Patents

Literature

102 results about "Wedge bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wedge bonding is a kind of wire bonding which relies on the application of ultrasonic power and force to form bonds. It is a popular method and is commonly used in the semiconductor industry.

Wire bonding method

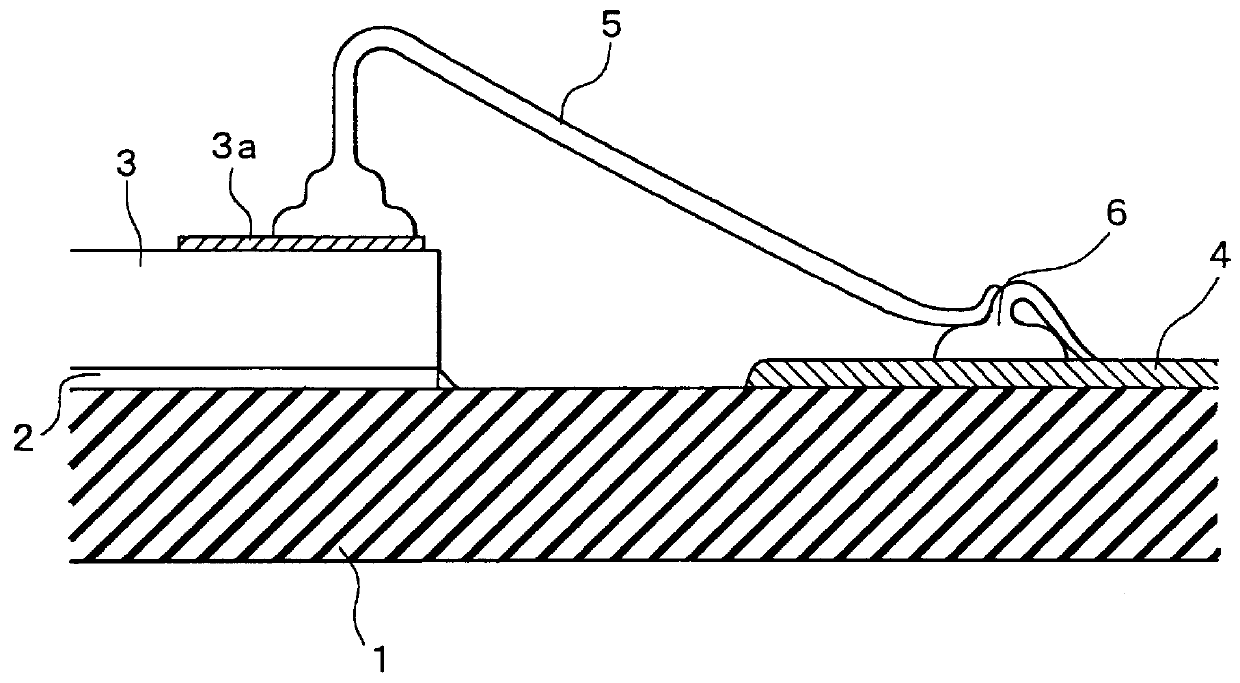

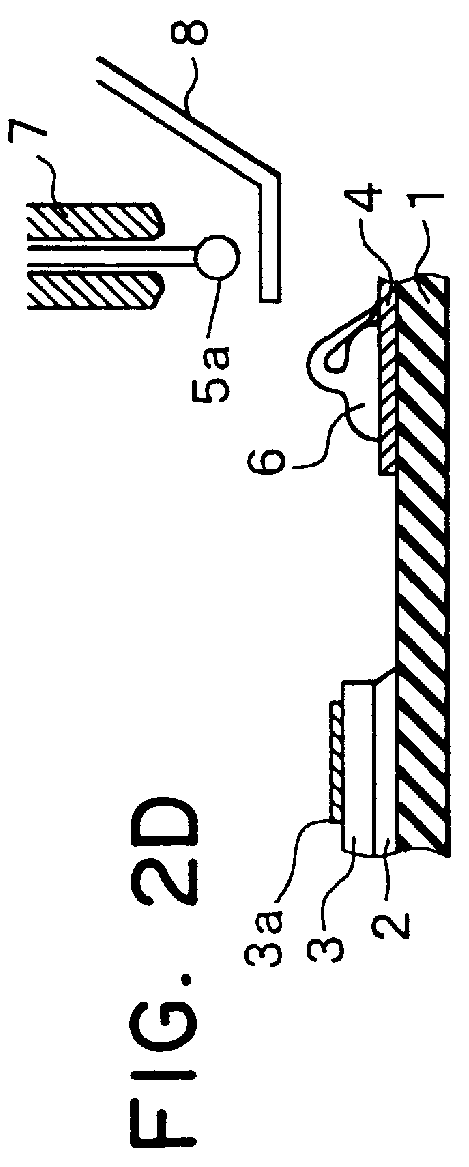

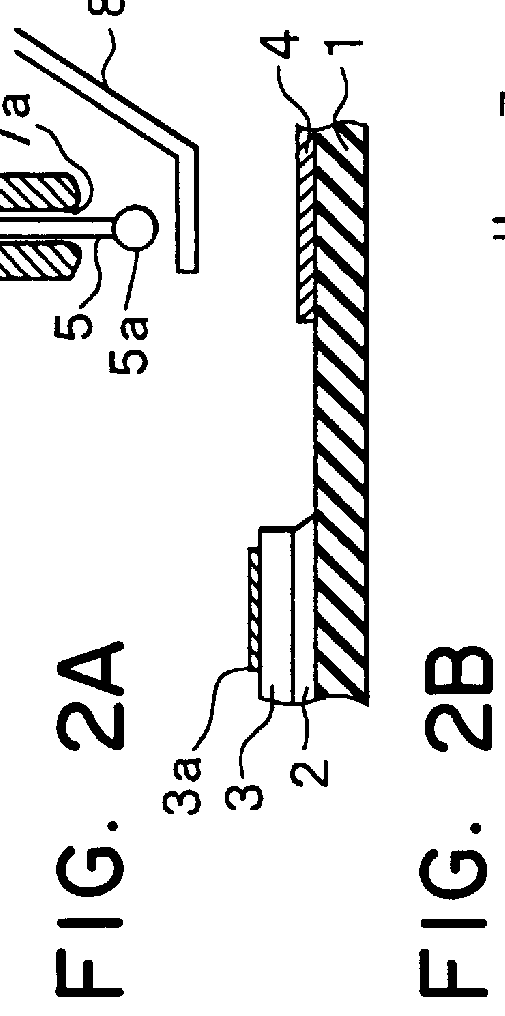

A ball is formed at the tip of a wire projecting from a capillary. The capillary is positioned above an interconnection, and ball bonding forms a bump on the interconnection. The capillary is then moved next to the bump and wedge bonding is carried out. Next, the capillary is moved upward and another ball is formed at the tip of the wire, and the wire is primary bonded to a bonding pad of a semiconductor chip. The wire is then looped and the capillary is positioned above the bump, and secondary bonding is carried out. As a result, the formation of tails on the bump is prevented.

Owner:DENSO CORP

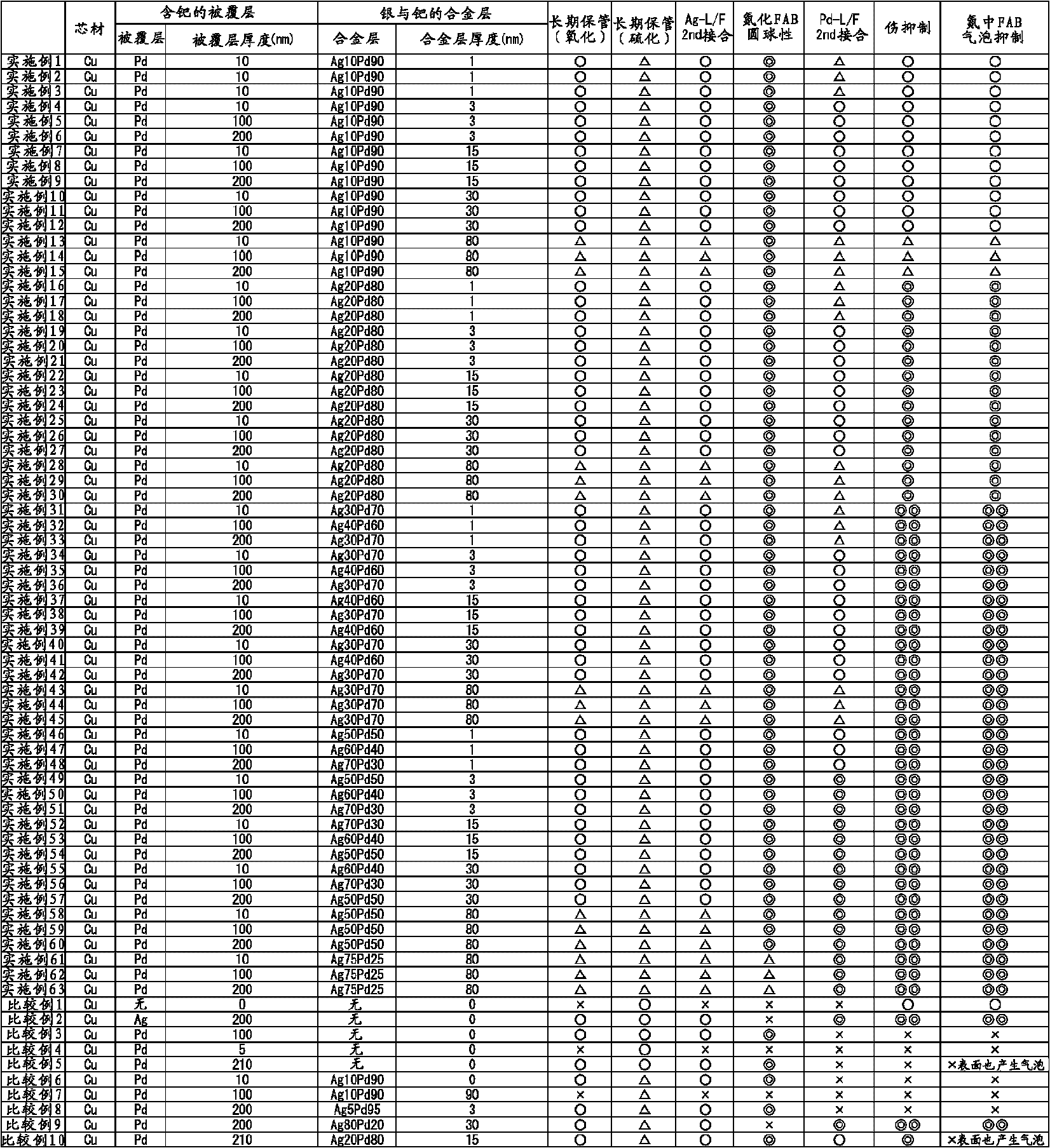

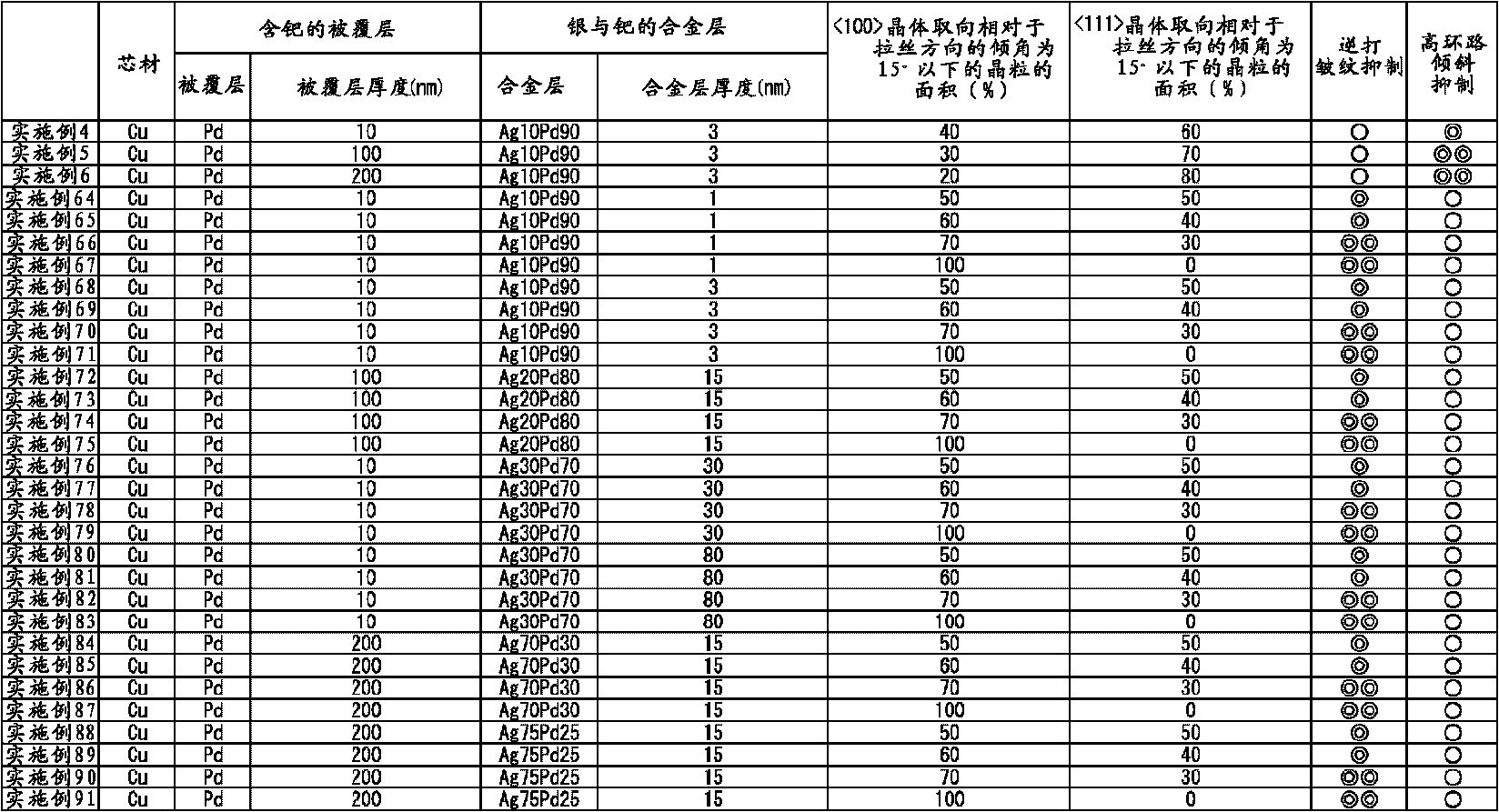

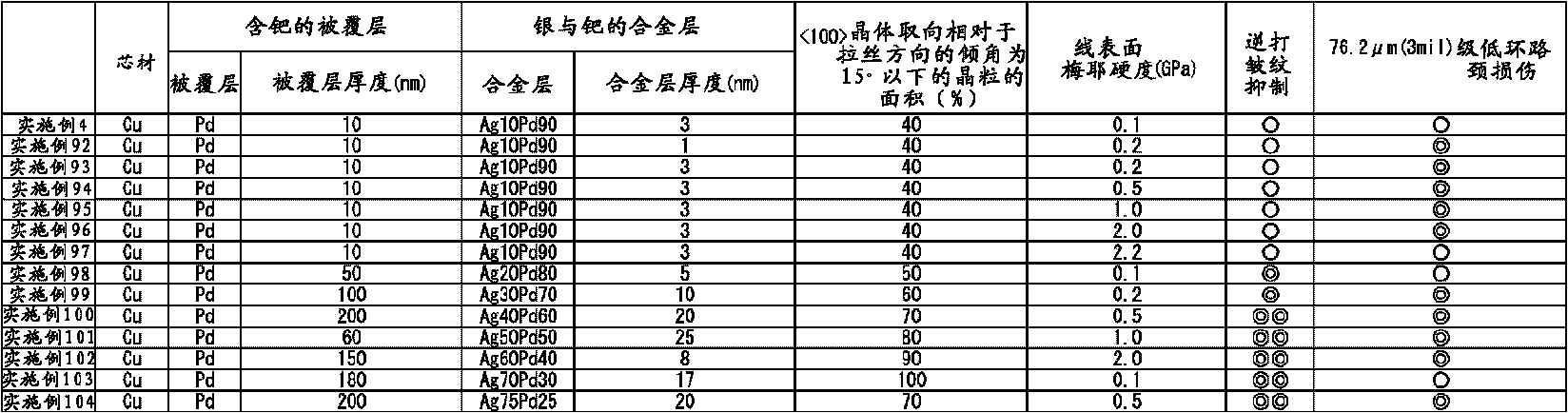

Bonding wire for semiconductor

ActiveCN102422404AImprove oxidation resistanceGood wedge jointSolid-state devicesSemiconductor/solid-state device manufacturingLead framePalladium

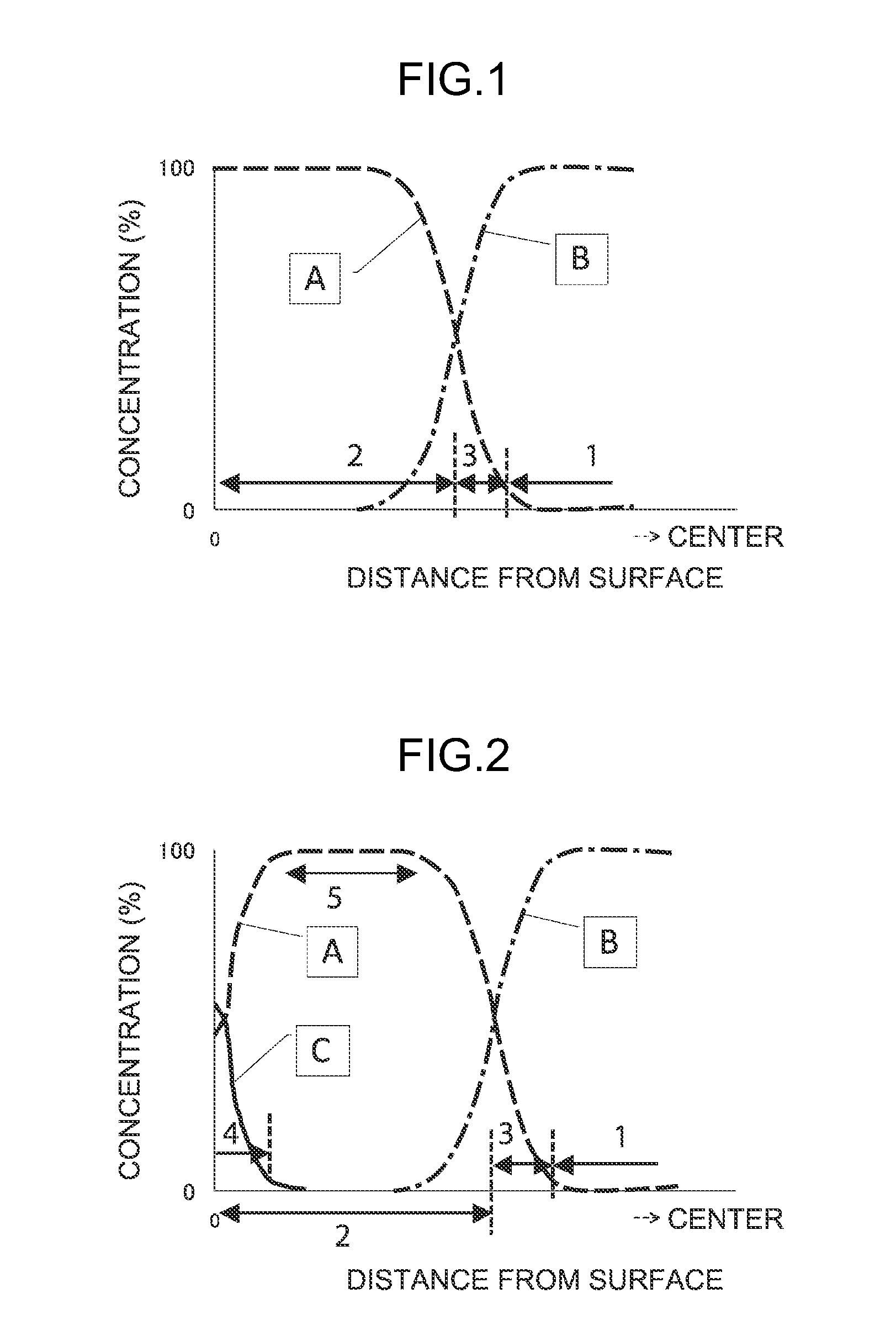

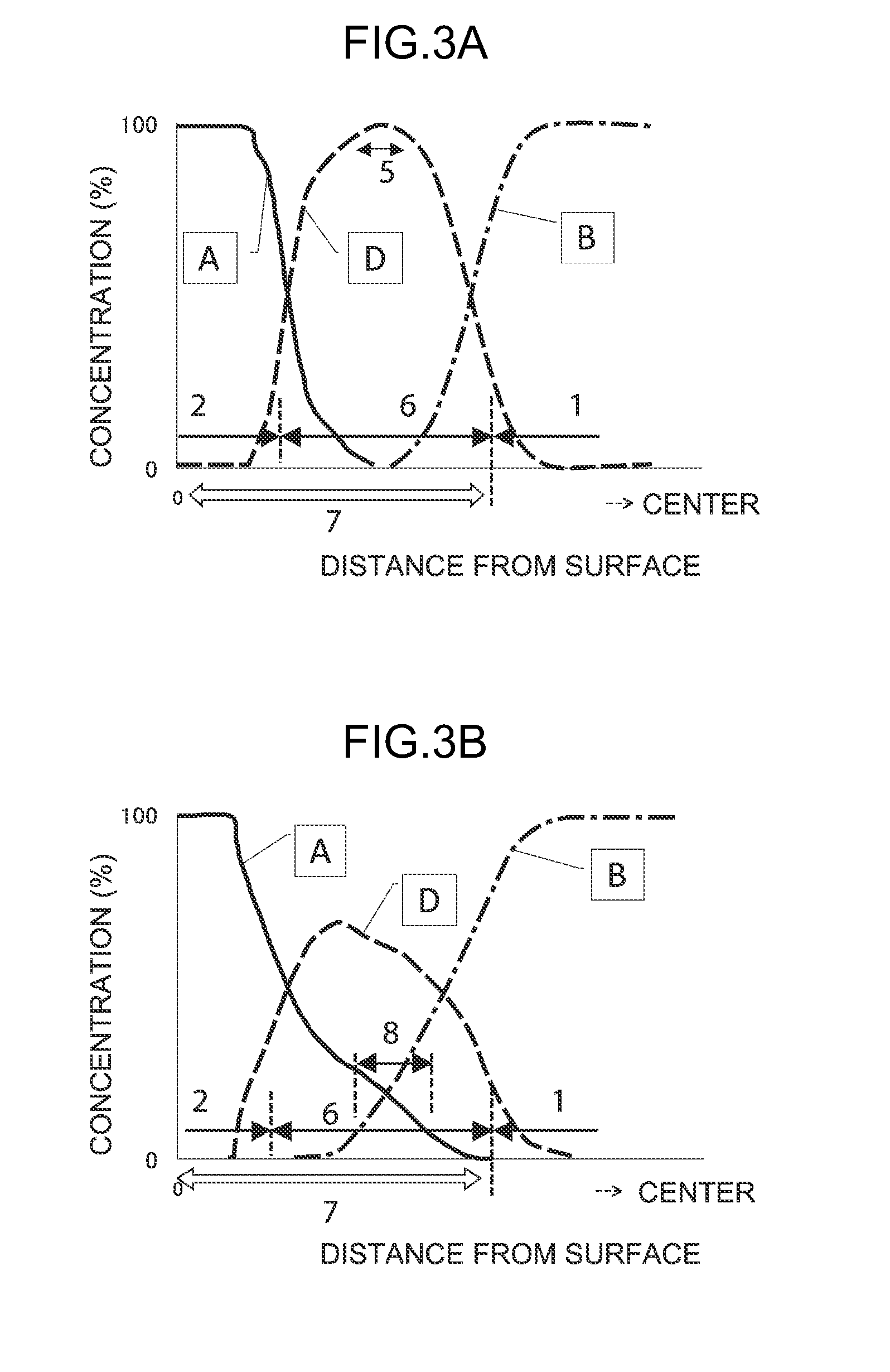

Disclosed is a bonding wire for semiconductor, which ensures good wedge bonding even of palladium-plated lead frames and has excellent oxidation resistance, and in which copper or a copper alloy is used as a core wire. The bonding wire is characterized by comprising a core wire that comprises copper or a copper alloy, a coating layer that is arranged on the surface of the core wire, has a thickness of 10 to 200 nm and contains palladium, and an alloy layer that is arranged on the surface of the coating layer, has a thickness of 1 to 80 nm and contains a noble metal and palladium, wherein the noble metal is silver or gold, and the noble metal is contained in the alloy layer at a concentration of 10 to 75 vol% inclusive.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD +1

