Method for treating raw water containing hardly decomposable substance

A treatment method and a technology that is difficult to decompose. It is applied in the fields of adsorbed water/sewage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problems of difficulty in high concentrations, insufficient treatment, and hindering chemical decomposition. achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

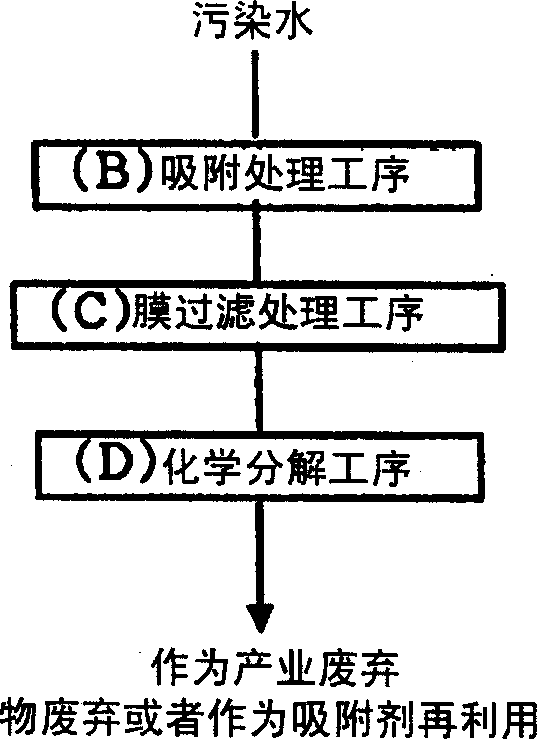

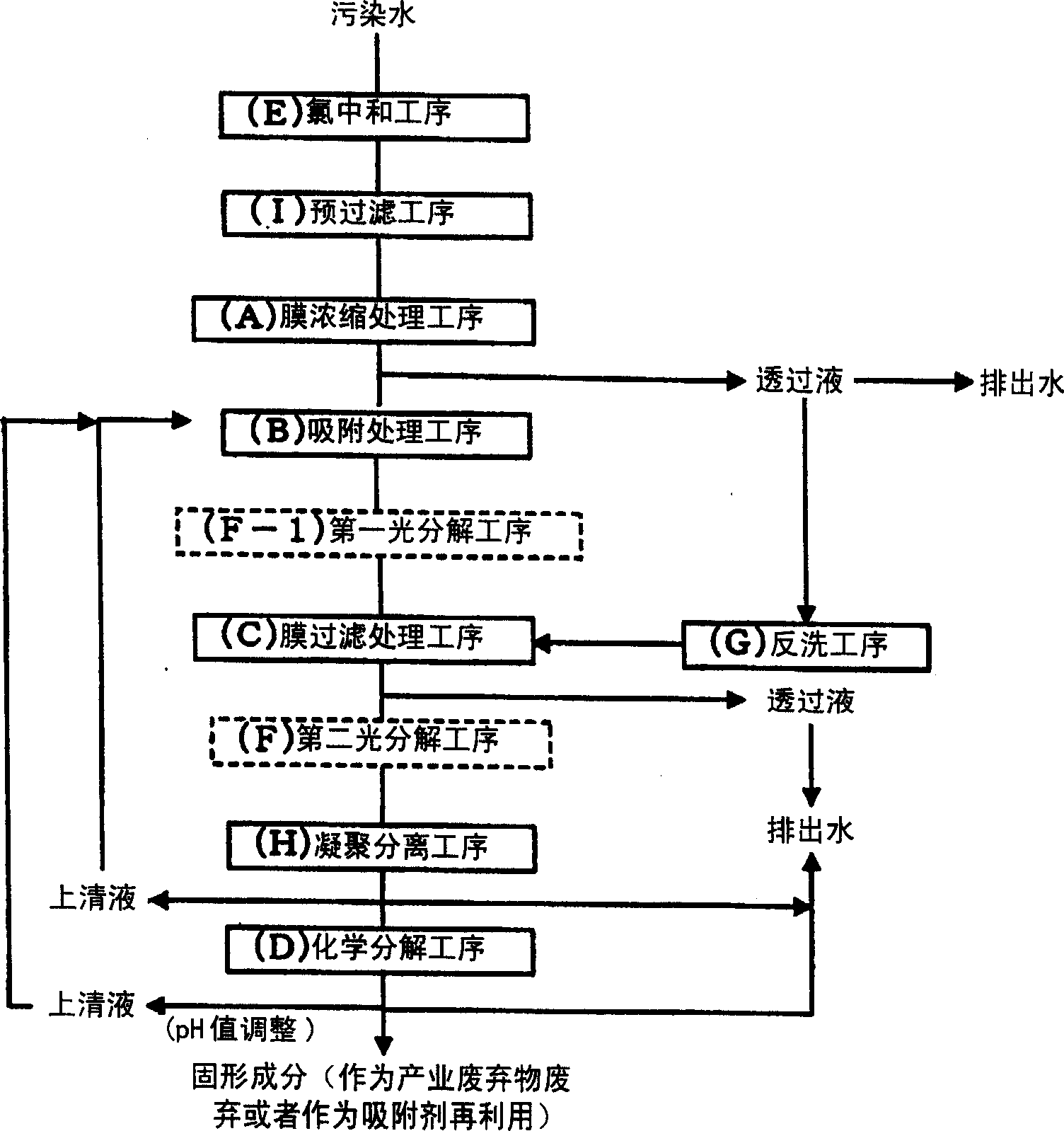

[0224] For example in Figure 4 In the embodiment of (a), an adsorbent is added to the water (raw water) containing hardly decomposable substances ((B-1) adsorption treatment step), and separated into a concentrate and a permeate by membrane filtration ((C-1) membrane Filtration treatment process). Regarding the concentrate, it is processed in the above-mentioned (D) chemical decomposition step. After further adding an adsorbent to the permeate ((B-2) adsorption treatment step), membrane filtration is performed again ((C-2) membrane filtration treatment step); the concentrate that has not passed through the filter membrane is returned In the (B-1) adsorption treatment step, since the permeate is below the discharge standard, it can be discharged to the outside as discharged water.

[0225] in Figure 4 In the embodiment of (b), by providing the (B) adsorption treatment step once and the (C) membrane filtration treatment step twice, a more economical system can be formed.

[0226] ...

Embodiment 1

[0249] Example 1 (refer to Figure 6)

[0250] (B) Adsorption treatment process

[0251] Put the raw water (dioxene concentration 6500pg-TEQ / L) into the adsorption tank with a residence time of 1 hour, add 1000ppm silica bath clay as an adsorbent, and stir to make it adsorb.

[0252] (C) Membrane filtration treatment process

[0253] Use an ultrafiltration membrane (hollow fiber type, molecular weight cut-off of 150,000) to filter the water with the above adsorbent, and add (return) a part of the liquid that fails to pass through the ultrafiltration membrane to the raw water with the adsorbent. Make it pass completely under 0.3MPa operating pressure. The permeate at this time was 2.5pg-TEQ / L, which was below the emission standard value (10pg-TEQ / L). As the washing water, the amount of permeate that is four times the amount of the permeate of the ultrafiltration membrane was backwashed for 1 minute, and the backwash was used as a concentrate (slurry).

[0254] (D) Chemical decomposi...

Embodiment 2

[0256] Example 2 (Refer to Figure 7)

