Yarn-dyed fabric yarn dyeing waste water treatment and online recycling method and device

A wastewater treatment and recovery method technology, which is applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high treatment cost, difficult to meet the discharge standard, and difficult treatment, so as to reduce the cost of pollution control , reduce the content, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

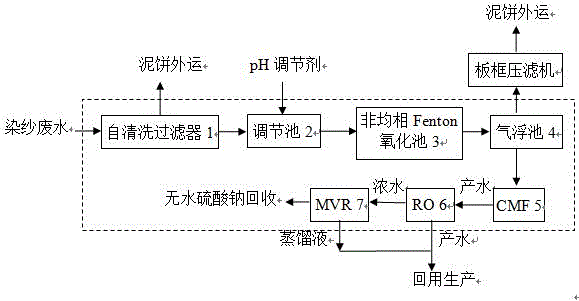

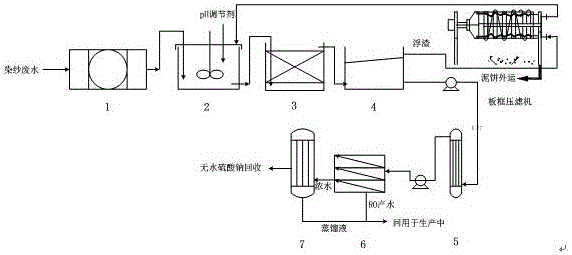

[0042] Such as figure 1 As shown, an efficient treatment and on-line recovery system for yarn-dyed fabric dyeing wastewater mainly includes self-cleaning filter 1, regulating tank 2, heterogeneous Fenton oxidation tank 3, air flotation tank 4, CMF5, RO6, and MVR7. Use sequential connection structure;

[0043] The self-cleaning filter 1 filters the wool, particles, flocs, etc. in the yarn dyeing wastewater. Through the intelligent (PLC) design, the system can automatically identify the impurity deposition speed, automatically discharge the sewage valve signal, and self-clean and filter The water from the device 1 enters the regulating tank 2;

[0044] The adjusting tank 2 homogenizes the water quality and quantity of the yarn dyeing wastewater, according to the Na in the wastewater 2 CO 3 Add appropriate amount of sulfuric acid to make Na in wastewater 2 CO 3 Fully converted to Na 2 SO 4 And continue to add sulfuric acid to adjust the pH value to a pH value range of 5~6 suitable for...

Embodiment 2

[0051] A high-efficiency treatment and online recovery method for yarn-dyed fabric dyeing wastewater:

[0052] (1) The self-cleaning filter filters the wool, particles and flocs in the dyeing wastewater to reduce turbidity, purify water quality and protect the normal operation of other equipment in the system;

[0053] (2) The adjustment tank homogenizes the water quality and quantity of the dyeing wastewater, adding sulfuric acid according to the content of Na2CO3 in the dyeing wastewater to make the Na in the wastewater 2 CO 3 Fully converted to Na 2 SO 4 And continue to add sulfuric acid to adjust the pH to a pH range of 5 suitable for Fenton reaction;

[0054] (3) The heterogeneous Fenton oxidation tank is filled with a new type of ternary supported activated carbon catalyst CuO-MnO 2 -ZnO / AC, the total filling volume is 1 / 3 of the effective volume of the heterogeneous Fenton oxidation tank. At the same time, 30% hydrogen peroxide is added to the heterogeneous Fenton oxidation tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com