Oil recovery method of closed circulation and viscosity breakback of hot oil in viscous oil well and device

A closed circulation, oil production device technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of formation pollution, inaccurate production measurement of oil wells, increase the load of production and transportation systems, etc., and achieve optimal aging life. , Excellent chemical stability, the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

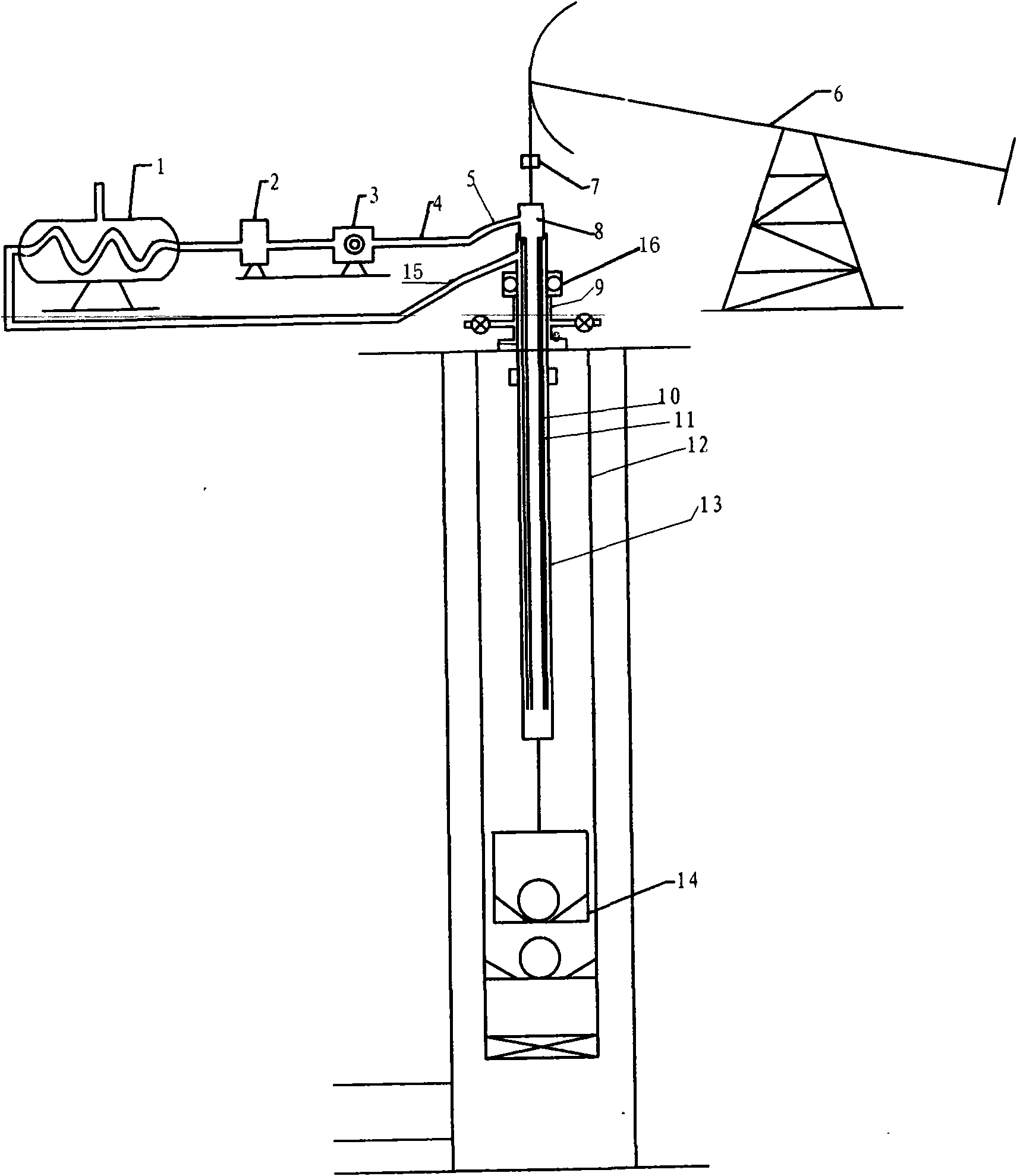

[0018] The closed cycle viscosity-reducing oil recovery method of hot oil in heavy oil wells includes heating crude oil and injecting it into the well. Heating crude oil and injecting it into the well is carried out in a special device. The coal or gas single system can adopt one well one system or multiple wells one system, and the injection of heated crude oil into the well is carried out in a closed cycle.

[0019] Wherein, the closed circulation of the heating crude oil injection well is injected from the telescopic central pipe 10 of the special device, and flows out through the annular space between the telescopic central pipe 10 and the telescopic outer pipe 13 . The nested central tube 10 is made of plasma-modified organic polymer material with good thermal insulation performance.

[0020] A closed circulation viscosity reduction oil recovery device for hot oil in a heavy oil well, comprising a heating system 1, a buffer tank 2, a booster pump 3, a surface process pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com