Surface treatment method for improving performance of piezoelectric ceramic

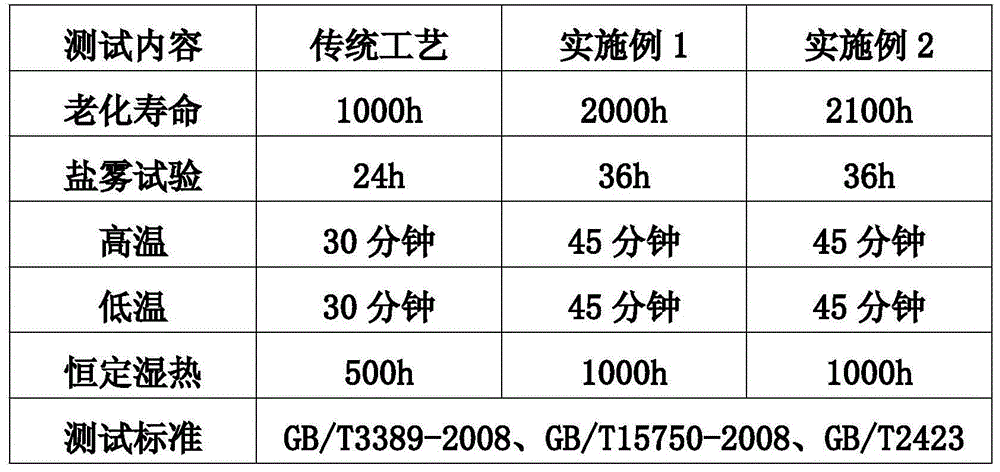

A piezoelectric ceramic and surface treatment technology, applied in the field of surface treatment to improve the performance of piezoelectric ceramics, can solve the problems of high and low temperature resistance and moisture resistance, salt spray corrosion resistance on the surface of piezoelectric ceramics, affecting the service life of piezoelectric ceramic components, etc. , to achieve the effect of improving resistance to salt spray corrosion and prolonging aging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: improve the surface treatment method of piezoelectric ceramic performance, comprise the steps:

[0029] ①Providing a piezoelectric ceramic body;

[0030] ② Prepare Ca(OH) with a concentration of 0.1g / L respectively 2 solution, a boric acid solution with a concentration of 0.2g / L and a calcium dihydrogen phosphate solution with a concentration of 1g / L, the boric acid solution and the calcium dihydrogen phosphate solution are mixed in a weight ratio of 1:1 to obtain boric acid and dihydrogen phosphate Calcium mixed solution, spare;

[0031] ③Immerse the piezoelectric ceramic body in Ca(OH) 2 In the solution for 5 seconds, product A is obtained;

[0032] ④Take out product A, heat and dry at 100°C for 30 minutes to obtain product B;

[0033] ⑤Soak product B in the mixed solution of boric acid and calcium dihydrogen phosphate for 5 seconds to obtain product C;

[0034] ⑥Take out product C, firstly dry it at 100°C for 30 minutes, and then keep it at 700-750...

Embodiment 2

[0035] Embodiment 2: improve the surface treatment method of piezoelectric ceramic performance, comprise the steps:

[0036] ①Providing a piezoelectric ceramic body;

[0037] ② Prepare Ca(OH) with a concentration of 0.15g / L respectively 2 solution, a boric acid solution with a concentration of 1g / L and a calcium dihydrogen phosphate solution with a concentration of 0.2g / L, the boric acid solution and the calcium dihydrogen phosphate solution are mixed in a weight ratio of 1:1 to obtain boric acid and dihydrogen phosphate Calcium mixed solution, spare;

[0038] ③Immerse the piezoelectric ceramic body in Ca(OH) 2 In the solution for 5 minutes, product A was obtained;

[0039] ④Take out product A, heat and dry at 150°C for 8 minutes to obtain product B;

[0040] ⑤ Soak product B in a mixed solution of boric acid and calcium dihydrogen phosphate for 5 minutes to obtain product C;

[0041] ⑥Take out product C, firstly dry it at 150°C for 8 minutes, and then keep it at 950-1000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com