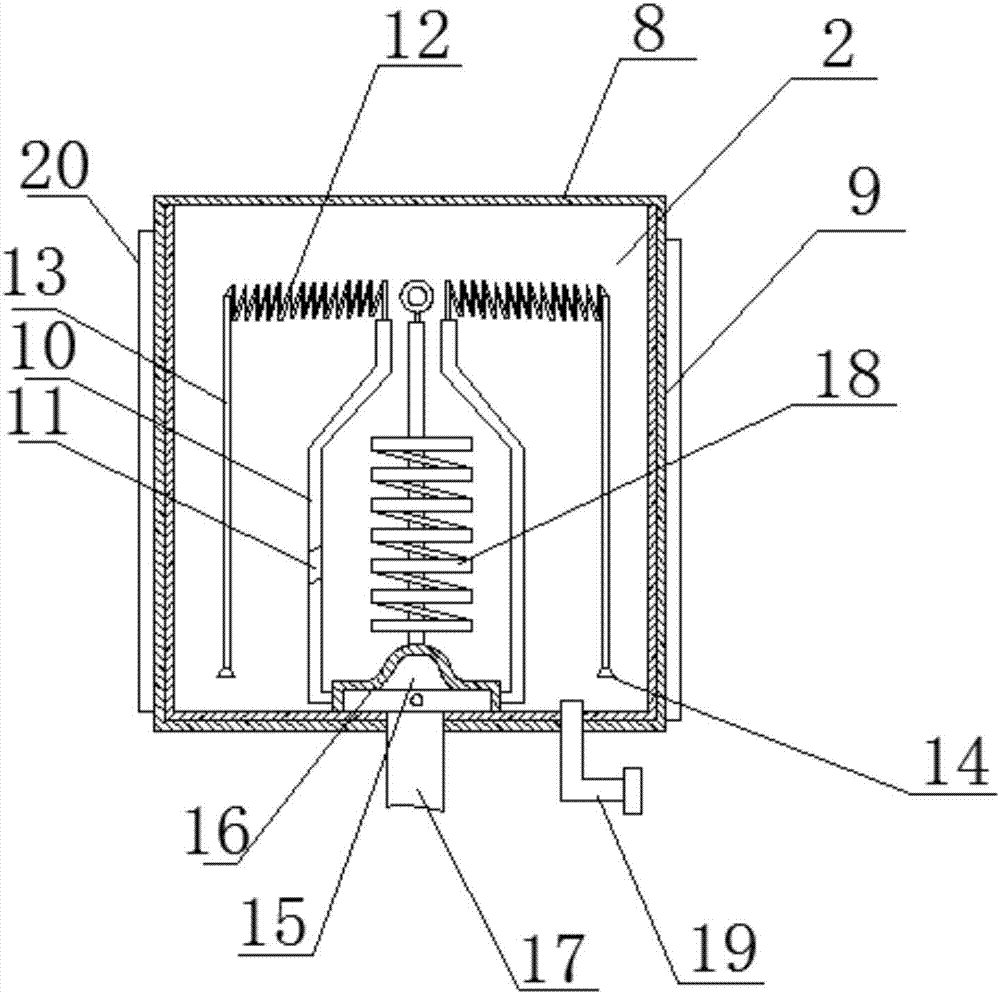

Exhaust heat recovery system

InactiveUS7021056B2Avoid cloggingHeating effectInternal combustion piston enginesRecuperative heat exchangersHigh energyExhaust fumes

The present invention relates to an exhaust heat recovery system that recovers exhaust heat that is generated by an electrical power generator for use in supplying hot water and air conditioning, and has as an object of providing an exhaust heat recovery system that realizes reduced costs and has a high energy efficiency. The exhaust heat recovery system provides a heat exchanger HEX1 for exhaust heat recovery that heats heating medium by heat exchange between exhaust gas generated at the power generator and heating medium that is circulated and used in a predetermined facility. In addition, the exhaust heat recovery system comprises a tank 13 that temporarily stores the heating medium, and an open-air pipe 41 that releases the contents of the tank 13.

