U-shaped capacitive liquid level meter

A technology of capacitive and liquid level gauges, which is applied in the direction of liquid level indicators for physical variable measurement, etc., can solve the problems of not working properly, large changes in dielectric coefficient, non-sticky insulating coating, etc., and achieve excellent electrical performance , Measuring stable, non-toxic, physiologically inert effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

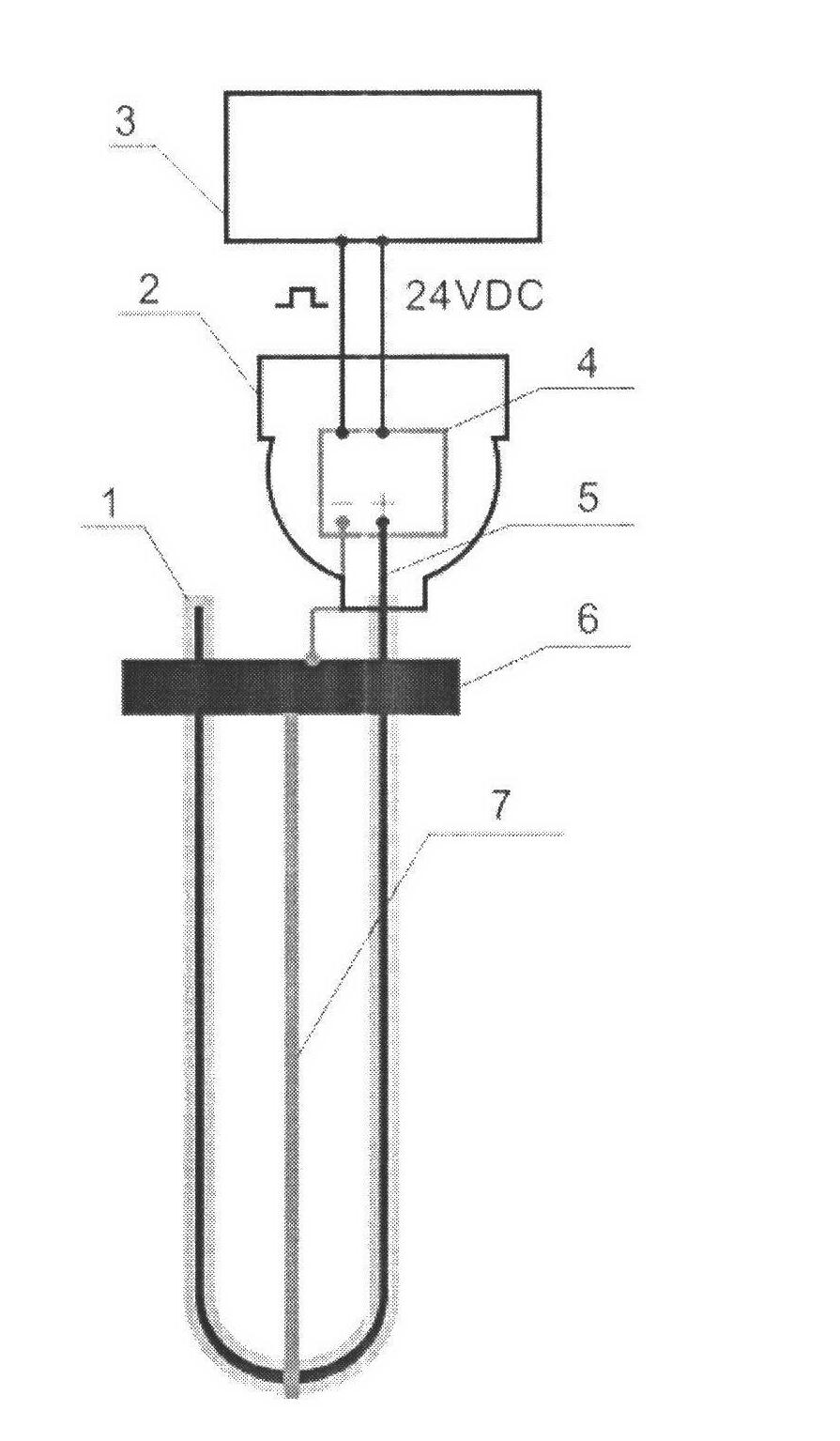

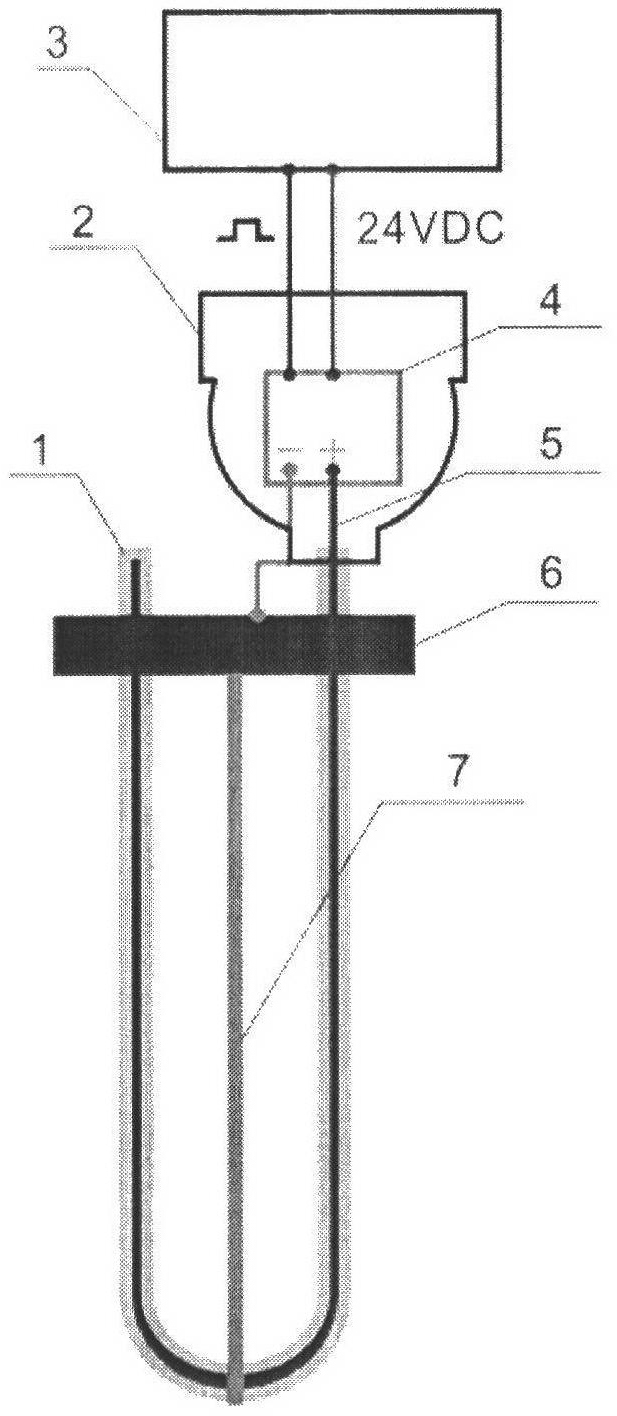

[0020] 1. Structural composition of a U-shaped capacitive liquid level gauge

[0021] The inner electrode 5 and the electrode insulating outer sleeve 1 have a U-shaped structure, the inner electrode 5 is inserted into the electrode insulating outer sleeve 1, the electrode insulating outer sleeve 1 is made of polytetrafluoroethylene material, the inner electrode 5 and the outer electrode 7 are made of stainless steel, When the present invention is applied, both ends of the inner electrode 5 are outside the container for measuring materials.