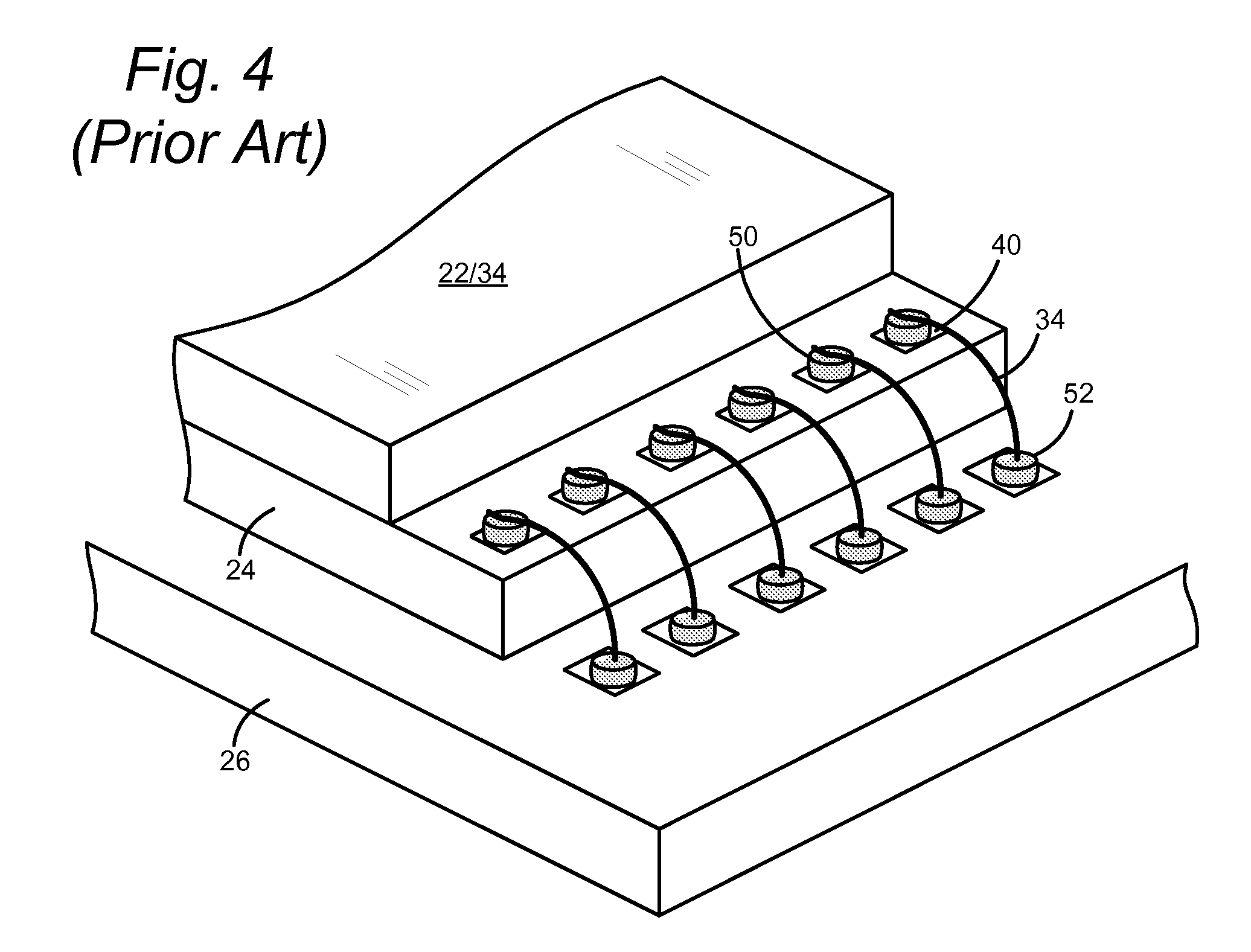

Semiconductor package and package stack made thereof

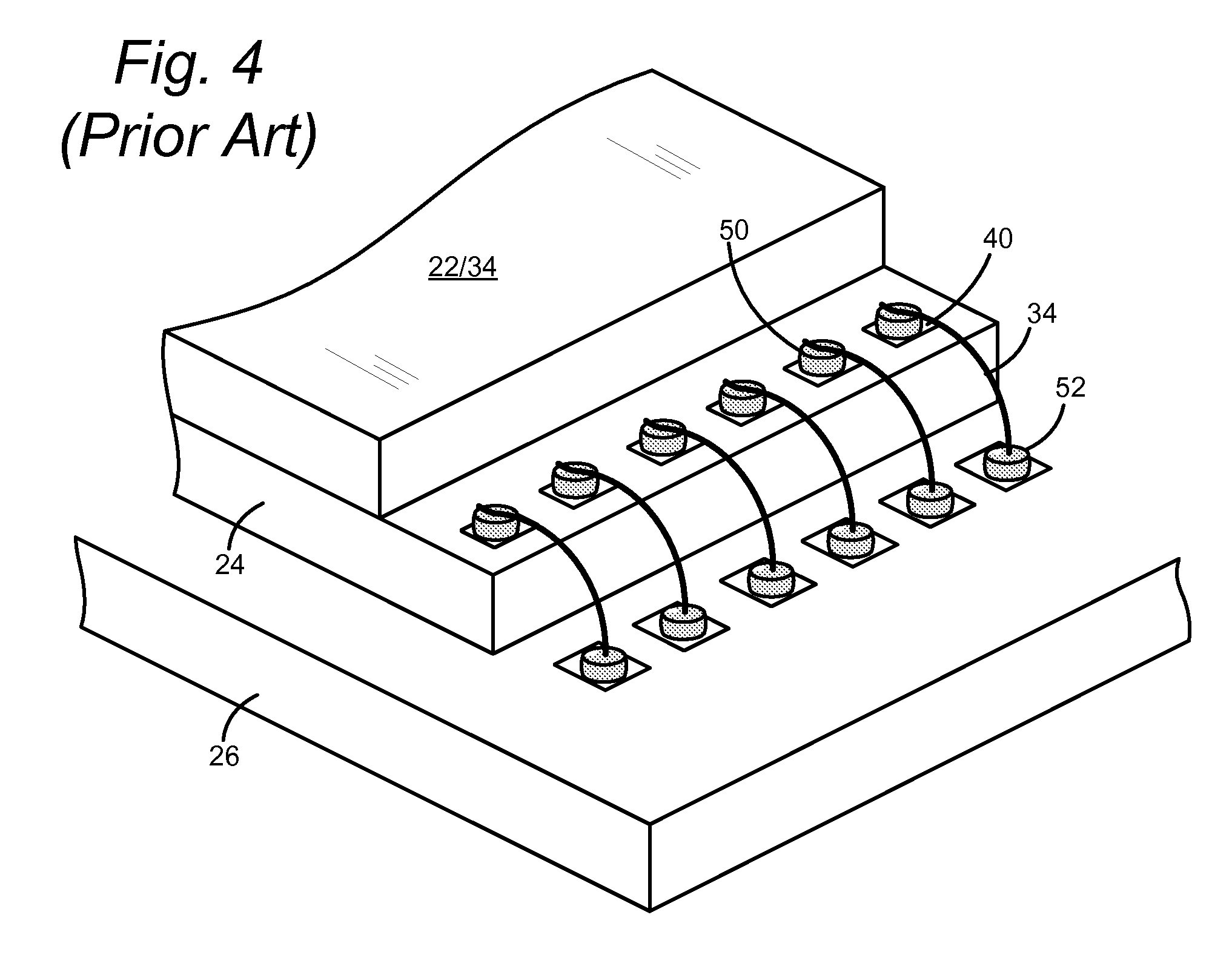

InactiveUS6812567B2Semiconductor/solid-state device detailsSolid-state devicesContact padDistribution pattern

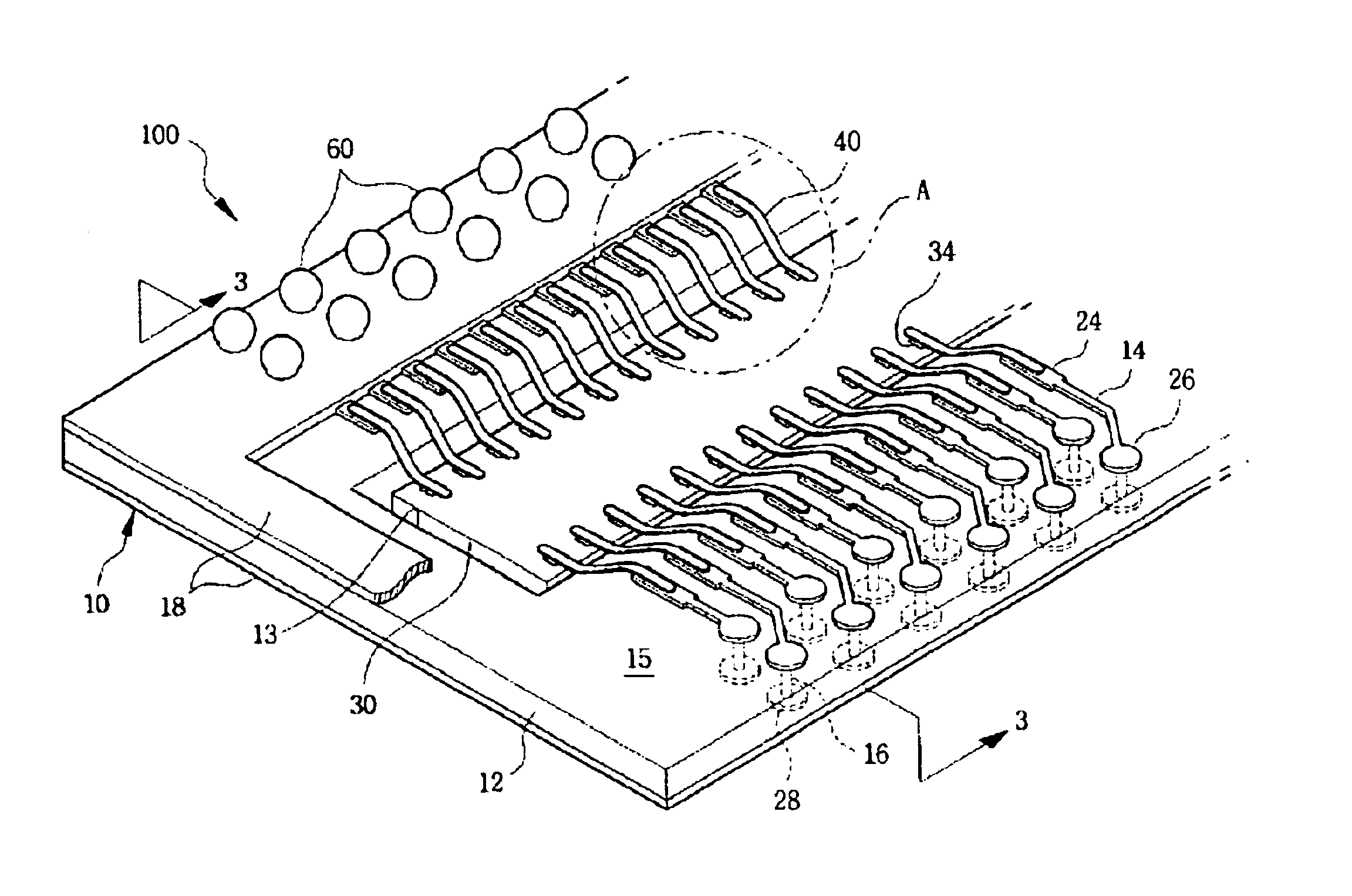

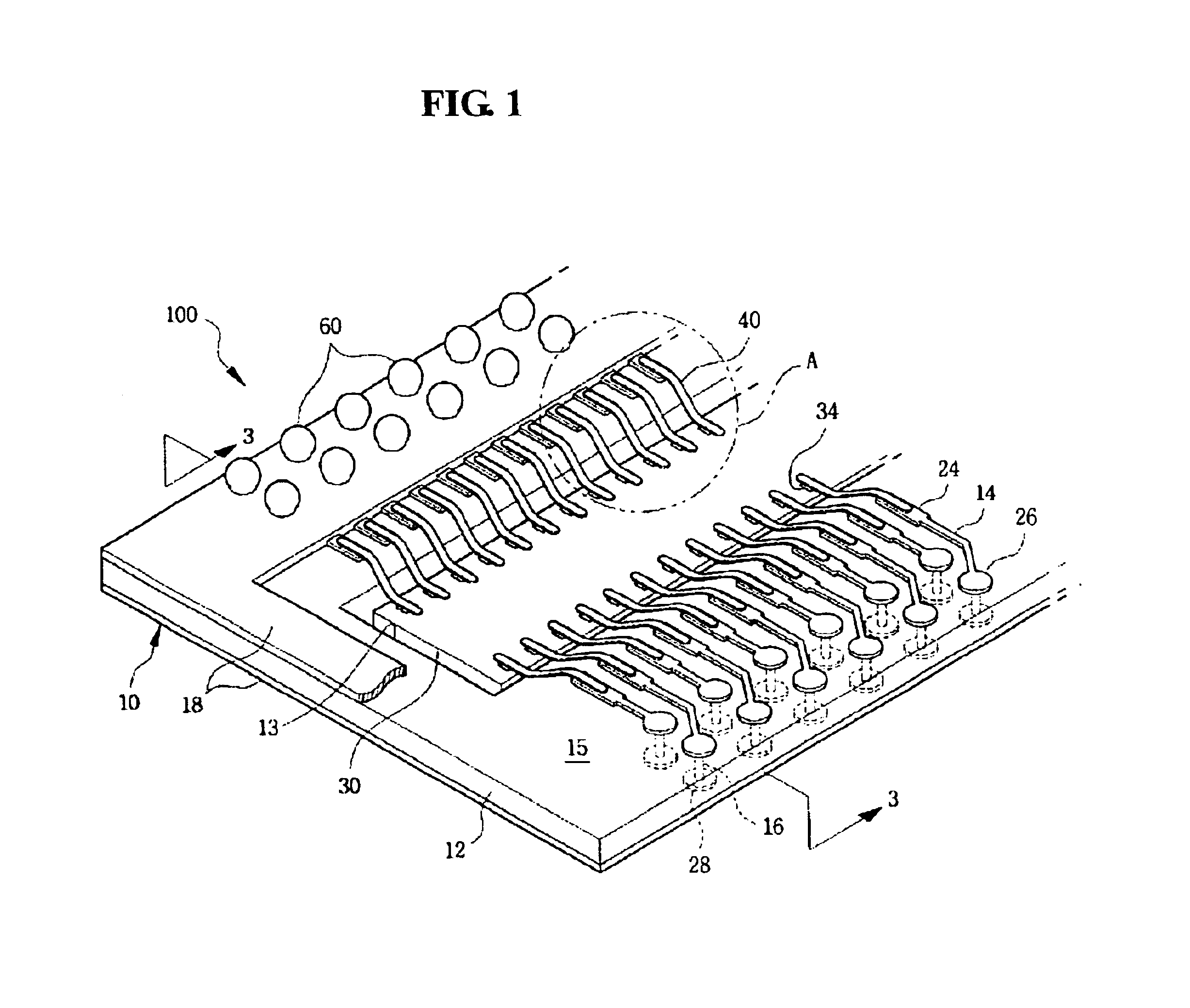

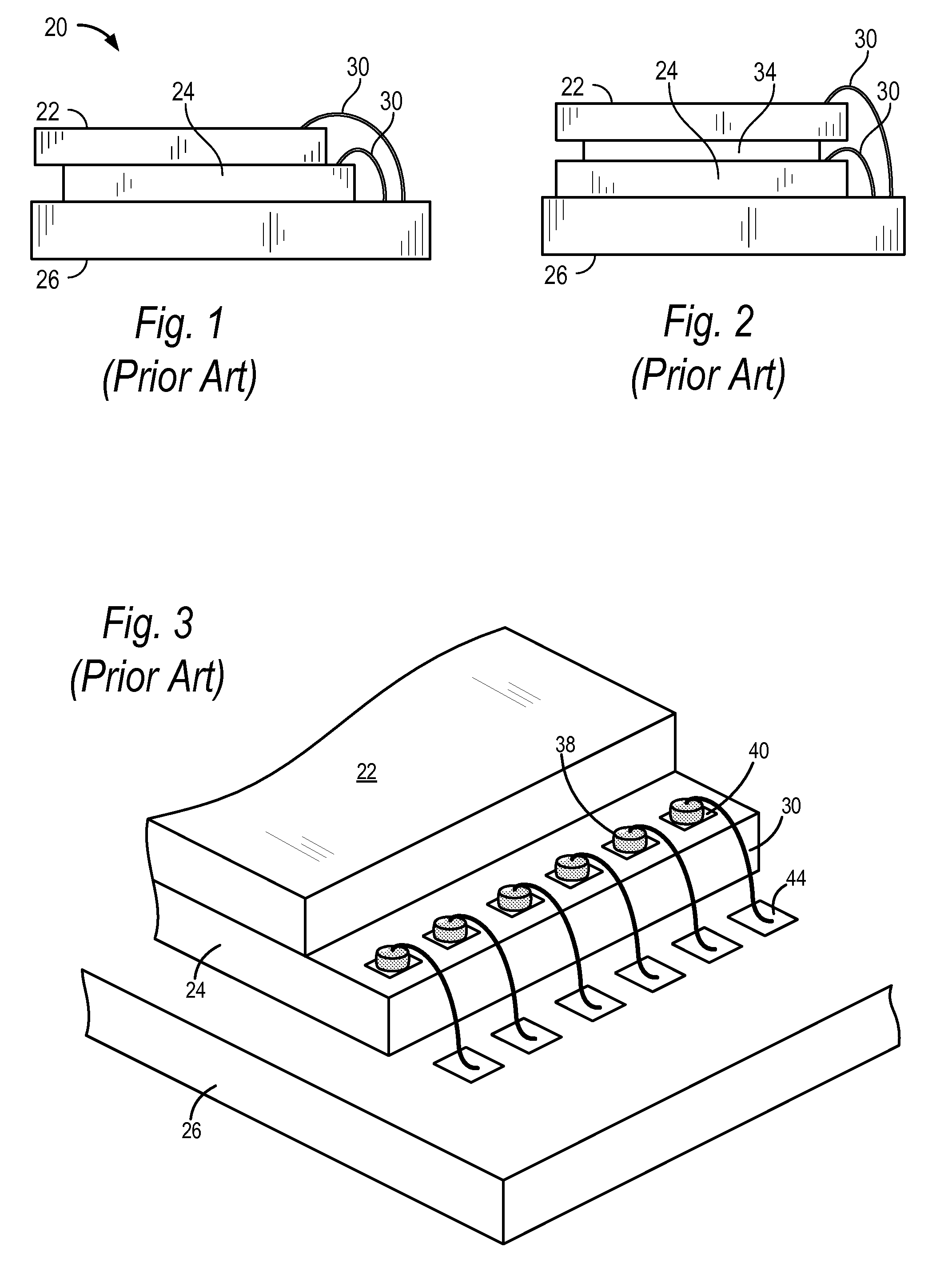

A semiconductor package comprises a board, a plurality of solder bump pads, a plurality of board pads, a plurality of distribution patterns, a plurality of contact pads, at least one chip, a plurality of bonding wire, an encapsulation part and a plurality of solder bumps. In order to reduce the height of the loop of the bonding wires for connecting the bonding pad on the semiconductor chip to the board pads on the board, the ends of the bonding wires are connected to the bonding pads and board pads respectively by wedge bonding. Thus, a very thin package can be obtained. In addition, a thin package stack can be obtained by stacking the very thin packages.

