Twin-stage impeller high-pressure axial flow draught fan for shipbuilding

A high-pressure shaft and flow fan technology, which is applied to the parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve the problem of no anti-skid measures, failure to ensure normal start and operation of fans, unreasonable structure, etc. problems, to achieve the effect of satisfying multi-station and adjustable air volume, ensuring normal startup and operation, and high protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

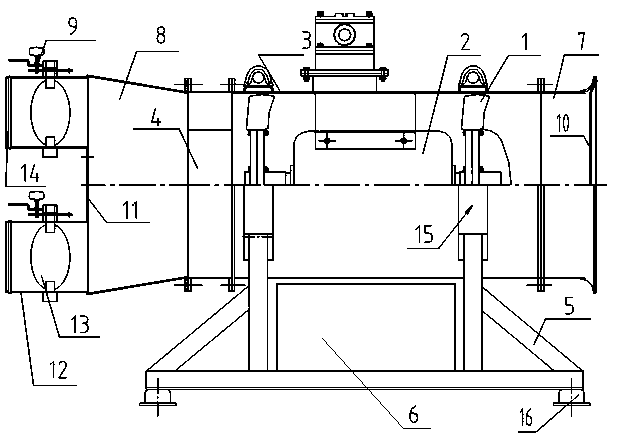

[0012] As shown in the accompanying drawings, a two-stage impeller high-pressure axial flow fan for shipbuilding is provided with a fan, and the fan is composed of an impeller 1, a motor 2, a blower 3, guide vanes 4, a bracket 5 and an electric control device 6, and the blower 3. Sitting on the bracket 5, the air duct 3 is provided with a motor 2 and an impeller 1. The motor 2 is connected to the electric control device 6 through wires. The two ends of the motor 2 are respectively provided with an impeller 1, and the impeller 1 is provided with a guide vane 4. It is characterized in that it is provided with an air collector 7, a reducing pipe 8 and a current collector 9, the reducing pipe 8 and the air collecting device 7 are respectively surrounded by metal plates in a tubular shape, the reducing pipe 8 is in the shape of a truncated cone, and the air collector 7 is in the shape of a cone. Trumpet-shaped, the air inlet end of the air duct 3 is connected to the small diameter e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com