Water dispersible granule for prevention and control of molluscs and preparation method of water dispersible granule

A mollusk, dispersing particle technology, applied in the fields of botanical equipment and methods, animal repellents, biocides, etc., can solve the problems of dust drift, low content of active ingredients, increased transportation costs, etc. and environmental pollution, high content of active ingredients, and low cost of environmental treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

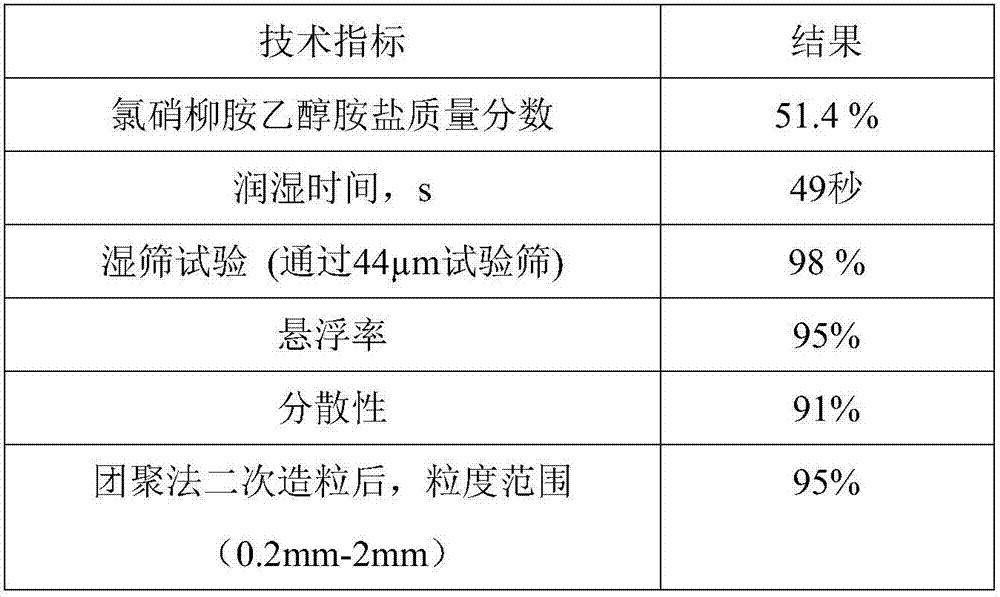

[0029] A water-dispersible granule for preventing and controlling molluscs, the water-dispersible granule is composed of the following components in mass percentage: 2% metaldehyde, 50% niclosamide ethanolamine salt, sodium dodecylbenzenesulfonate 2%, methylnaphthalenesulfonate formaldehyde condensate 8%, anhydrous sodium sulfate 2.5%, modified starch 3%, polyether modified organosilane 0.5%, water-soluble starch to make up 100%.