Owner:SAMSUNG ELECTRONICS CO LTD

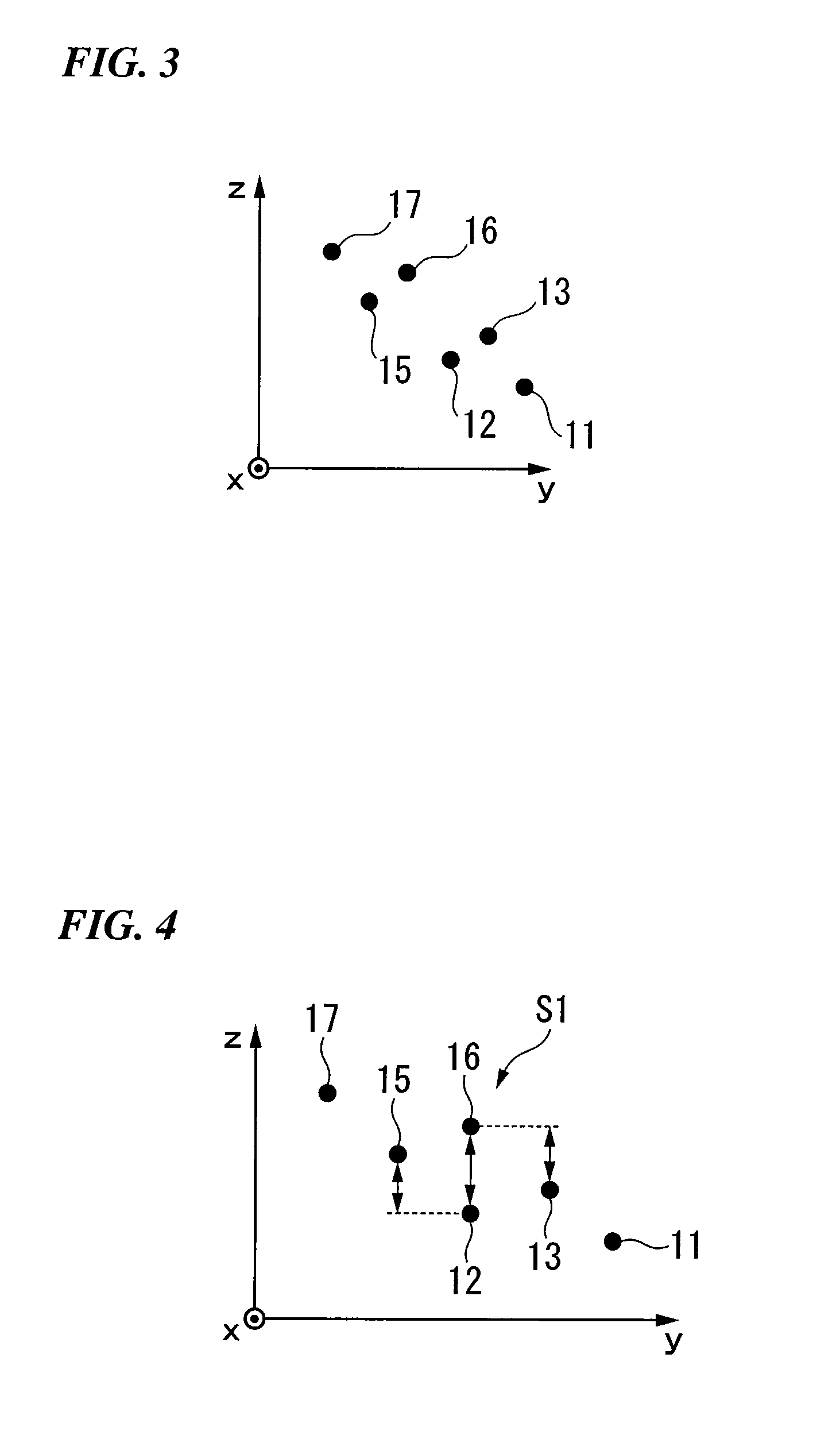

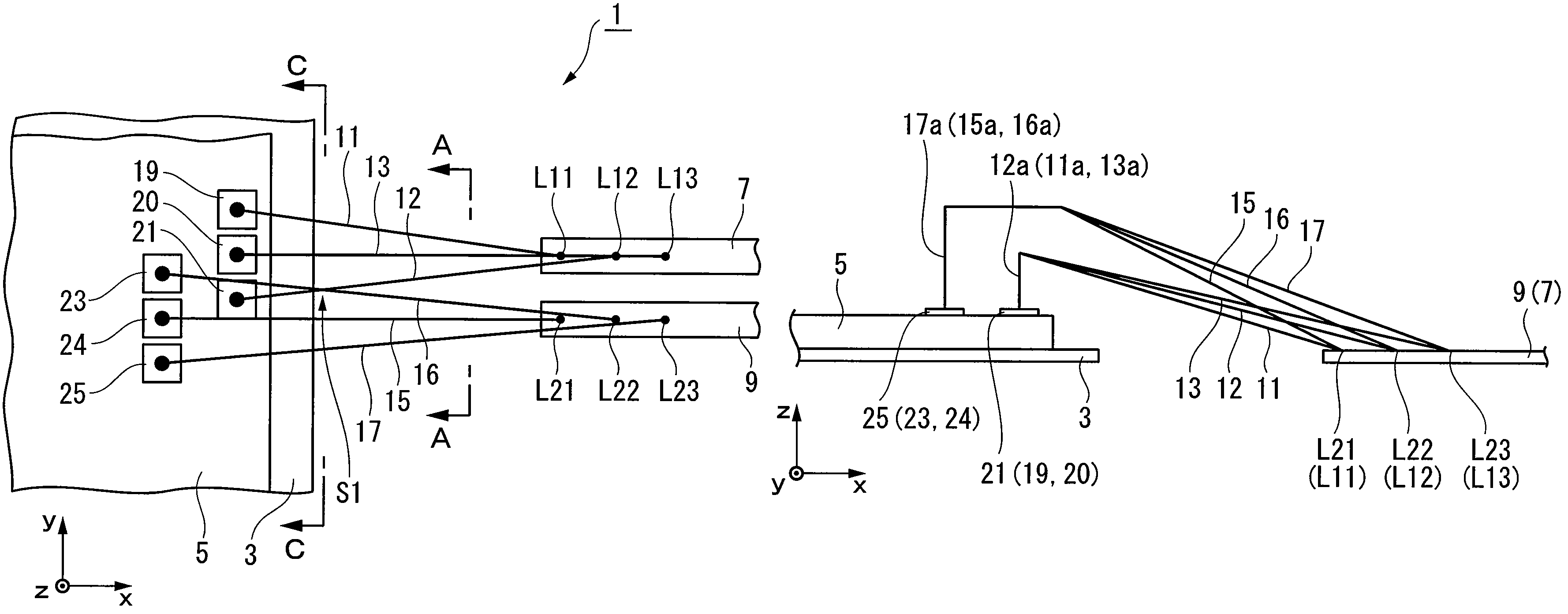

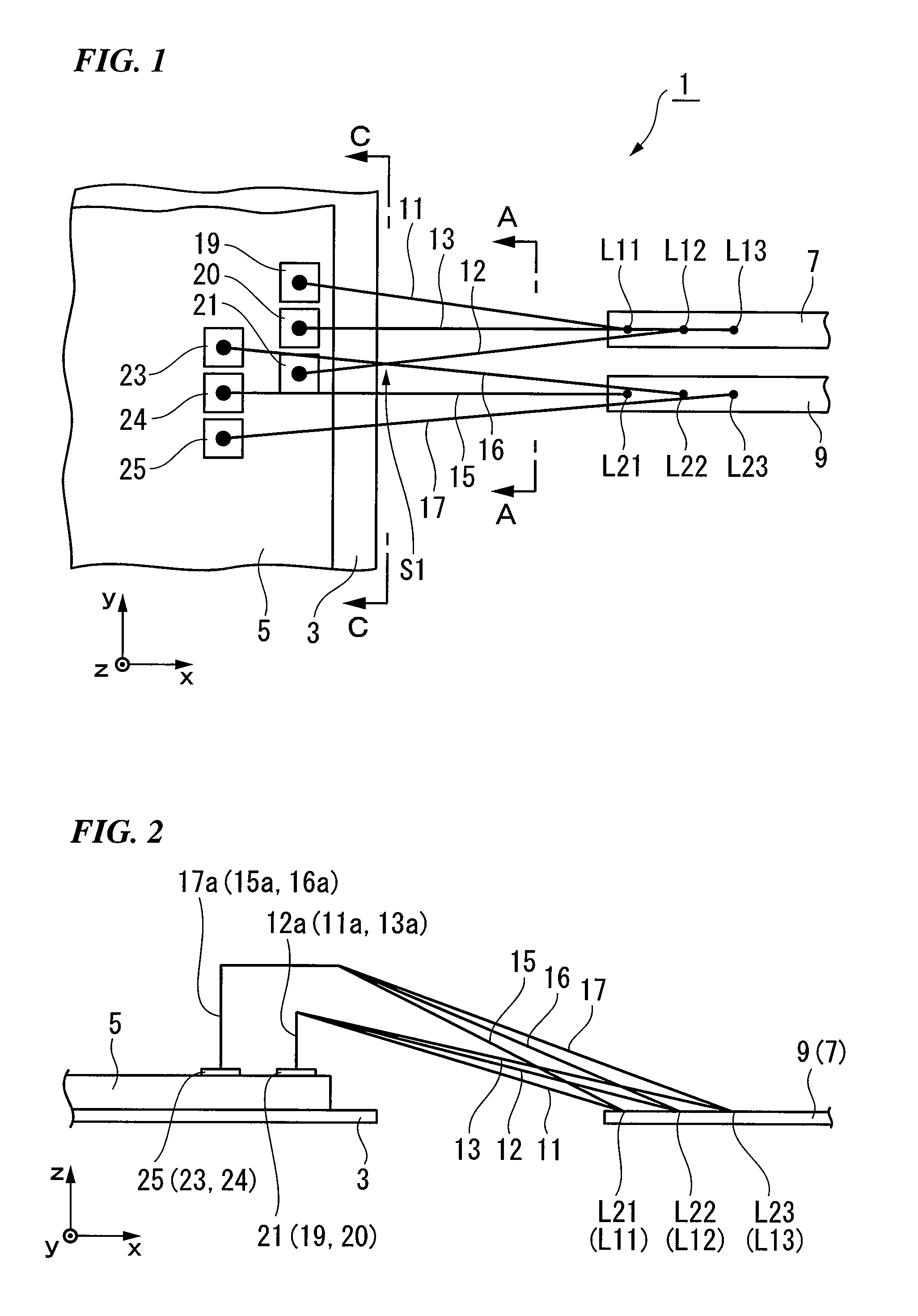

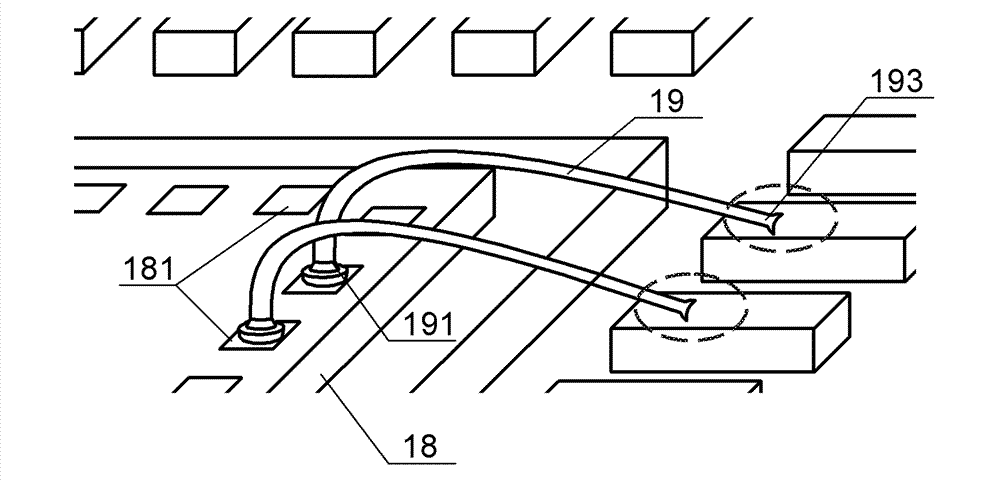

Semiconductor device and wire bonding method therefor

InactiveUS20080088012A1Reliably prevent electric short-circuiting from occurringSmall sizeSemiconductor/solid-state device detailsSolid-state devicesDevice materialLead bonding

