Manufacturing method for die

A manufacturing method and mold technology are applied in the field of mold manufacturing to achieve the effects of promoting crystallization and suppressing the generation of flash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] In Example 1, the following materials were used.

[0090] Crystalline resin: polyphenylene sulfide resin (PPS resin) (manufactured by Polyplastics Co., Ltd., "FORTRON 1140A64" T c2 : 225°C)

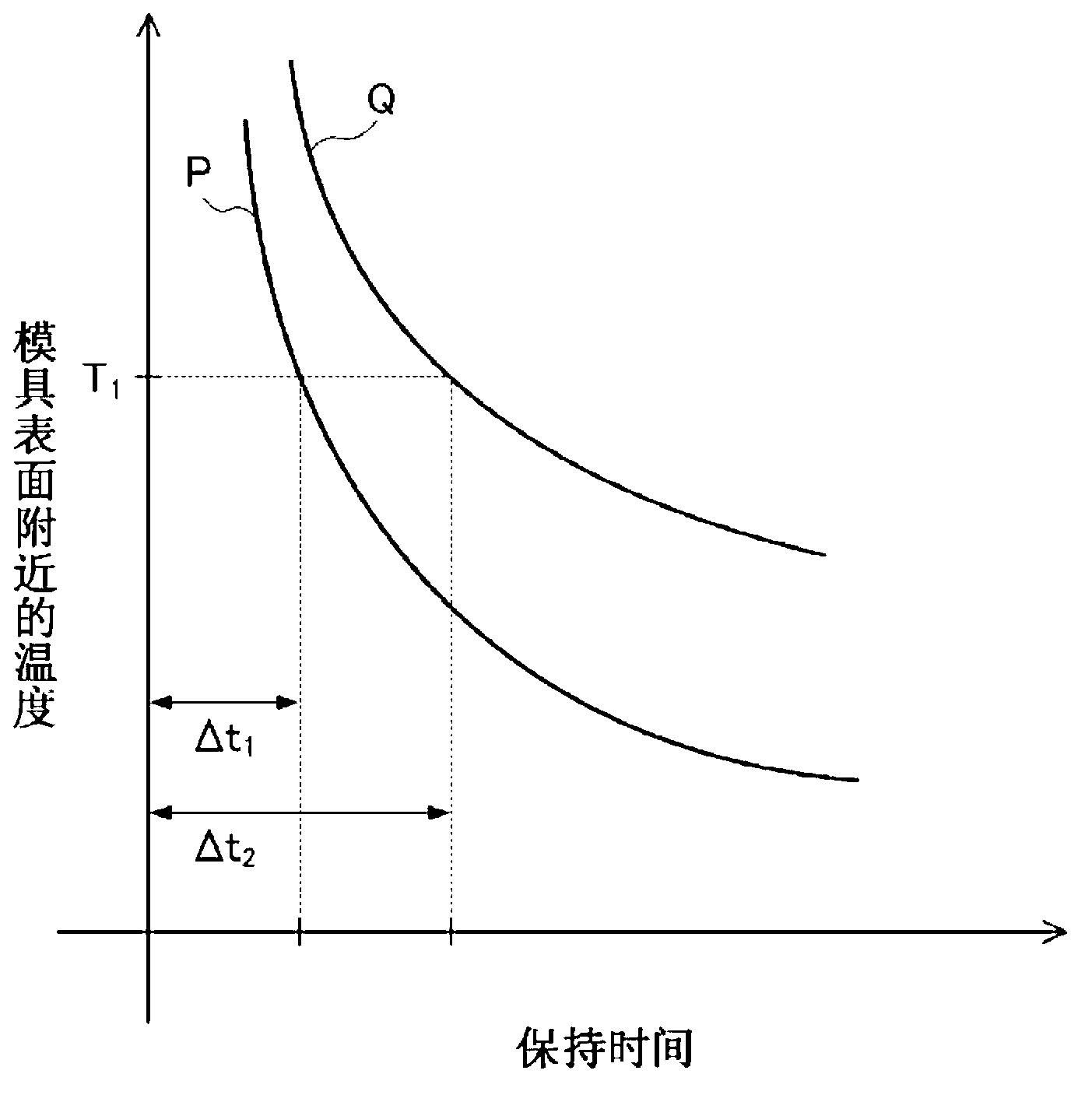

[0091] The relationship between the crystallization speed (LogK (K is the speed)) of the above-mentioned crystalline resin and the resin temperature (°C) is shown in Figure 4 . The temperature at which the crystallization rate is sufficiently fast is set to 150° C. or higher. In addition, the desired degree of crystallinity was set to 30%.

[0092] Heat insulation layer: polyimide resin (polyimide resin varnish (manufactured by Fine Chemical Japan Co., LTD.), spraying with a thermal conductivity of 0.2W / m·K, baking at 250°C for 1 hour, Then grind the polyimide side.)