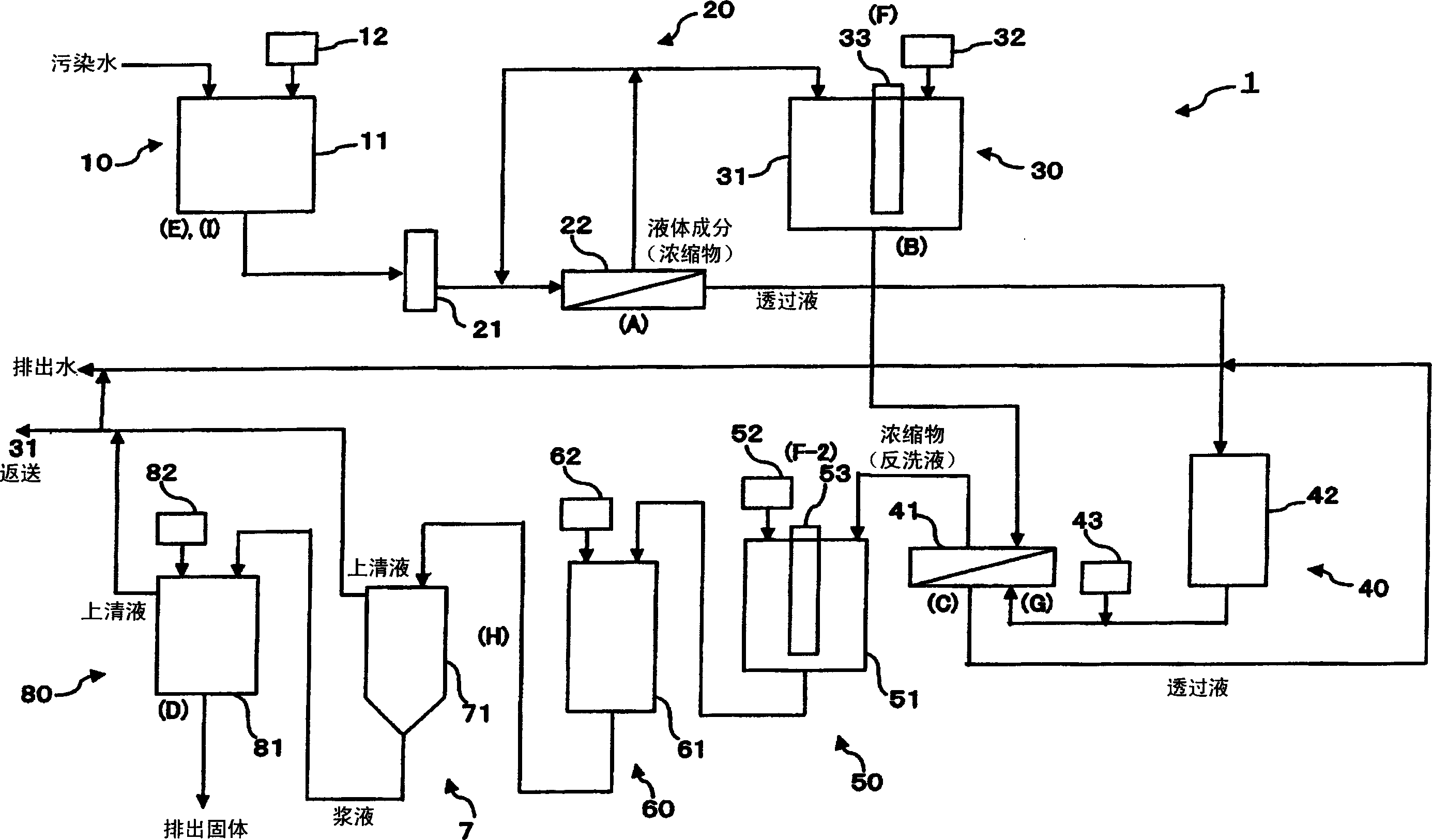

[0257] (A) Membrane concentration treatment process

[0258] The raw water (dioxene concentration 6500pg-TEQ / L) is filtered by reverse osmosis membrane (spiral type, 95% sodium chloride rejection rate). A part of the liquid component (concentrated water) that failed to pass through the reverse osmosis membrane is added (returned) to the raw water, and filtered under an operating pressure of 1 MPa or more. Use 2 / 3 of the processing volume as the permeate. At this time, the concentration of dioxene in the permeate is 1pg-TEQ / L, which is below the emission standard value (10pg-TEQ / L).

[0259] (B) Adsorption treatment process

[0260] The concentrated water of 1 / 3 of the treatment amount obtained in the step (A) was put into an adsorption tank for a residence time of 1 hour in the same manner as in Example 1, 2000 ppm of activated clay was added as an adsorbent, and the mixture was stirred and adsorbed.

[0261] (C) Membrane filtration treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com