Heat-dissipation sheet assembly manufactured by using electrochemical method

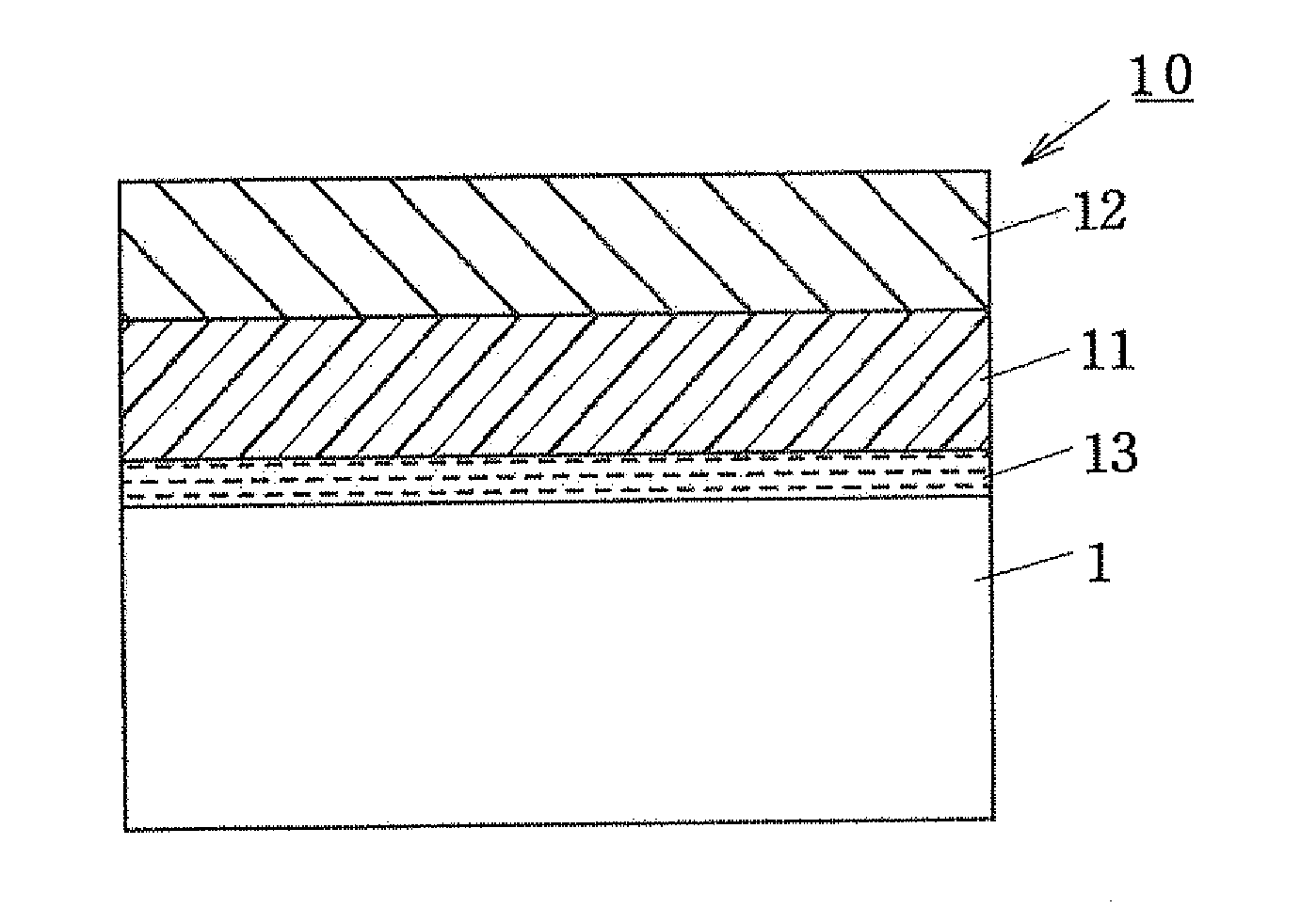

a technology of heat-dissipation sheet and electrochemical method, which is applied in the direction of lighting and heating apparatus, semiconductor/solid-state device details, soldering apparatus, etc., can solve the problems of increasing structural complexity and preciseness, and the heat-dissipation sheet layer b>91/b> may be peeled off or damaged, so as to achieve the effect of easy separation from the adhesion layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which the preferred embodiments of the invention are shown so that those of ordinary skill in the art can easily carry out the present invention.

