Surface treatment for improving bioactivity and wear-resistant ability of titanium alloy surfaces

A bioactive, wear-resistant technology, applied in the coating and other directions, to achieve the effect of enhancing the bonding force, avoiding phase transition and embrittlement, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The Ti-29Nb-13Ta-4.6Zr sample was oxidized in air at 400°C for 24 hours, and then furnace cooled to room temperature. After this treatment, the surface hardness of the Ti-29Nb-13Ta-4.6Zr sample increased by about 300MPa (see Table 1), which is beneficial to the improvement of the alloy's wear resistance.

[0030] Soak the oxidized alloy in 10M NaOH solution at 60°C for 24 hours, and then dry it in air at 40°C for 24 hours.

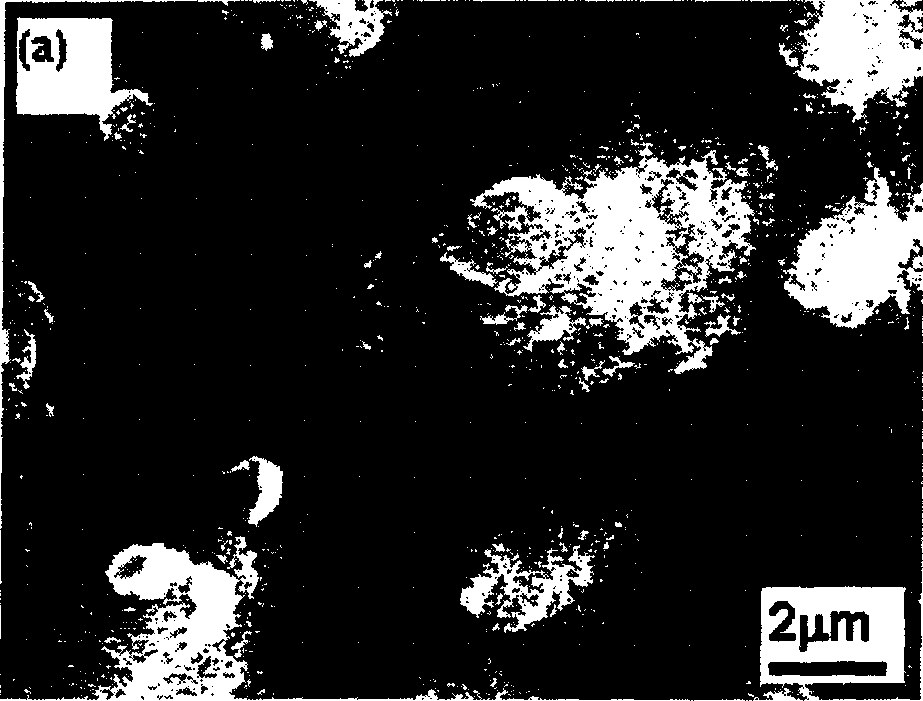

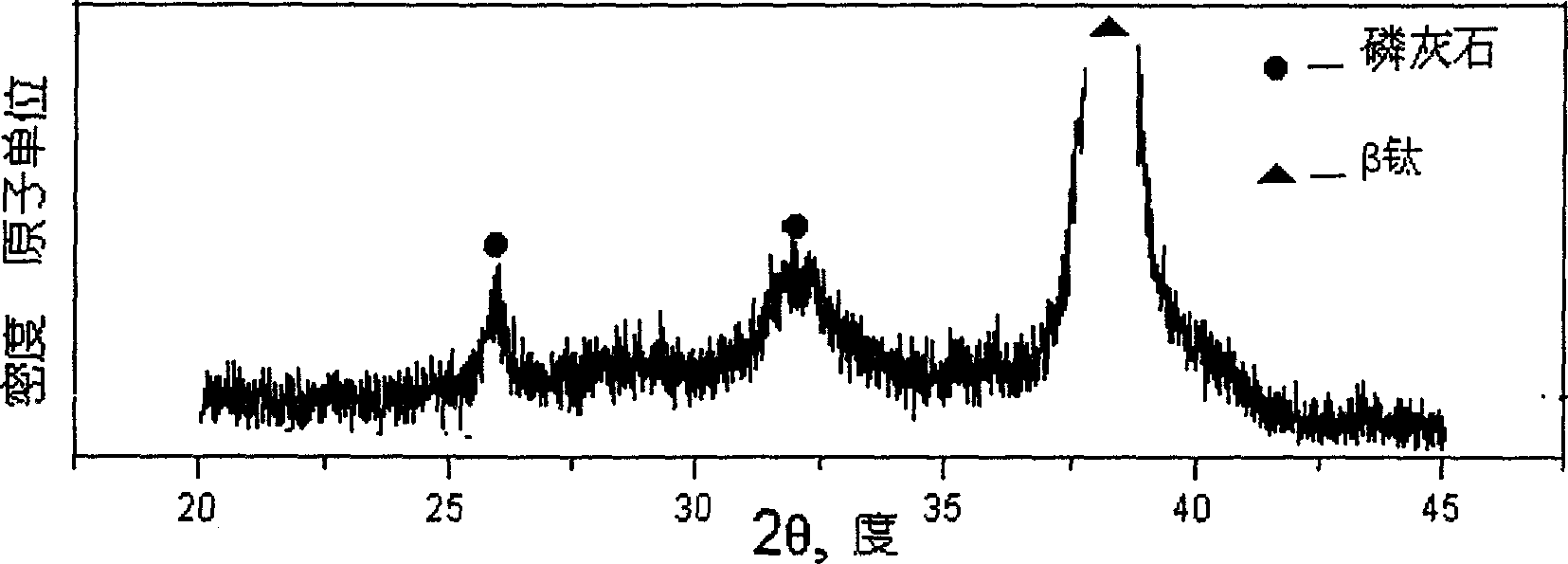

[0031] The oxidized and alkali-treated Ti-29Nb-13Ta-4.6Zr samples were immersed in SBF and FCS solutions for 4 weeks to obtain spherical hydroxyapatite coatings (see figure 1 ), the X-ray diffraction pattern of the spherical hydroxyapatite coating is shown in image 3 .