[0022] 2. Working principle of a U-shaped capacitive liquid level gauge

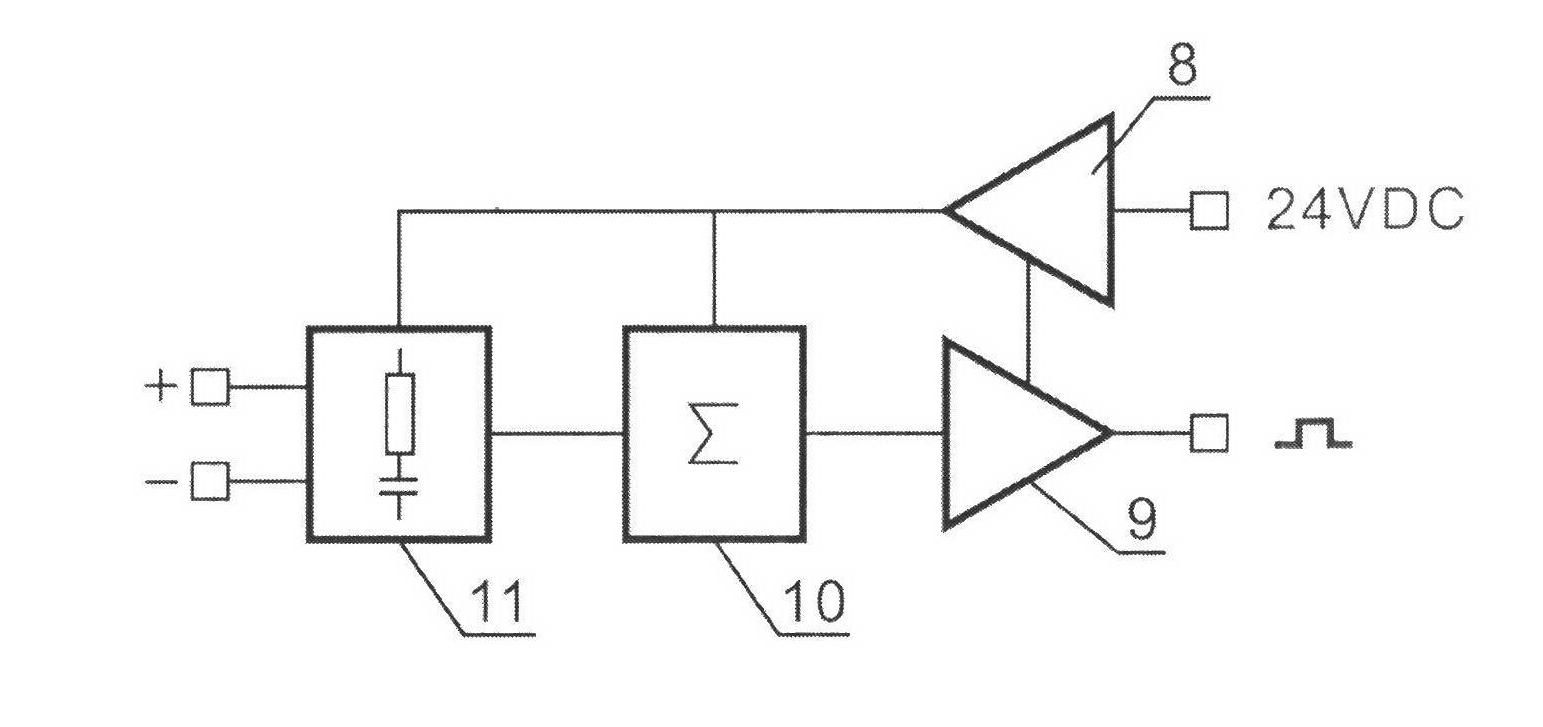

[0023] The inner electrode 5 with an insulating jacket is used as the positive pole of the capacitor, and the outer electrode 7, the metal tank shell of the container for measuring the material and the material are used as the negative pole, and the two together form a capacitor. As the liquid level of the material changes and the relative area of the capacitance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com