Salt mist-resisting alloy wire and manufacturing process thereof

A production process and alloy wire technology, applied in the field of salt spray-resistant alloy wire and its production process, can solve problems such as metal corrosion, achieve uniform and smooth coating, reduce production cost, and reduce thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

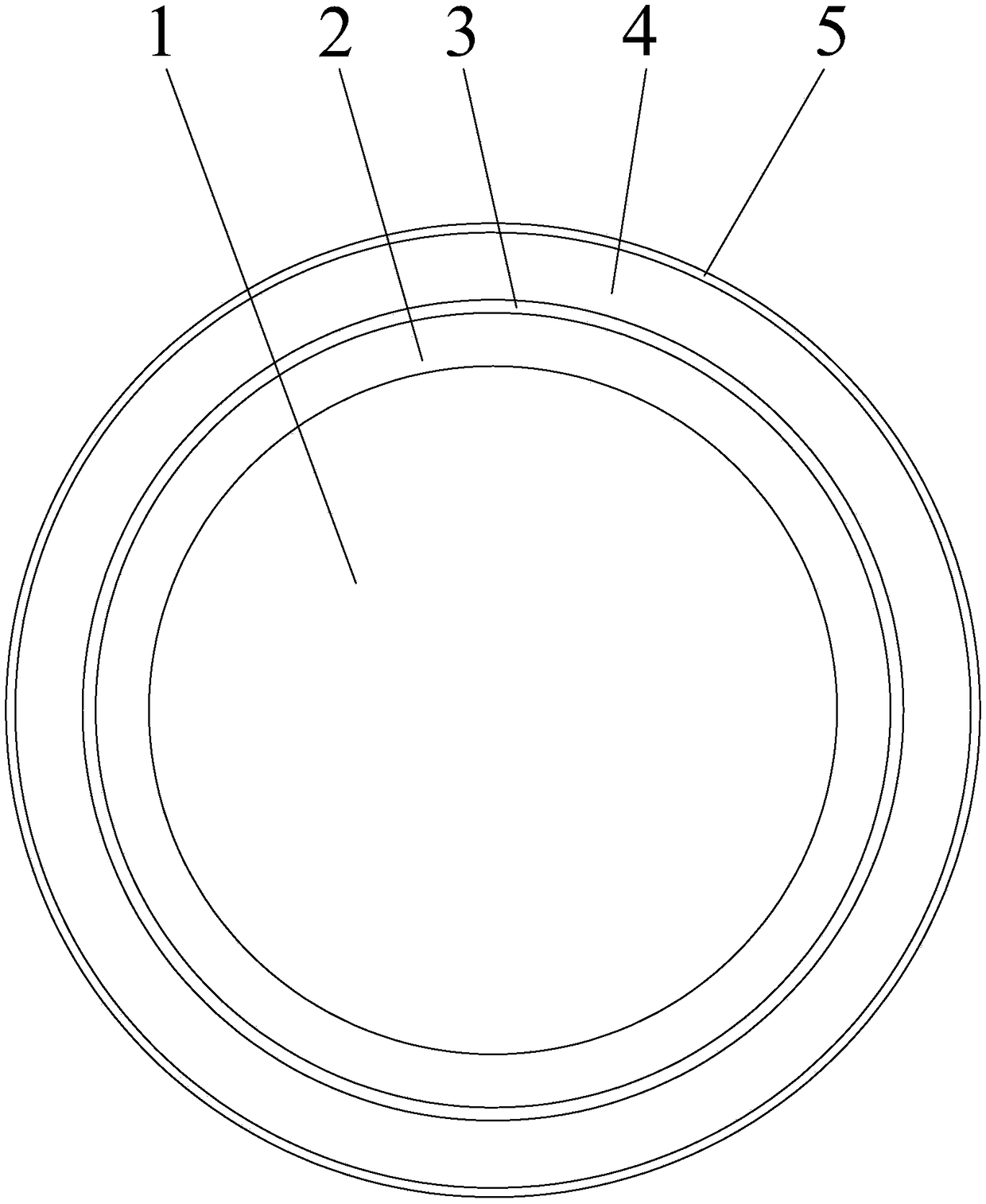

[0038] Such as figure 1 As shown, the present invention provides a salt spray resistant alloy wire, comprising a steel wire conductor 1, the steel wire conductor 1 is made of low carbon steel, and the outside of the steel wire conductor 1 is wrapped with a copper plating layer 2, and the copper plating layer 2 The outside is wrapped with a nickel-plated layer 3, the outside of the nickel-plated layer 3 is wrapped with a tin-plated layer 4, the thickness of the tin-plated layer 4 is greater than the thickness of the nickel-plated layer 3, and the outside of the tin-plated layer 4 is wrapped A polishing film 5 is provided.

[0039] Among them, the preferred thickness of the copper plating layer is 6-8 μm, the thickness of the nickel plating layer is 2-3 μm, and the thickness of the tin plating layer is 4-6 μm.

[0040] Preferably, the copper plating layer has a thickness of 6 μm, the nickel plating layer has a thickness of 2 μm, and the tin plating layer has a thickness of 5 μm...

Embodiment 2

[0044] Based on Example 1, it is used to prepare the salt spray resistant alloy wire in Example 1, and its manufacturing process is:

[0045] Step 1, material selection, choose low-carbon steel wire as the substrate, clean the surface of the low-carbon steel wire, including deoxidation, deburring and stain cleaning, and then perform online continuous softening and annealing, and draw and straighten through the wire drawing machine. The surface cleaning treatment is to avoid affecting the subsequent process;

[0046] Step 2, quenching and tempering, the low-carbon steel wire is heated by an induction heating device, the heating temperature is 820 ° C ~ 850 ° C, the heating time is 8s ~ 12s, the cooling is completed through the cooling oil pool, and the subsequent cleaning is completed through the ultrasonic cleaning pool. Then complete the tempering treatment through the tempering furnace to improve the hardness and performance of the stainless steel wire, transform its interna...

Embodiment 3

[0066] Based on Example 1, it is used to prepare the salt spray resistant alloy wire in Example 1, and its manufacturing process is:

[0067] Step 1, material selection, choose low-carbon steel wire as the substrate, clean the surface of the low-carbon steel wire, including deoxidation, deburring and stain cleaning, and then perform online continuous softening and annealing, and draw and straighten through the wire drawing machine. The surface cleaning treatment is to avoid affecting the subsequent process;

[0068] Step 2, quenching and tempering, the low-carbon steel wire is heated by an induction heating device, the heating temperature is 830°C, the heating time is 10s, the cooling is completed through the cooling oil pool, the subsequent cleaning is completed through the ultrasonic cleaning pool, and then the tempering furnace is completed Tempering treatment improves the hardness and performance of stainless steel wire, transforms its internal structure into tempered low-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com