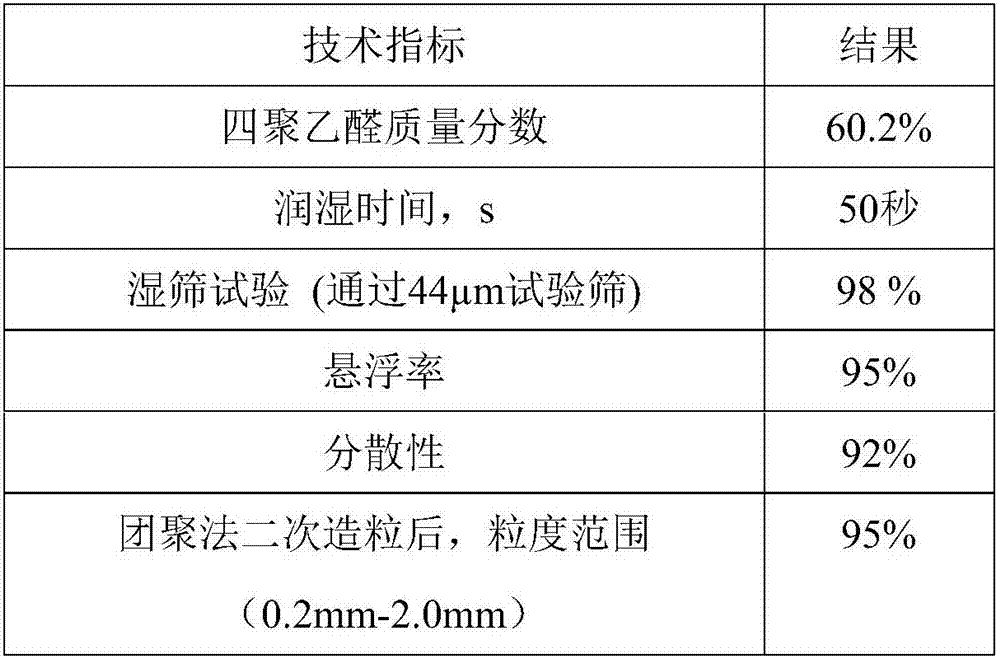

[0030] The preparation method of water-dispersible granules is as follows: put various materials into a high-shear homogeneous kettle, add appropriate amount of ion-free, carry out high-speed dispersion, and then repeatedly sand-grind on a sand mill until 95% of the particles are less than 5 μm. Spray drying and granulation to obtain water-dispersible granules. The technical indicators of the water-dispersible granules prepared in this embodiment are shown in Table 1.

[0031] Table 1

[0032] technical indicators result Metaldehyd...

Embodiment 2

[0034] A water-dispersible granule for preventing and controlling molluscs, the water-dispersible granule is composed of the following components in mass percentage: 60% metaldehyde, 2% fatty alcohol polyoxyethylene ether, 5.5% polymer polychitosan, 3% of modified lignosulfonate, 3% of cellulose, 5% of modified starch, 0.5% of polyether modified organosilane, and 100% of water-soluble starch.

[0035] The preparation method of water-dispersible granules is as follows: put various materials into a high-shear homogeneous kettle, add appropriate amount of ion-free, carry out high-speed dispersion, and then repeatedly sand-grind on a sand mill until 95% of the particles are less than 5 μm. Spray drying granulation to obtain water-dispersible granules with small particle size, and continue to spray water droplets containing binder on the obtained small-size water-dispersible granules (using agglomeration method for secondary granulation) to obtain water-dispersible granules with lar...

Embodiment 3

[0039] A water-dispersible granule for preventing and controlling molluscs, the water-dispersible granule is composed of the following components in mass percentage: metaldehyde 70%, fatty alcohol polyoxyethylene ether 3%, polycarboxylate sodium salt 5%, Tea saponin 6%, cellulose 3%, modified starch 3%, polyether modified organosilane 0.5%, and water-soluble starch make up 100%.

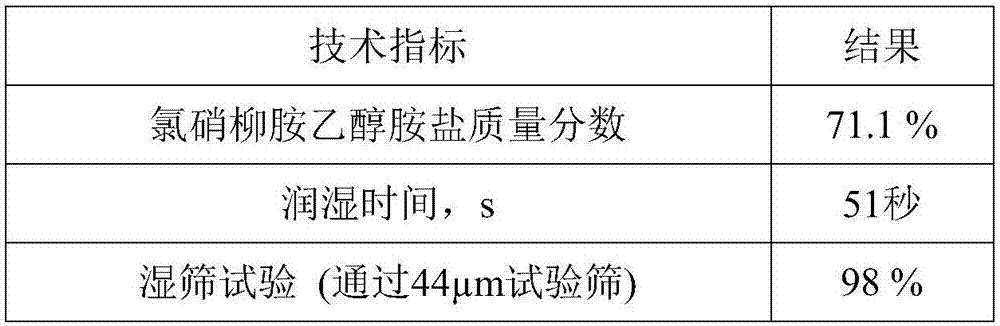

[0040] The preparation method of water-dispersible granules is as follows: put various materials into a high-shear homogeneous kettle, add appropriate amount of ion-free, carry out high-speed dispersion, and then repeatedly sand-grind on a sand mill until 95% of the particles are less than 5 μm. Spray drying and granulation to obtain water-dispersible granules. The technical indicators of the water-dispersible granules prepared in this embodiment are shown in Table 3.

[0041] table 3

[0042] technical indicators result Metaldehyde mass fraction 70.5% Wetting time, s 53 secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com