[0093] T c2 Determination method: Using a differential scanning calorimeter (DSC7 manufactured by PerkinElmer), keep the thermoplastic resin at 340°C for 2 minutes in a nitrogen atmosphere, then lower the temp...

Embodiment 2

[0108] Changed insulation layer material from polyimide to silica (ceramic 1), L S = 2.5 mm or 5 mm, and in the same manner as in Example 1, the relationship between the temperature of the resin at a depth of 7 μm from the cavity surface and the retention time of the resin in the mold was derived. Table 4 shows the time during which the resin temperature was maintained at 150° C. or higher and the crystallinity on the side where the heat-shielding layer was formed under each molding condition. Among them, the molding conditions of the derived relational expressions are the mold temperature of 100°C, the heat insulation layer (ceramic 1) of 2.5mm, the mold temperature of 100°C, and the heat insulation layer (ceramic 1) of 5mm.

[0109] In addition, the specific gravity, specific heat, thermal conductivity, and thermal diffusivity of the ceramic 1 are as follows. The thermal conductivity was calculated by measuring the thermal diffusivity by the laser flash method. The specifi...

Embodiment 3

[0117] According to the above examples, it was confirmed that the degree of crystallinity can be adjusted to 30% or more by keeping the resin flowing into the mold at a temperature of 150° C. or higher for 0.1 second or longer.

