Sulfur-based intercalated hydrotalcite modified charcoal-based adsorption material and preparation and application thereof

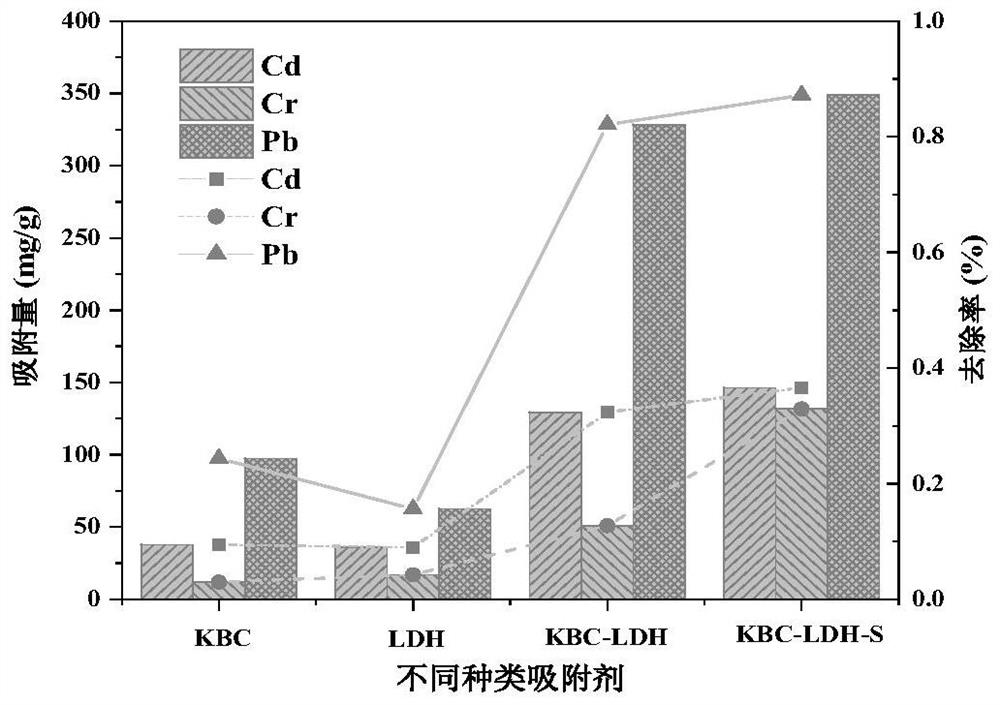

An adsorption material, biochar technology, applied in water pollutants, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of small adsorption of yin and yang HMs ions, increased hydrotalcite loading, and poor adsorption performance. Achieve broad industrial application prospects, improve load stability, and enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

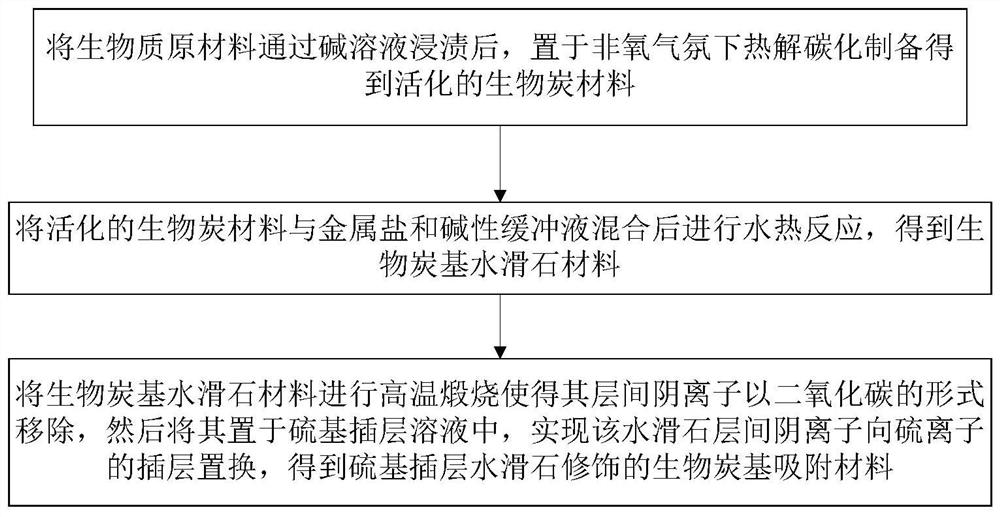

[0043] The preparation method of the biochar-based adsorption material modified by a kind of sulfur-based intercalation hydrotalcite provided by the invention, such as figure 1 shown, including the following steps:

[0044] (1) After the biomass raw material is impregnated with an alkaline solution, it is placed in a non-oxygen atmosphere and pyrolytically carbonized to prepare an activated biochar material;

[0045] (2) The activated biochar material obtained in step (1) is mixed with a metal salt and an alkaline buffer to perform a hydrothermal reaction to obtain a biochar-based hydrotalcite material; the metal salt includes at least one divalent metal salt and a trivalent metal salt;

[0046] (3) The biochar-based hydrotalcite material obtained in step (2) is calcined at a high temperature so that its interlayer anions are removed in the form of carbon dioxide, and then placed in a sulfur-based intercalation solution to realize the hydrotalcite interlayer anions Intercala...

Embodiment 1

[0072] The preparation method of the biochar-based adsorption material modified by sulfur-based intercalation hydrotalcite in this embodiment is specifically carried out according to the following steps:

[0073] (a) Preparation of activated biochar materials by alkaline solution impregnation pyrolysis. Wash the selected bamboo chips with alcohol, dry them in an oven at a temperature of 70°C for 24 hours, take them out and cool them, and crush them through a 100-mesh sieve; then select 10 g of the above-mentioned biomass powder and stir in 100 mL of 2mol / L KOH solution Soak for 8-24 hours and dry to constant weight to get KOH-activated biochar;

[0074] (b) Hydrotalcite was loaded on the surface of biochar material by urea hydrothermal method. Select 15g of the above biochar, and metal salt (0.04mol Mg(NO 3 ) 2 , 0.02mol Al(NO 3 ) 3 ) together in 200ml of alkaline buffer solution, magnetically stirred for 2h, the alkaline buffer solution is prepared from 0.2mol urea, 0.04...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com