Activated carbon desorption reusing device

An activated carbon and desorption technology, applied in filter regeneration, filtration separation, petroleum industry, etc., can solve the problems of poor treatment effect and high treatment cost, achieve safe and effective treatment, improve desorption efficiency, reduce manufacturing costs and The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

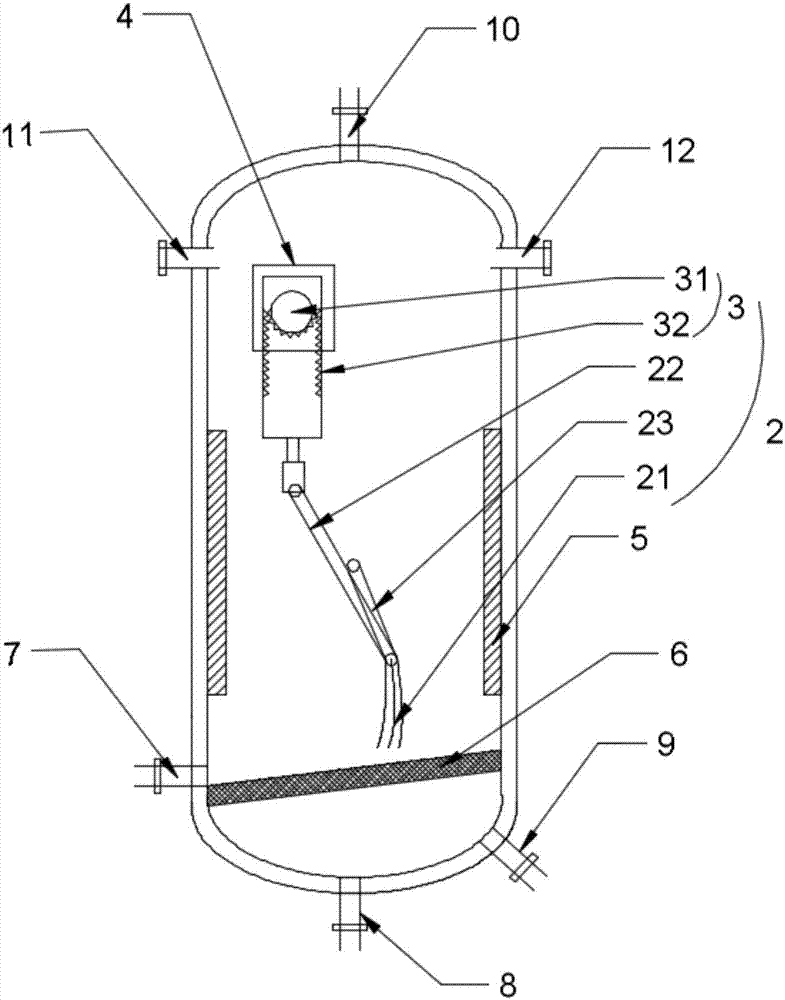

[0027] An activated carbon desorption and reuse device, comprising a tank body 1 and a stirring device 2 fixed inside the tank body 1, the stirring device 2 includes a stirring grip 21, a connecting rod structure 3 driving the stirring grip 21, and a driving connecting rod structure 3 The rotating motor, the stirring device 2 is vertically arranged inside the tank body 1, the microwave generator assembly 5 is fixed on the inner wall of the tank body 1, and an inclined vibrating screen 6 is arranged below the stirring grab 21, and the tank body 1 is provided with a gas outlet 10, and the lower part of the tank body 1 is provided with an activated carbon outlet 7 and a sewage outlet 8. The activated carbon outlet 7 is located at the lower side of the inclined vibrating screen 6 .

