Using method of recovery adsorption tower in in-situ leaching mining uranium water treatment technology

A technology of hydrometallurgy treatment and adsorption tower, which is applied in the direction of contaminated groundwater/leachate treatment, water/sewage treatment, water/sewage treatment equipment, etc., and can solve the problem of affecting resin saturation capacity, increasing mines, and fluctuations in adsorption resin saturation capacity Larger problems, to achieve stable capacity, reduce production costs, and improve the recovery rate of water smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0054] 1. Carry out the feasibility test of connecting the transformed tail liquid to the recovery adsorption tower

[0055] 1.1 Preparation of test equipment

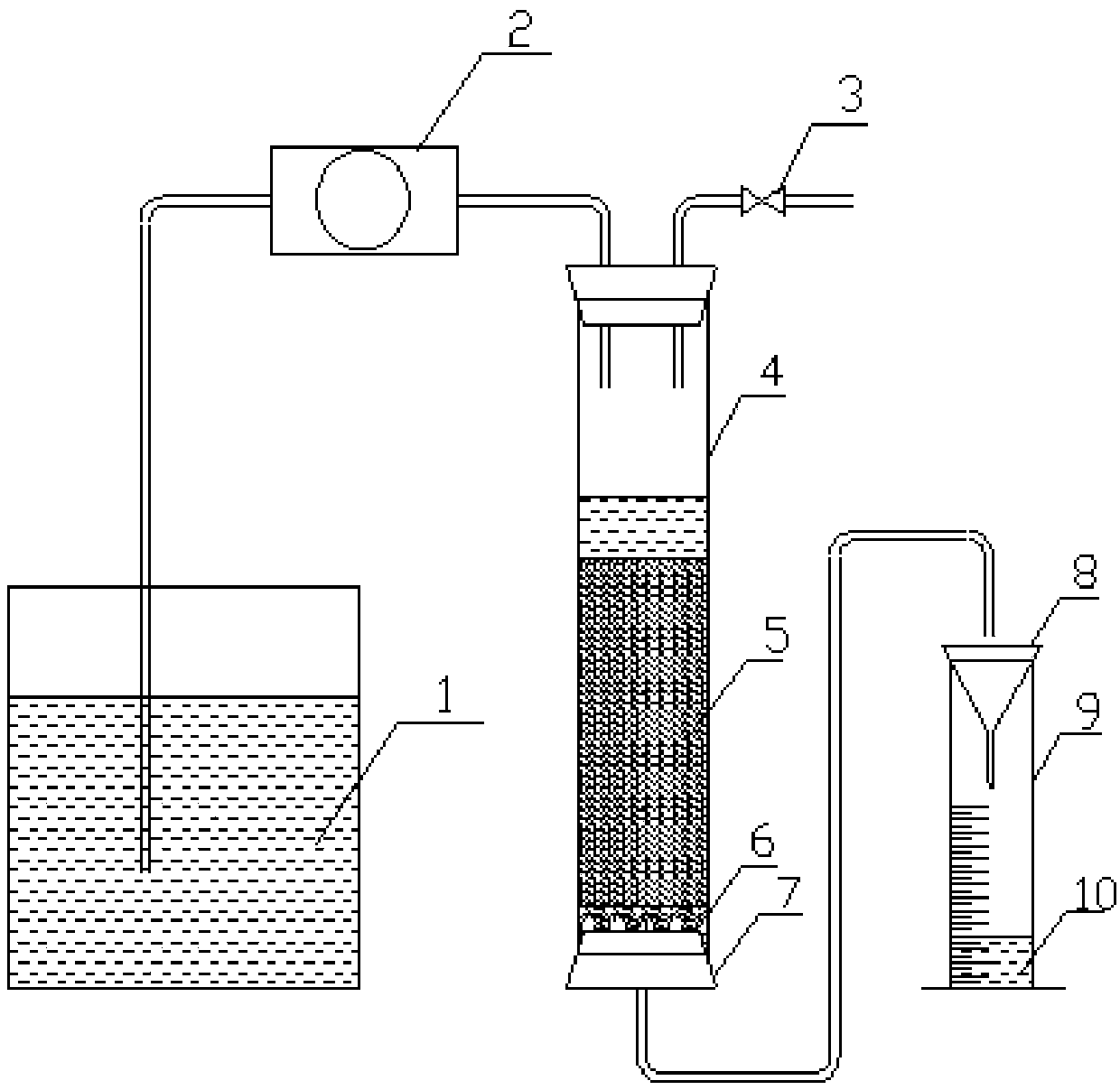

[0056] like figure 1 As shown, the sample bottle is used to place the inlet 1. The inlet of the peristaltic pump 2 communicates with the liquid inlet 1 in the sampling bottle through a rubber hose, and the outlet of the peristaltic pump 2 communicates with the upper end of the ion-exchange glass column 4 through a rubber hose. The ion-exchange glass column 4 is used to place the depleted uranium resin 5, and its upper and lower ends are sealed by a cork 7, and asbestos 6 is arranged on the lower end of the cork 7. The lower end of the ion-exchange glass column 4 communicates with the funnel 8 through a rubber hose, and the rubber hose is located above the funnel 8 . The funnel 8 is placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com