Semiconductor thermal expansion glass mat and production method thereof

A production method and glass mat technology, which are applied in the laying of solid insulation and the shape/style/structure of winding insulation, etc., can solve the problems of poor motor operation reliability, dust pollution of the environment, movement of gaskets, etc., to extend the life of the motor, The effect of prolonging the aging life and enhancing the heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

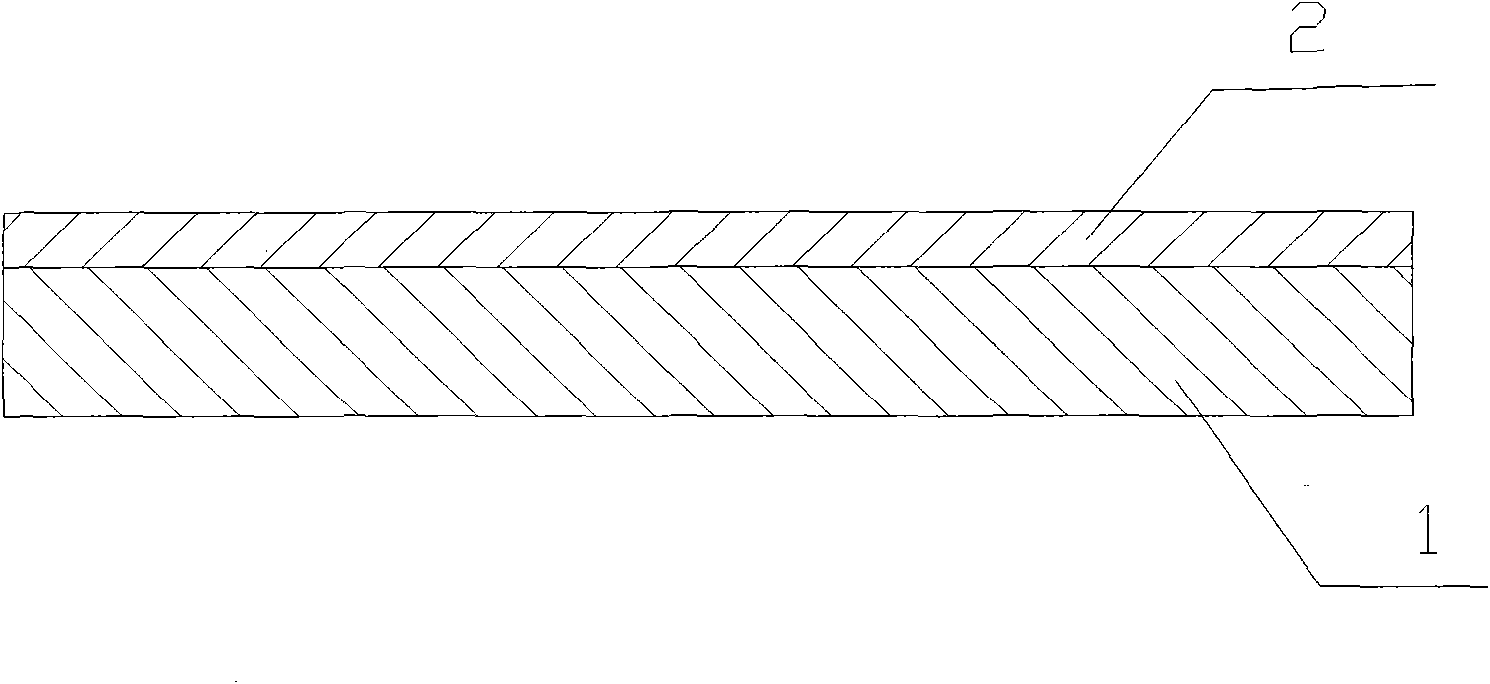

[0015] The semiconductor heat-expandable glass mat in this embodiment comprises a heat-expandable glass mat 1 and a semiconductor low-resistance cloth 2, and the semiconductor low-resistance cloth 2 is thermocompressed on one side of the heat-expandable glass mat 1, and the thickness of the heat-expandable glass mat 1 is 3mm, and the semiconductor The low-resistance cloth 2 has a thickness of 0.2±0.02mm and a surface resistance of 200Ω. Semiconductor thermal expansion glass mat density is 1.4-1.5g / cm 3 , the adhesive content is 5% to 11% (weight percentage), 80 ℃, 30min, the thermal expansion rate is greater than or equal to 50% in the thickness direction, 130 ℃, 30min, the thermal expansion rate is greater than or equal to 100% in the thickness direction, the surface before dipping Resistance 10 3 -10 6 Ω, the surface resistance after dipping paint is greater than or equal to 10 12 Ω.

