Continuous anodic electrolytic cell for preparing high performance aluminum alloy

An anode electrolysis and aluminum alloy technology, which is applied in the field of high-performance aluminum alloy preparation equipment, can solve the problems of difficult control, poor quality of high-performance aluminum alloy, complicated operation, etc., and achieve the effect of simple production process, low cost and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

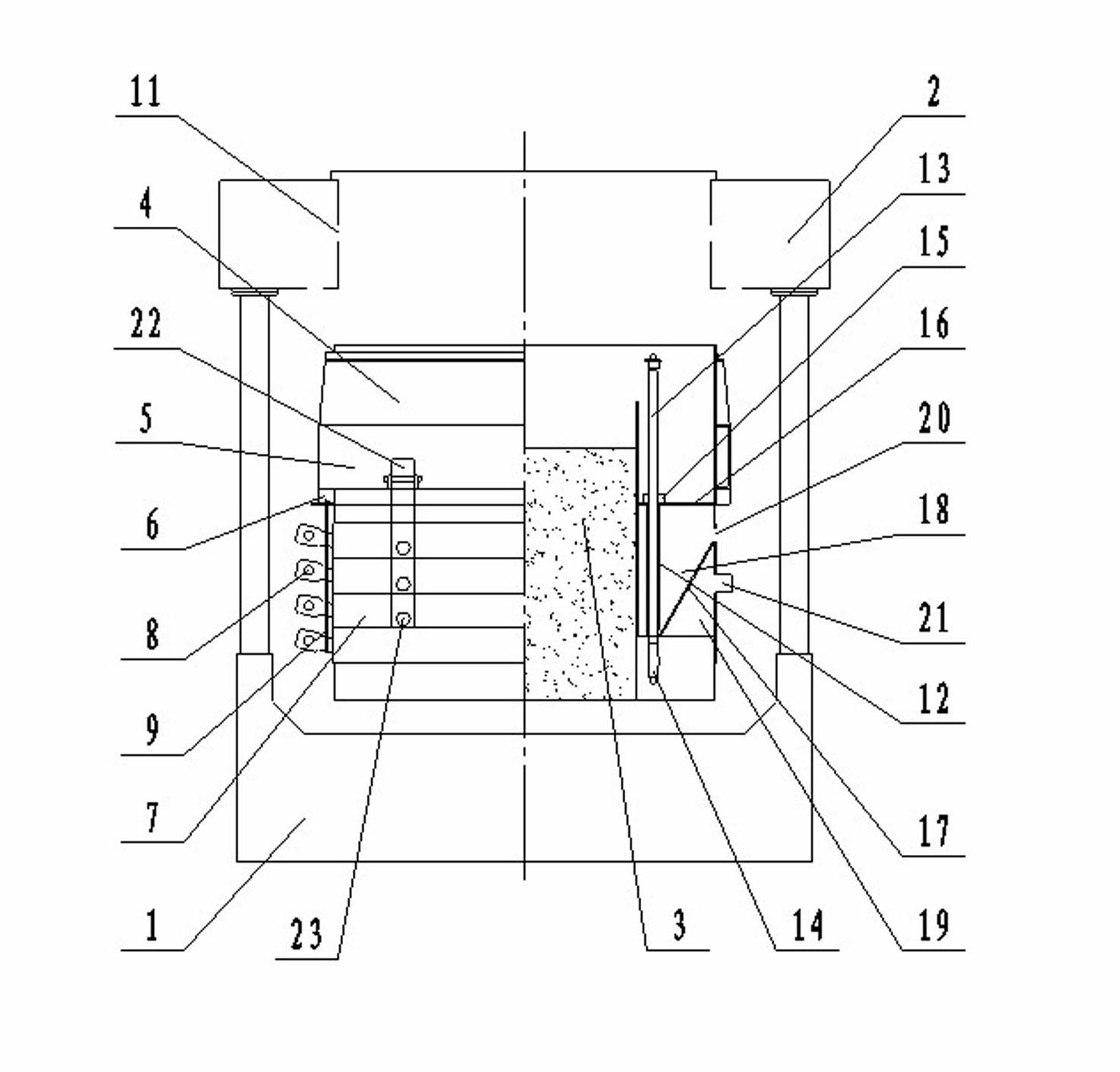

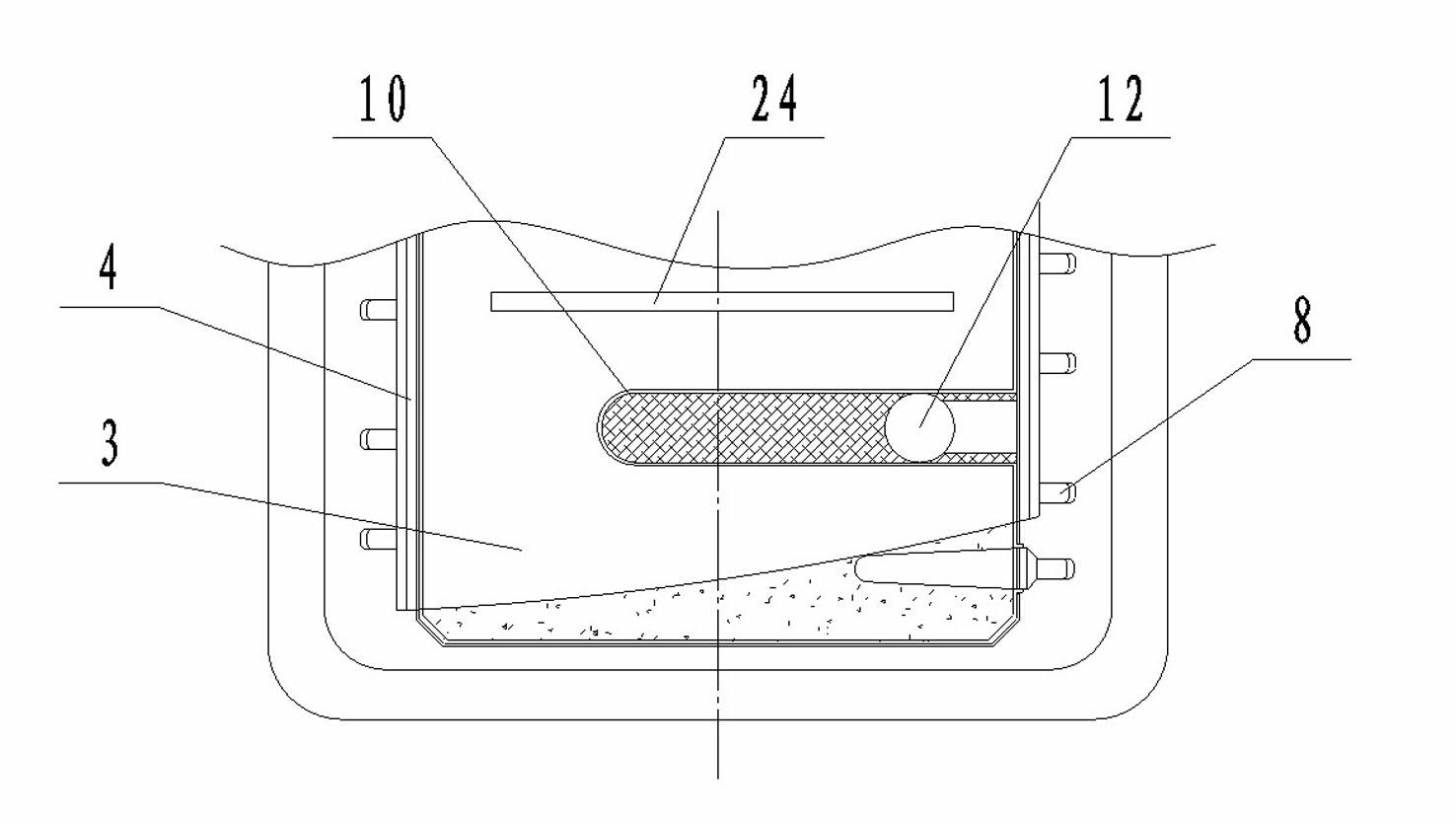