Embodiment 2

[0033] The Ti-29Nb-13Ta-4.6Zr sample was oxidized in air at 400°C for 24 hours, and then furnace cooled to room temperature. After this treatment, the surface hardness of the Ti-29Nb-13Ta-4.6Zr sample increased by about 300MPa (see Table 1), which is beneficial to the improvement of the alloy's wear resistance.

[0034] Soak the oxidized alloy in 10M NaOH solution at 60°C for 24 hours, and then dry it in air at 40°C for 24 hours.

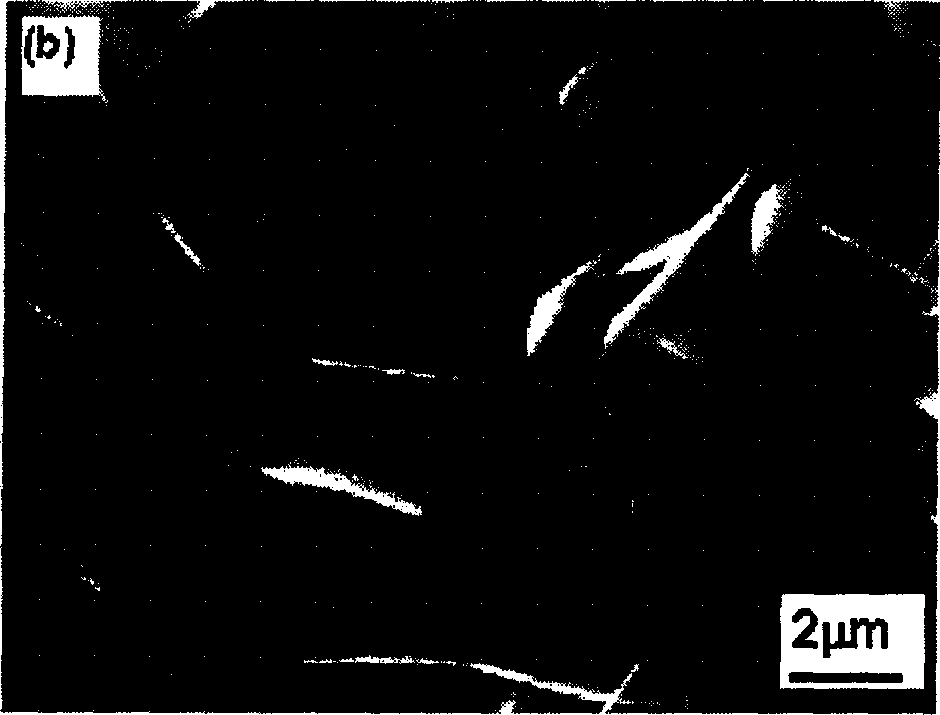

[0035] The oxidized and alkali-treated Ti-29Nb-13Ta-4.6Zr samples were immersed in SBF and FCS solutions for 4 weeks and 2 weeks, respectively, to obtain needle-shaped hydroxyapatite coatings (see figure 2), the X-ray diffraction pattern of needle-like hydroxyapatite coating is shown in Figure 4 .

[0036] Vickers Hardness (MPa)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com