Preparation method of basalt fiber fabric reinforced nylon 6 prepreg composite material

A fiber fabric and composite material technology, which is applied in the field of preparation of basalt fiber fabric reinforced nylon 6 prepreg composite material, can solve the problems affecting the performance of composite materials, low molecular weight monomers cannot be removed, and monofilament level impregnation cannot be guaranteed. Achieve excellent mechanical properties, low residual content, and dense composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation method of basalt fiber fabric reinforced nylon 6 composite material prepreg is as follows:

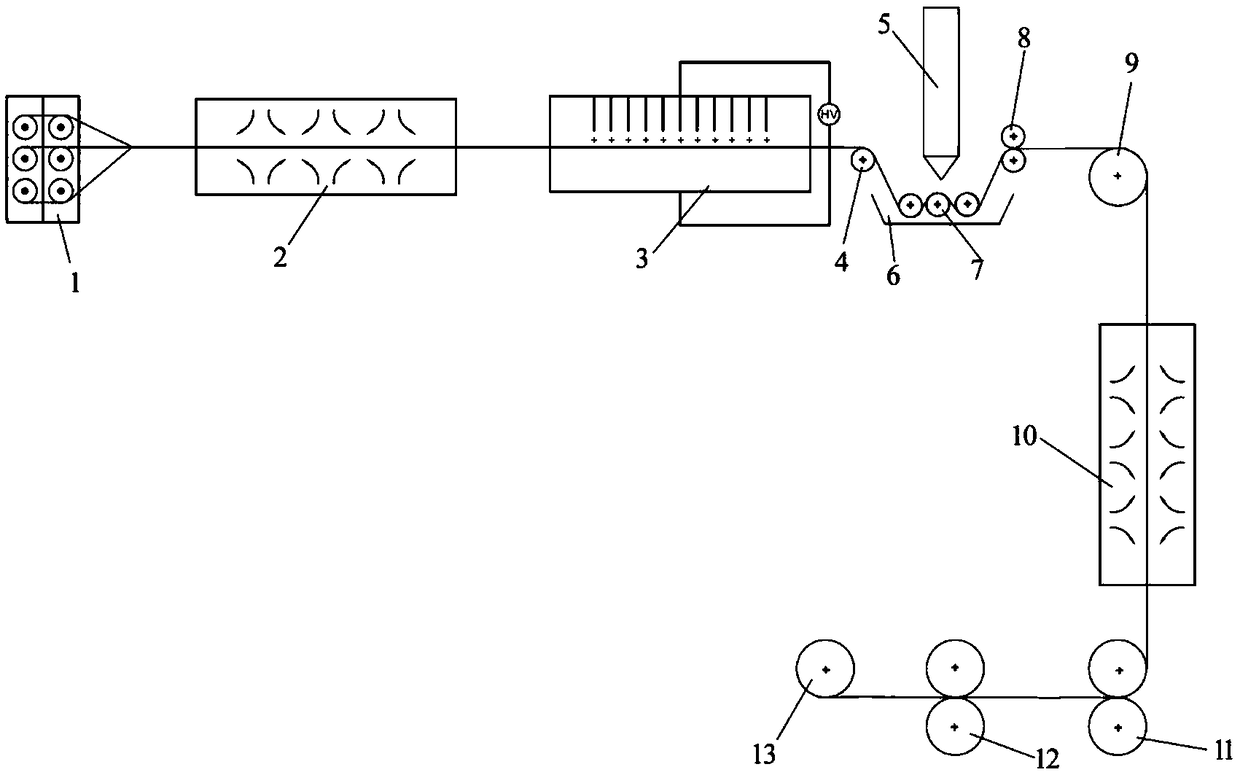

[0019] (1) Weigh 600 parts by weight of caprolactam and heat it to 80°C to melt, then remove a small amount of water through vacuum distillation, then divide the molten liquid into two parts of equal weight, and add them to liquid feeding devices A and B at a constant temperature of 80°C middle. Add 0.024 parts by weight of sodium caprolactam to liquid feeding device A and mix thoroughly; add 0.024 parts by weight of toluene-2,4-diisocyanate to liquid feeding device B and mix thoroughly; The mixture is added at the same rate figure 1 Mix evenly in the twin-screw extruder 5 with medium length-to-diameter ratio of 44, extrusion temperature of 80°C, and main engine speed of 500r / min to form a reactive caprolactam melt, and extrude into the dipping tank 6 with a constant temperature of 80°C for basalt fiber Fiber cloth impregnation;

[0020] (2) Pull 400 parts by...

Embodiment 2

[0023] The preparation method of basalt fiber fabric reinforced nylon 6 composite material prepreg is as follows:

[0024](1) Weigh 200 parts by weight of caprolactam and heat it to 100°C to melt, remove a small amount of water through vacuum distillation, then divide the molten liquid into two parts of equal weight, and add them to liquid feeding devices A and B at a constant temperature of 100°C middle. Add 0.2 parts by weight of sodium caprolactam to liquid feeding device A and mix thoroughly; add 0.2 parts by weight of toluene-2,4-diisocyanate to liquid feeding device B and mix thoroughly; The mixture is added at the same rate figure 1 Mix evenly in the twin-screw extruder 5 with medium length-to-diameter ratio of 44, extrusion temperature of 100°C, and main engine speed of 800r / min to form a reactive caprolactam melt, and extrude to the dipping tank 6 with a constant temperature of 100°C for basalt fiber Fiber cloth impregnation;

[0025] (2) Pull 800 parts by weight ...

Embodiment 3

[0028] The preparation method of basalt fiber fabric reinforced nylon 6 composite material prepreg is as follows:

[0029] (1) Weigh 400 parts by weight of caprolactam and heat it to 90°C to melt, then remove a small amount of water through vacuum distillation, then divide the molten liquid into two parts of equal weight, and add them to liquid feeding devices A and B at a constant temperature of 90°C middle. Add 2.008 parts by weight of sodium caprolactam to liquid feeding device A, and fully mix; Add 2.008 parts by weight of toluene-2,4-diisocyanate to liquid feeding device B, and fully mix; Then, liquid feeding device A and liquid feeding The mixture in Apparatus B is added at the same rate figure 1 Mix evenly in the twin-screw extruder 5 with medium length-to-diameter ratio of 44, extrusion temperature of 90°C, and main engine speed of 650r / min to form a reactive caprolactam melt, and extrude to the dipping tank 6 with a constant temperature of 90°C for basalt fiber Fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com