Owner:THE TOKYO ELECTRIC POWER CO INC

Composite body and method of producing the same

InactiveUS6190762B1Heating effectLow ductilityPretreated surfacesCeramic layered productsCermetMicrowave sintering

A cermet or hard metal body is formed from elemental metal, carbon and a nitrogen source such as a metal nitride or an organic nitrogen source by microwave sintering such that chemical reaction occurs with the formation of carbides and / or carbonitrides. The elemental metal, carbon and nitrogen source are mixed together and prepressed to form the green body which is subjected to the microwave radiation in reaction sintering.

Owner:WIDIA

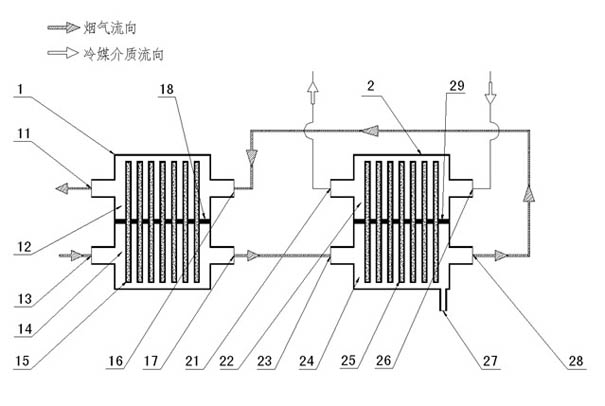

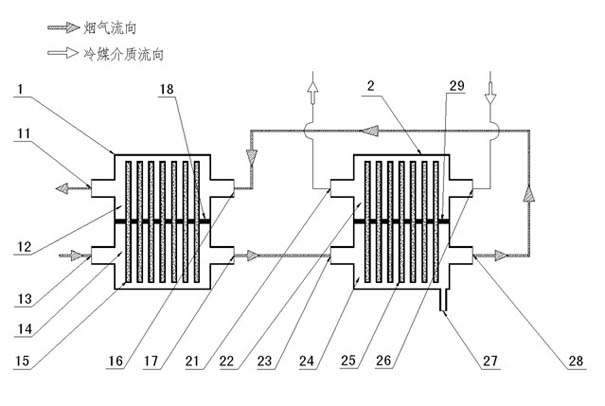

Device and method for condensing, drying and heating flue gas

InactiveCN102058994AHelp flowHeating effectDispersed particle separationVapor condensationFlue gasWater vapor

The invention discloses a device and method for condensing, drying and heating flue gas, in particular to a device and method for recovering and recycling condensed water in the flue gas and meeting the temperature requirement for diffusing pollutants in the flue gas to the upper air. A heat fluid outlet of a high-temperature heat tube heat exchanger of the device is connected with a heat fluid inlet of a low-temperature heat tube heat exchanger; a heat fluid outlet of the low-temperature heat tube heat exchanger is connected with a cold fluid inlet of the high-temperature heat tube heat exchanger. The method comprises the following steps of: introducing wet flue gas into an evaporation section of the high-temperature heat tube heat exchanger; heating a high-temperature heat tube; feedingthe wet flue gas subjected to temperature drop into an evaporation section of the low-temperature heat tube heat exchanger; feeding a coolant medium into the evaporation section of the low-temperature heat tube heat exchanger; reducing the temperature of the wet flue gas to below a dew point of water vapor under the action of the low-temperature heat tube; condensing the water vapor in the wet flue gas into water and discharging the water from a flue gas condensed water outlet; discharging the coolant medium absorbing the heat from a cold fluid outlet of the low-temperature heat tube heat exchanger; and heating the condensed dried flue gas by a high-temperature heat tube and discharging the heated flue gas by a chimney.

