Control method of oil temperature of compressor

A control method and compressor technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as slow heating, wear and tear, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

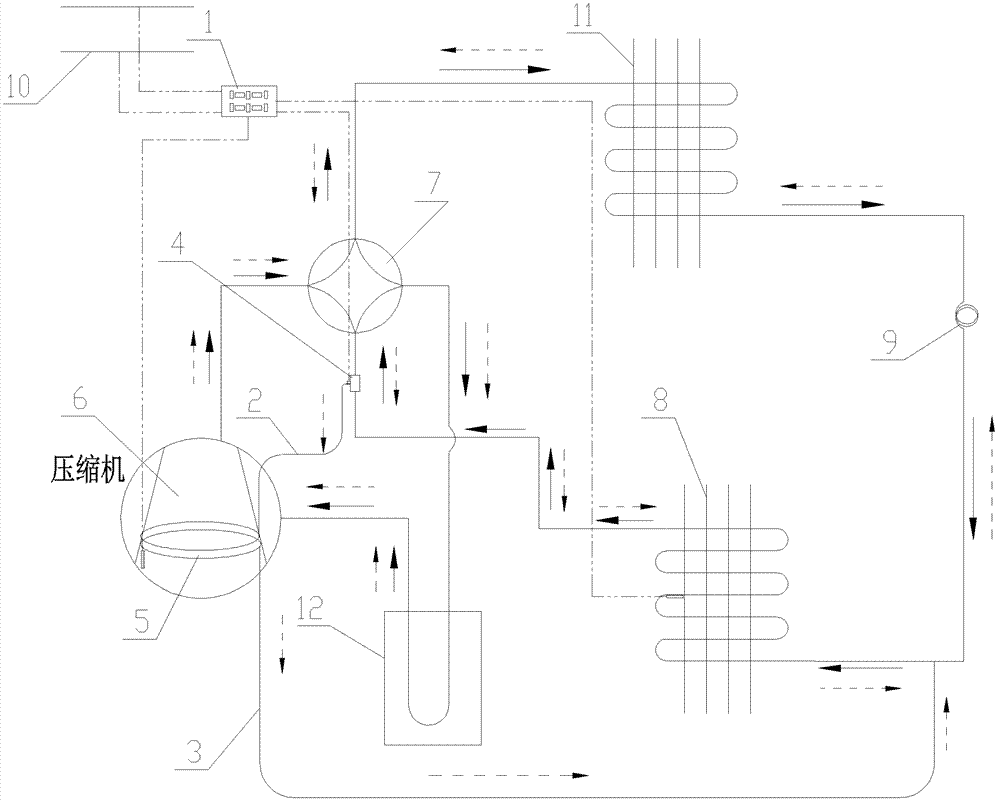

[0010] The present invention will be further described below in conjunction with accompanying drawing.

[0011] In the method for controlling the oil temperature of the compressor in the present invention, when the compressor 6 is started or running, if the ΔT-prescribed value<0, then the high-temperature refrigerant in the pipeline used to transport the high-temperature refrigerant during the heating of the air conditioner is led to the compressor. machine 6 to heat the bottom surface of the compressor 6 shell, in actual use, only a small part of the high-temperature refrigerant is drained to heat the compressor 6 shell; during the process of heating the compressor 6 shell by the high-temperature refrigerant, if ΔT- If the specified value is greater than or equal to 0 and lasts for 3 minutes, then disconnect the high-temperature refrigerant leading to the compressor 6, that is, stop using the high-temperature refrigerant to heat the bottom of the compressor 6 shell, otherwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com