Pump body die casting welding method

A welding method and die-casting technology, which are applied to pump components, variable displacement pump parts, and parts of pumping devices for elastic fluids, etc., which can solve the problems of easy formation of pores in the pump body, many surface burrs, and insufficient smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

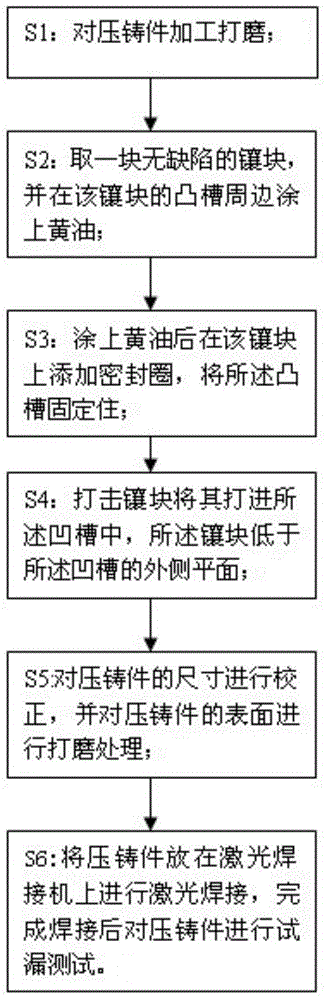

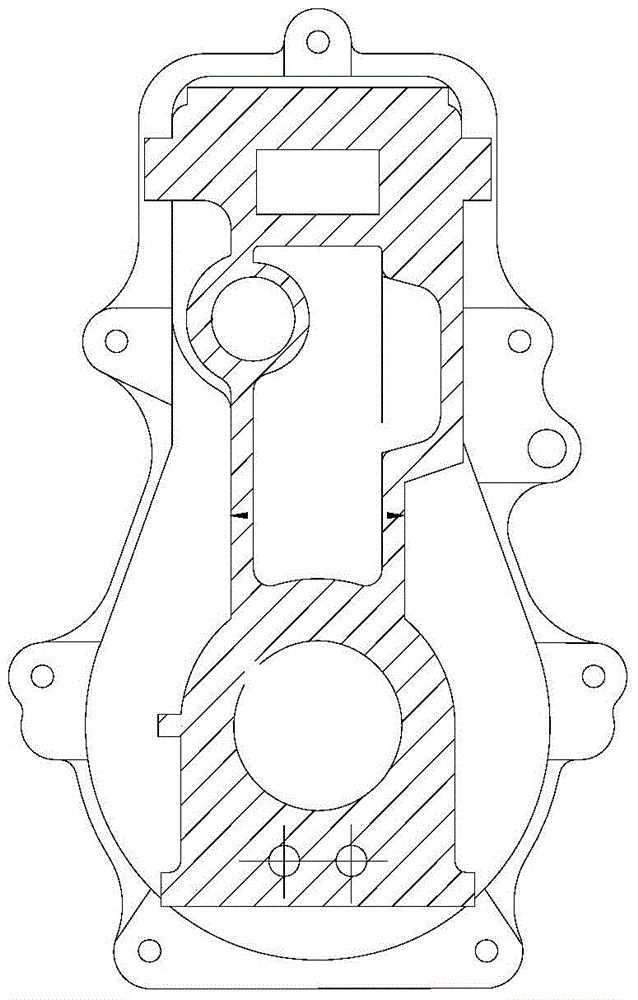

[0023] This embodiment provides a method for welding pump body die castings, such as figure 1 As shown, it includes the following steps:

[0024] S1: Process and polish the die-casting parts until there are no burrs, dies, fleshy and missing meat in the groove of the die-casting parts;

[0025] S2: Take a non-defective insert, and apply butter around the convex groove of the insert;

[0026] S3: Add a sealing ring to the insert after applying butter to fix the convex groove;

[0027] S4: hit the insert to drive it into the groove, the insert is lower than the outer plane of the groove;

[0028] S5: Correct the size of the die casting, and polish the surface of the die casting;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com