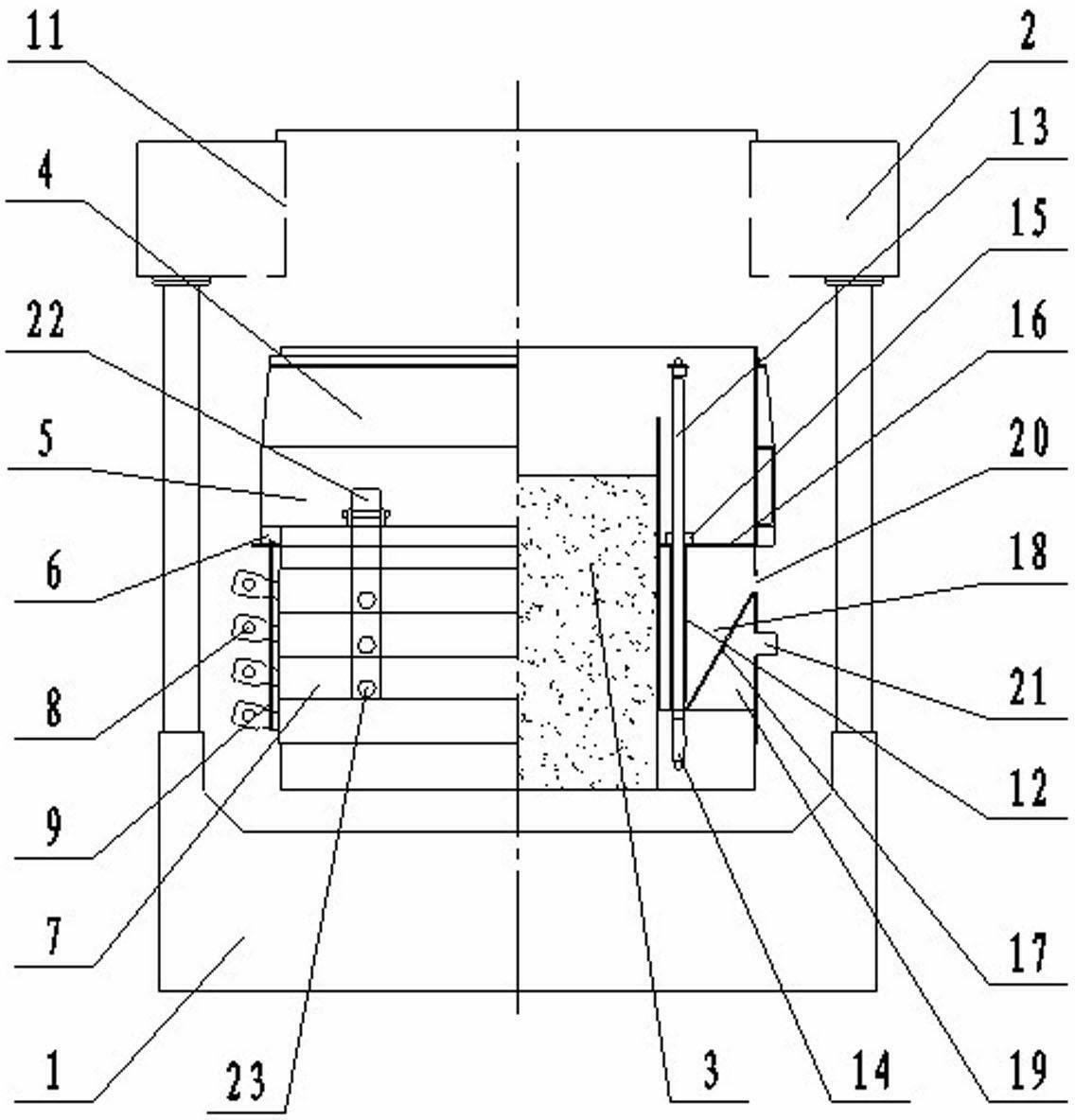

[0017] A continuous anode electrolytic cell for high-performance aluminum alloy preparation, including a continuous anode device, a cathode device 1 and a metal platform 2 located above the continuous anode device, the number of continuous anode devices is one or more, and a single continuous anode device is composed of four sides The anode body 3 wrapped with aluminum foil or aluminum plate is composed of the anode box body. The upper part of the anode box body is provided with a sleeve-shaped metal frame 4 which is set around the anode body 3. The outer wall of the metal frame 4 is provided with a load-bearing fastening ring 5, which is tightly loaded. The lower side of the fixed ring 5 is fixed with a load-bearing hook connector 6, and the lower part of the anode box is provided with a number of sealing cover frames 7 arranged up and down. There are a number of conductive rod holes on the sealed cover plate. One end of the conductive rod hole is inserted outside the sealed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com