Automatic cleaning line of button cell

An automatic cleaning, button battery technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, cleaning methods and utensils, etc., can solve problems such as low efficiency and poor cleaning quality, and achieve high accuracy, flexibility, equipment Full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

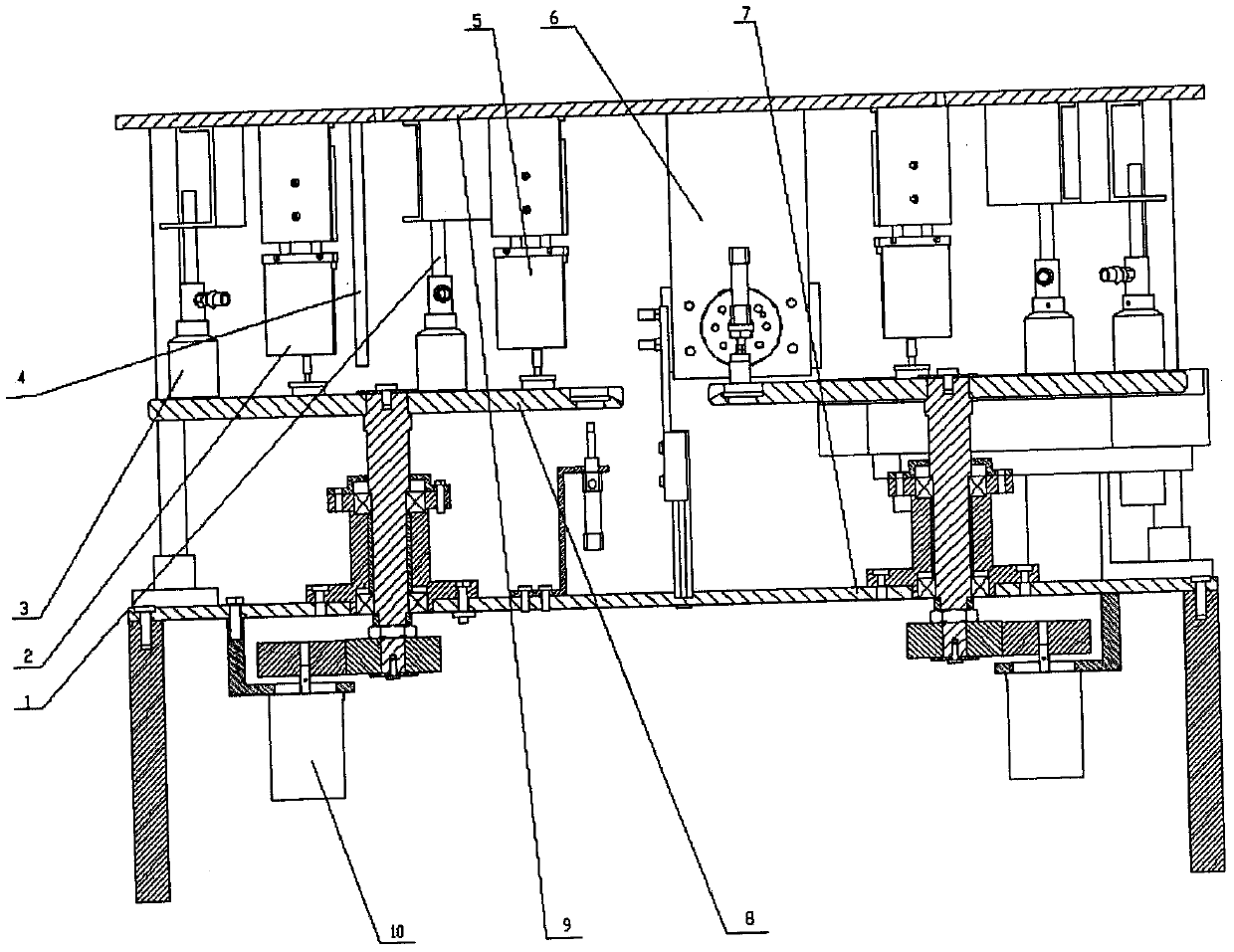

[0009] Such as figure 1 As shown, a button battery automatic cleaning line includes a frame assembly, a cleaning liquid spraying mechanism (1), a scrubbing mechanism (2), a water spraying mechanism (3), an air jet drying mechanism (4), a grinding and polishing mechanism ( 5), turning mechanism (6), pneumatic control system and electric control system and control program; Described rack assembly comprises big workbench (7) and the turntable (8) that is fastened on the upper surface of big workbench, the turntable The upper part is equipped with a small workbench (9), and the upper part of the lower bottom plate of the large workbench is equipped with a control cabinet; the spray cleaning liquid mechanism (1), the scrubbing mechanism (2), the water spray mechanism (3), and the air jet drying mechanism (4), grinding and polishing mechanism (5), turning mechanism (6) are all installed on the described small workbench (9); The described spray cleaning liquid mechanism (1) is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com