VPI stator wire bar

A stator bar and magnet wire technology, applied in the direction of winding insulation materials, winding insulation shape/style/structure, manufacturing motor generators, etc., can solve the problems of high cost, overall thickness, multiple layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further explain below in conjunction with accompanying drawing:

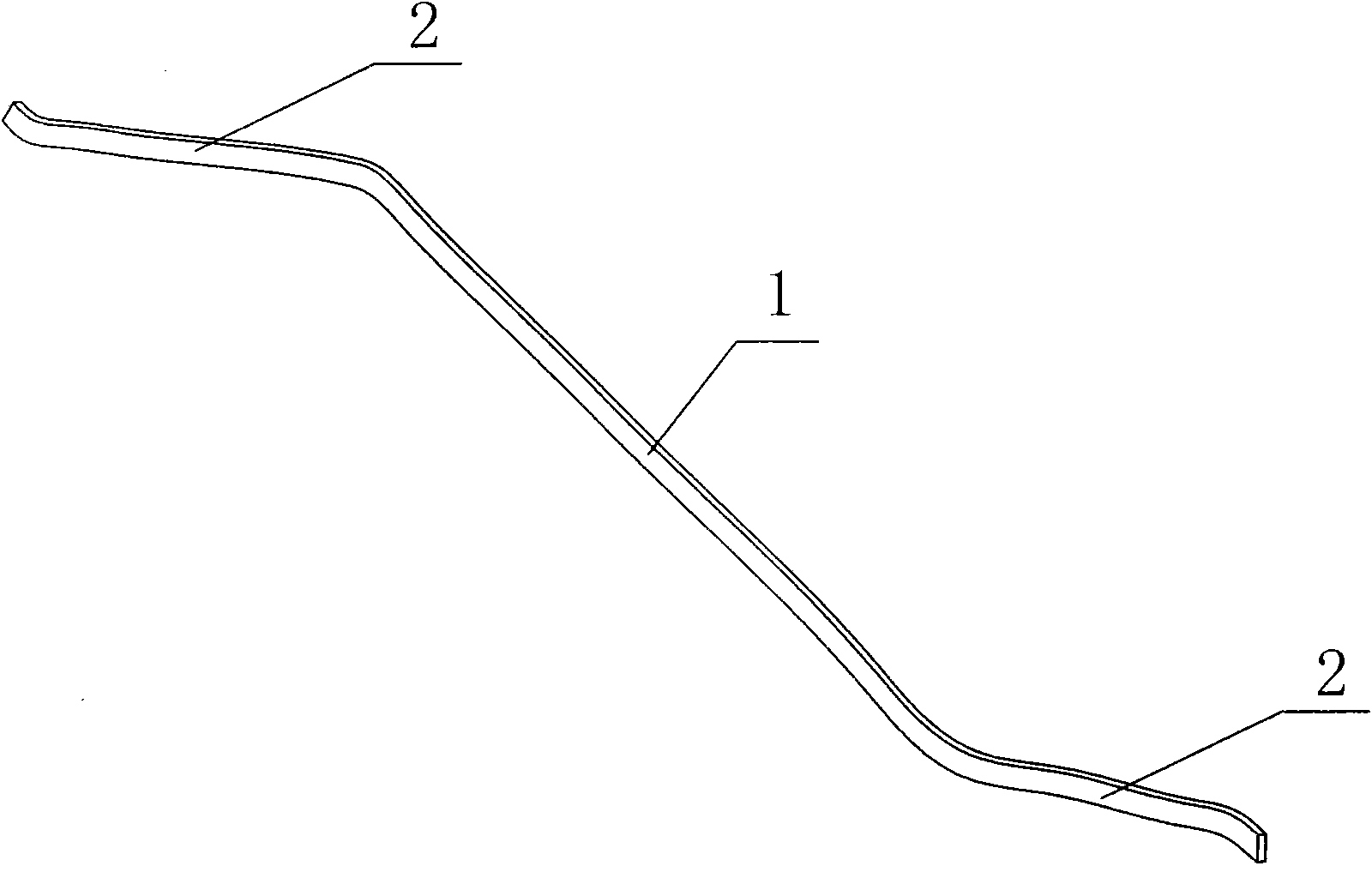

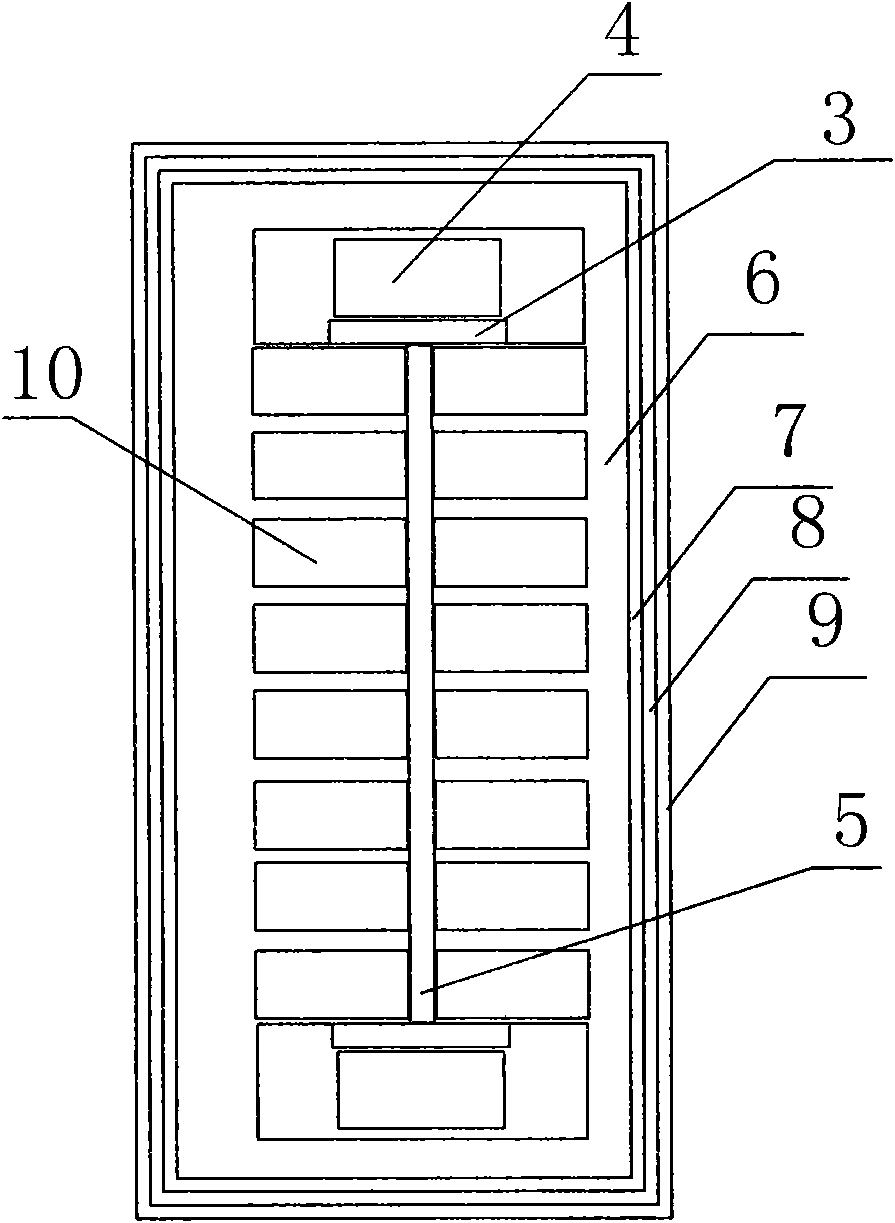

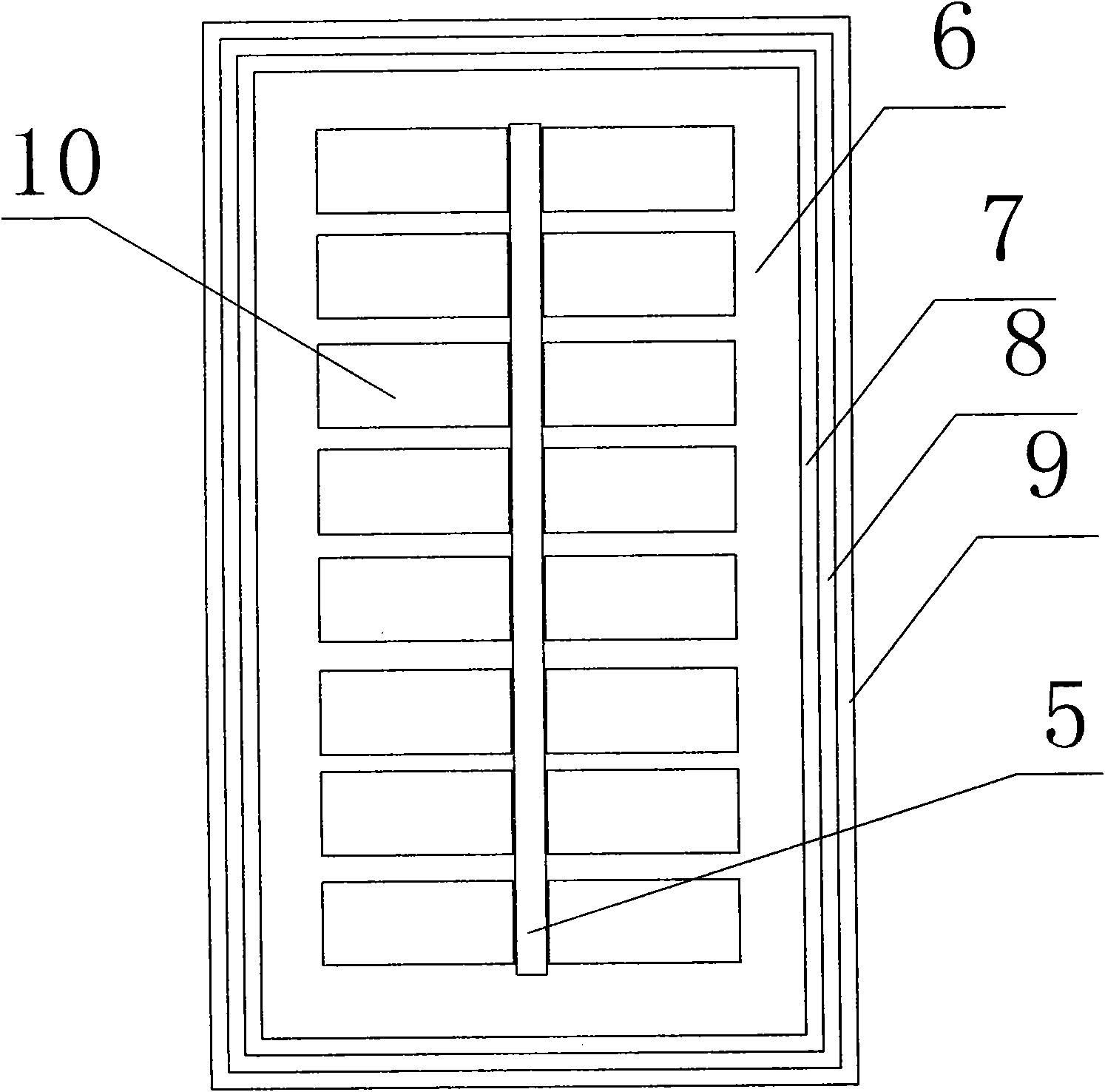

[0012] Such as Figure 1~3 As shown, a VPI stator bar is composed of a straight part 1 and two ends 2. The straight part includes a wire plate, a transposition gasket 3, a transposition filling 4, an inter-row insulation 5, and an inner equalizing layer 6. Ground insulation 7. Anti-corona treatment 8. Additional insulation 9. Magnet wire 10. Inter-row insulation 5 covers the lead plate. Transposition gasket 3 is installed on both sides of the row insulation 5. Magnet wire 10 covers the row. Insulation 5 and transposition spacer 3, transposition filling 4 are fixed on both sides, internal pressure equalization layer 6, ground insulation 7, anti-corona treatment 8, additional insulation 9 cover the above structure in sequence, and the ends include conductive plates , row-to-row insulation 5, inner equalizing layer 6, ground-to-ground insulation 7, anti-corona treatment 8, additional insulation 9, magnet wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com