Machining method for micro-miniature part with open hole

A processing method and micro-miniature technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of excessive size and position deviation, and difficult to remove burrs, so as to reduce the opening error and simplify the deburring steps. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

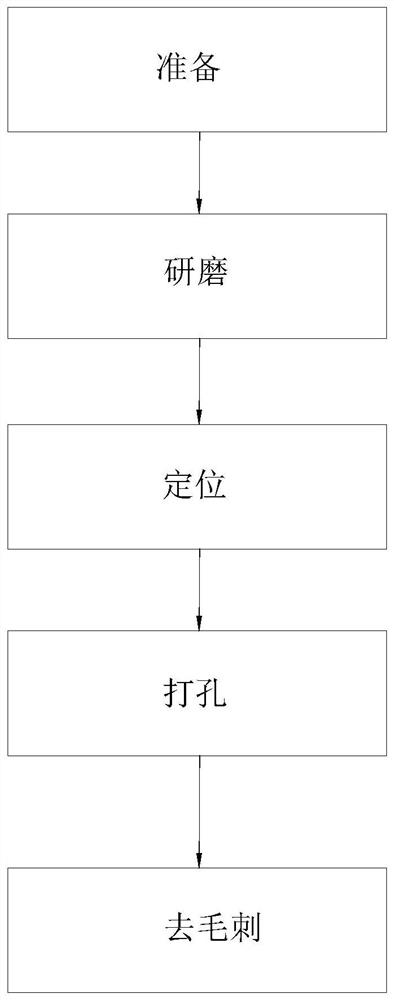

[0038] see Figure 4 , The method for processing micro-miniature parts with openings 21 provided in the first embodiment includes the following steps: preparation, grinding, positioning, drilling, deburring, regrinding, demagnetization and preparation for shipment.