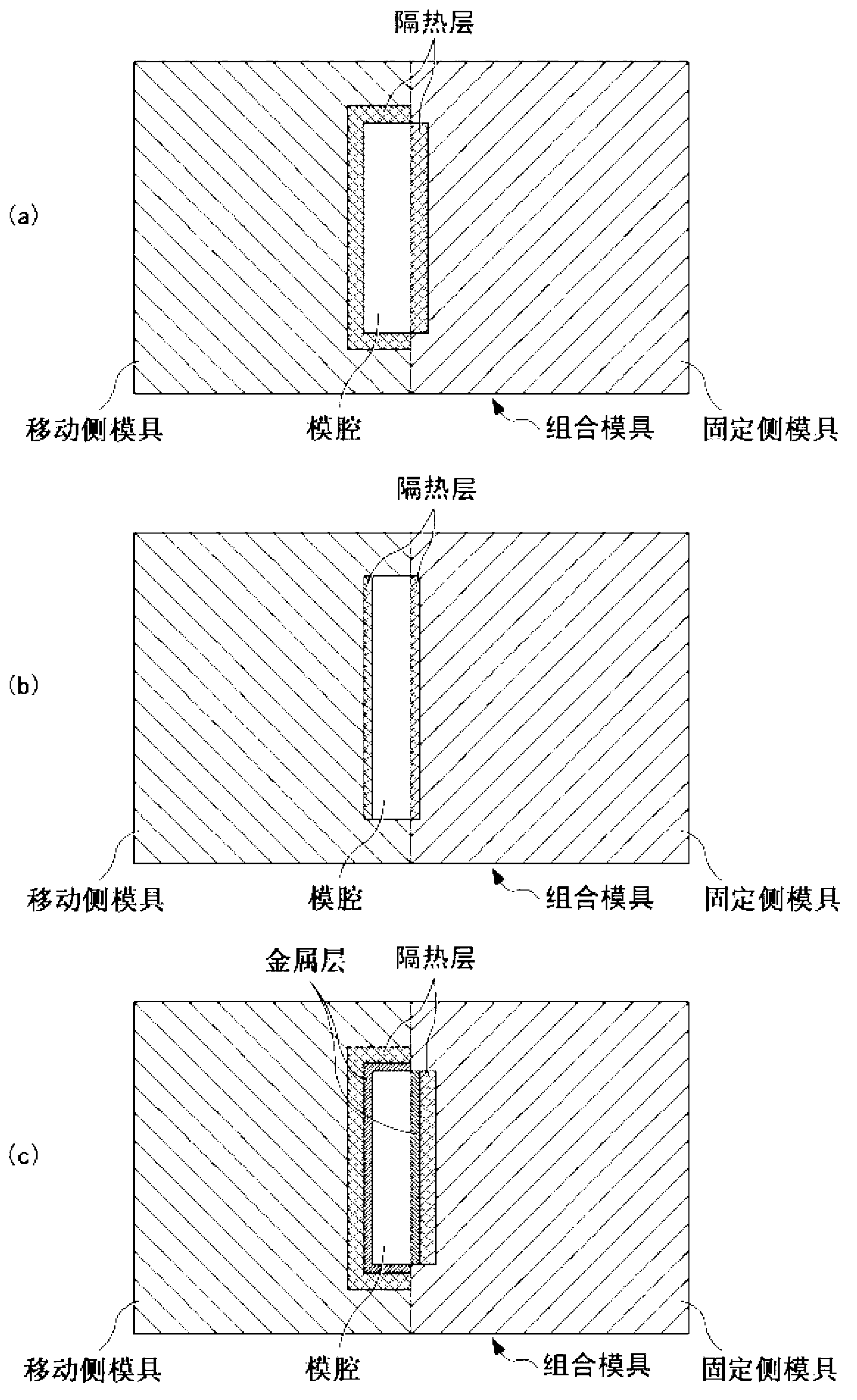

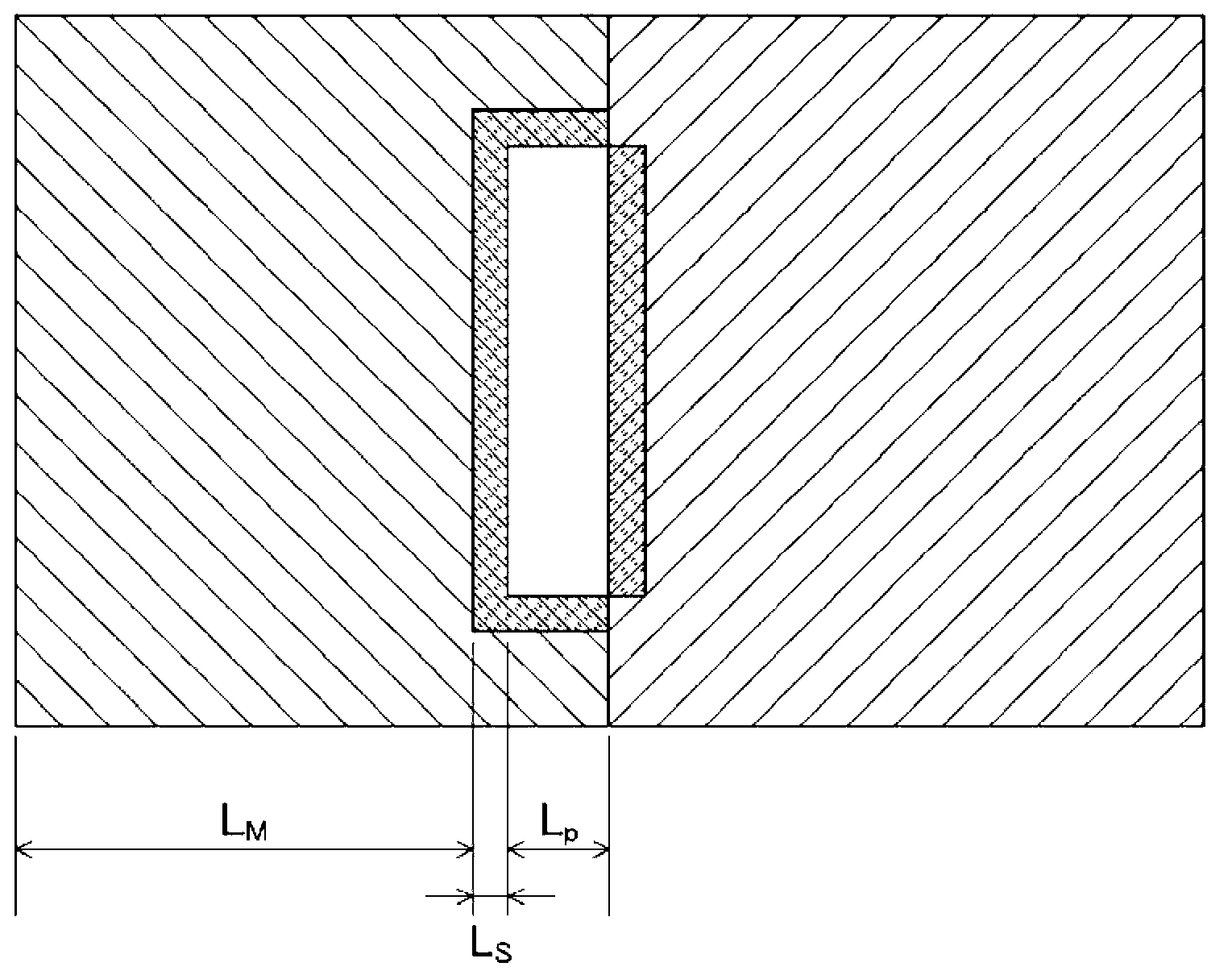

[0118] In Example 3, the thermal insulation layer was changed to a porous zirconia layer (ceramic 2) sprayed with zirconia peroxide, and it was derived using Therm1 (one-dimensional thermal conductivity analysis software). In this case, the resin flowing into the mold was kept at 150°C The thickness of the insulation layer above the state 0.1 second or more. In addition, as in Example 1, the mold is assumed to be Figure 5 Die shown. That is, L M =10mm, L P =0.7mm. The specific gravity, specific heat, thermal conductivity, and thermal diffusivity of the materials constituting the mold and the resin used the values shown in Table 5 below.

[0119] table 5

[0120]

[0121]Using Therm1 (one-dimensional thermal conductivity analysis software...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal diffusivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com