Plate Fixed Heating Unit Device

A heating unit and board technology, applied in heating methods, lighting and heating equipment, household heating, etc., can solve the problems of easy deformation, large gap between boards, no heating, heat preservation and moisture resistance, etc., and achieve fast heating speed, uniform heating, The effect of large specific heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

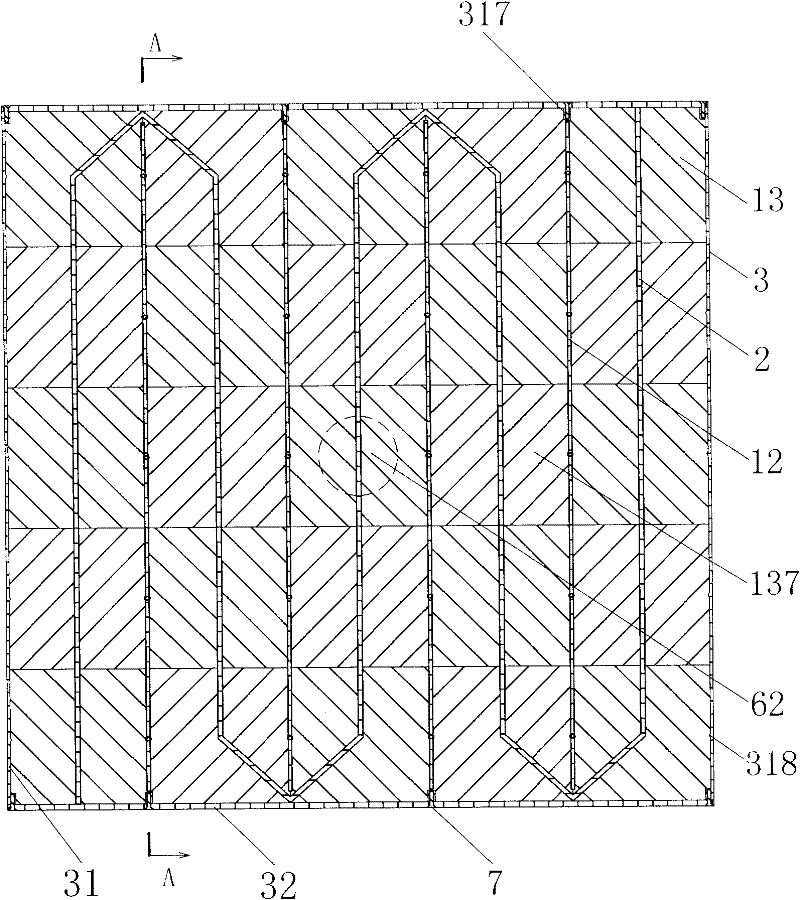

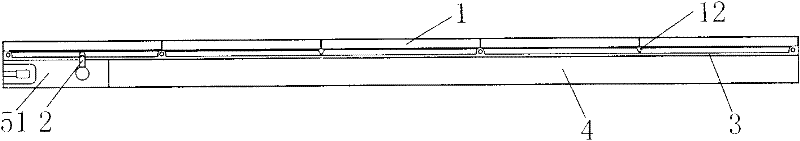

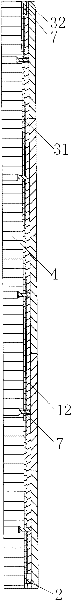

[0118] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 15 As shown, the present invention includes a decorative board layer 1, a connecting frame 3 and a moisture-proof and heat-insulating layer 4 of a built-in heating device 2 arranged in sequence, and also includes a fixed lock 6 arranged on the connecting frame 3 and the moisture-proof and heat-preserving layer 4 and a moisture-proof and heat-preserving layer. Two electrical connection blocks for layer 4; as figure 2 As shown, the first electrical connection block 51 and the second electrical connection block 52 are respectively placed on two opposite corners of the moisture-proof insulation layer 4, arranged in antiparallel, the heating device 2 is built into the decorative board layer 1, and the two ends are respectively connected to the second 1. The second electrical connection blocks 51 and 52 are connected, and when assembled, the ends of the electrical connection blocks of the two unit devices are in c...

Embodiment 2

[0130] Embodiment 2: The overall structure of this embodiment is the same as that of Embodiment 1. The difference is that in this embodiment, the decorative layer 1 is composed of two bricks 13. In this embodiment, two glue-injected first electrical connection blocks 51 are placed On the two adjacent corners of the moisture-proof insulation layer 4, the same direction is arranged in parallel. The first stiffener 12 that adopts in this example, as Figure 19 , Figure 19 (a), Figure 19 As shown in (b), its cross-section is a trapezoidal structure with a first threaded hole protrusion 121 on it. In this example, on the two frames of the first main board bracket 31 where the first side plate 32 is installed, there are symmetrically respectively a heating wire outlet 314 and a third bolt hole protrusion 317 for fixing the first side plate 32, and there are holes on the thin plate for The first bolt hole 312 of the second reinforcing rib 14 is fixed. In order to make the prese...

Embodiment 3

[0131] Embodiment 3: The overall structure of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, the decorative plate layer 1 is composed of 9 bricks 13 . The first stiffener 12 section that adopts in this example is triangular and the arched structure that combines with triangular one side, and Figure 25 , Figure 25 (a), Figure 25 The second reinforcing rib 14 shown in (b) has the same structure, and has a second threaded hole protrusion 141 for fixing the reinforcing rib of this example. Its installation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com