Recovery and treatment method for hazardous waste in production of aluminum alkyl

A technology for hazardous waste and production process, applied in chemical instruments and methods, purification/separation of hydrocarbons and hydrocarbons, etc., which can solve the problems of long oxidation time, long contact time between activated carbon and polymer solution, and increased product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] After replacing the 300L reactor with nitrogen, add 100L of waste solvent containing 15% (weight ratio) of alkylaluminum and 10% (weight ratio) of aluminum powder into the reactor, start stirring, and add carbon dioxide to the solvent through the bottom tube In the process, the feeding speed is controlled at 5 liters / minute. Excess carbon dioxide is vented to atmosphere through the exhaust port. When the temperature is lower than 40°C, the system pressure is maintained at normal pressure ~ 0.1MPa. The carbon dioxide flow was stopped and water was added at a controlled rate. At the same time, the reaction temperature is controlled to be 10-60° C., and the pressure in the mixing process is not higher than 0.3 MPa. Fully stir and mix, and the gas generated during the reaction is passed into the torch system. The reacted mixture solution is filtered, and the separated oil-water mixture is collected, left to stand, naturally separated, and the supernatant obtained after d...

Embodiment 2

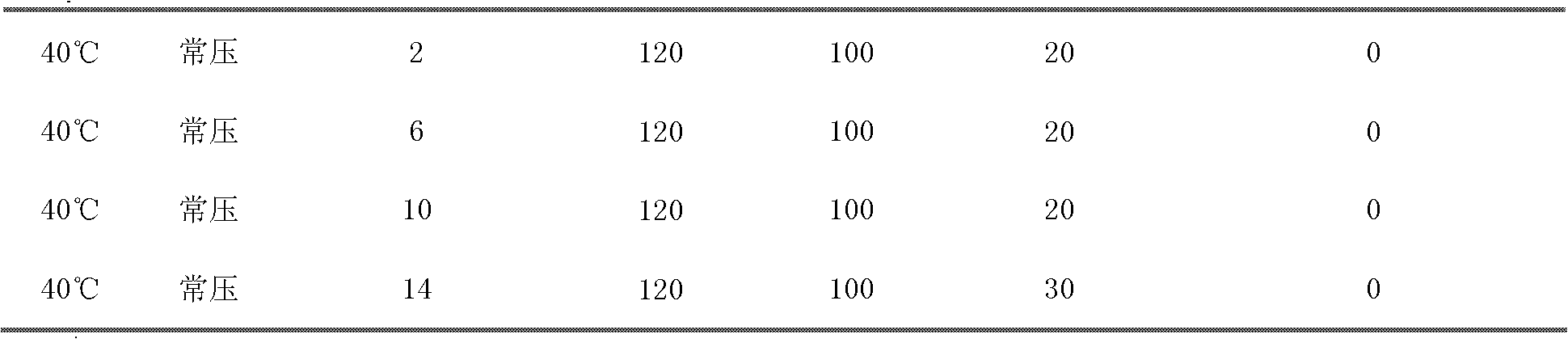

[0017] The processing steps are the same as in Example 1, except that the content of alkylaluminum in the raw material accounts for 2%, 6%, 10%, and 14% of the solvent respectively. The factors that need to be controlled in the reaction are shown in Table 2.

[0018] Table 2 Factors to be controlled in reaction

[0019]

[0020]

Embodiment 3

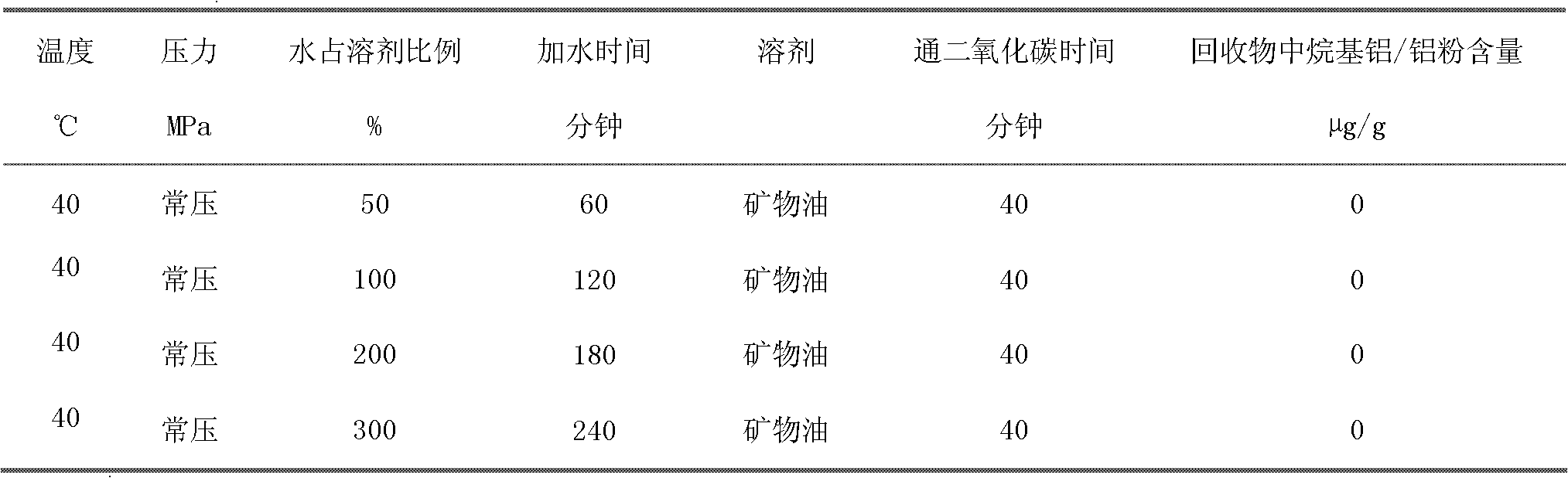

[0022] The processing steps and raw materials are the same as in Example 1, except that the ratios of the amount of water added to the solvent are 50%, 100%, 200%, and 300%, respectively. The factors that need to be controlled in the reaction are shown in Table 3.

[0023] Factors to be controlled in table 3 reaction

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com