Owner:SOUTHEAST UNIV

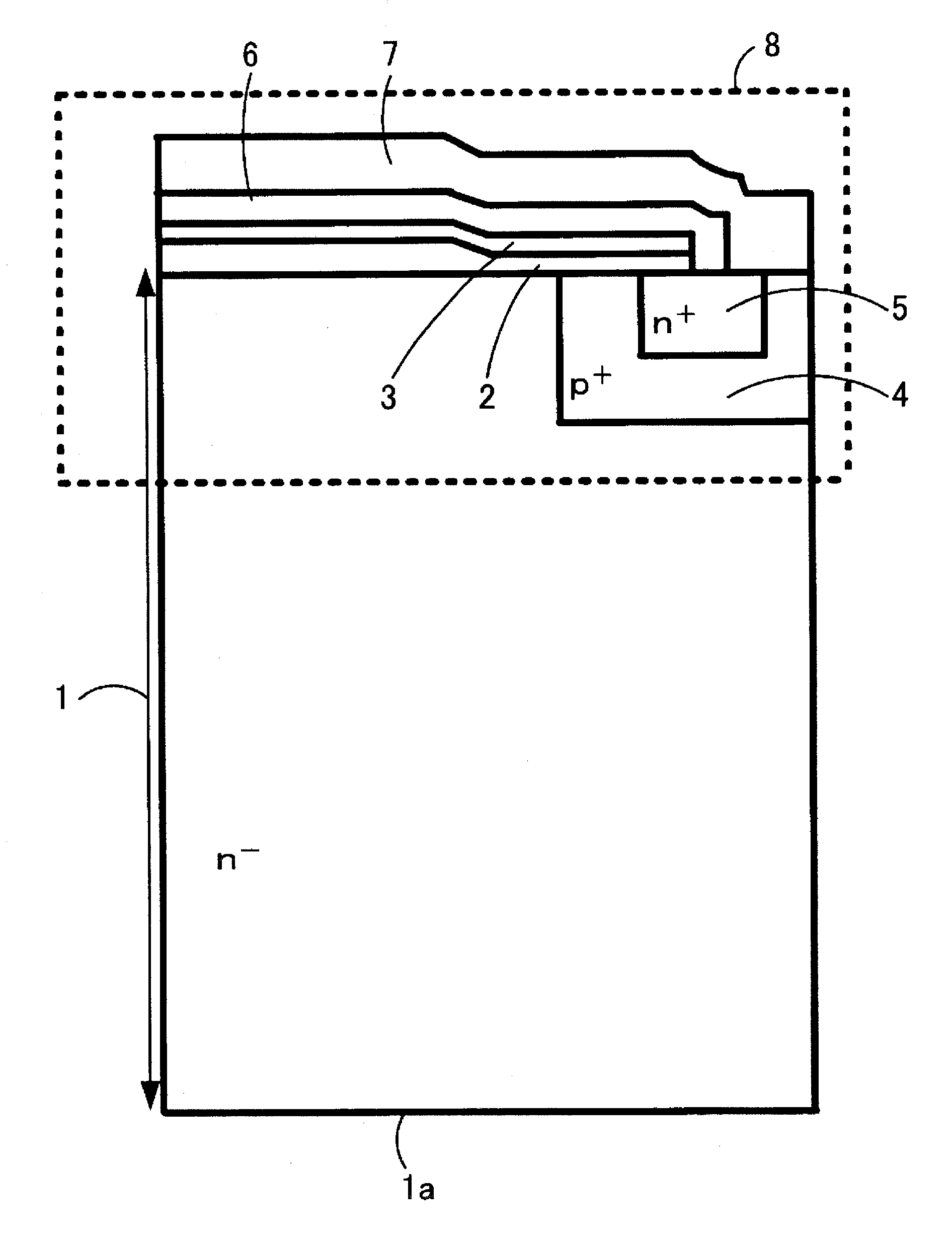

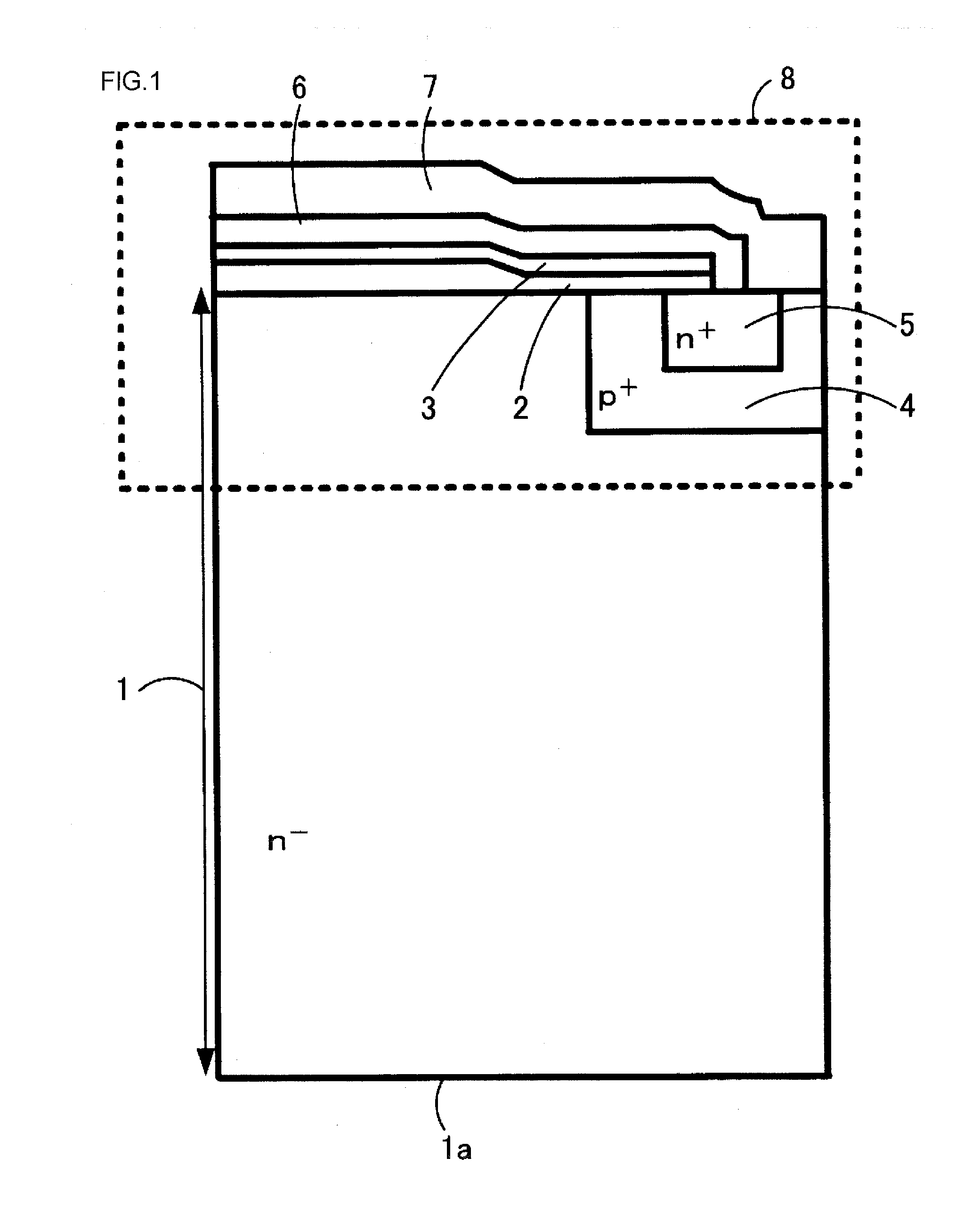