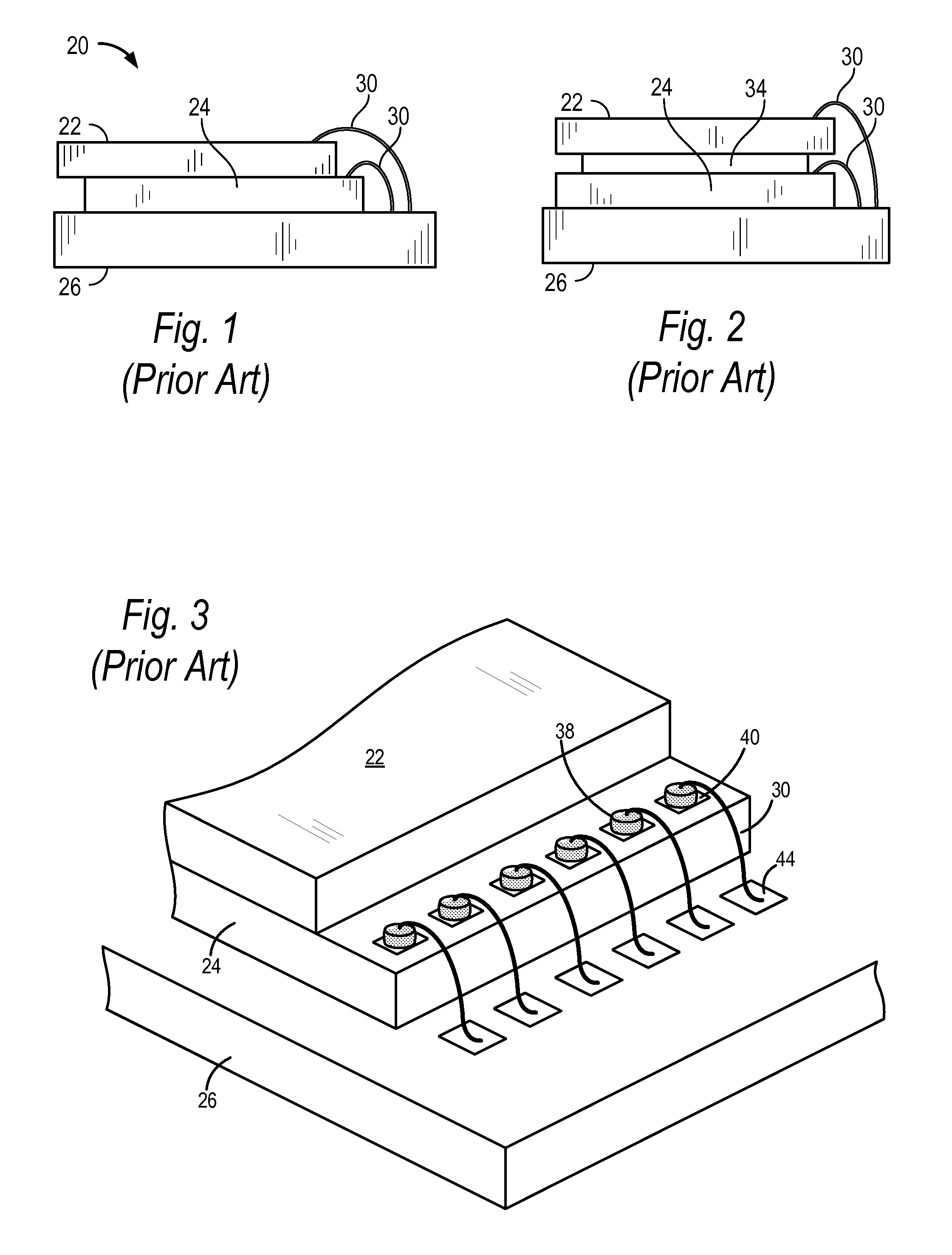

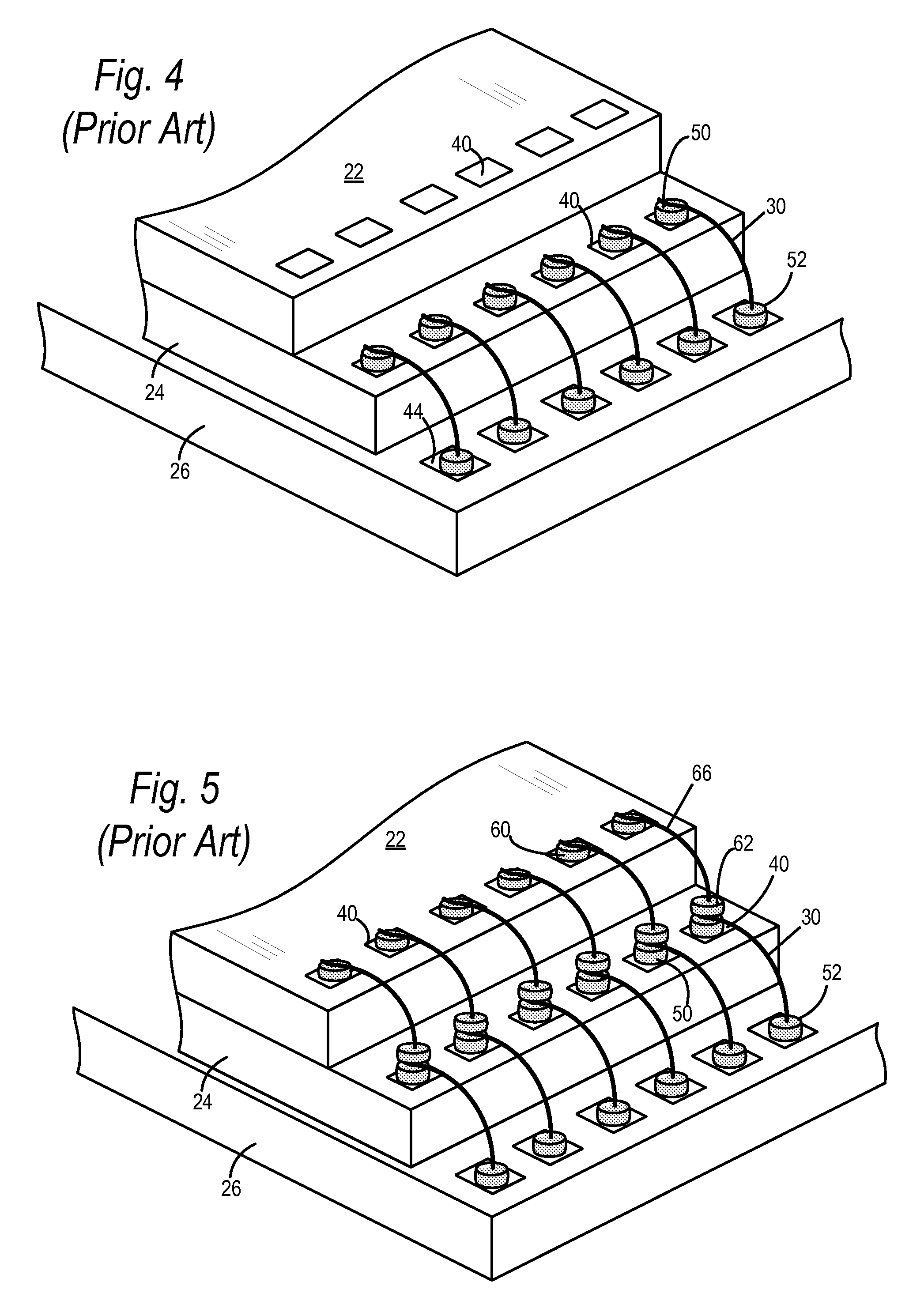

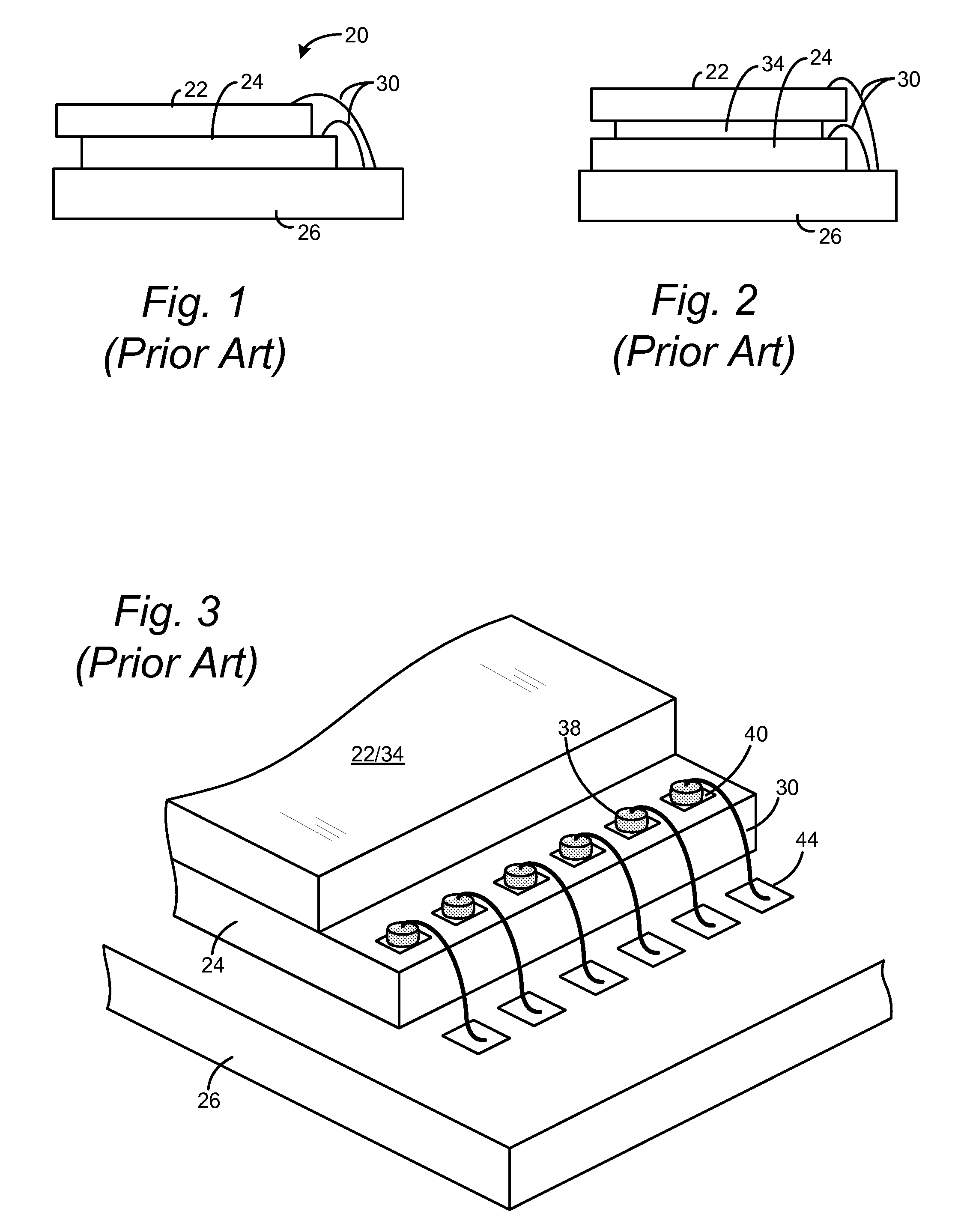

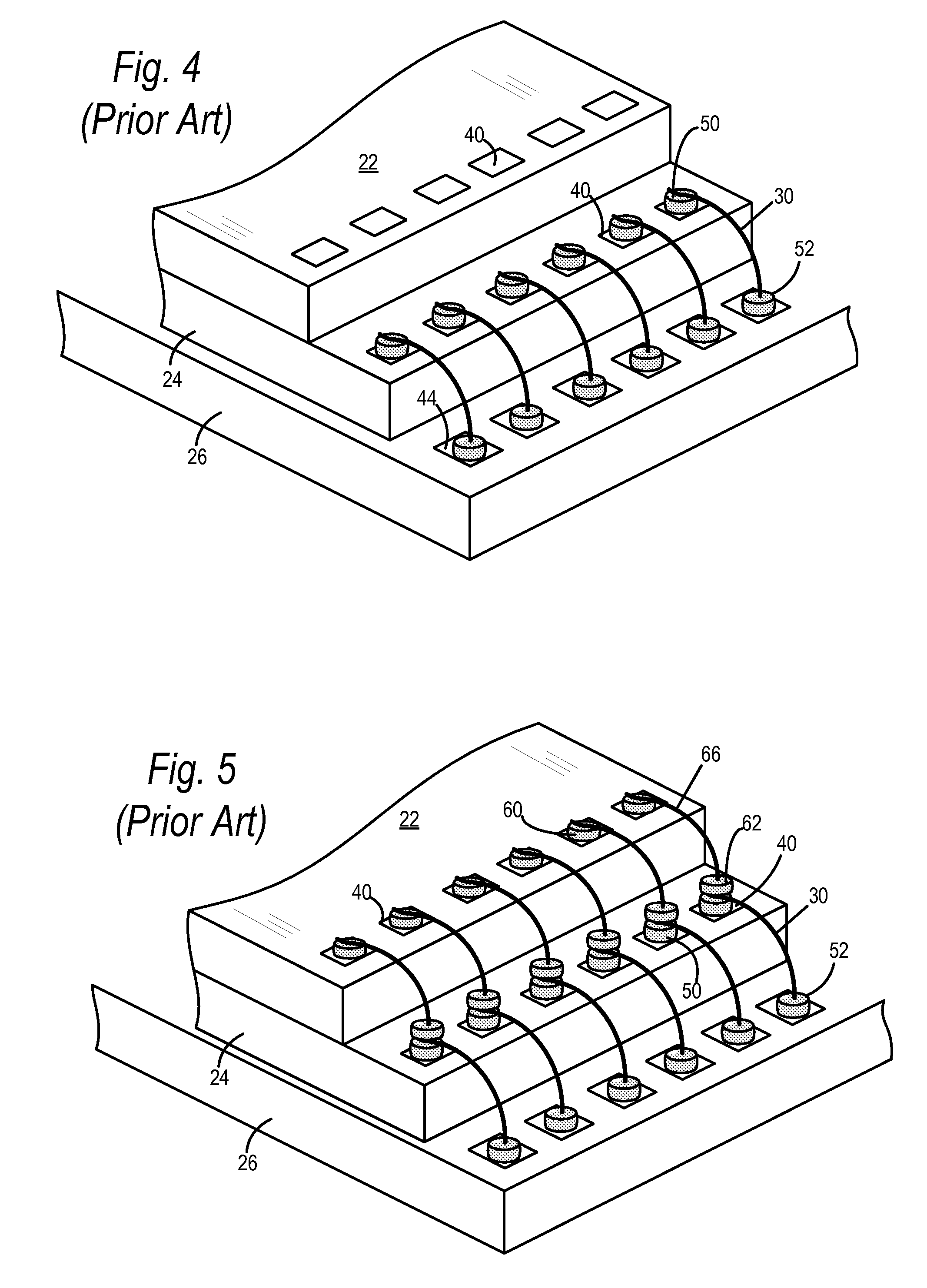

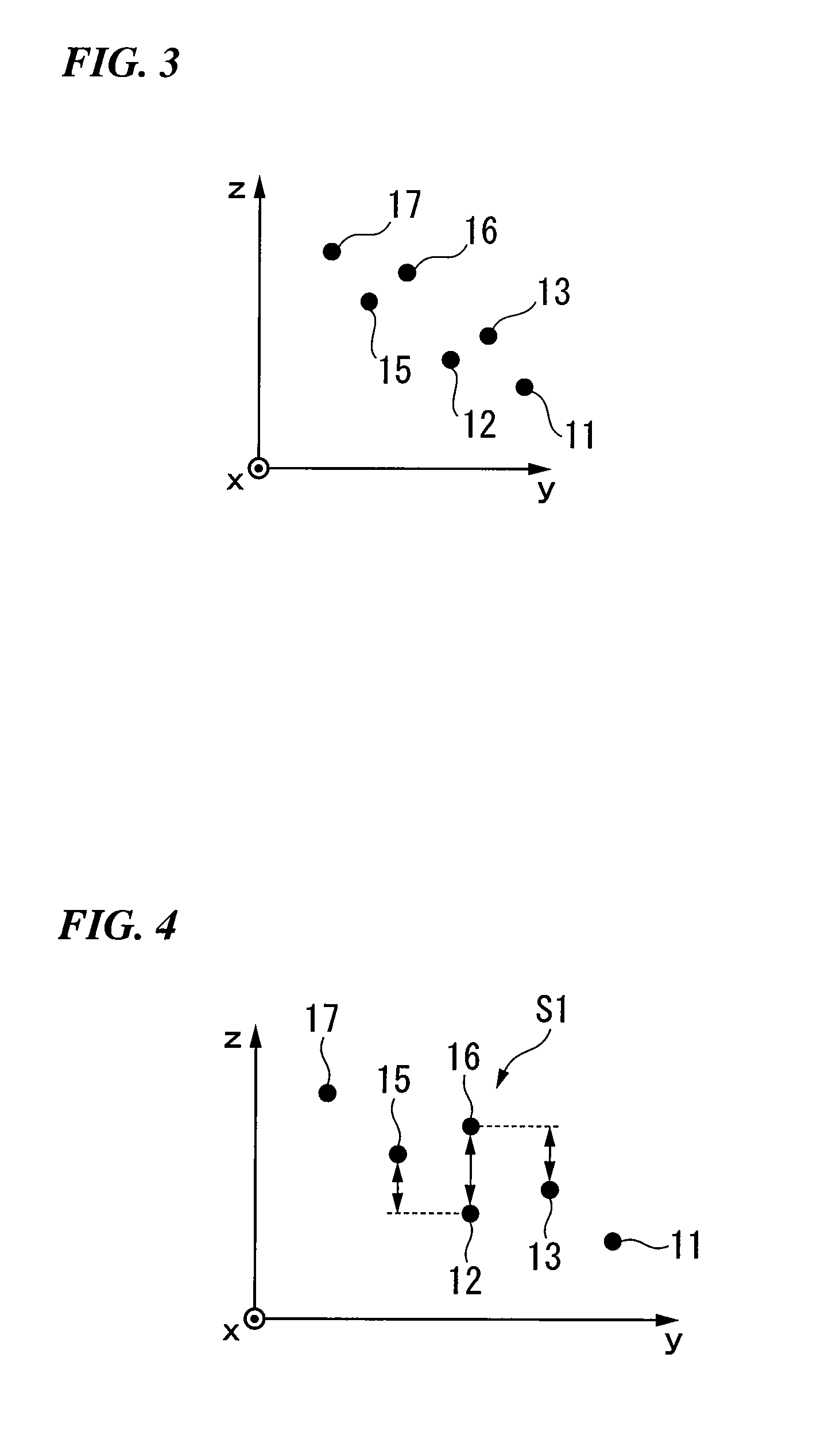

In a semiconductor device, first wires each having a relatively low loop height are formed between a first lead and a plurality of first electrode pads aligned in a first line, and then second wires each having a relatively high loop height are formed between a second lead and a plurality of second electrode pads aligned in a second line, wherein the second line is distanced from the first line in view of the first and second leads. Wire bonding is sequentially performed so as to increase the height difference between the first wire and the second wire, thus avoiding the occurrence of electric short-circuiting between adjacently arranged wires. In wire bonding, a bump forming process, a ball bonding process, and a wedge bonding process are sequentially performed. It is preferable that the second lead be vertically distanced from the first lead in the thickness direction.

Owner:YAMAHA CORP

Bonding wire for semiconductor

ActiveUS20110120594A1Reduce tensionLarge spanSolid-state devicesWelding/cutting media/materialsWire rodHydrogen concentration

It is an object of the present invention to provide a multilayer wire which can accomplish both ball bonding property and wire workability simultaneously, and which enhances a loop stability, a pull strength, and a wedge bonding property. A semiconductor bonding wire comprises a core member mainly composed of equal to or greater than one kind of following elements: Cu, Au, and Ag, and an outer layer formed on the core member and mainly composed of Pd. A total hydrogen concentration contained in a whole wire is within a range from 0.0001 to 0.008 mass %.

