A clean and continuous process for reducing metal magnesium

A metal magnesium and process technology, applied in the field of non-ferrous light metal metallurgy, can solve problems such as complex processes and multiple equipment, and achieve the effects of strong controllability, low labor productivity, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

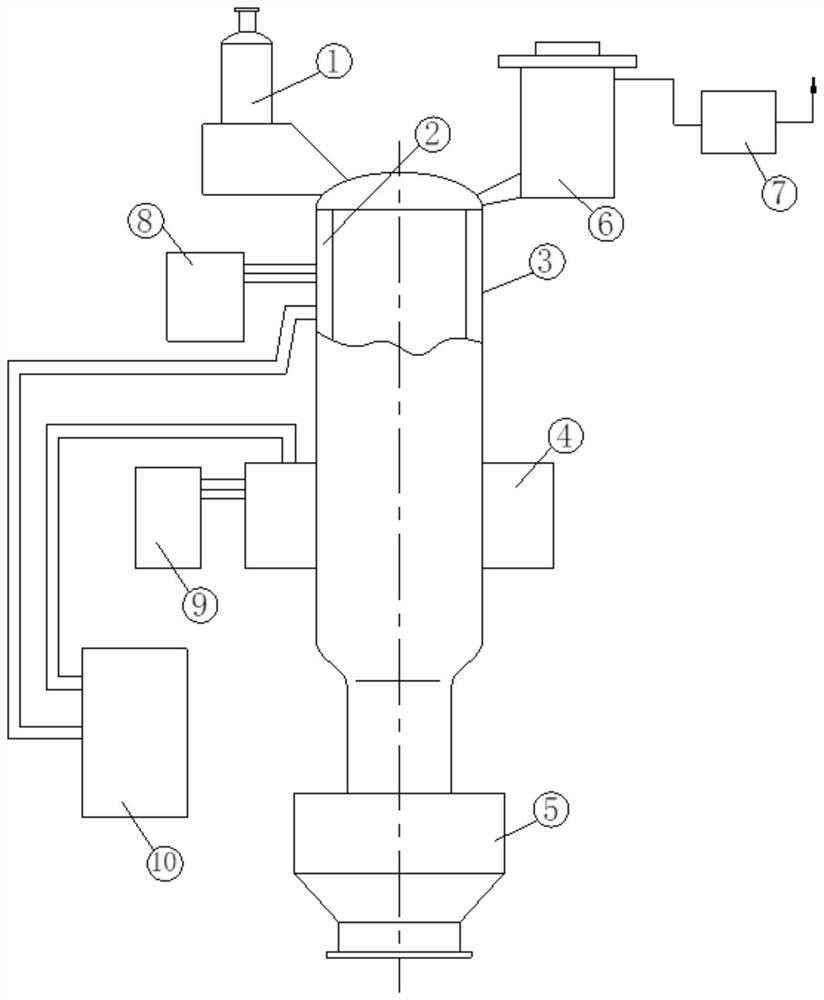

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in combination with specific embodiments.

[0029] A clean, continuous process for reducing metal magnesium is carried out in the following process steps. First, magnesium oxide and aluminum powder are ground and mixed uniformly, wherein the weight ratio of magnesium oxide and reducing agent aluminum powder is MgO:Al=2.7~3.1:1, The change of the proportion of ingredients has little effect on the quality and reduction rate of magnesium (the quality and reduction rate of magnesium are determined by the process temperature and time), but it has a greater impact on magnesium aluminum spinel. When MgO:Al= When the ratio is 2.7:1, high-quality magnesium-aluminum spinel products with a magnesium-aluminum spinel content of more than 90% can be obtained; when the ratio of MgO:Al=3.1:1, a magnesium-aluminum spinel content of more than 75% can be obtained The magnesium-rich magnesium-aluminum spinel product; then the mixed ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com