Frame of a three-wheeled motorcycle

A technology for three-wheeled motorcycles and frames, which is applied to motor vehicles, bicycles, transportation and packaging, etc., and can solve the problems of poor anti-collision strength of three-wheeled motorcycles, long auxiliary time for production and assembly, and low production efficiency. Achieve the effects of easy installation and welding, ensuring rigidity and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

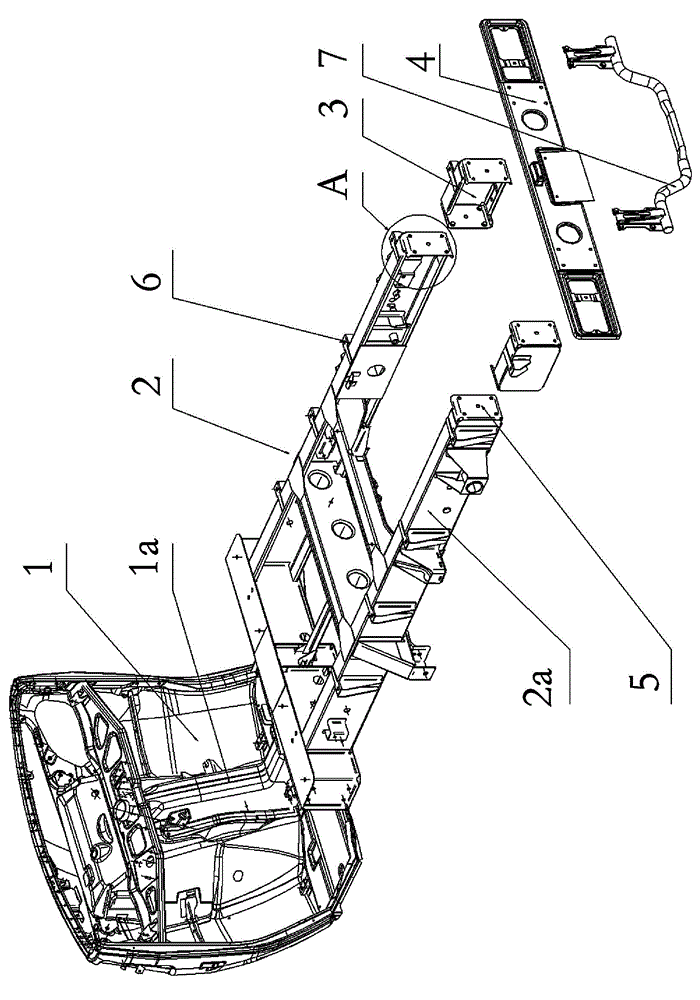

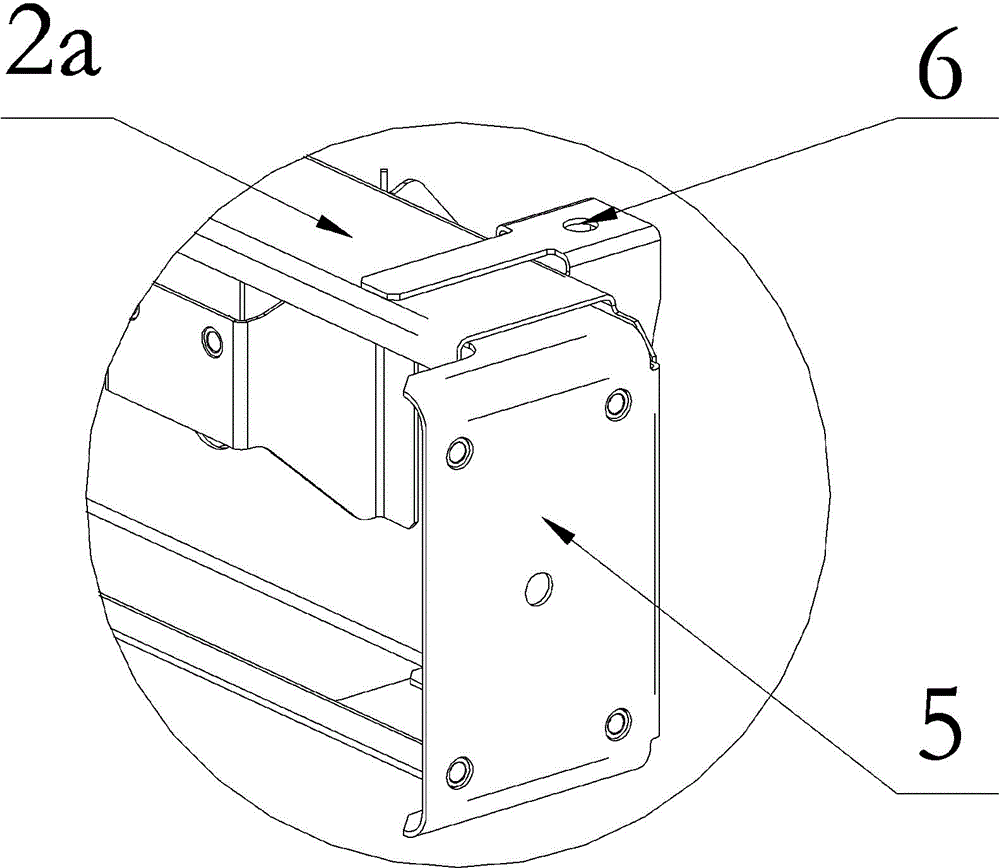

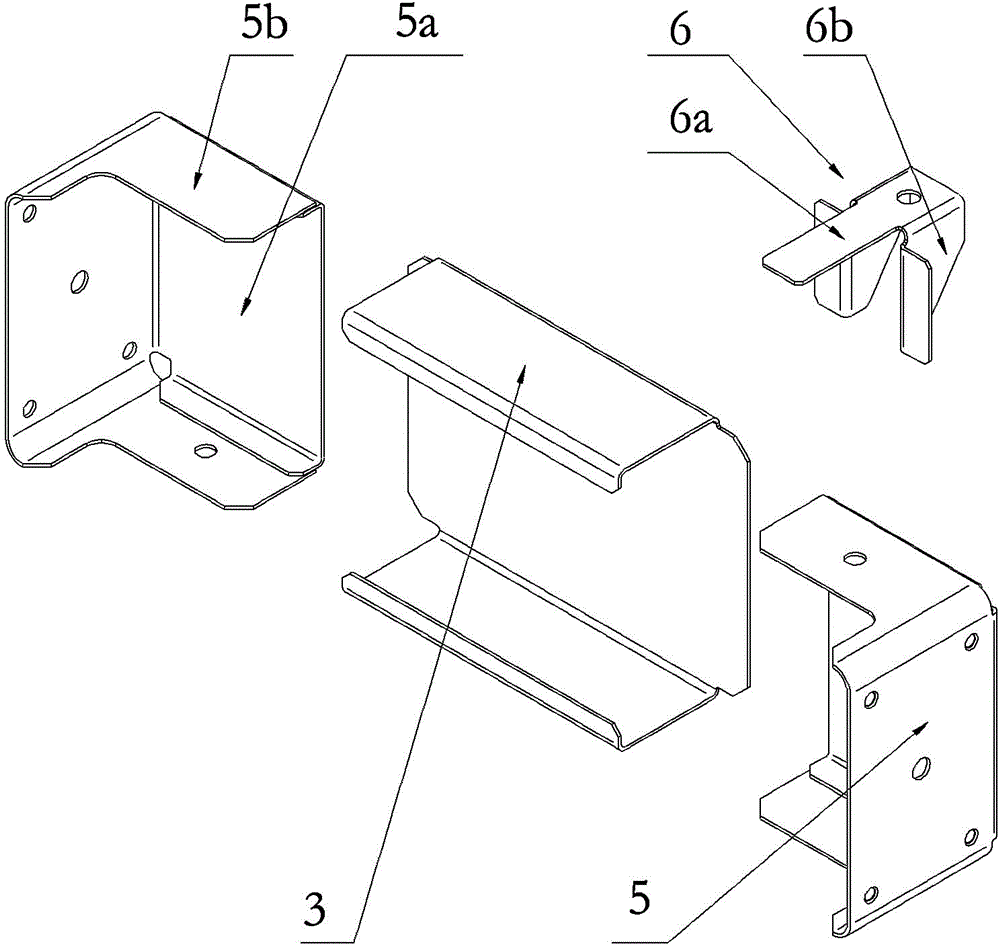

[0034] see Figure 1 ~ Figure 4, is an embodiment of the frame of a three-wheeled motorcycle, including a cab bottom beam frame 1 with a keel 1a, and a cargo box support beam frame 2 with two parallel longitudinal beams 2a, and the keel is located at the driver's seat The middle part of the beam frame at the bottom of the room is used to support the front part of the three-wheeled motorcycle. Several beams of the cargo box supporting beam frame are welded and fixed to two parallel longitudinal beams. The cargo box supporting beam frame 2 is fixedly connected with the cab bottom beam frame 1, and the fixing method of the cargo box supporting beam frame and the cab bottom beam frame can be bolted, riveted, welded, etc. In this embodiment, the cargo box supports The beam frame and the bottom beam frame of the cab are welded and fixed to make the frame stronger. It also includes two extended beam bodies 3 for increasing the length of the longitudinal beam 2a, and a rear tail bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com