Owner:NIPPON STEEL CHEMICAL CO LTD +1

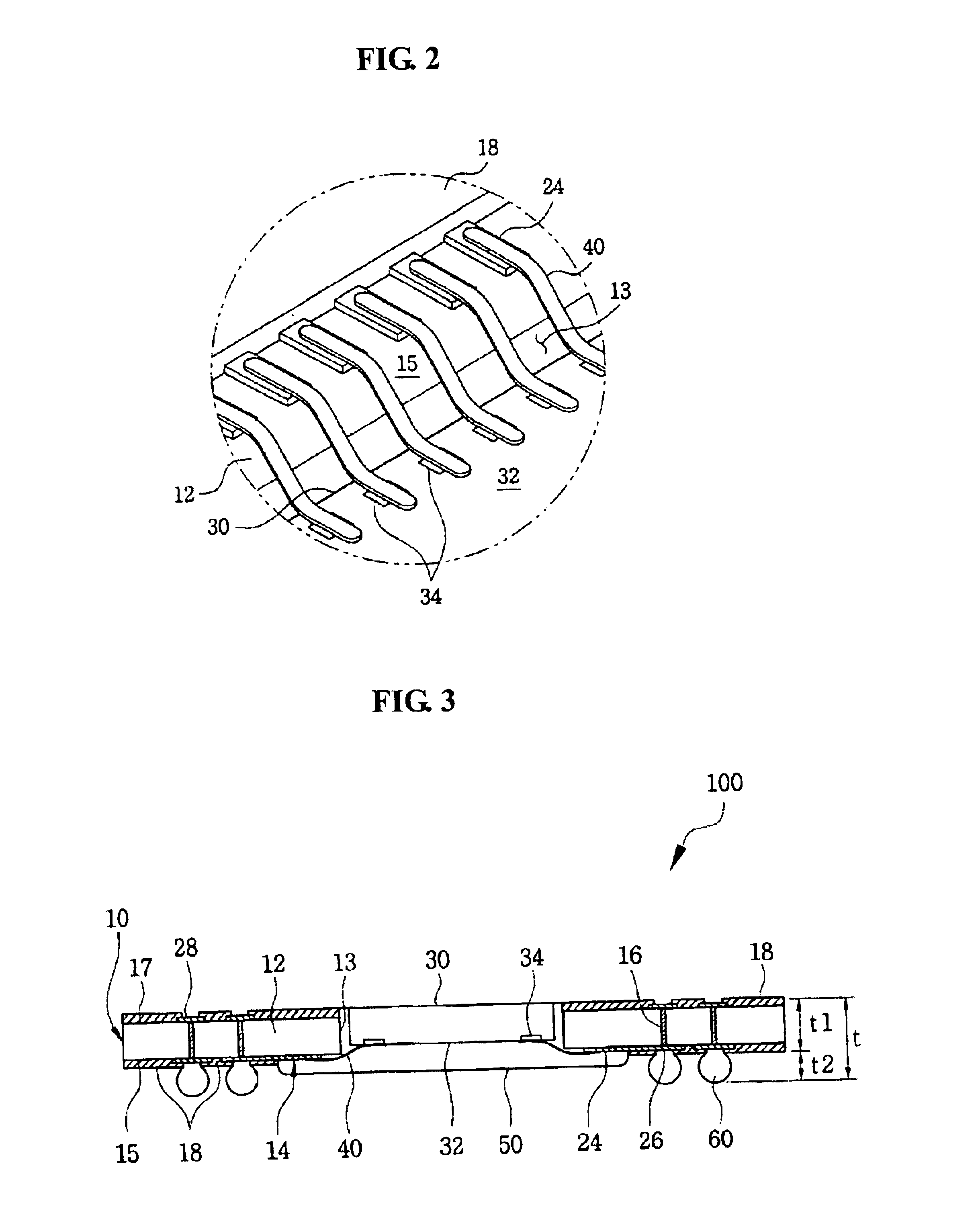

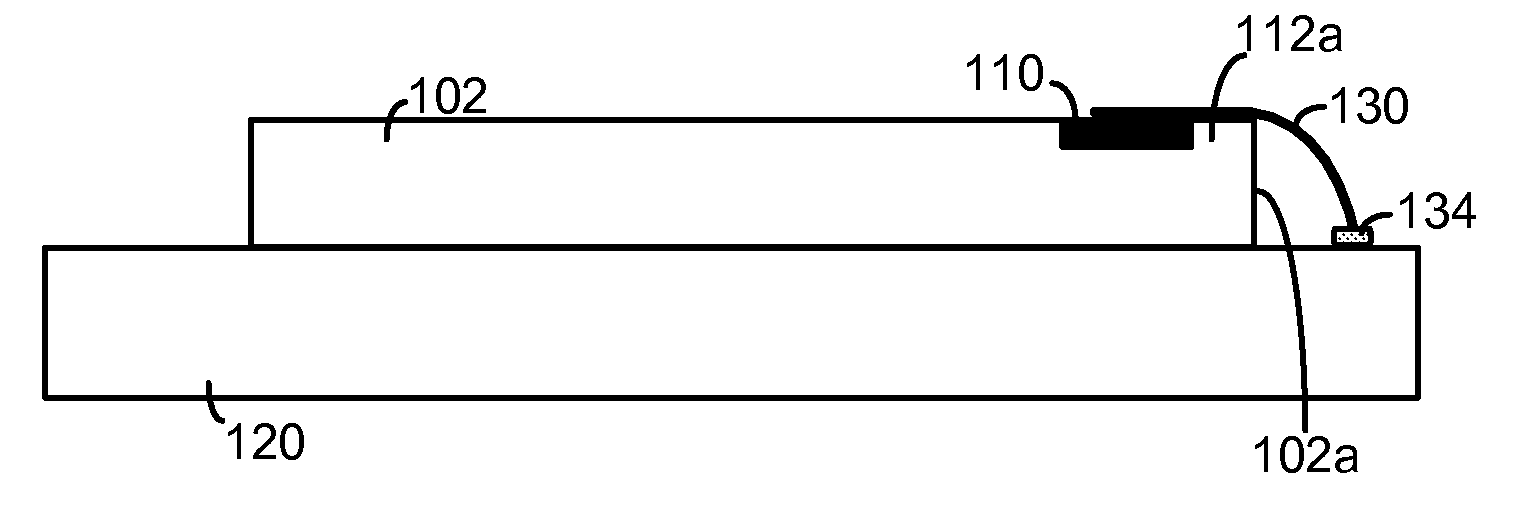

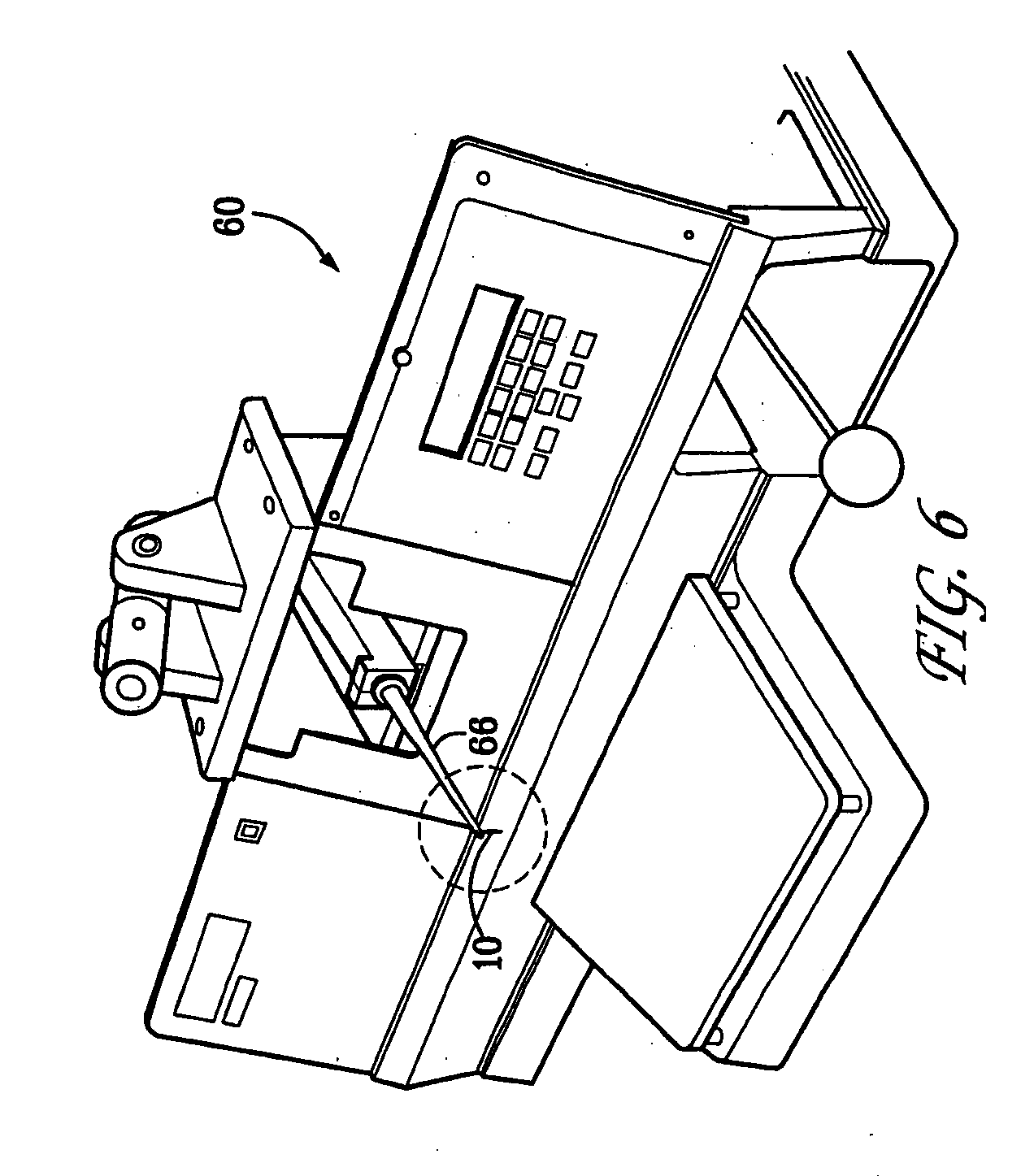

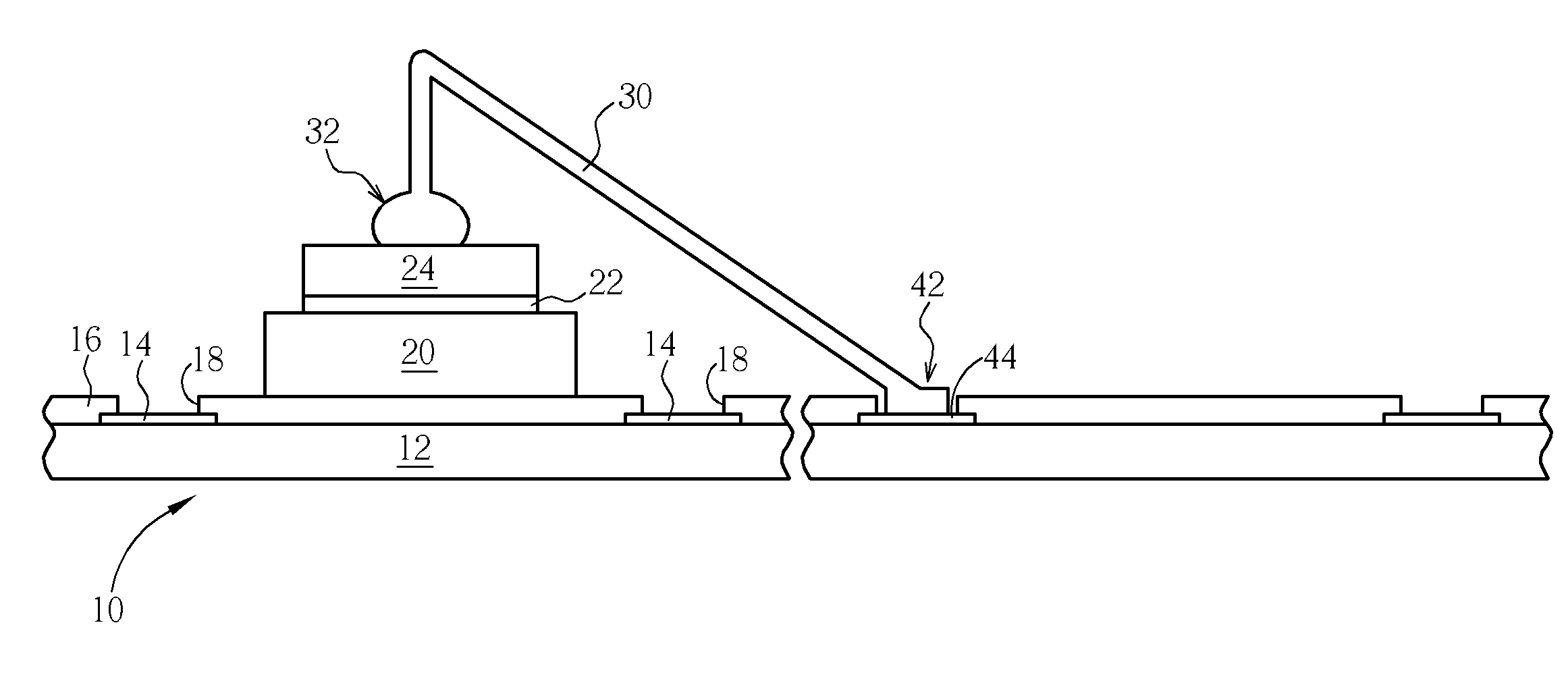

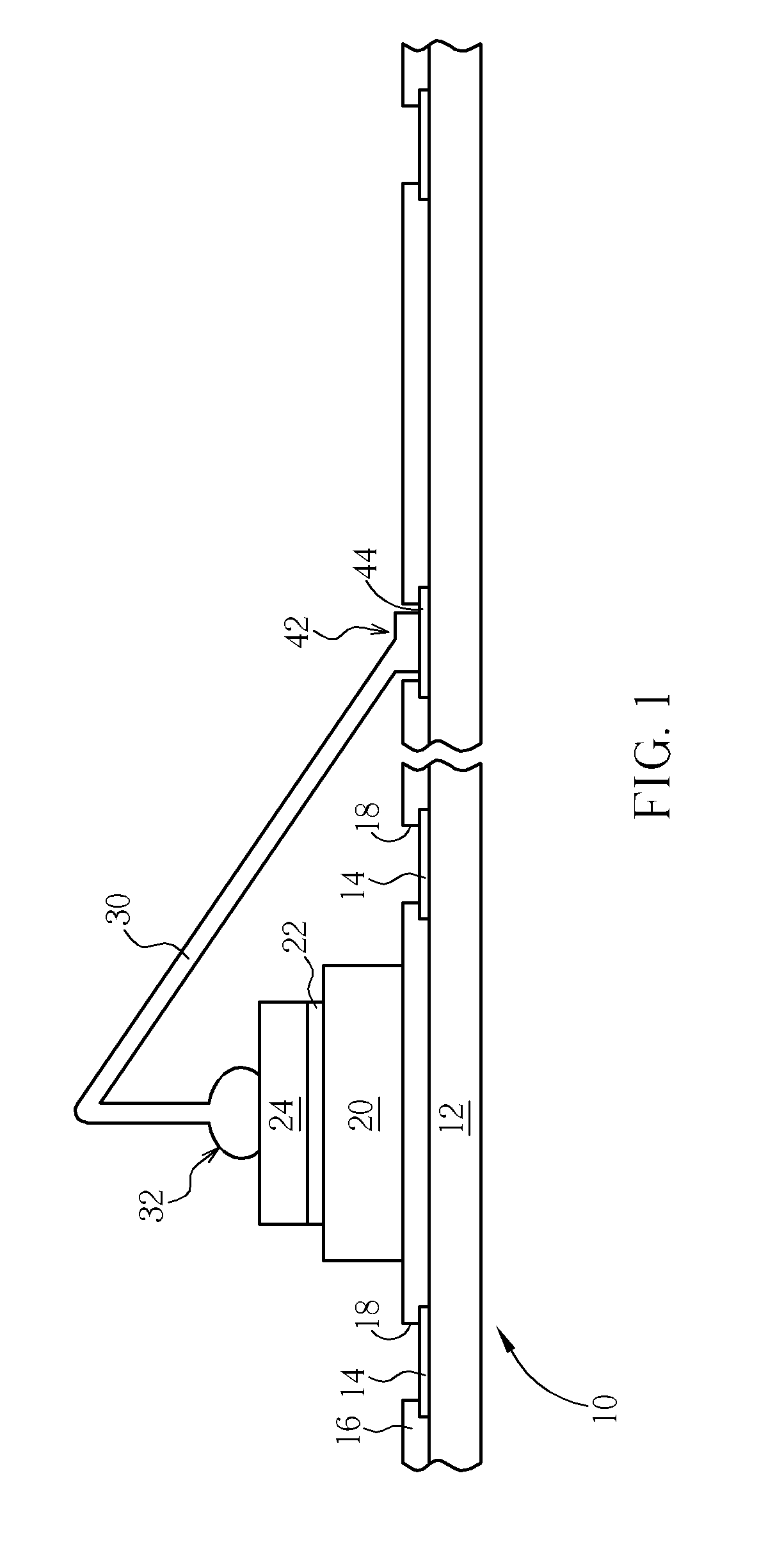

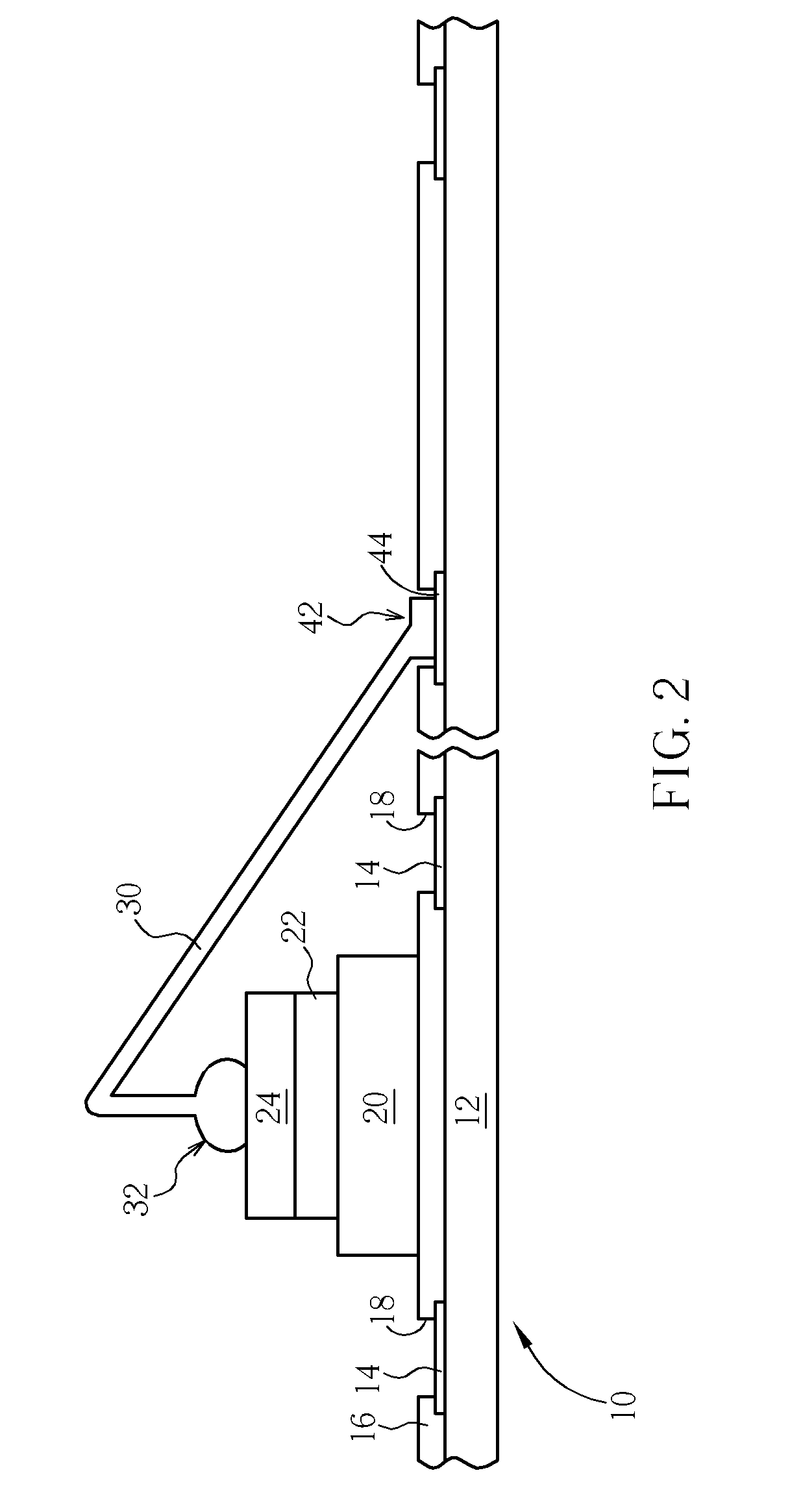

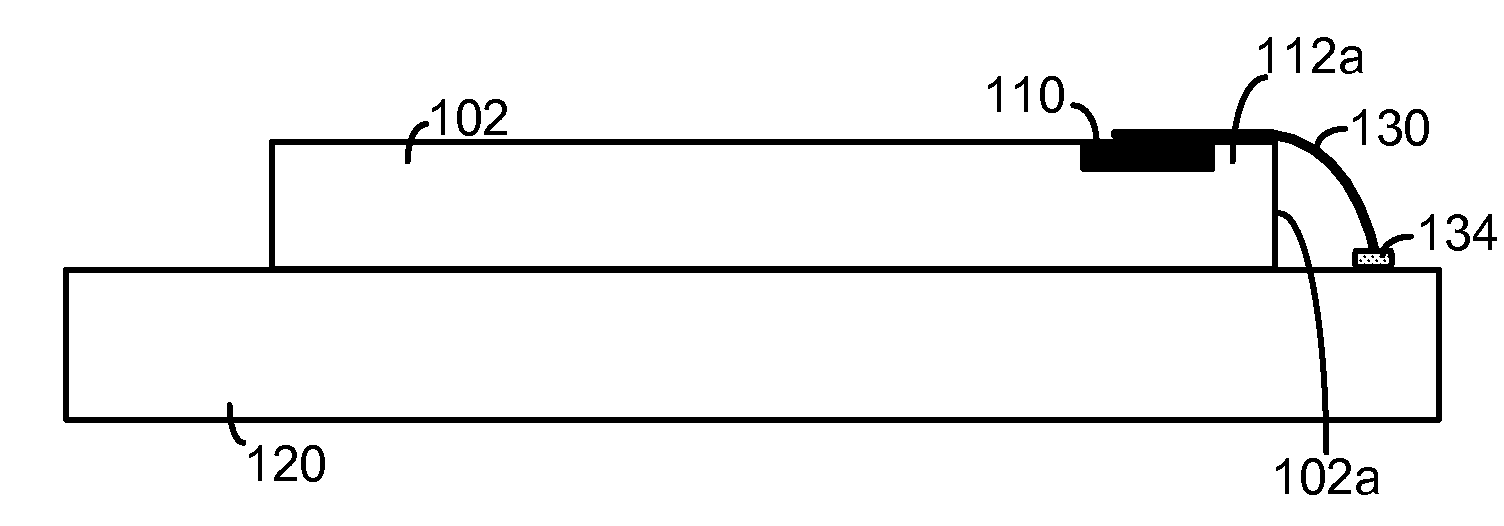

Semiconductor device package and method for manufacturing same

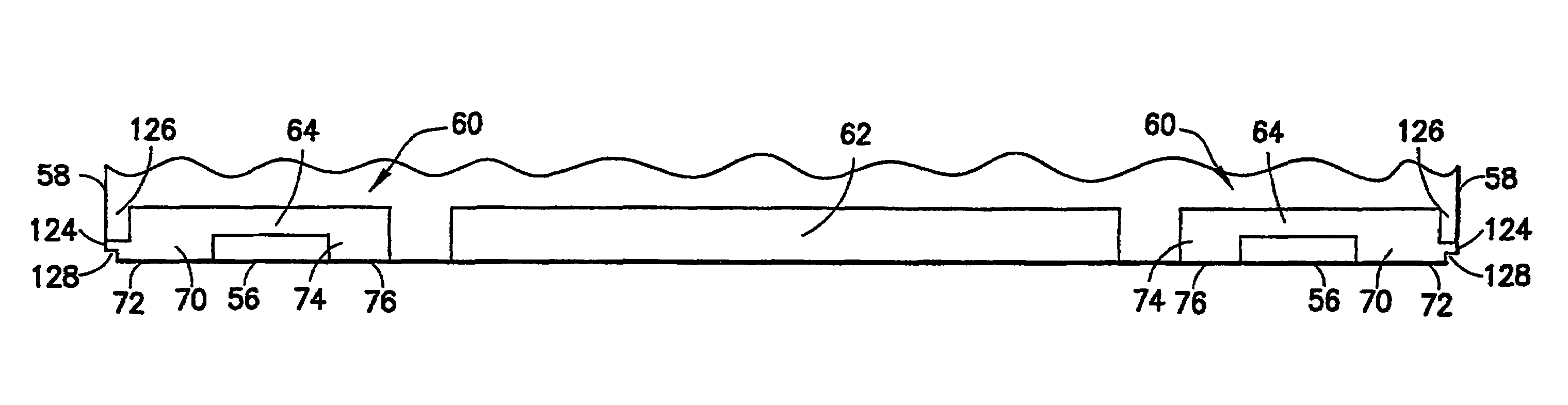

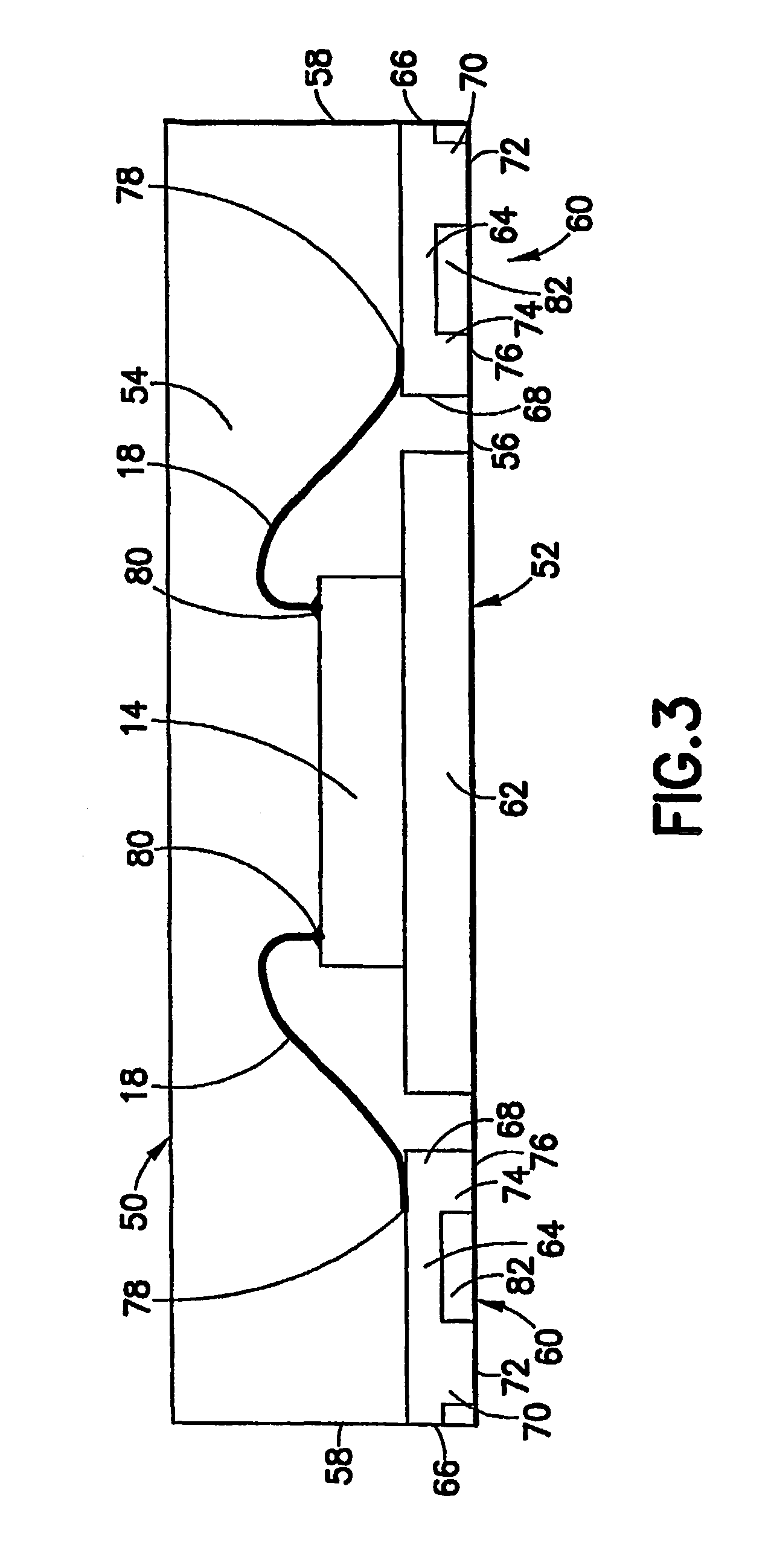

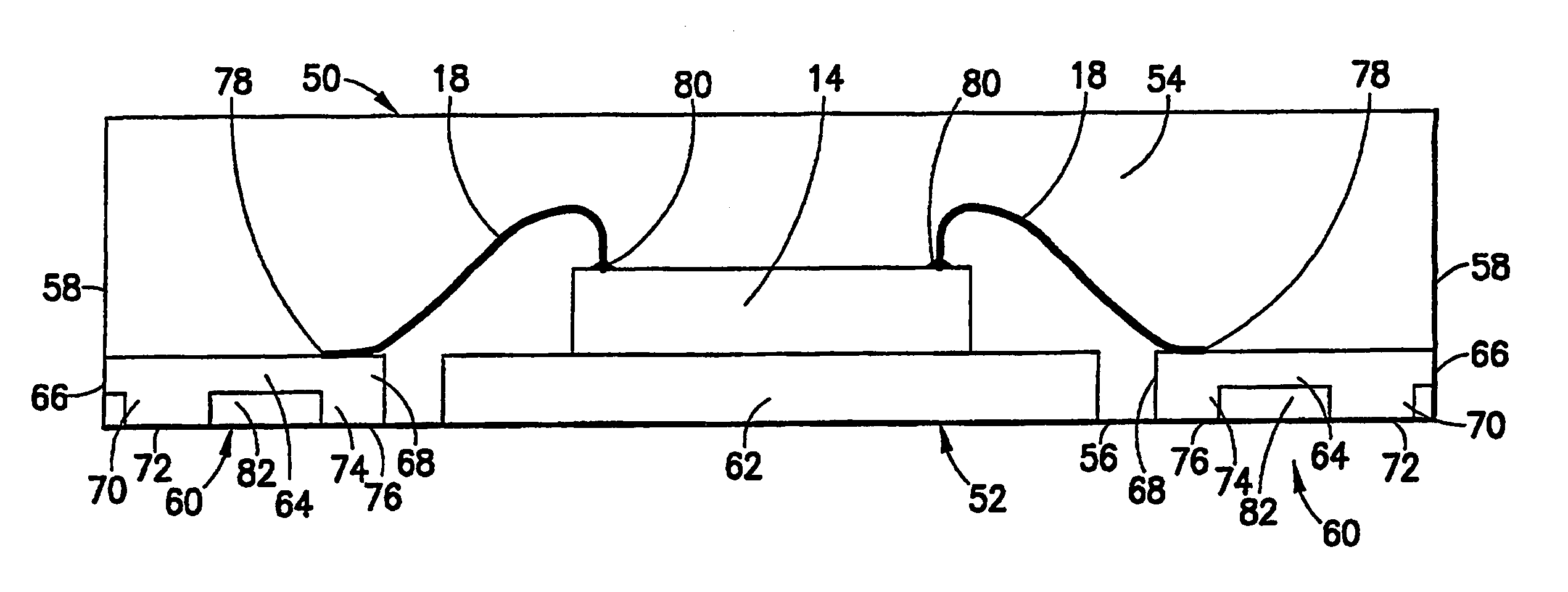

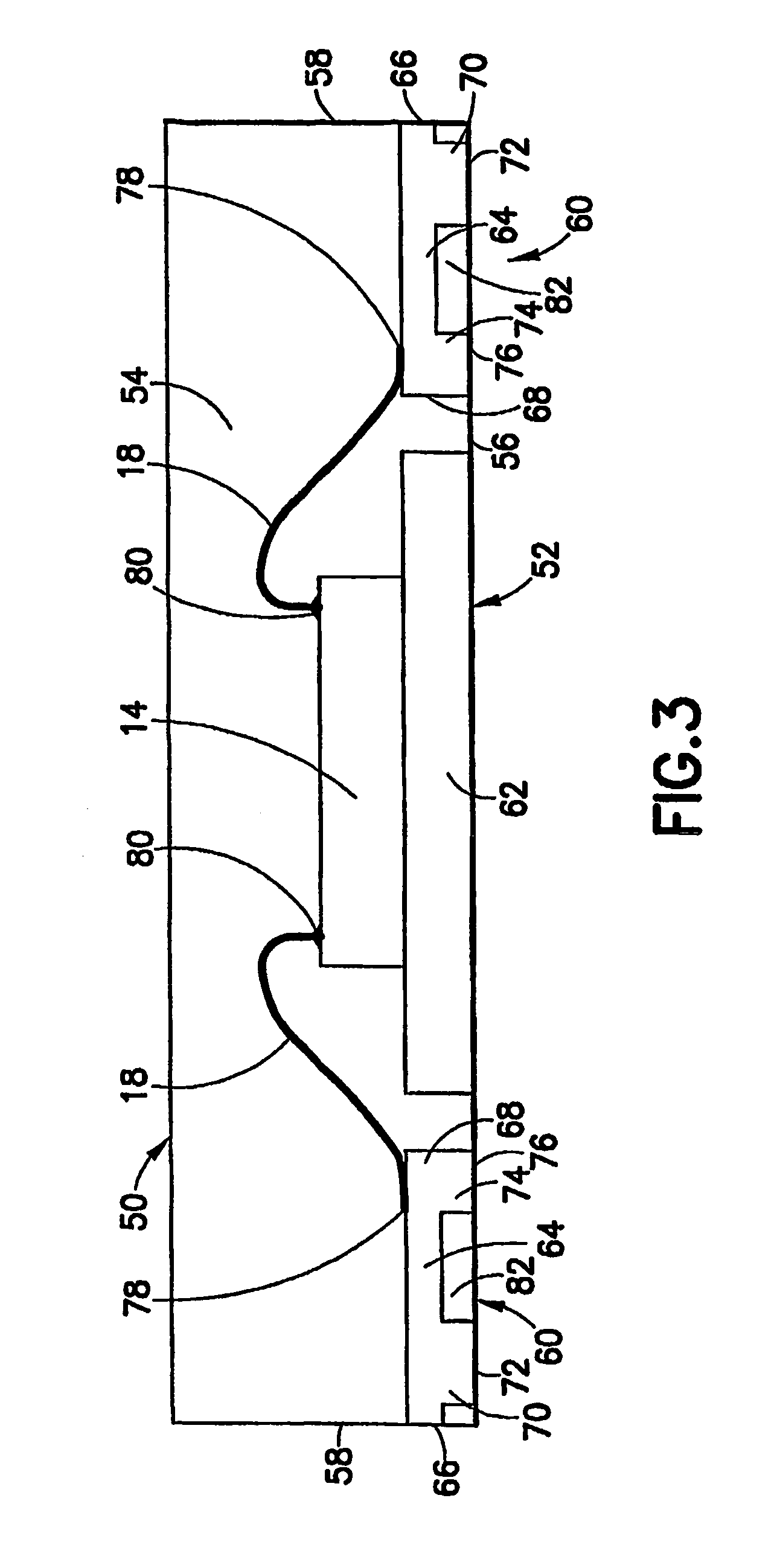

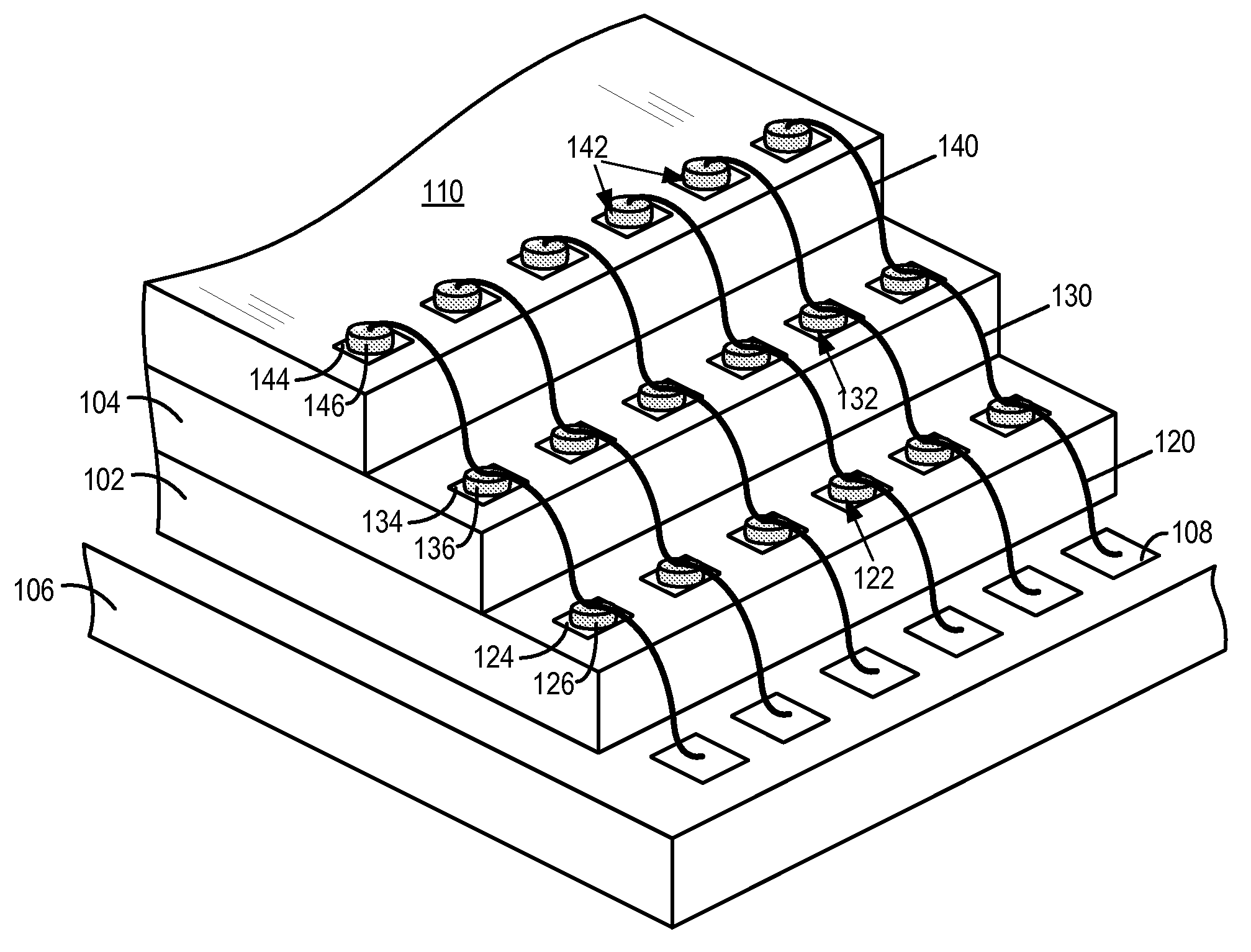

A lead frame (52, 100, 112) for a semiconductor device (die) package (50, 102, 110) is described. Each of the leads (60) in the lead frame (52, 100, 112) includes an interposer (64) having one end (66) disposed proximate the outer face (58) of the package (50, 102, 110) and another end (68) disposed proximate the die (14). Extending from opposite ends of the interposer (64) are a board connecting post (70) and a support post (74). A bond site (78) is formed on a surface of the interposer (64) opposite the support post (74). Each of the leads (60) is electrically connected to an associated input / output (I / O) pad (80) on the die (14) via wirebonding, tape bonding, or flip-chip attachment to the bond site (78). Where wirebonding is used, a wire electrically connecting the I / O pad (80) to the bond site (78) may be wedge bonded to both the I / O pad (80) and the bond site (78). The support post (74) provides support to the end (68) of the interposer (64) during the bonding and coating processes.(FIG. 3).

Owner:UNISEM M BERHAD

Semiconductor device package and method for manufacturing same

ActiveUS20070161157A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialInterposer

A lead frame (52, 100, 112) for a semiconductor device (die) package (50, 102, 110) is described. Each of the leads (60) in the lead frame (52, 100, 112) includes an interposer (64) having one end (66) disposed proximate the outer face (58) of the package (50, 102, 110) and another end (68) disposed proximate the die (14). Extending from opposite ends of the interposer (64) are a board connecting post (70) and a support post (74). A bond site (78) is formed on a surface of the interposer (64) opposite the support post (74). Each of the leads (60) is electrically connected to an associated input / output (I / O) pad (80) on the die (14) via wirebonding, tape bonding, or flip-chip attachment to the bond site (78). Where wirebonding is used, a wire electrically connecting the I / O pad (80) to the bond site (78) may be wedge bonded to both the I / O pad (80) and the bond site (78). The support post (74) provides support to the end (68) of the interposer (64) during the bonding and coating processes.