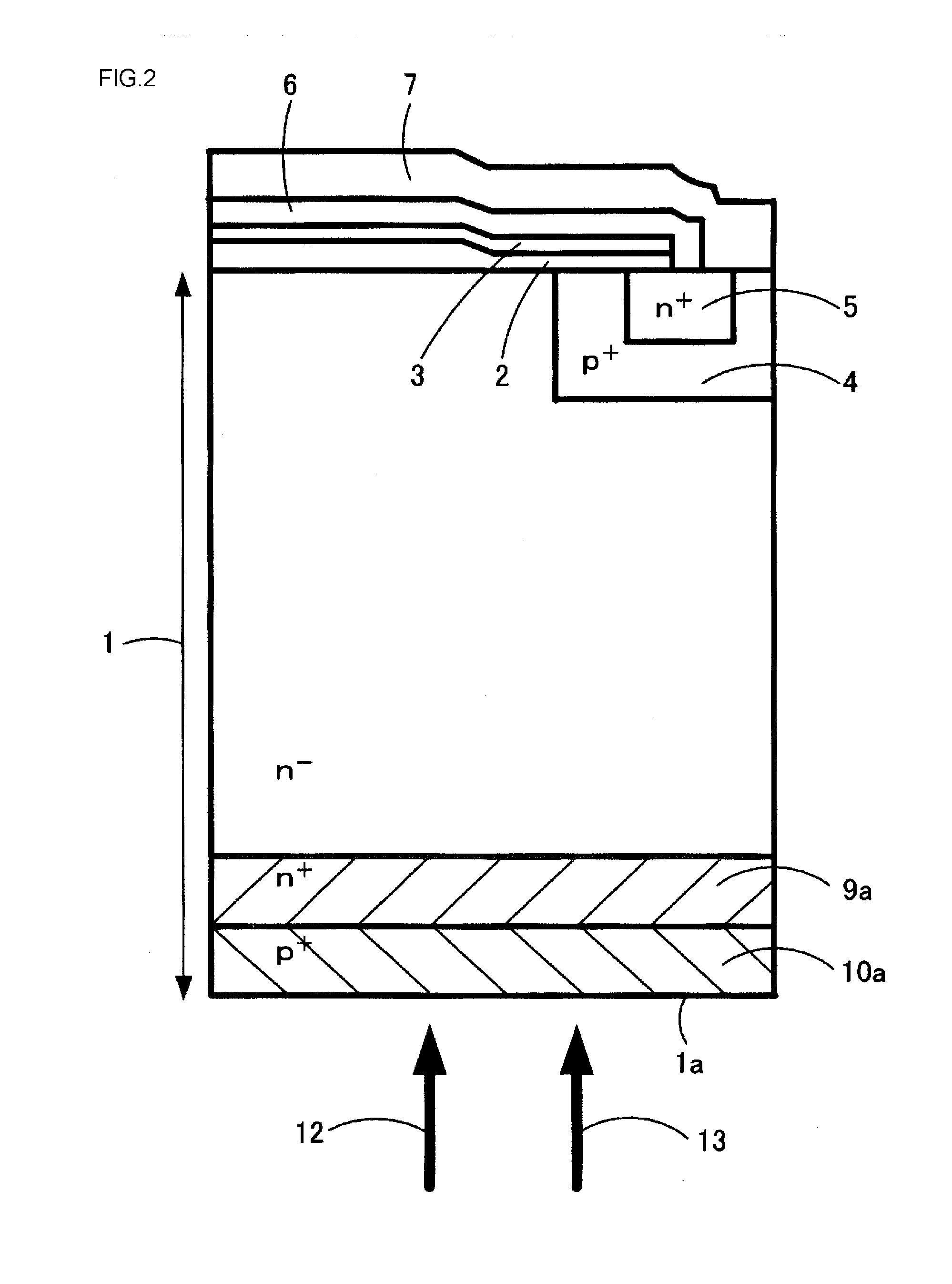

Method for manufacturing semiconductor device

InactiveUS20120329257A1Improve featuresHigh activation rateTransistorSemiconductor/solid-state device manufacturingDopantLaser light

