Hue adjusting process for high-whiteness coating white cardboard

A white cloth cardboard, high whiteness technology, applied in the field of hue adjustment process of high whiteness coated white cardboard, can solve the problems of difficult wastewater treatment, narrow control range, long adjustment time, etc., to achieve the difficulty of wastewater treatment The effect of reducing and reducing production costs and adjusting time is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A process for adjusting the hue of high-whiteness coated white cardboard, comprising the steps of:

[0020] 1. Raw paper production:

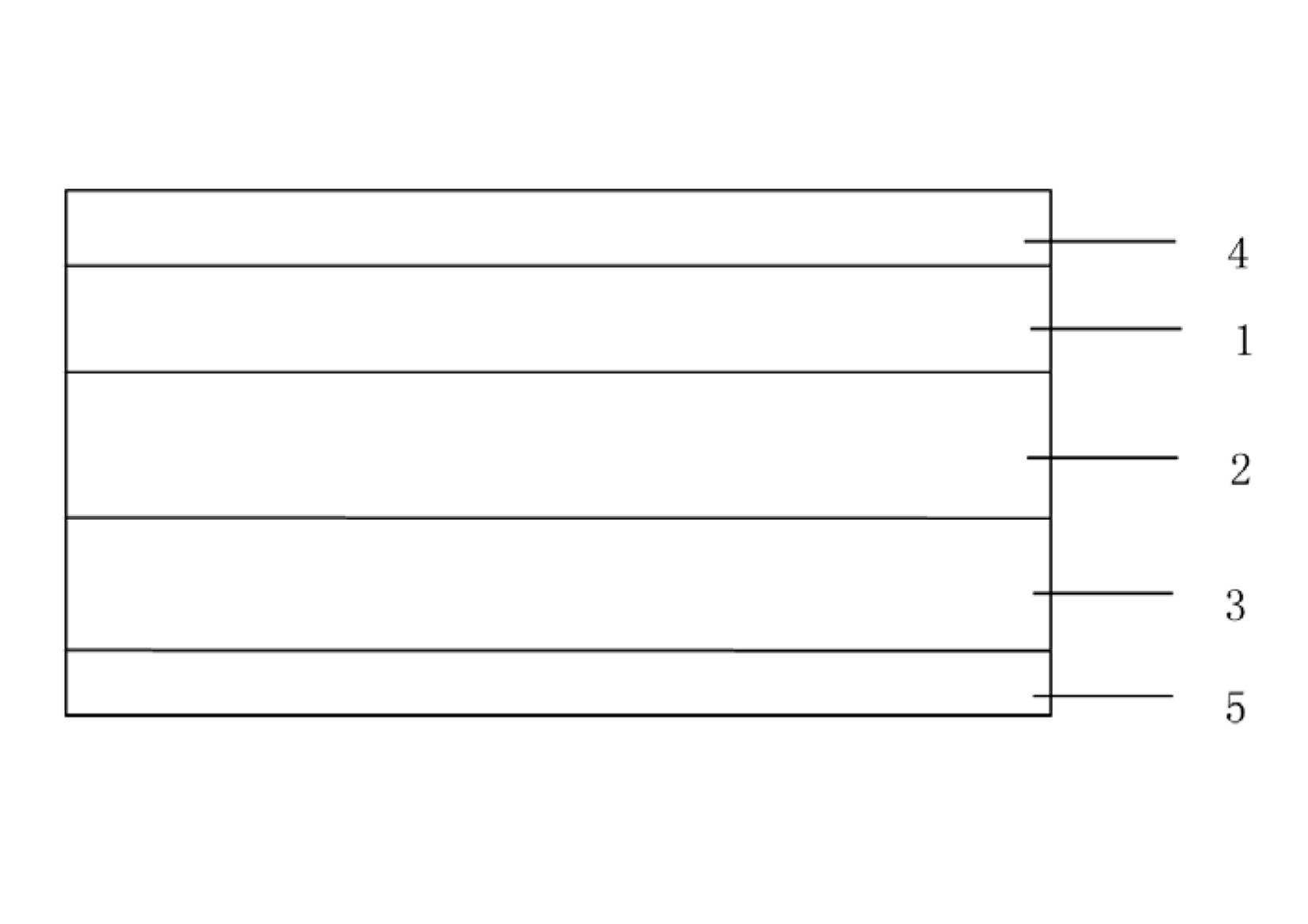

[0021] Face paper layer: the face paste made by beating and batching goes through the head box, enters the headbox, and is sent to the face net to form the face paper layer;

[0022] Core paper layer: The core pulp made by beating and batching enters the headbox and is sent to the core wire to form the core paper layer through the head box. 5wt% violet aqueous solution is pumped into the head box at a flow rate of 10.4 L / h, wherein the amount of blue dye is 0.05kg / ton of paper, and the amount of violet is 0.08kg / ton of paper;

[0023] Bottom paper layer: The bottom pulp made by beating and batching goes through the head box and enters the headbox to be sent to the bottom wire to form the bottom paper layer;

[0024] The surface paper layer, the core paper layer and the bottom paper layer are copied to obtain the base paper;

[0025] 2...

Embodiment 2

[0029] A process for adjusting the hue of high-whiteness coated white cardboard, comprising the steps of:

[0030] 1. Raw paper production:

[0031] Face paper layer: the face paste made by beating and batching goes through the head box, enters the headbox, and is sent to the face net to form the face paper layer;

[0032] Core paper layer: The core pulp made by beating and batching enters the headbox and is sent to the core wire to form the core paper layer through the head box. 8wt% violet aqueous solution is pumped into the head box at a flow rate of 10.0 L / h, wherein the amount of blue dye is 0.07kg / ton of paper, and the amount of violet is 0.05 kg / ton of paper;

[0033] Bottom paper layer: The bottom pulp made by beating and batching goes through the head box and enters the headbox to be sent to the bottom wire to form the bottom paper layer;

[0034] The surface paper layer, the core paper layer and the bottom paper layer are copied to obtain the base paper;

[0035] ...

Embodiment 3

[0039] A process for adjusting the hue of high-whiteness coated white cardboard, comprising the steps of:

[0040] 1. Raw paper production:

[0041] Face paper layer: the face paste made by beating and batching goes through the head box, enters the headbox, and is sent to the face net to form the face paper layer;

[0042] Core paper layer: the core pulp made by beating and batching passes through the head box, enters the headbox and sends it to the core wire to form the core paper layer. Pump 4 wt% violet aqueous solution into the head box at a flow rate of 10.5 L / h, wherein, the amount of blue dye is 0.12kg / ton of paper, and the amount of violet is 0.15kg / ton of paper;

[0043] Bottom paper layer: The bottom pulp made by beating and batching goes through the head box and enters the headbox to be sent to the bottom wire to form the bottom paper layer;

[0044] The surface paper layer, the core paper layer and the bottom paper layer are copied to obtain the base paper;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com