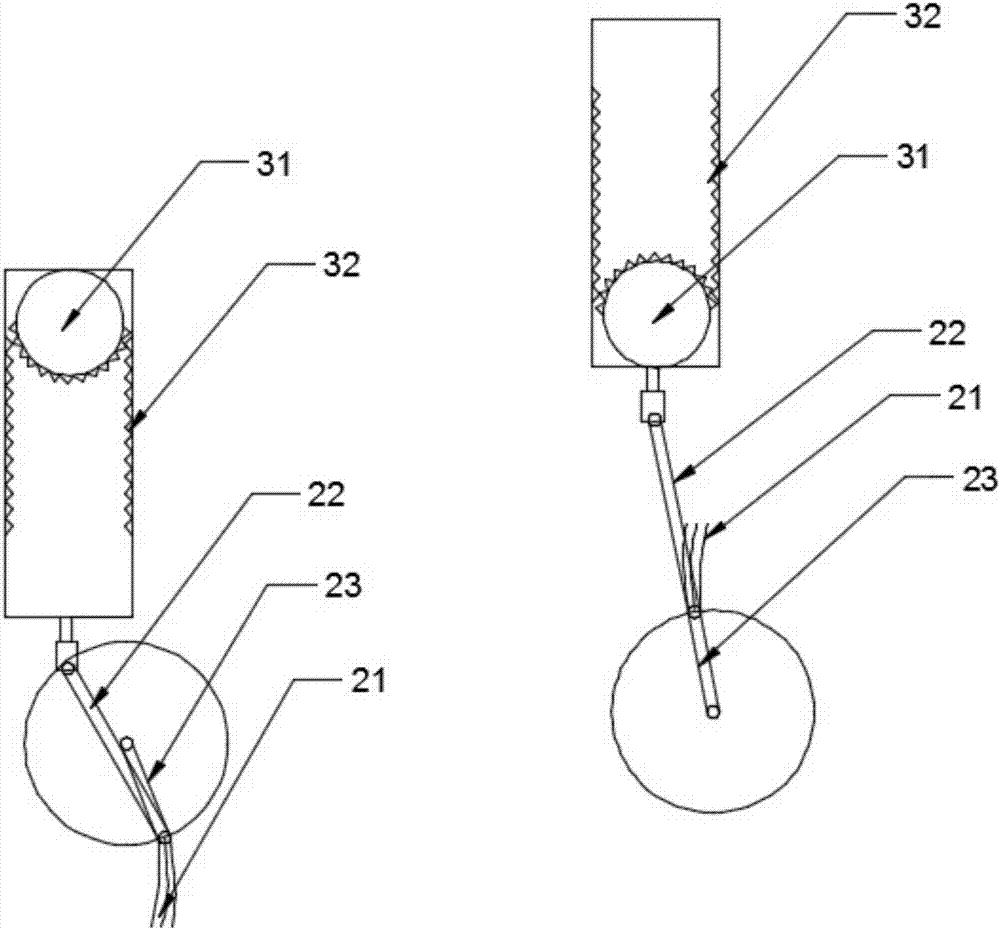

[0028] The connecting rod structure 3 includes an incomplete gear shaft 31, a toothed metal frame 32 sleeved outside the incomplete gear shaft 31 and used in conjunction with the incomplete gear shaft...

Embodiment 2

[0036] An activated carbon desorption and reuse device, comprising a tank body 1 and a stirring device 2 fixed inside the tank body 1, the stirring device 2 includes a stirring grip 21, a connecting rod structure 3 driving the stirring grip 21, and a driving connecting rod structure 3 The rotating motor, the stirring device 2 is vertically arranged inside the tank body 1, the microwave generator assembly 5 is fixed on the inner wall of the tank body 1, and an inclined vibrating screen 6 is arranged below the stirring grab 21, and the tank body 1 is provided with a gas outlet 10, and the lower part of the tank body 1 is provided with an activated carbon outlet 7, a sewage outlet 8 and a steam inlet 9.

[0037] The connecting rod structure 3 includes an incomplete gear shaft 31, a toothed metal frame 32 sleeved outside the incomplete gear shaft 31 and used in conjunction with the incomplete gear shaft 31, and a long connecting rod hingedly connected to the lower end of the toothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com