A method for manufacturing a semiconductor device, the method including forming a front face structure of a semiconductor device on a first main face of a semiconductor substrate, grinding a second main face of the semiconductor substrate and reducing the semiconductor substrate in thickness to a thickness equal to or less than 100 μm, ion implanting a dopant into the second main face of the semiconductor substrate of reduced thickness, and activating the dopant by irradiating the second main face with laser light and performing laser annealing while the semiconductor substrate of reduced thickness is heated.

Owner:FUJI ELECTRIC CO LTD

Domestic coffee machine

The invention discloses a domestic coffee machine. The domestic coffee machine includes a machine body and a base, a water tank is arranged in the machine body, the lower end of the water tank is provided with a communication pipeline, a heat-insulation storage tank is further arranged on the machine body, a heating device and a temperature sensor are arranged in the heat-insulation storage tank, the upper end of the water tank is provided with a cover, electric heating wires are arranged in the water tank, the bottom of the water tank is provided with a water inlet pipe and a water outlet pipe, the portion, close to the water inlet end of the water inlet pipe, of the bottom of the water tank is provided with a water retaining hood, the side face of the water retaining hood is provided with a plurality of vertical diversion pipes, the upper ends of the diversion pipes are connected with spiral pipes, the outer ends of the spiral pipes are provided with vertical reflux pipes, the lower ends of the reflux pipes are provided with water distribution spray nozzles, the electric heating wires are located over the water retaining hood, the outer side of the water tank is provided with capacitor electrode probes, the upper ends of the capacitor electrode probes are close to the opposite top locations of the water tank, and the lower ends of the capacitor electrode probes are close to the opposite bottom locations of the water tank. The domestic coffee machine is simple in structure, convenient to use, good in heating effect and environmentally friendly, the energy is saved, and water-level monitoring is convenient.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

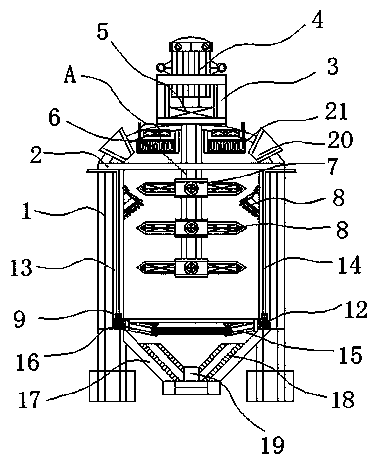

Reaction kettle with omni-directional cleaning and drying functions for chemical machinery

ActiveCN109277067AReduced lifespanEasy to cleanDrying gas arrangementsChemical/physical/physico-chemical stationary reactorsChemical compositionFixed frame

The invention discloses a reaction kettle with omni-directional cleaning and drying functions for chemical machinery and belongs to that technical field of chemical machinery. The reaction kettle comprises a reaction shell and a liquid inlet, the top of the reaction shell is provided with a sealing cover, the liquid inlet is arranged at the left and right ends of the sealing cover, the sealing capand the liquid inlet are poured and assembled. The top of the sealing cap is fixedly provided with a first fixing frame by welding, and the interior of the first fixing frame is provided with a motor, and the interior of the reaction shell is provided with a mounting plate. The invention has the advantages that the reaction kettle with omni-directional cleaning and drying functions for chemical machinery is provided with a spray assembly, when the reaction liquid inside the reaction shell is taken out after a plurality of processes, a part of the reaction liquid will remain inside the reaction shell. Under the cooperation of continuous water supply of the connecting water pipe, the device uses the spray assembly to take out the liquid to clean the remaining chemical components inside thereaction shell.

Owner:NINGXIA JIAFENG CHEMICALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com