Owner:UNISEM M BERHAD

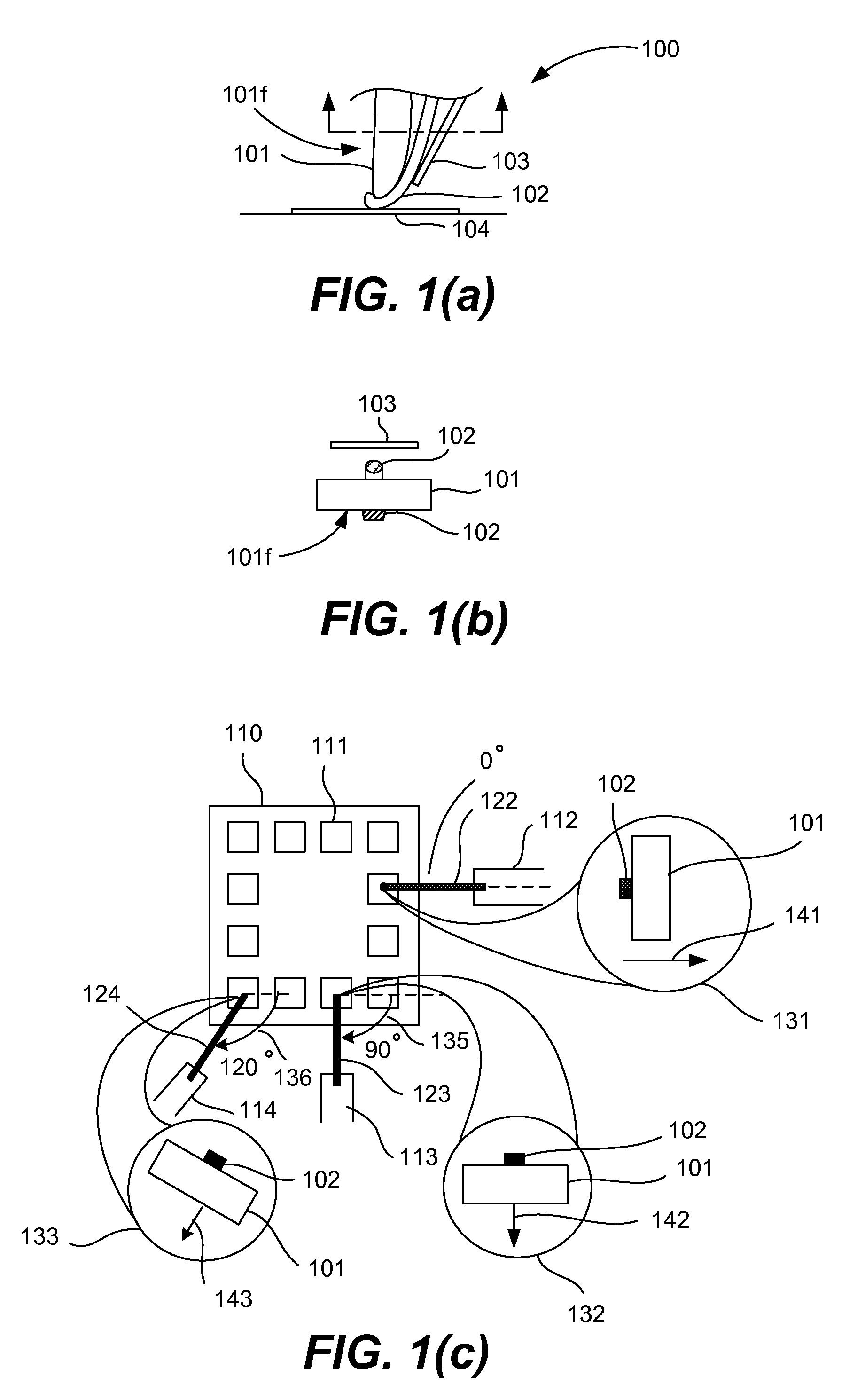

Wire bonding deflector for a wire bonder

ActiveUS7918378B1Improved high speed wedge bonding of bondSolid-state devicesWelding/cutting auxillary devicesElectronic systemsIntegrated circuit layout

Methods and systems are described for enabling the efficient fabrication of wedge-bonding of integrated circuit systems and electronic systems.

Owner:NAT SEMICON CORP

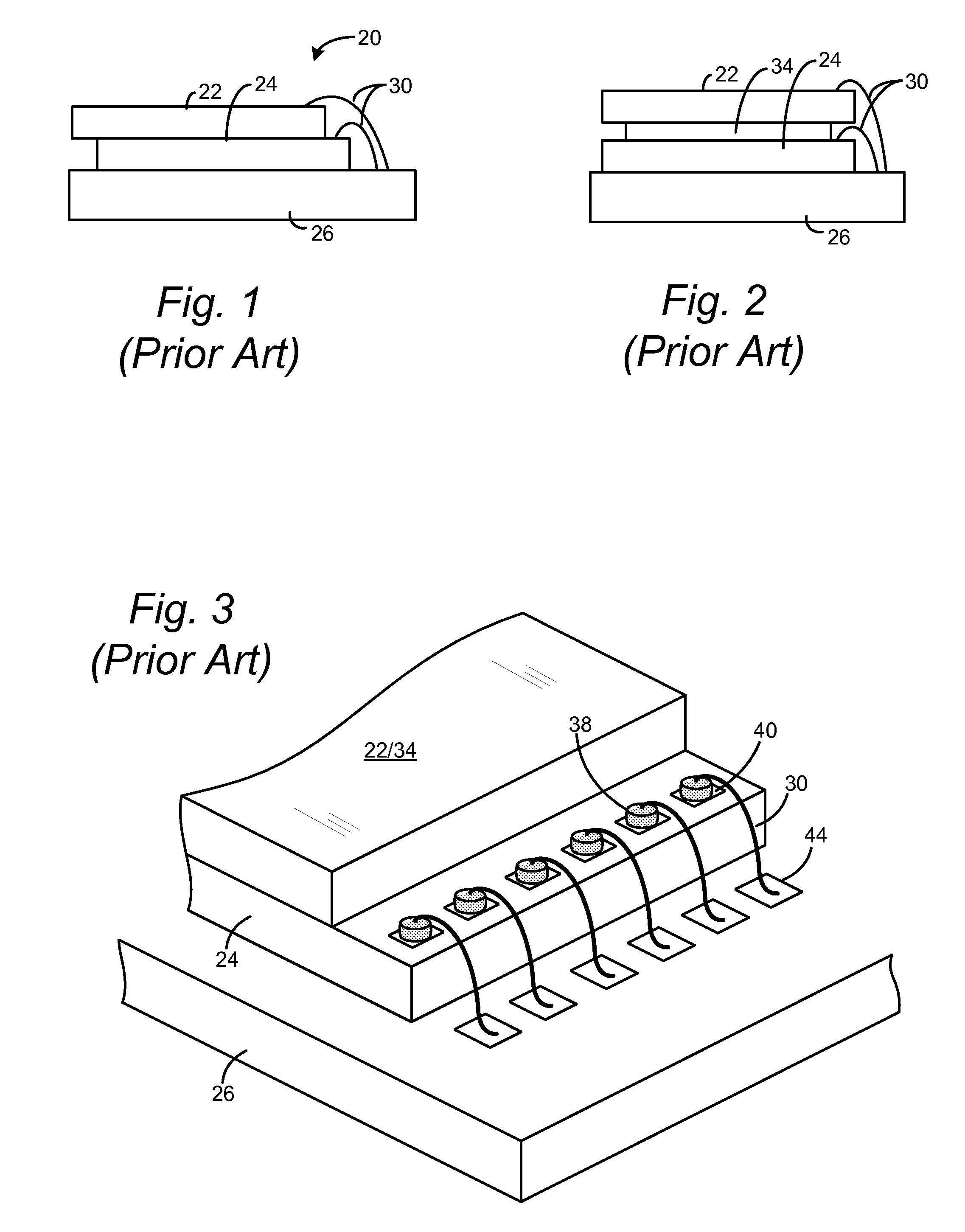

Wire on wire stitch bonding in a semiconductor device

InactiveUS20090321952A1Few stepsLess fabrication timeSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor package

A low profile semiconductor package is disclosed including at least first and second stacked semiconductor die mounted to a substrate. The first semiconductor die may be electrically coupled to the substrate with a plurality of stitches in a forward ball bonding process. The second semiconductor die may in turn be electrically coupled to the first semiconductor die using a second set of stitches bonded between the die bond pads of the first and second semiconductor die. The second set of stitches may each include a lead end having a stitch ball that is bonded to the bond pads of the second semiconductor die. The tail end of each stitch in the second set of stitches may be wedge bonded directly to lead end of a stitch in the first set of stitches.

Owner:SANDISK TECH LLC

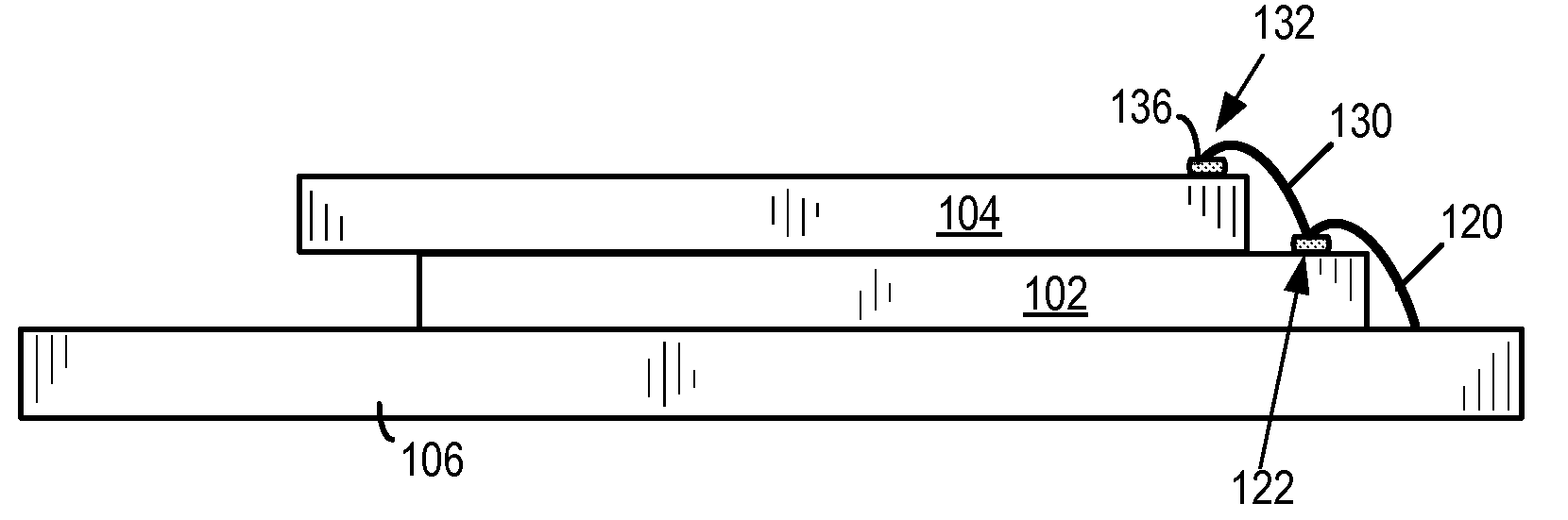

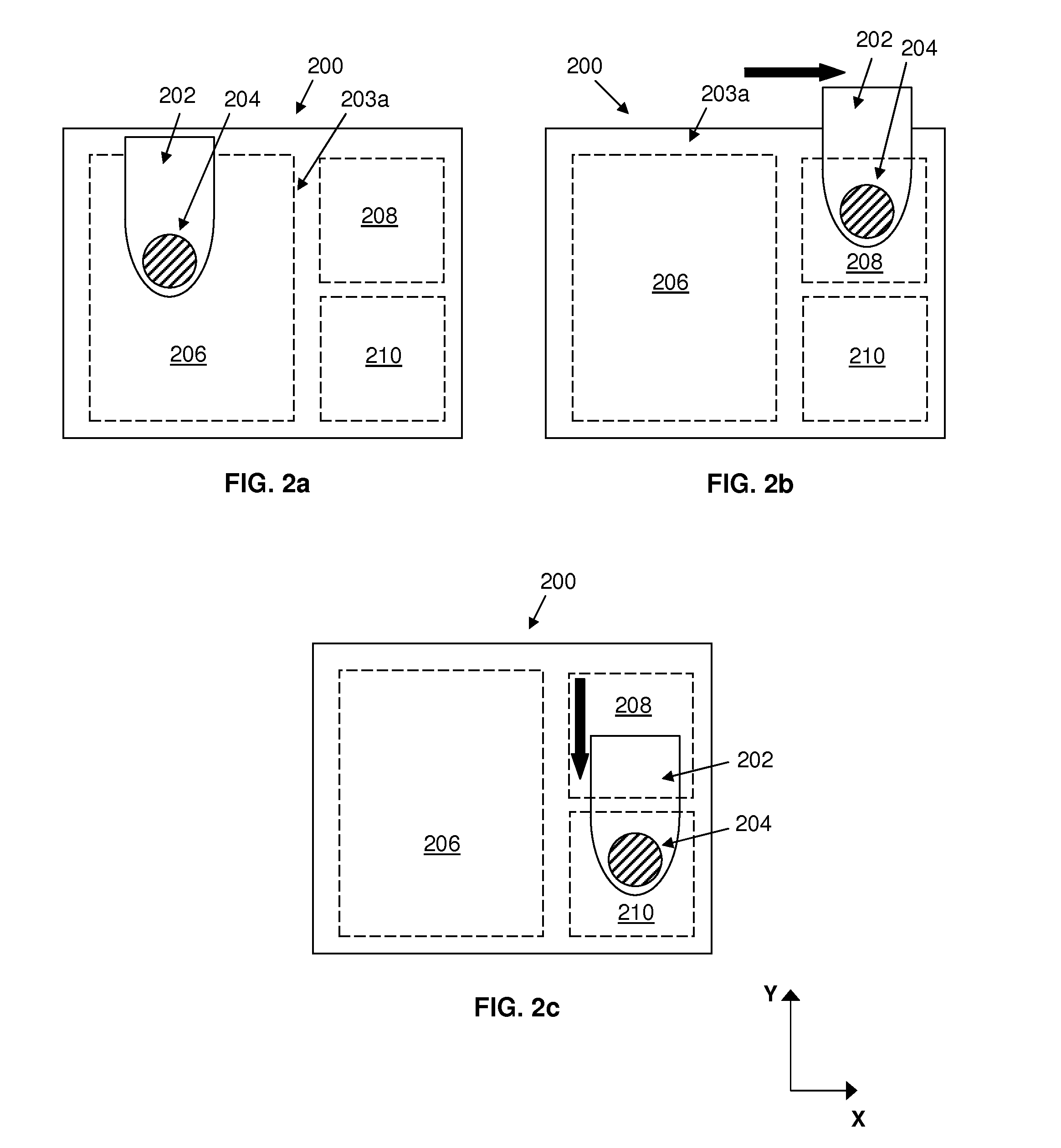

Method of fabricating stacked wire bonded semiconductor package with low profile bond line

ActiveUS20090325344A1Increase heightSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorSemiconductor package

A method of fabricating a low profile semiconductor package is disclosed including at least first and second stacked semiconductor die mounted to a substrate. The first and / or second semiconductor die may be fabricated with a plurality of redistribution pads formed over and electrically coupled to a plurality of bond pads. After the semiconductor die are formed and diced from the wafer, the die may be mounted to the substrate using a low profile reverse wire bond according to the present invention. In particular, a wedge bond may be formed between the wire and the redistribution pad without having to use a second wire bond ball on the die bond pad as in conventional reverse ball bonding processes.

Owner:SANDISK TECH LLC

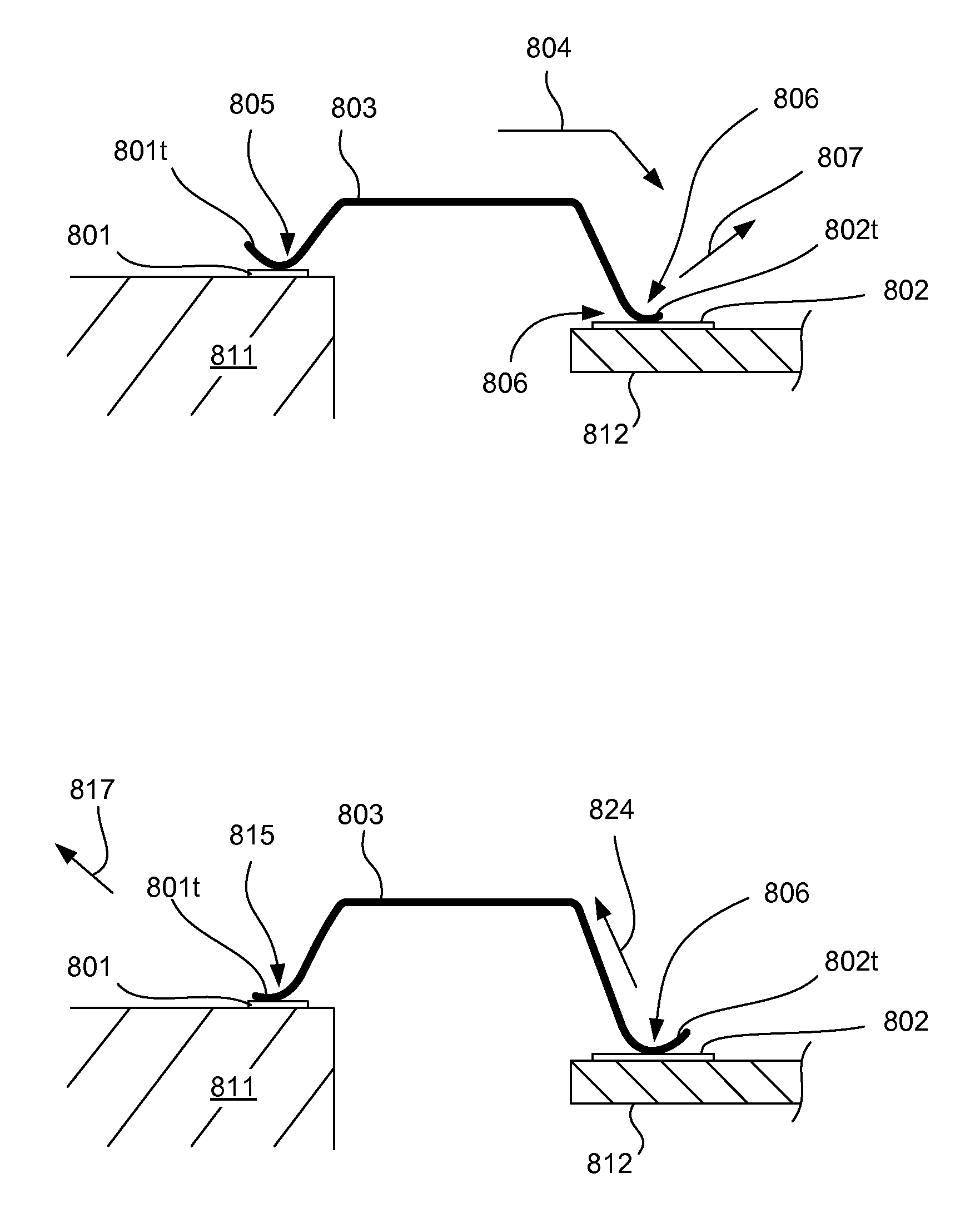

Wirebonding method and device enabling high-speed reverse wedge bonding of wire bonds

InactiveUS20120032354A1Improved high speed wedge bonding of bondSemiconductor/solid-state device detailsSolid-state devicesElectronic systemsElectron

Methods and systems are described for enabling the efficient fabrication of wedge bonding of integrated circuit systems and electronic systems. In particular a reverse bonding approach can be employed.

Owner:NAT SEMICON CORP

Method of fabricating wire on wire stitch bonding in a semiconductor device

InactiveUS20090321501A1Few stepsLess fabrication timeSemiconductor/solid-state device detailsSoldering apparatusElectrical conductorSemiconductor package

A low profile semiconductor package is disclosed including at least first and second stacked semiconductor die mounted to a substrate. The first semiconductor die may be electrically coupled to the substrate with a plurality of stitches in a forward ball bonding process. The second semiconductor die may in turn be electrically coupled to the first semiconductor die using a second set of stitches bonded between the die bond pads of the first and second semiconductor die. The second set of stitches may each include a lead end having a stitch ball that is bonded to the bond pads of the second semiconductor die. The tail end of each stitch in the second set of stitches may be wedge bonded directly to lead end of a stitch in the first set of stitches.

