Preparation method for aluminum alloy surface chromium-free corrosion-resistant chemical conversion membrane formation solution and membrane layer

A technology of aluminum alloy surface and chemical conversion coating, applied in the direction of metal material coating process, etc., can solve the problems of high cost, high film forming temperature, unsatisfactory corrosion resistance, etc. The effect of salt spray corrosion performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

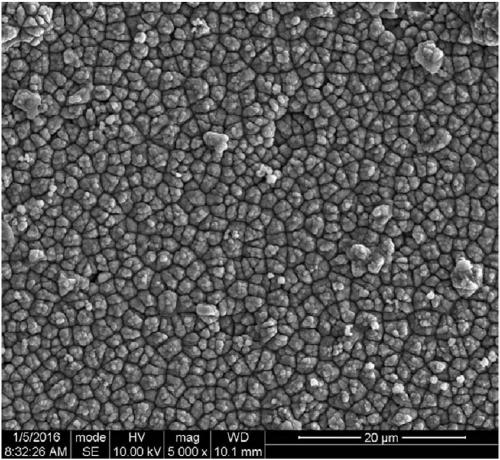

Image

Examples

Embodiment 1

[0036] In this example, the method for preparing a chromium-free corrosion-resistant chemical conversion film on the surface of an aluminum alloy is processed according to the following process flow:

[0037] (1) Grinding

[0038] The surface of the rolled 5083 aluminum alloy was polished with 1000-grit sandpaper, and a hole was punched in the middle of the upper part of the aluminum alloy sample for the convenience of hanging the aluminum alloy sample.

[0039] (2) Degreasing

[0040] The aluminum alloy sample was ultrasonically treated in a degreasing solution for 5 minutes at room temperature, and rinsed with running water for 1 minute after degreasing. Wherein, the composition of the chemical degreasing solution is: 20g / L sodium hydroxide, 20g / L sodium carbonate, 5g / L sodium silicate, and the balance is water.

[0041] (3) Alkaline washing

[0042] Soak the degreased aluminum alloy sample in the alkali cleaning solution for 20 seconds, the temperature of the alkali clea...

Embodiment 2

[0053] In the present embodiment, the preparation method of the chromium-free corrosion-resistant chemical conversion coating on the aluminum alloy surface is processed according to the following process flow:

[0054] (1) Grinding

[0055] The surface of the rolled 6061 aluminum alloy was polished with 1000-grit sandpaper. In order to facilitate the suspension of the aluminum alloy sample, a hole was punched in the upper middle of the aluminum alloy sample.

[0056] (2) Degreasing

[0057] The aluminum alloy samples were ultrasonically treated in degreasing solution for 3 min at room temperature, and rinsed with running water for 1.5 min after degreasing. Wherein, the composition of the chemical degreasing solution is: 10g / L potassium hydroxide, 20g / L potassium carbonate, 3g / L sodium silicate, and the balance is water.

[0058] (3) Alkaline washing

[0059] The aluminum alloy samples after degreasing were immersed in the alkaline washing solution for 30 seconds, the temper...

Embodiment 3

[0067] In the present embodiment, the preparation method of the chromium-free corrosion-resistant chemical conversion coating on the aluminum alloy surface is processed according to the following process flow:

[0068] (1) Grinding

[0069] The surface of the rolled 2024 aluminum alloy was polished with 1000-grit sandpaper. In order to facilitate the suspension of the aluminum alloy sample, a hole was punched in the upper middle of the aluminum alloy sample.

[0070] (2) Degreasing

[0071] The aluminum alloy samples were ultrasonically treated in degreasing solution for 12 minutes at room temperature, and rinsed with running water for 2 minutes after degreasing. Wherein, the composition of the chemical degreasing solution is: 20g / L sodium carbonate, 10g / L sodium phosphate, 5g / L sodium silicate, 3g / L sodium dodecylbenzenesulfonate, and the balance is water.

[0072] (3) Alkaline washing

[0073] The aluminum alloy samples after degreasing were immersed in the alkaline washi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com