Prestressed pipe pile coated with active material pile body and construction method

A technology of prestressed pipe piles and active materials, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low bearing capacity, poor durability of thin-walled pipe piles, and difficult shape of cement soil, etc., and achieve the loss of bearing capacity Small, reduce mud pollution, improve pile strength and pile side friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In this embodiment, the production requirements of geotextile bag suture, reinforcement body and restraint body, prefabricated expanded pile tip production technical requirements, prestressed pipe pile prefabrication and pile sinking construction technical requirements, active material mix design requirements, etc. will not be repeated, and the key points Embodiments of the present invention will be described.

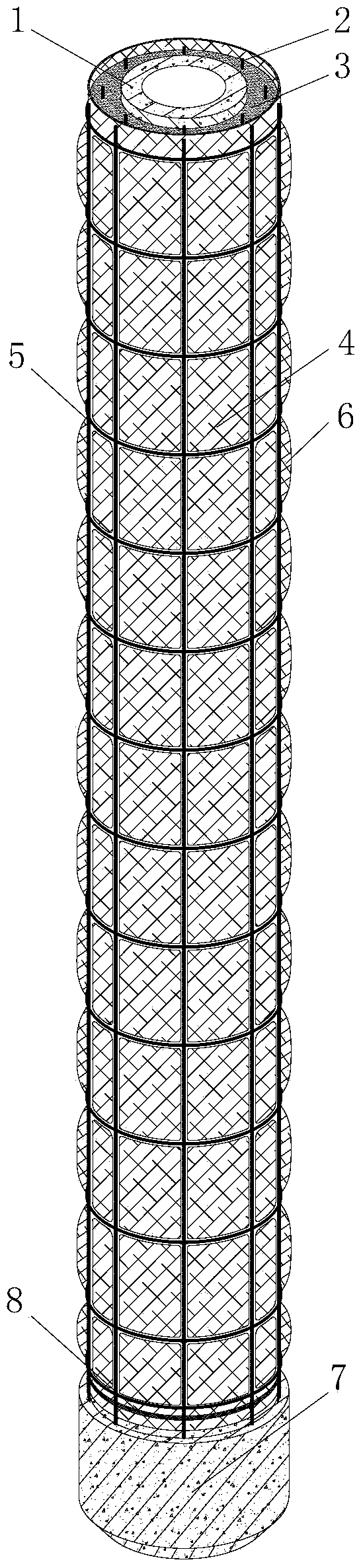

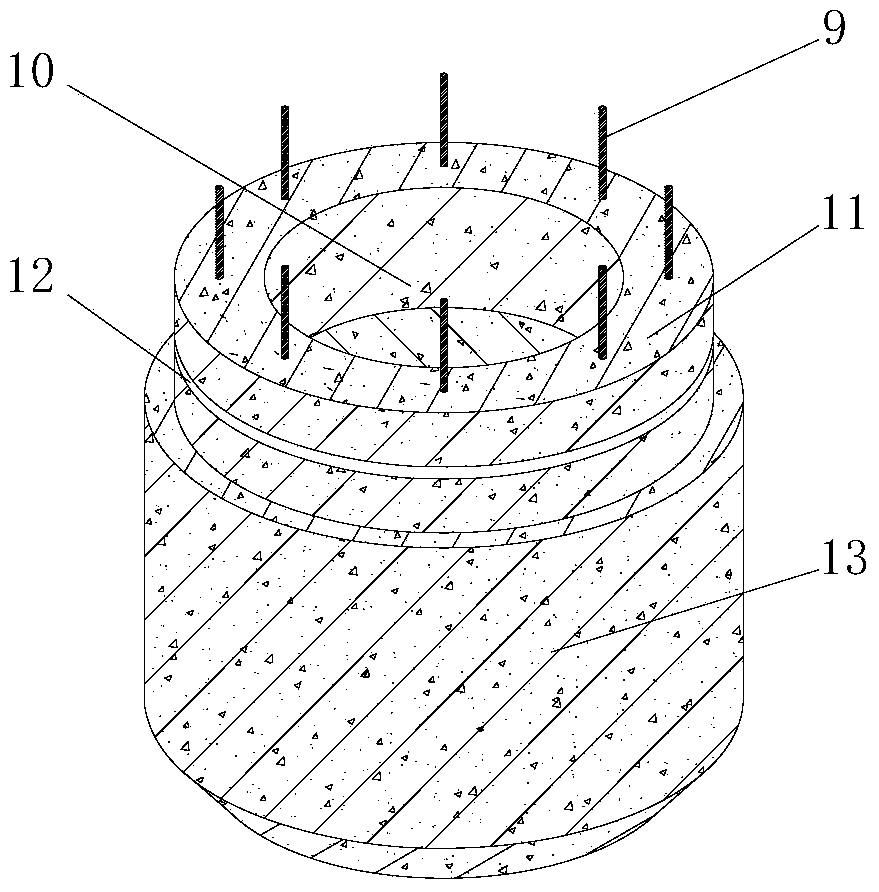

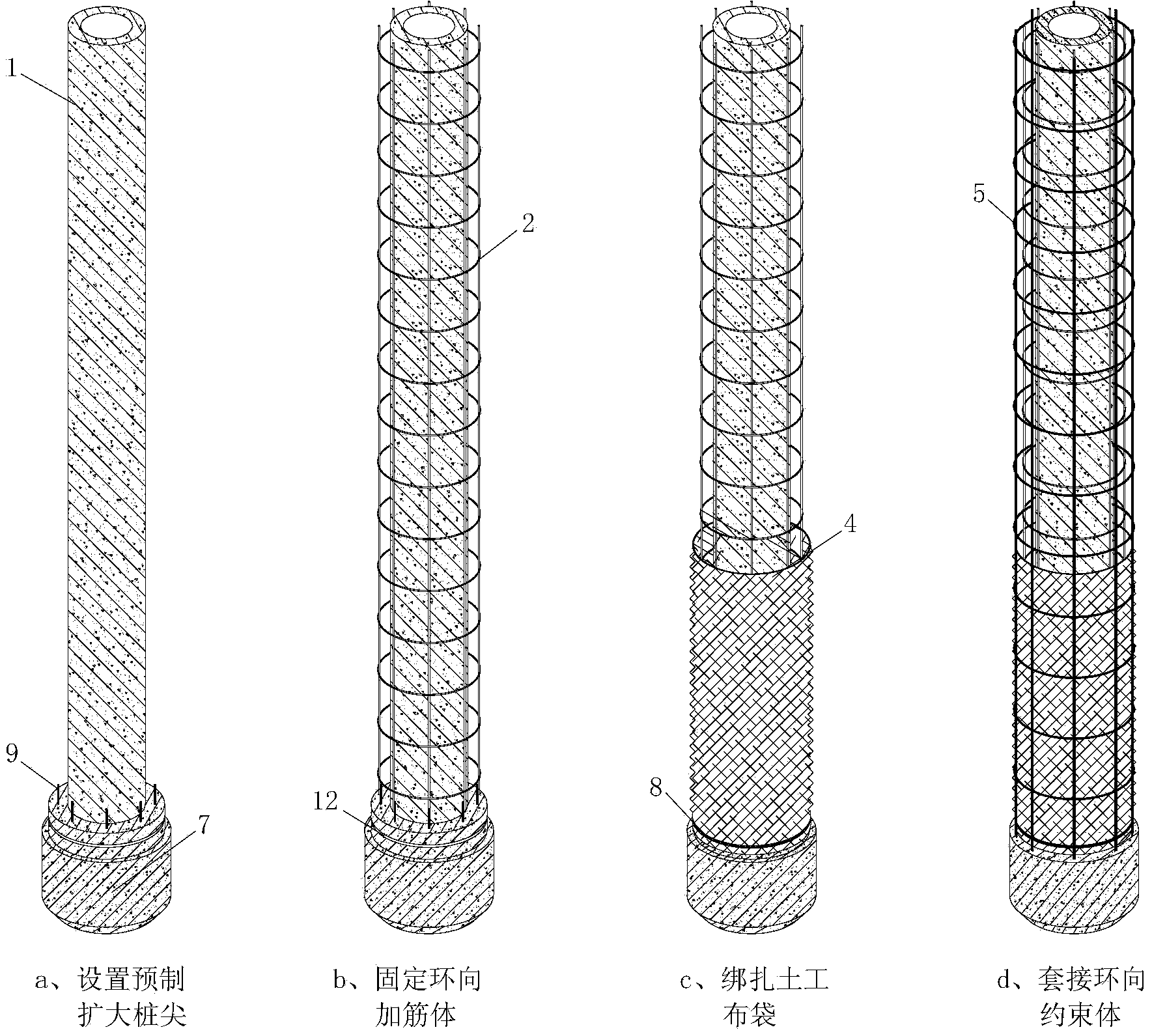

[0038] figure 1 It is a schematic diagram of a prestressed pipe pile with an outsourcing active material pile body of the present invention; figure 2 It is a schematic diagram of the detailed structure of the prefabricated enlarged pile tip of the present invention; image 3 It is a schematic diagram of the combination process of a prestressed pipe pile with an outsourcing active material pile body before pile formation of the present invention. refer to Figure 1~3 As shown, a prestressed pipe pile with an outsourced active material pile body mainly includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com