Owner:SANDISK TECH LLC

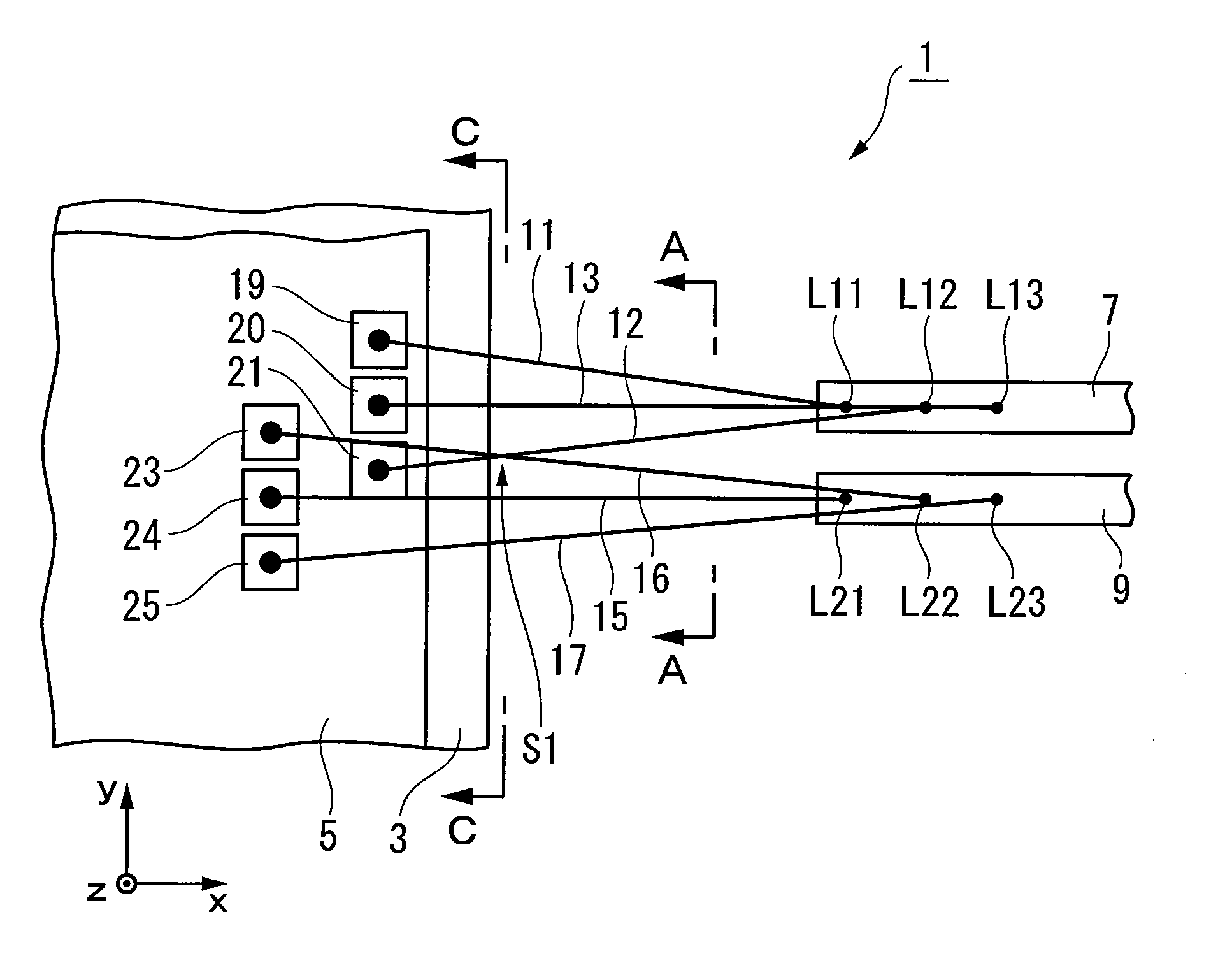

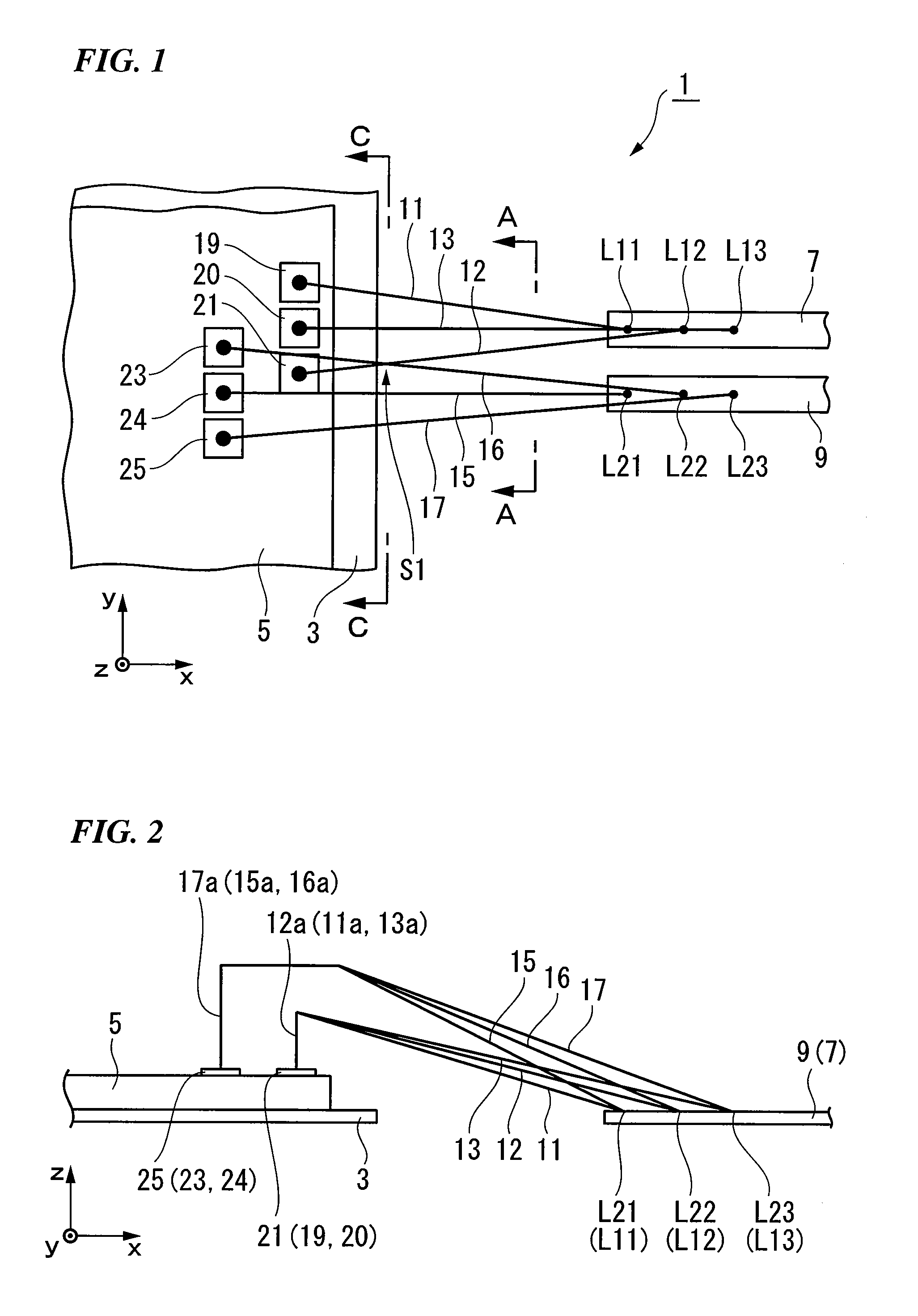

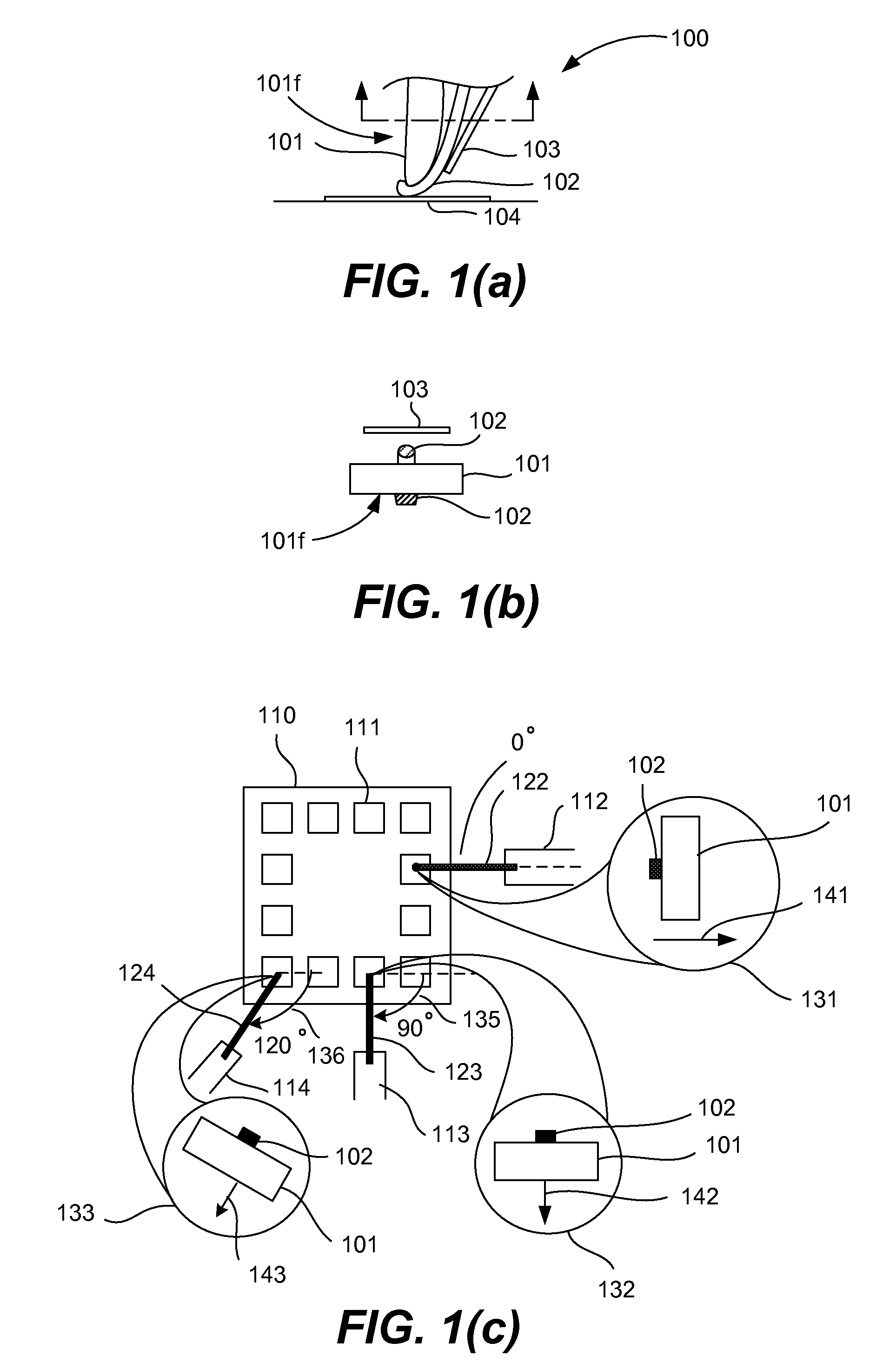

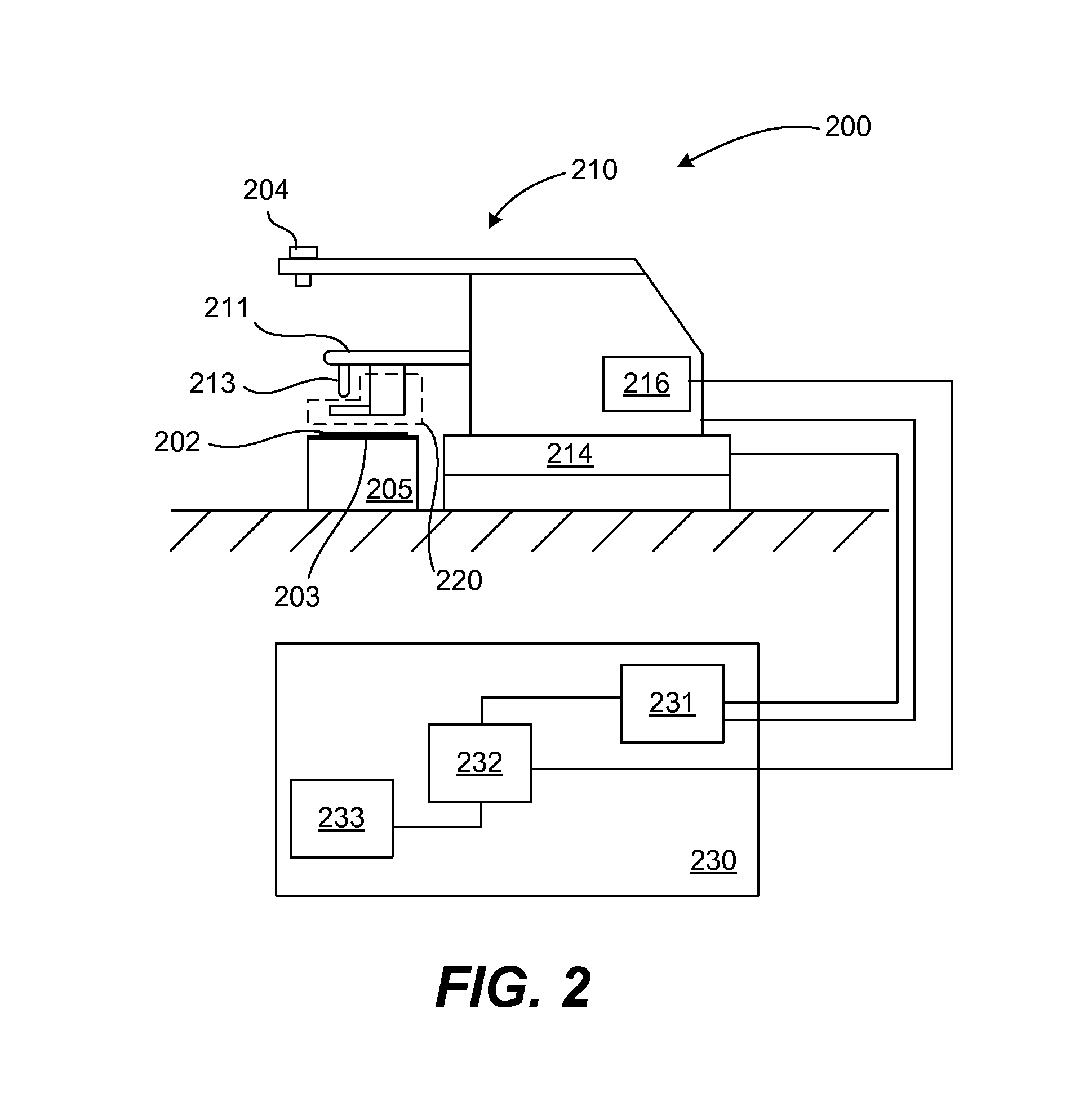

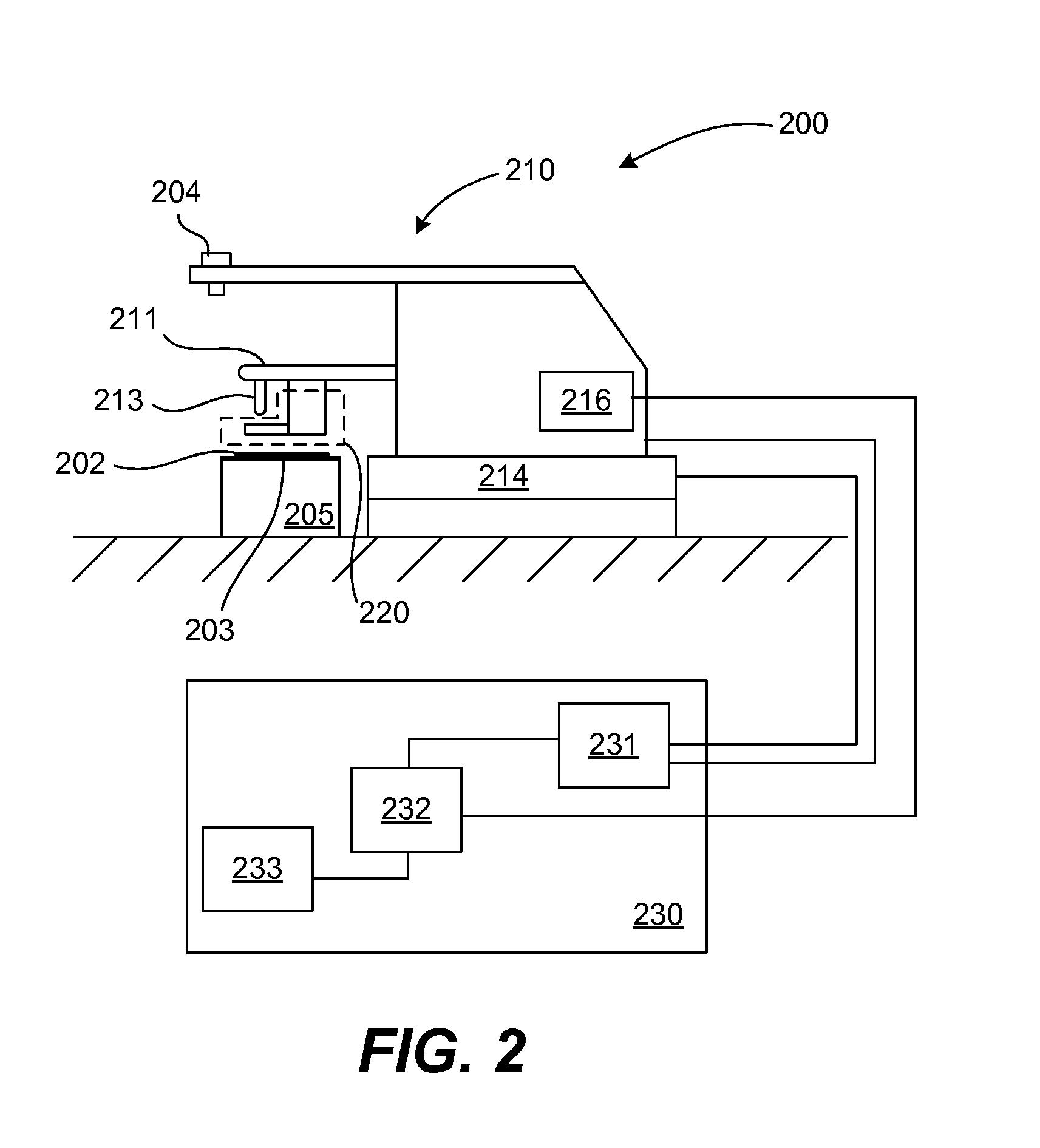

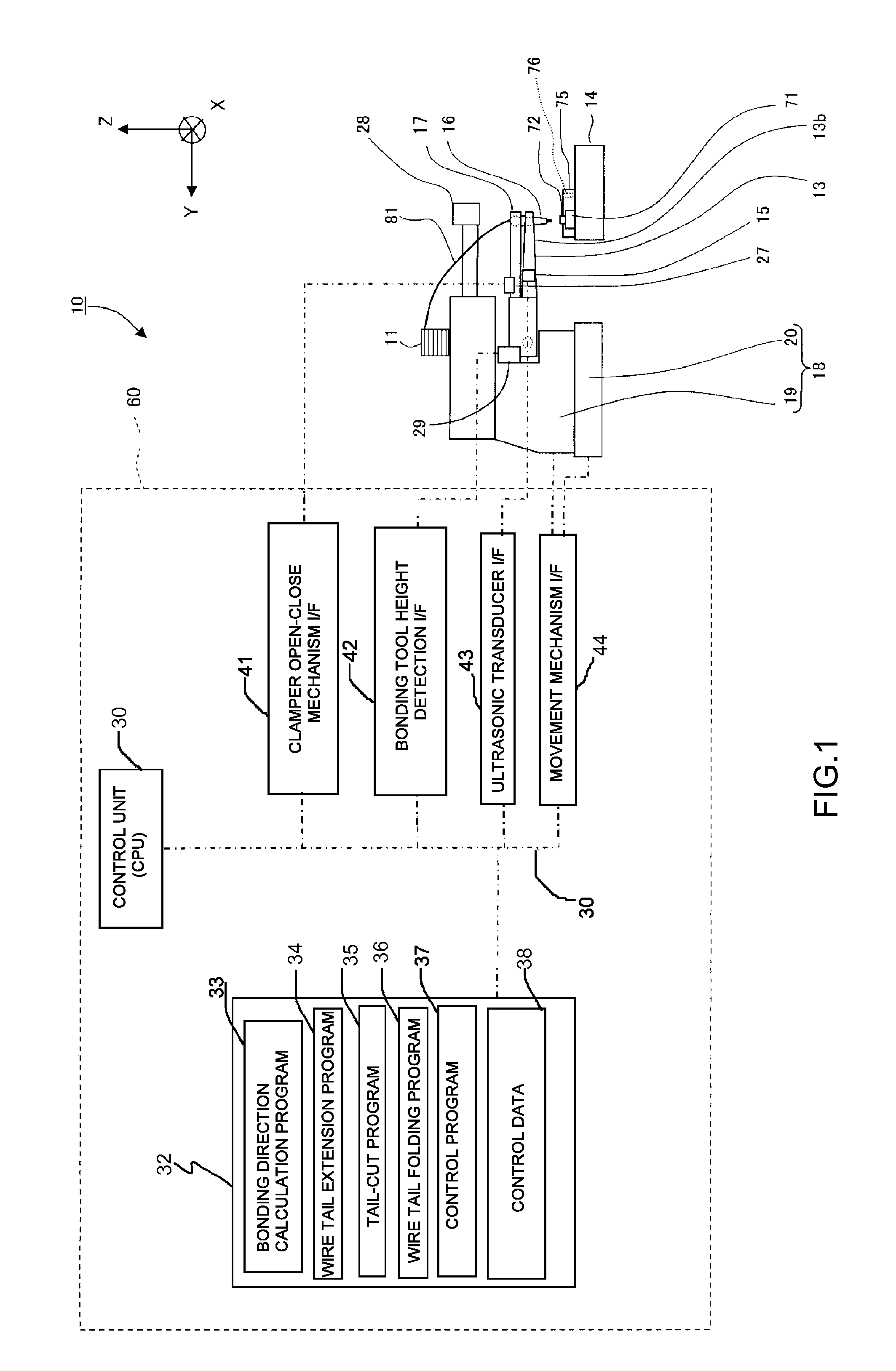

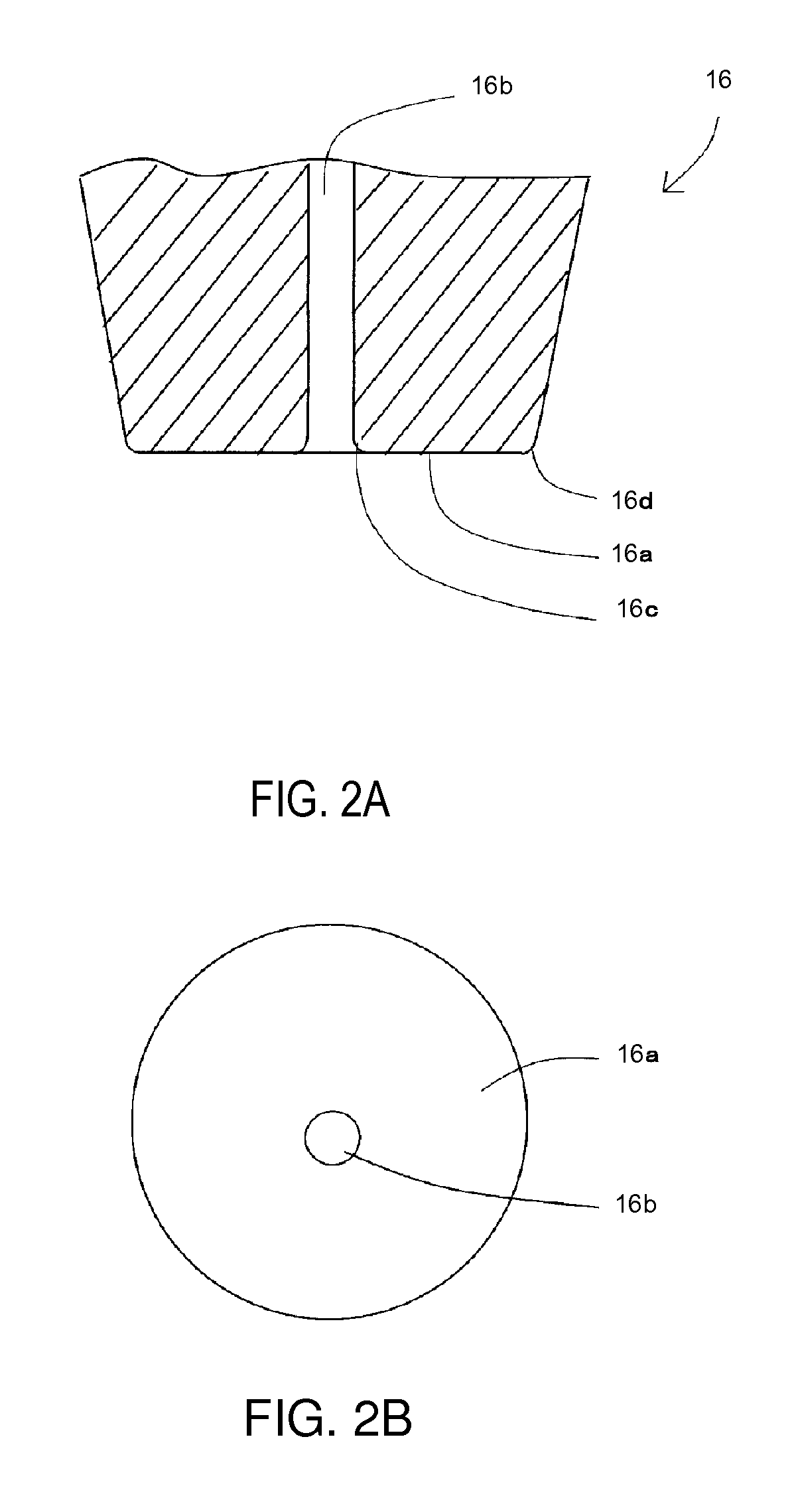

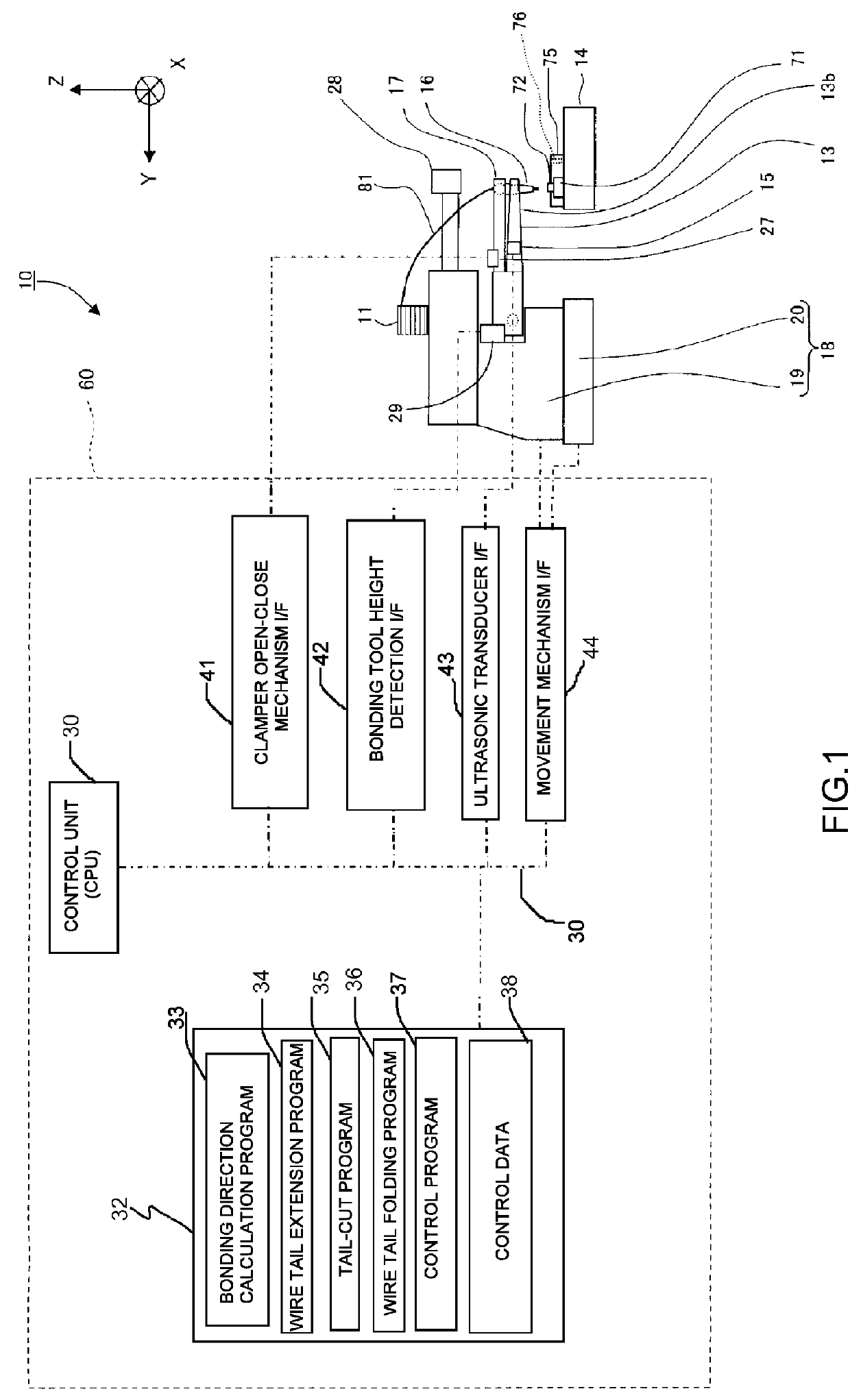

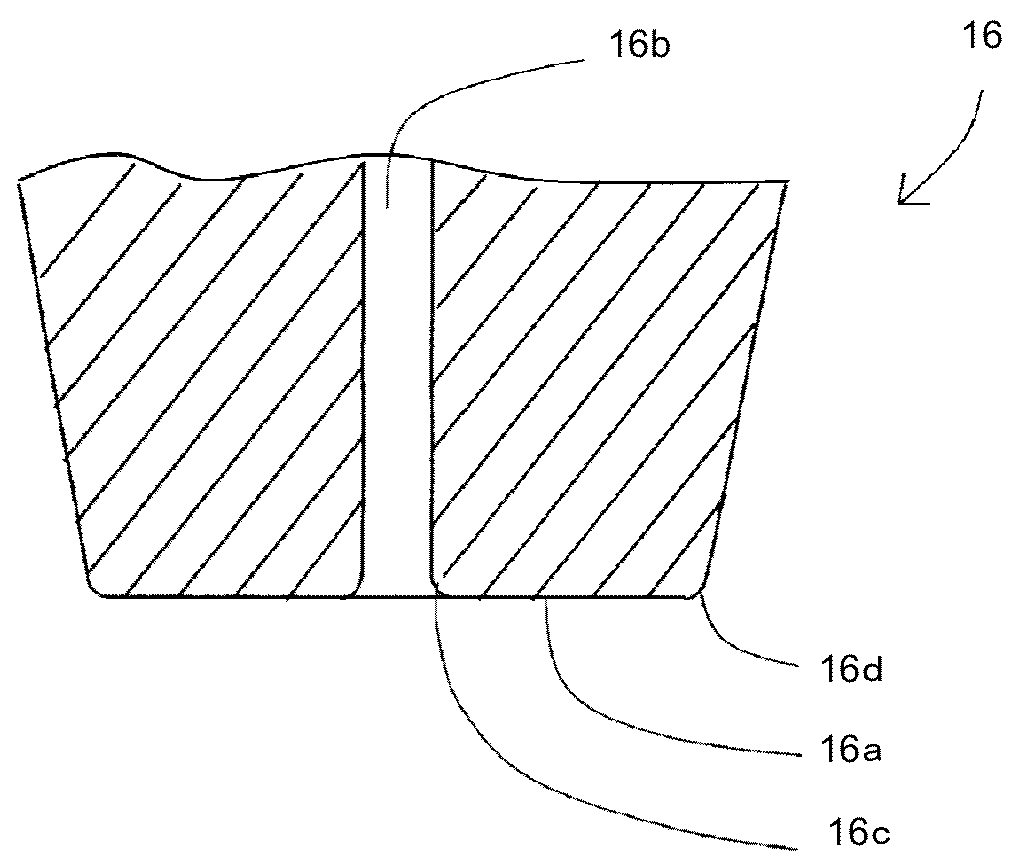

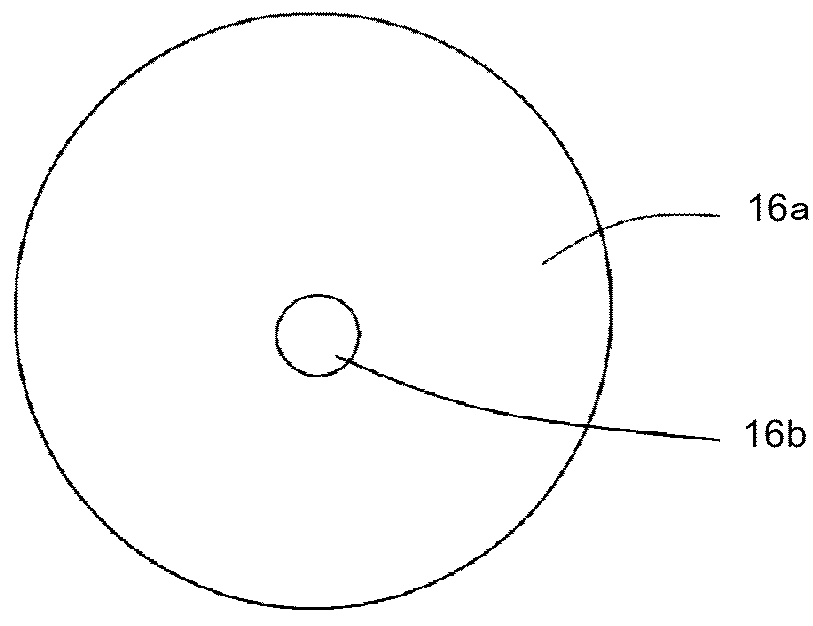

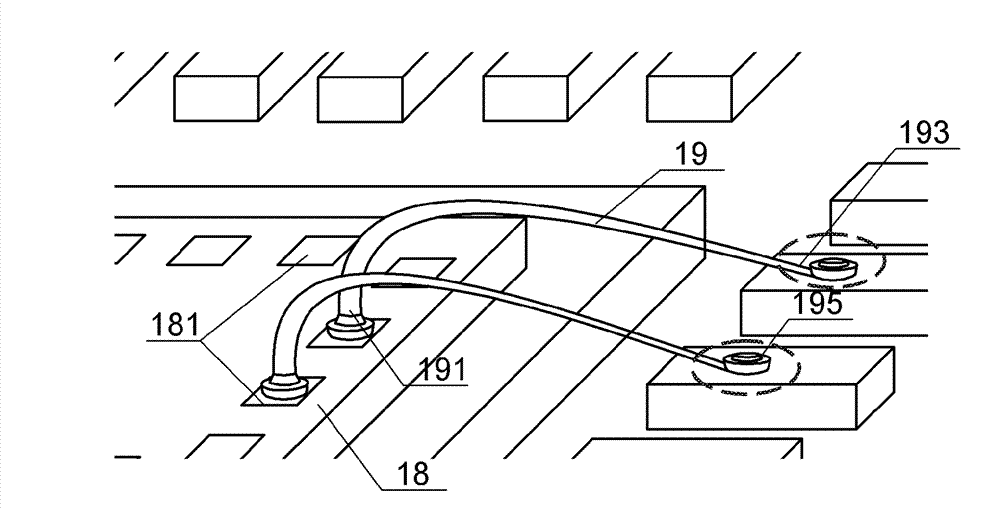

Wire bonding apparatus and bonding method

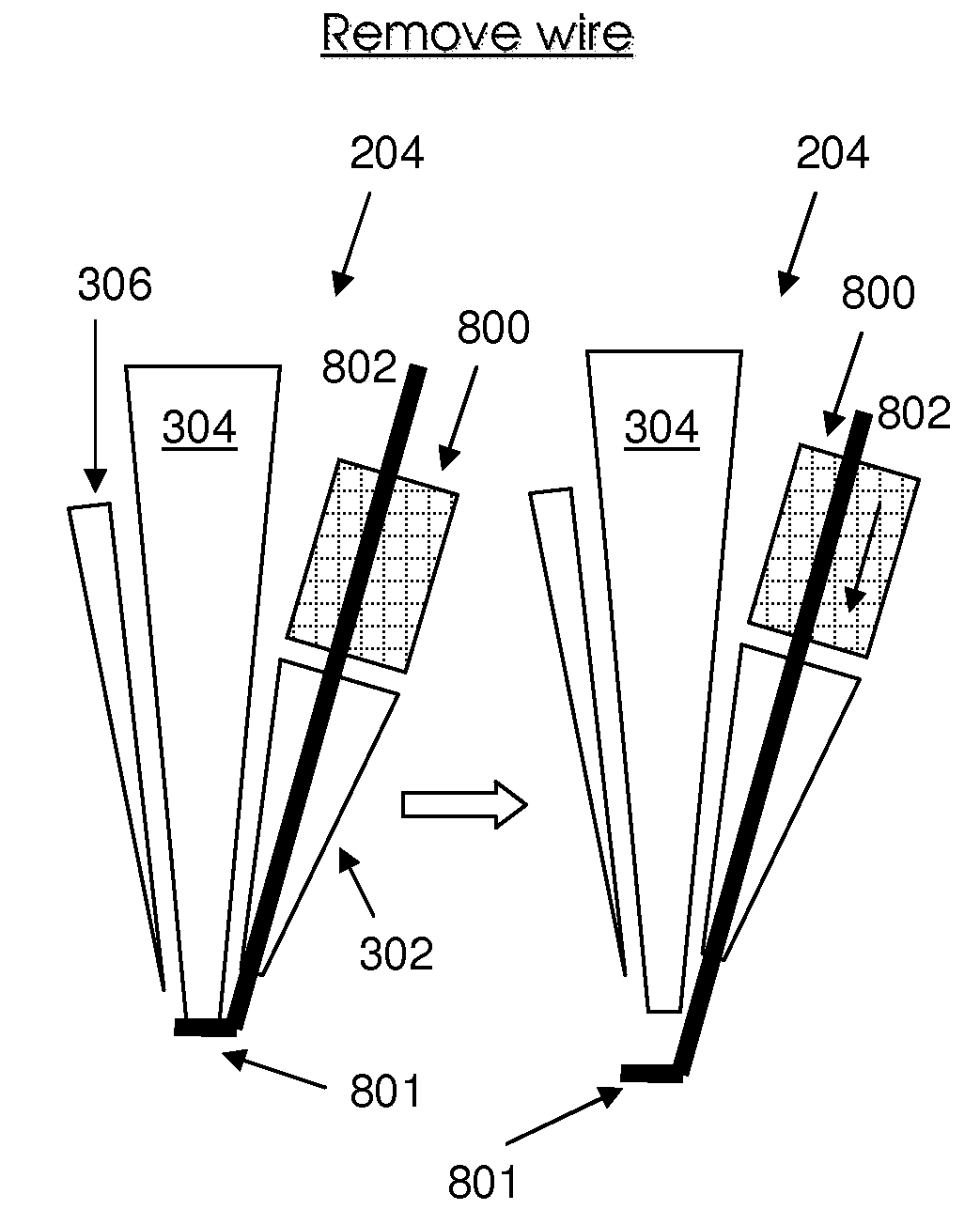

ActiveUS20140138426A1Semiconductor/solid-state device detailsWelding/cutting auxillary devicesEngineeringMechanical engineering

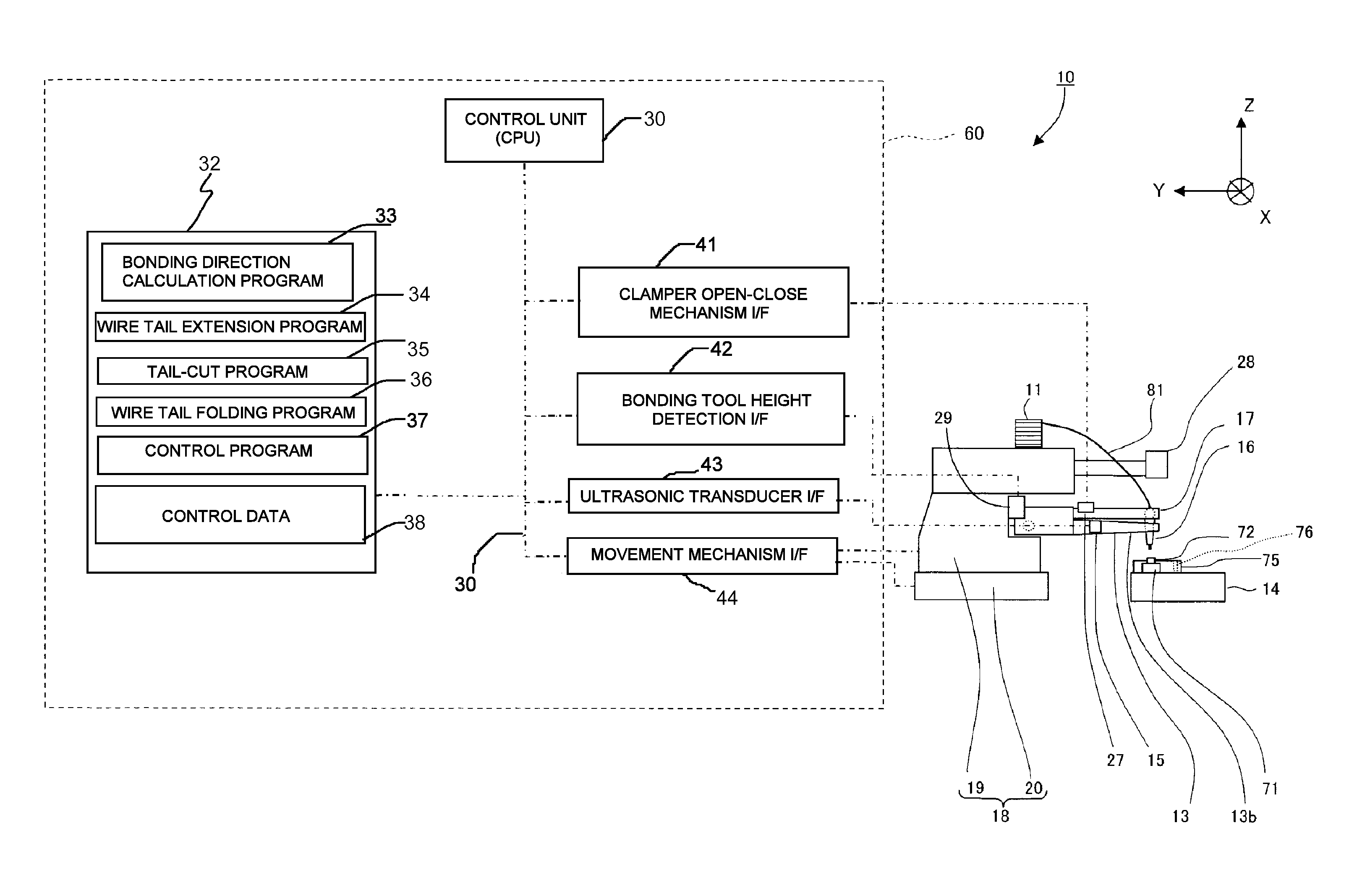

Provided is a wire bonding apparatus capable of performing high-speed wedge wire bonding, the apparatus including: a bonding tool having a through hole and a pressing surface for pressing a wire; a clamper for holding the wire; and a control unit. The control unit includes: wire tail extension unit that moves the bonding tool, after wedge bonding of the wire to a first lead, upward and along a second straight line connecting a second pad and a second lead, and causes the wire to extend from the through hole in a direction along the second straight line from the second pad to the second lead; and tail cut unit that, after causing the wire tail to extend, cuts the wire tail by moving the bonding tool in the direction along the second straight line connecting the second pad and the second lead while the clamper is closed.

Owner:SHINKAWA CO LTD

Semiconductor device and wire bonding method therefor

InactiveUS7777353B2Reliably prevent electric short-circuiting from occurringSmall sizeSemiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

In a semiconductor device, first wires each having a relatively low loop height are formed between a first lead and a plurality of first electrode pads aligned in a first line, and then second wires each having a relatively high loop height are formed between a second lead and a plurality of second electrode pads aligned in a second line, wherein the second line is distanced from the first line in view of the first and second leads. Wire bonding is sequentially performed so as to increase the height difference between the first wire and the second wire, thus avoiding the occurrence of electric short-circuiting between adjacently arranged wires. In wire bonding, a bump forming process, a ball bonding process, and a wedge bonding process are sequentially performed. It is preferable that the second lead be vertically distanced from the first lead in the thickness direction.