Embodiment 2

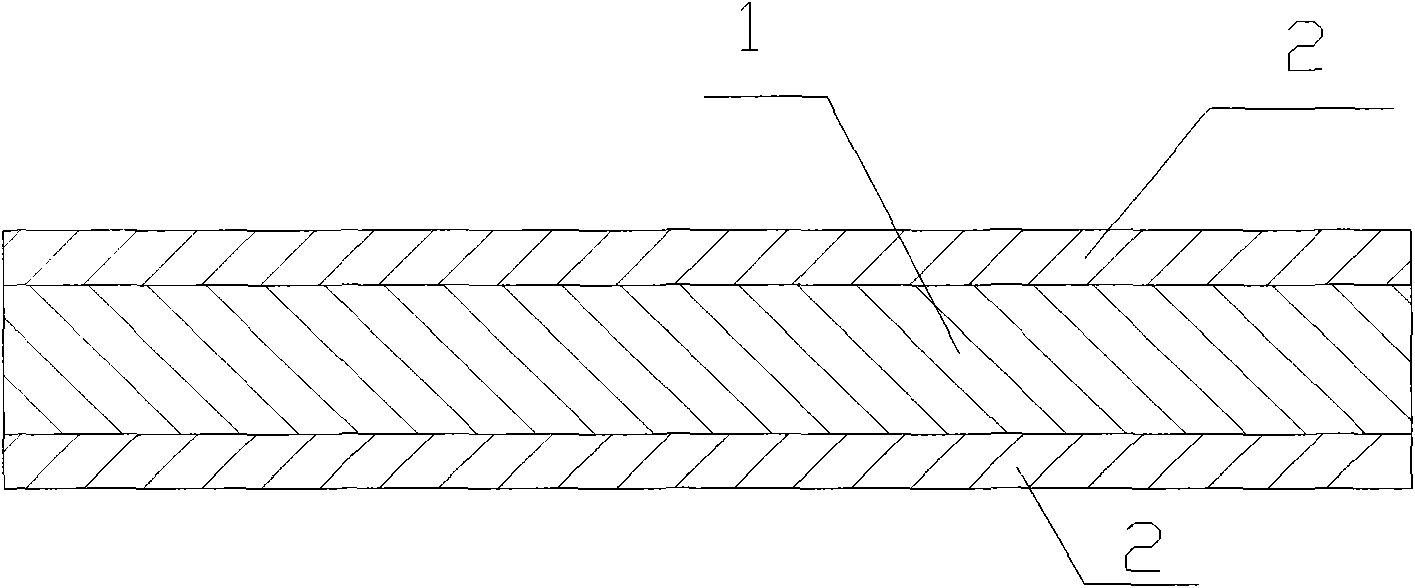

[0017] The semiconductor heat-expandable glass mat in this embodiment comprises a heat-expandable glass mat 1 and a semiconductor low-resistance cloth 2, and the semiconductor low-resistance cloth 2 is hot-compressed and compounded on both sides of the heat-expandable glass mat 1, and the thickness of the heat-expandable glass mat 1 is 1mm. The low-resistance cloth 2 has a thickness of 0.2±0.02mm and a surface resistivity of 1500Ω. Semiconductor thermal expansion glass mat density is 1.4-1.5g / cm 3 , the adhesive content is 5% to 11% (weight percentage), 80 ℃, 30min, the thermal expansion rate is greater than or equal to 50% in the thickness direction, 130 ℃, 30min, the thermal expansion rate is greater than or equal to 100% in the thickness direction, the surface before dipping Resistance 10 3 -10 6 Ω, the surface resistance after dipping paint is greater than or equal to 10 12 Ω.

[0018] The conventional thickness of the heat-expandable glass felt of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com