Epoxy resin emulsion and application thereof in water-based paint

A water-based epoxy resin and emulsion technology, applied in the field of coatings, can solve the problems of affecting the service life of coatings and poor weather resistance, and achieve the effect of improving salt spray corrosion resistance and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the second described aqueous epoxy resin emulsion, comprises the steps:

[0035]Step 1, preparation of polyether polyol: add glycerin and KOH into the reaction kettle, replace with nitrogen, then vacuum dehydrate, then add propylene oxide, heat for reaction, after the reaction, add diatomaceous earth for neutralization , and then perform suction filtration, and the filtrate is distilled under reduced pressure to remove water and low boiling point substances to obtain polyether polyol; wherein, the molar ratio of glycerin, propylene oxide and KOH is 1:35-50:0.2-0.3;

[0036]

[0037] Step 2, hydroxyl substitution reaction: in parts by weight, mix 20-25 parts of polyether polyol, 0.1-0.2 parts of sodium hydride, and 400-500 parts of N, N-dimethylformamide, and carry out at room temperature Reaction, after the reaction is finished, filter, and in the filtrate, it is a polyether polyol substituted by Na;

[0038]

[0039] The third step, the...

Embodiment 1

[0064] The preparation of the second aqueous epoxy resin emulsion that adopts in the coating:

[0065] The first step, the preparation of polyether polyol: add glycerin and KOH into the reaction kettle, replace with nitrogen, then vacuumize and dehydrate, then add propylene oxide, and heat for reaction. The reaction temperature is 105°C, and the reaction time is 5h. After the reaction is over, add diatomaceous earth for neutralization, and then perform suction filtration, and the filtrate is distilled under reduced pressure to remove water and low boiling point substances to obtain polyether polyols; wherein, the molar ratio of glycerin, propylene oxide and KOH is 1:35 : 0.2;

[0066] Step 2, hydroxyl substitution reaction: in parts by weight, mix 20 parts of polyether polyol, 0.1 part of sodium hydride, and 400 parts of N,N-dimethylformamide, and react at 20°C for 0.5h. After the reaction Filter, and in the filtrate, it is polyether polyol substituted by Na;

[0067] The th...

Embodiment 2

[0076] The preparation of the second aqueous epoxy resin emulsion that adopts in the coating:

[0077] The first step, the preparation of polyether polyol: Add glycerin and KOH into the reaction kettle, replace with nitrogen, then vacuumize and dehydrate, then add propylene oxide, and heat for reaction. The reaction temperature is 115°C and the reaction time is 8h. After the reaction is over, add diatomaceous earth for neutralization, and then perform suction filtration, and the filtrate is distilled under reduced pressure to remove water and low boiling point substances to obtain polyether polyols; wherein the molar ratio of glycerin, propylene oxide and KOH is 1:50 : 0.3;

[0078] Step 2, hydroxyl substitution reaction: in parts by weight, mix 25 parts of polyether polyol, 0.2 part of sodium hydride, and 500 parts of N, N-dimethylformamide, and react at 30°C for 1 hour. Filtrate, in the filtrate, be the polyether polyol substituted through Na;

[0079] The third step, the ...

PUM

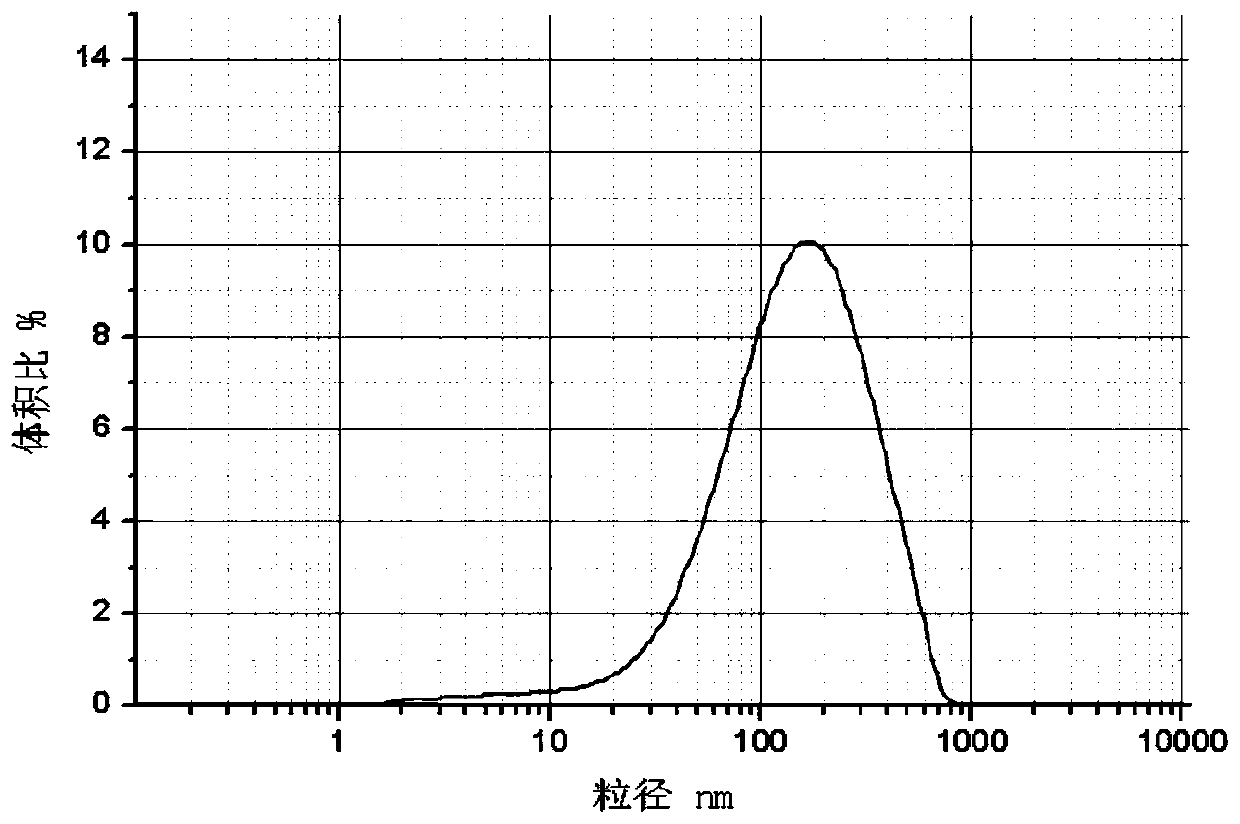

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com