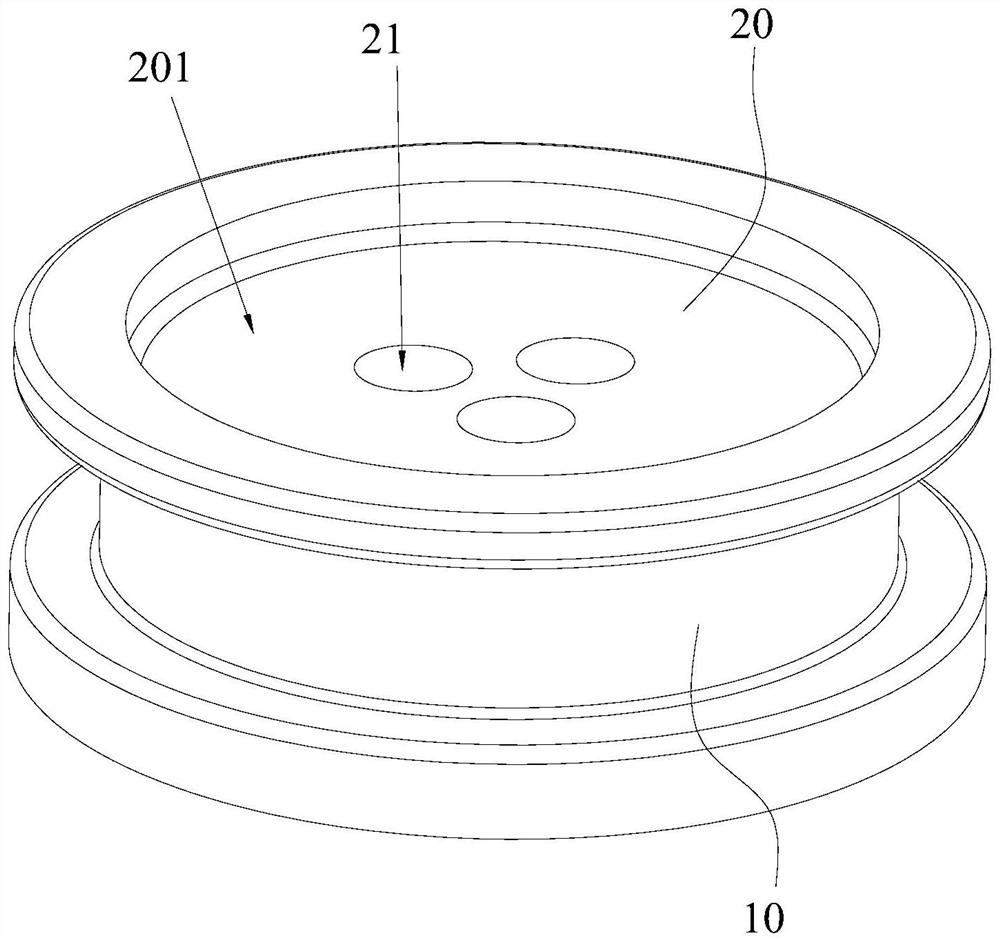

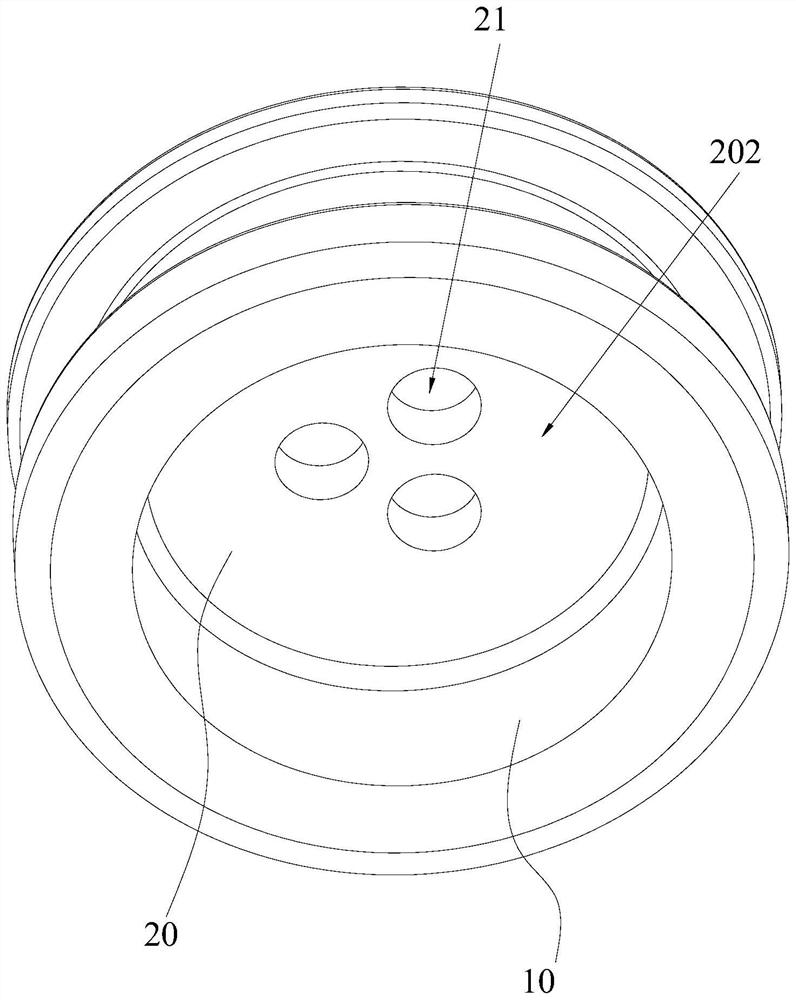

[0039] In the preparation step, the stainless steel material is first prepared, and the features of the product to be punched are turned by the CNC lathe. The product to be punched is made of stainless steel as a whole. part. Specifically, the cross-sectional outer diameter of the product to be punched in this embodiment is 3.35 mm, and the thickness is 1.225 mm. see figure 2 and image 3 , the product to be punched includes a cylinder 10 and a panel 20 sealed at one end of the cylinder 10, the other end of the cylinder 10 is open, the section of the cylinder 10 is circular, and the panel 20 is a circular shape that fits with the cylinder 10. The thickness of the panel 20 from the surface to be punched to the...

Embodiment 2

[0061] The second embodiment provides a method for processing micro-miniature components with openings 21. The difference between the second embodiment and the first embodiment is the deburring step. In the second embodiment, the deburring step includes: first The burrs are removed by blasting dry ice and then by sandblasting.

[0062] In the step of spraying dry ice for deburring, it is also carried out twice. The first time is to spray dry ice in the direction from the back side 202 to the grinding surface 201 to blow off part of the burrs and slag, and a small part of the burrs or slag may pass through The opening 21 is blown toward the grinding surface 201 , and the second time is to spray dry ice from the grinding surface 201 to the back surface 202 to blow off the scattered burrs or slag on the grinding surface 201 .

[0063]Since the dry ice on the panel 20 absorbs heat, water vapor will be generated on the panel 20. Therefore, the perforated product after spraying dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com