Flexible automatic robotic catheter and seat ring assembly equipment

A technology for assembling equipment and robots, applied in metal processing equipment, assembling machines, manufacturing tools, etc., can solve the problems of high process complexity, high production cost, long working hours, etc., to save money, simplify processing, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

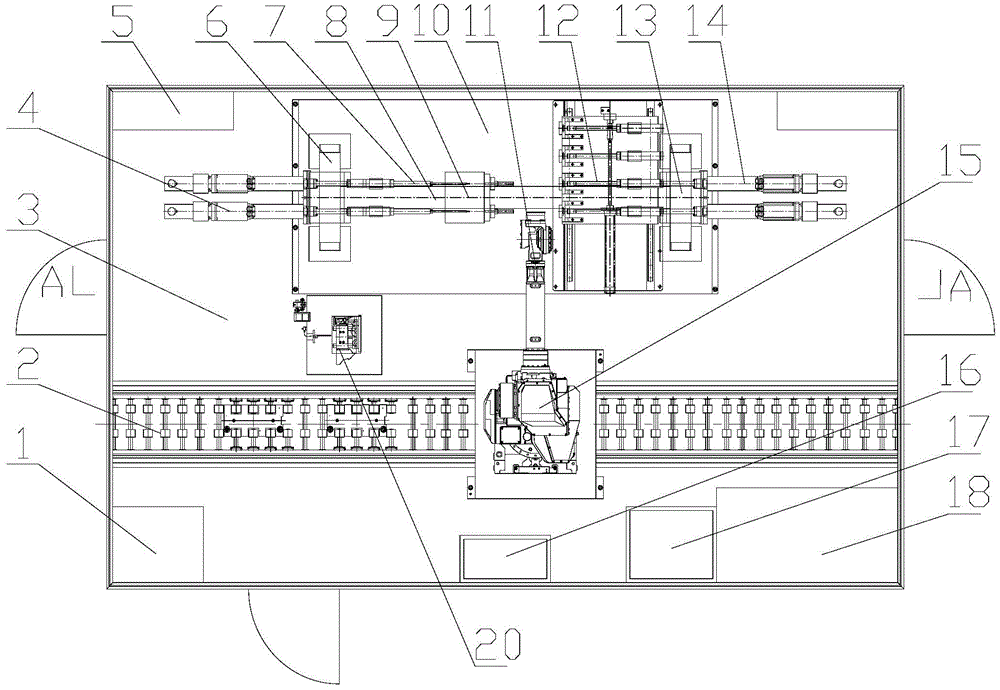

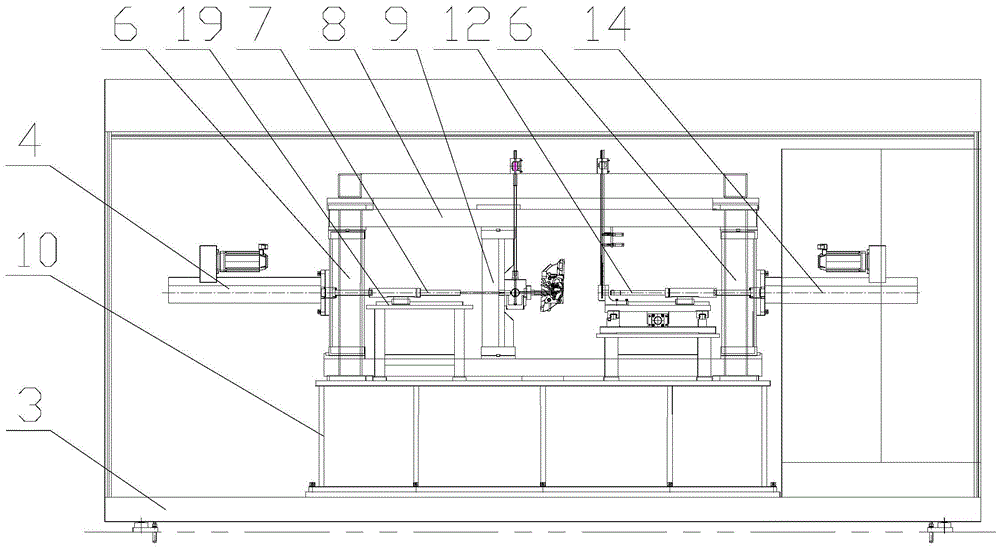

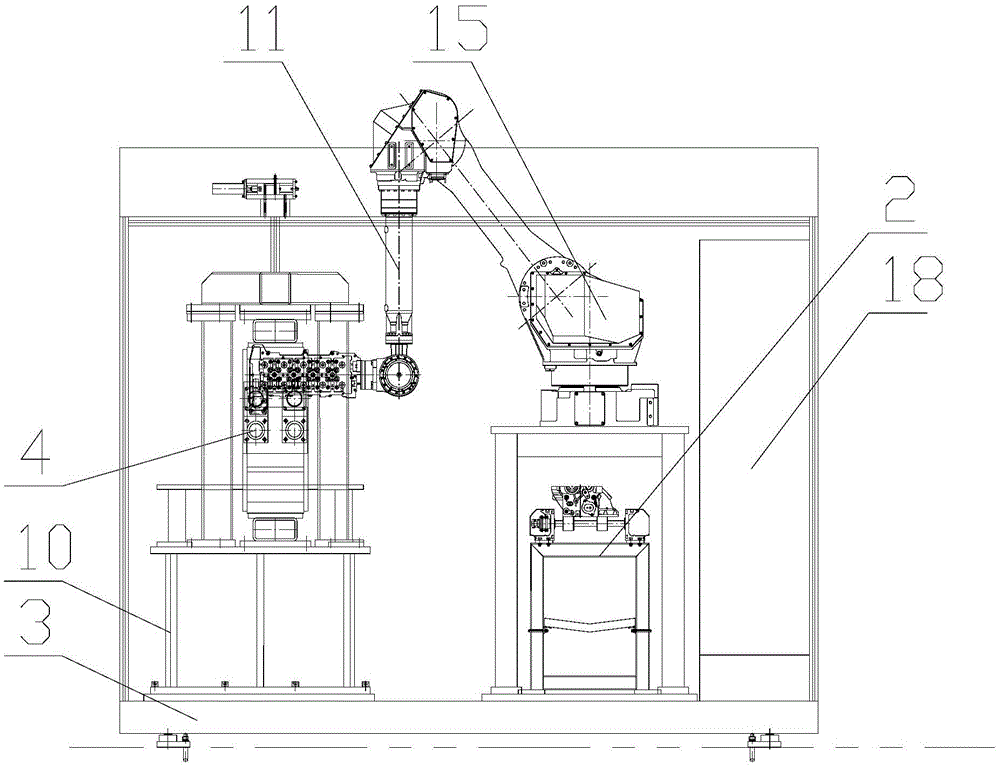

[0030] The specific embodiment of the present invention is as shown in the accompanying drawings, flexible automatic robot catheter, seat ring assembly equipment, including machine tool chassis 3, bed frame 10, automatic logistics roller table 2 and assembly robot 15; Bed frame 10 is contained in machine tool chassis 3, an automatic logistics roller table 2 and an assembly robot 15 are installed next to it; it is characterized in that the upper part of the bed frame 10 is equipped with an internal force closed frame bed; There are conduit pressure head assembly device and seat ring pressure head assembly device; the conduit pressure head assembly device and seat ring pressure head assembly device are connected to the external automatic feeding device through the catheter directional material distribution device and the seat ring directional material distribution device;

[0031] The internal force closed frame bed includes installation support plate I6, installation support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com