Method for treating inert aluminum ash in aluminum ash treatment technology

A treatment process, aluminum ash technology, applied in chemical instruments and methods, preparation of alkali metal aluminate/aluminum oxide/aluminum hydroxide, aluminum compounds, etc., can solve the problems of a large amount of solid waste and less than effective treatment, and achieve The effect of improving efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

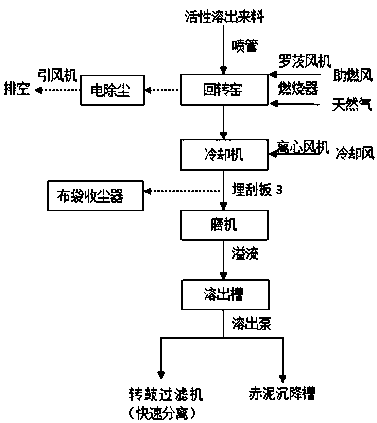

[0045] This embodiment provides a method for inert aluminum ash treatment in the aluminum ash treatment process, such as figure 1 As shown, the mixture of aluminum ash and raw slurry, that is, the mixture of inert aluminum ash, carbonate, oxalate, caustic alkali, and milk of lime, is fired in turn through a rotary kiln, cooled by a cooler, and finally cooked in a ball mill. Material dissolution.

Embodiment 2

[0047] On the basis of Example 1, this embodiment is further limited: the temperature in the rotary kiln is 900-1000° C., and the sintering time is 30 minutes.

Embodiment 3

[0049] On the basis of Example 1, this embodiment further defines: after the aluminum ash and water are made into a slurry of 0.8-1.1Kg / L, the raw meal with a moisture content of 37-41% and an alkali ratio of 0.95-1.05 The slurry is evenly mixed and fired in a rotary kiln, wherein the mass ratio of aluminum ash to raw slurry is 1:0.47-1:0.49.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com