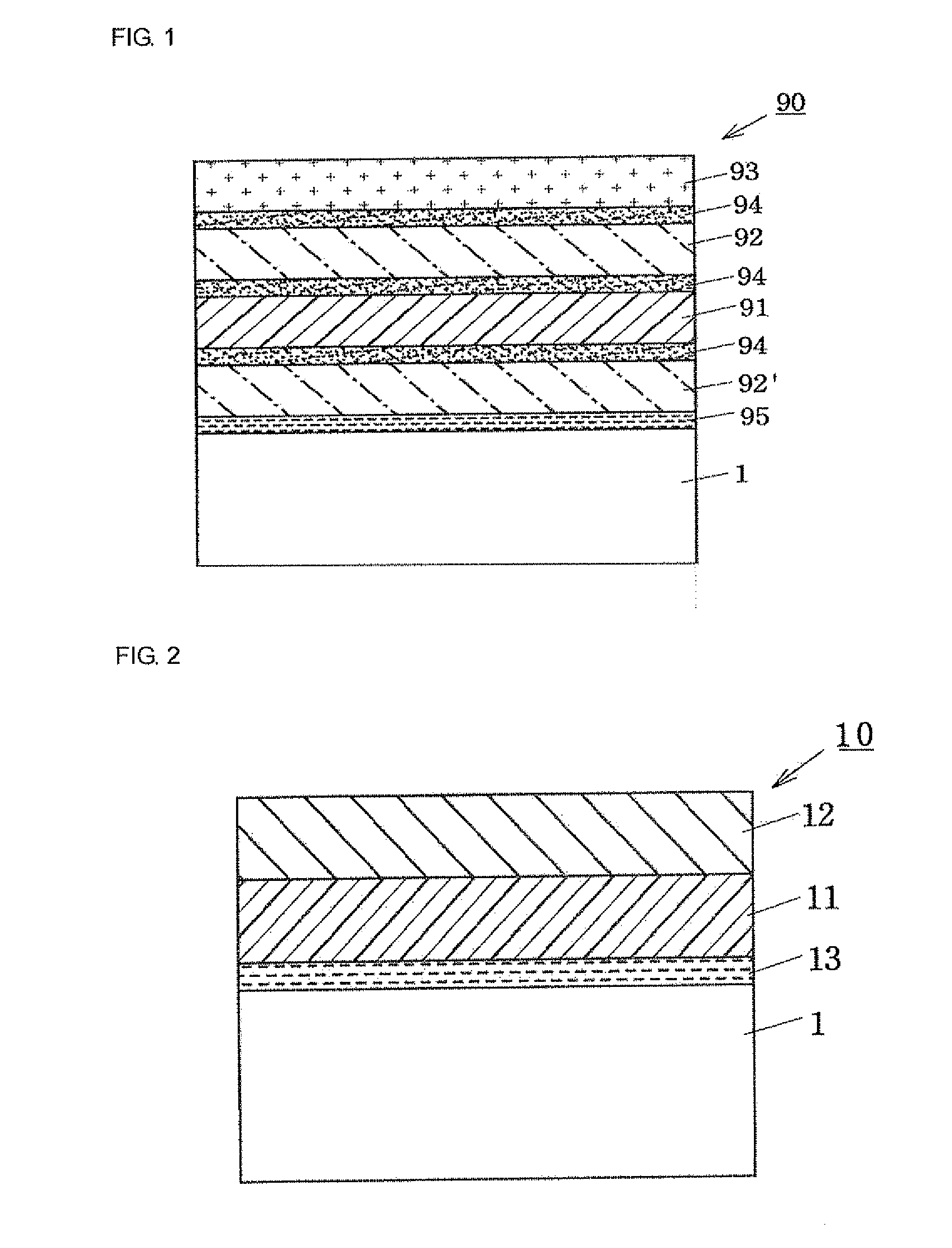

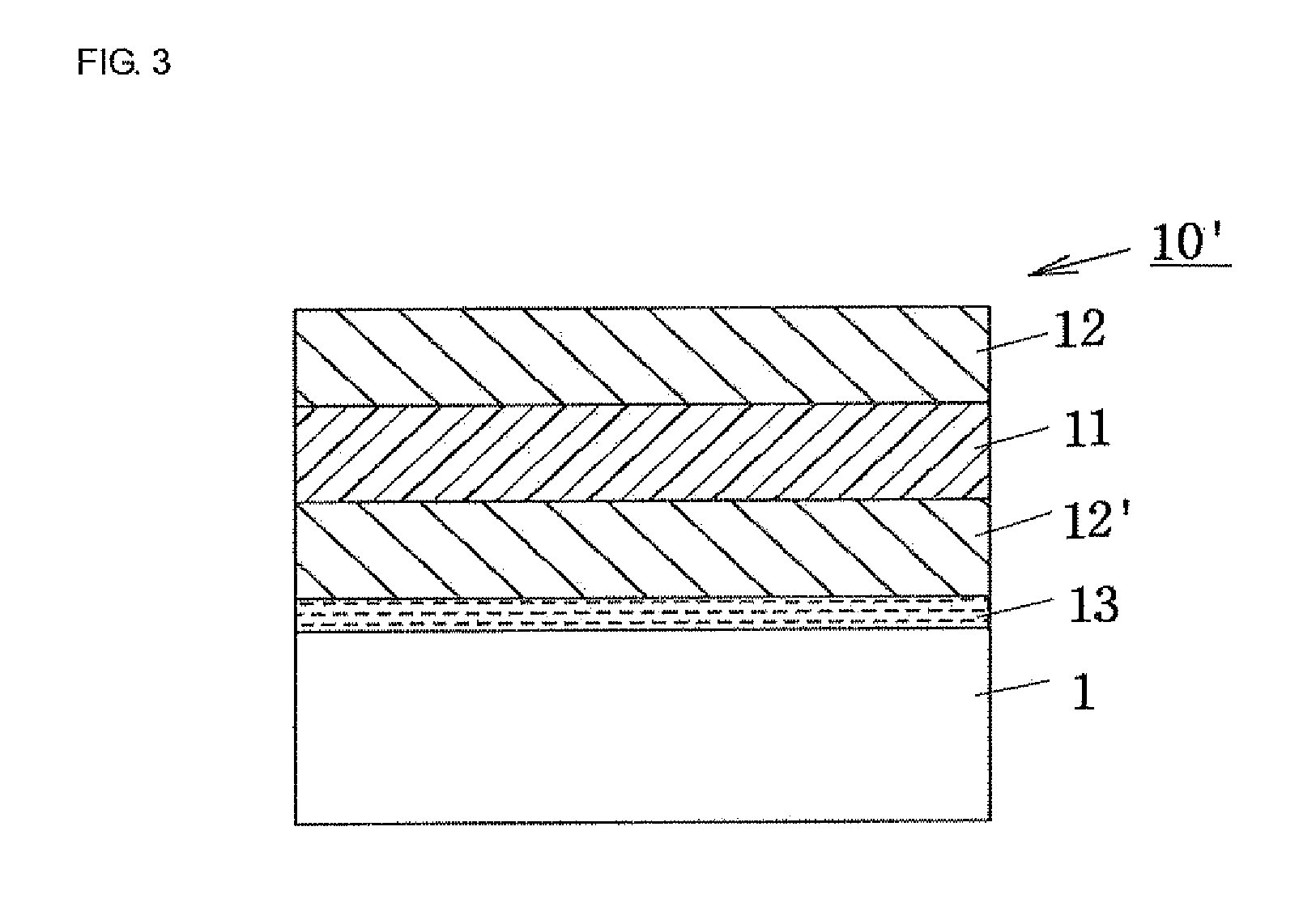

[0022]FIGS. 2 and 3 are schematic cross-sectional views of heat-dissipation sheet assemblies 10, 10′ according to the present invention. FIG. 2 is a cross-sectional view of the heat-dissipation sheet assembly 10 according to one embodiment of the present invention, wherein a protection layer 12 is electrodeposited on only one side of a heat-dissipation sheet 11. FIG. 3 is a cross-sectional view of the heat-dissipation sheet assembly 10′ according to another embodiment of the present invention, wherein protection layers 12, 12′ are electrodeposited on and under a heat-dissipation sheet layer 11.

[0023]As shown in FIGS. 2 and 3, the heat-dissipation sheet assemblies 10, 10′ comprise the heat-dissipation sheet layer 11 having...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com