Owner:YAMAHA CORP

Wedge bonder and a method of cleaning a wedge bonder

ActiveUS20130341377A1Welding/cutting auxillary devicesSolid-state devicesInterconnectionMechanical engineering

Disclosed is a wedge bonder, comprising a wedge for bonding a wire to surfaces to form an electrical interconnection therebetween, a cleaning device for cleaning the wedge, and a positioning device to which the wedge is mounted. In particular, the positioning device is operative to move the wedge to the cleaning device for cleaning. A method of cleaning a wedge of a wedge bonder is also disclosed.

Owner:ASMPT SINGAPORE PTE LTD

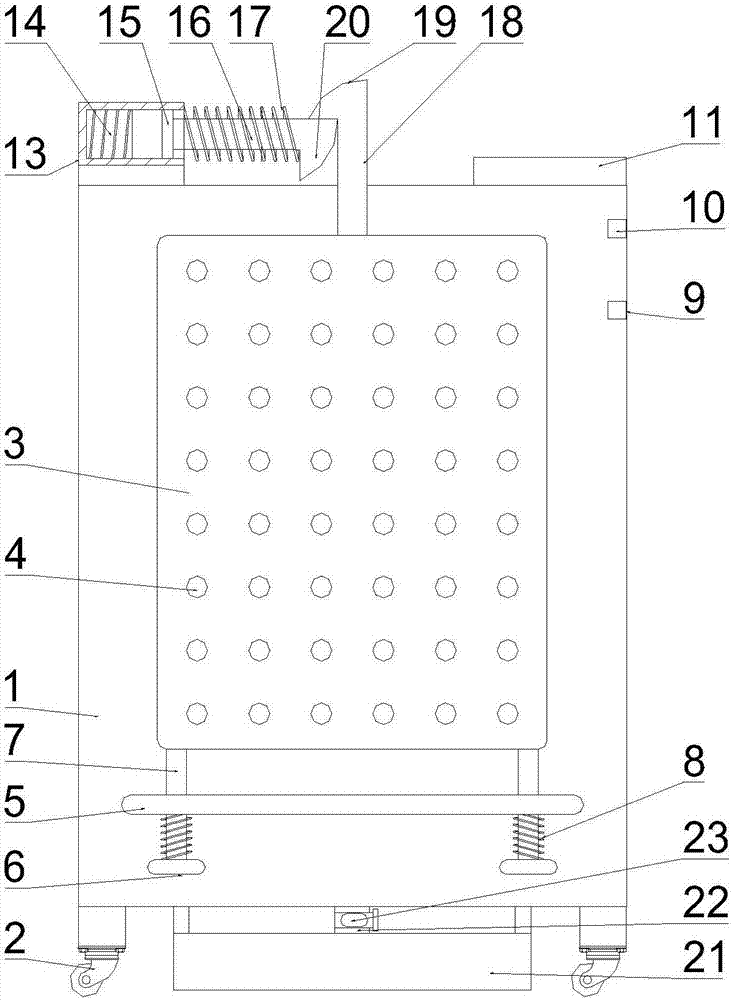

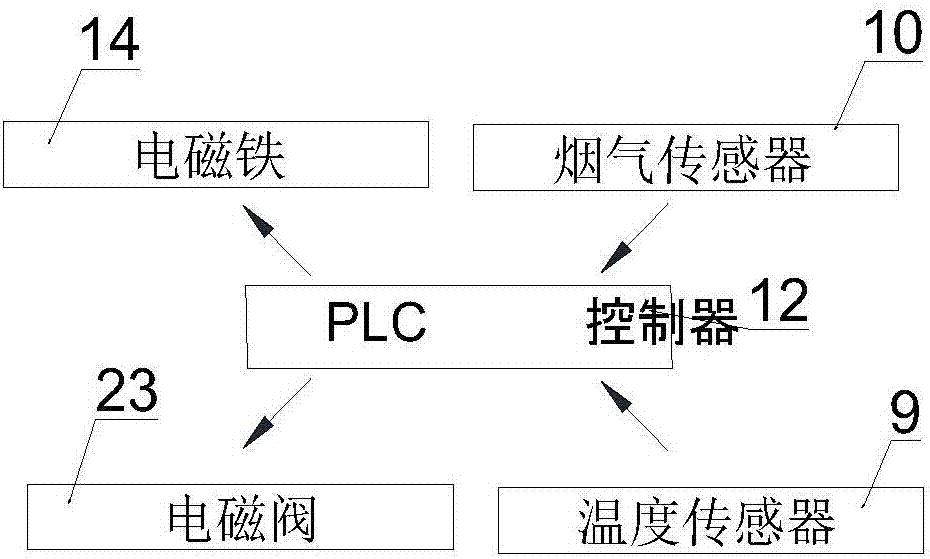

Power cabinet with fire extinguishing function

InactiveCN107275937ASave oxygenImprove ventilationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsSolenoid valveCoil spring

The invention discloses a power cabinet with a fire extinguishing function, comprising a cabinet body, an electromagnet, a sleeve, a first movable rod, a second movable rod, a first wedging block, a second wedging block, a fixed plate, and a guide column and movable plate; when a fire occurs inside the cabinet, the electromagnet is energized through the action of the temperature sensor and the smoke sensor, and the second wedge-shaped block and the first wedge-shaped block are separated from each other through the attraction of the electromagnet to the iron block. At this time, due to the effect of the first coil spring, the movable plate moves down and resets. At this time, the first cooling hole and the second cooling hole no longer overlap, so that the outside air enters the cabinet, and at the same time the solenoid valve is opened, then The nitrogen in the nitrogen tank enters the cabinet, thereby reducing the oxygen in the cabinet rapidly, which has the effect of quickly extinguishing the fire. When the cabinet returns to normal, pull the movable plate upwards, and the first heat dissipation hole and the second heat dissipation hole overlap at this time , It is convenient for the usual ventilation inside the cabinet, and the operation is simple and fast.

Owner:深圳泽土网络信息有限公司

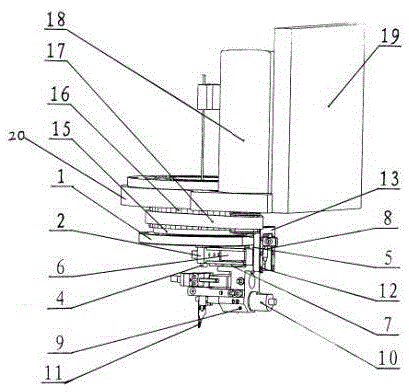

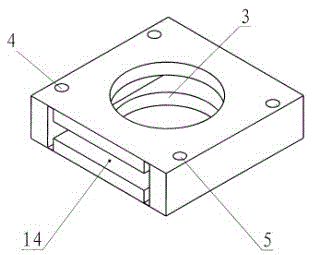

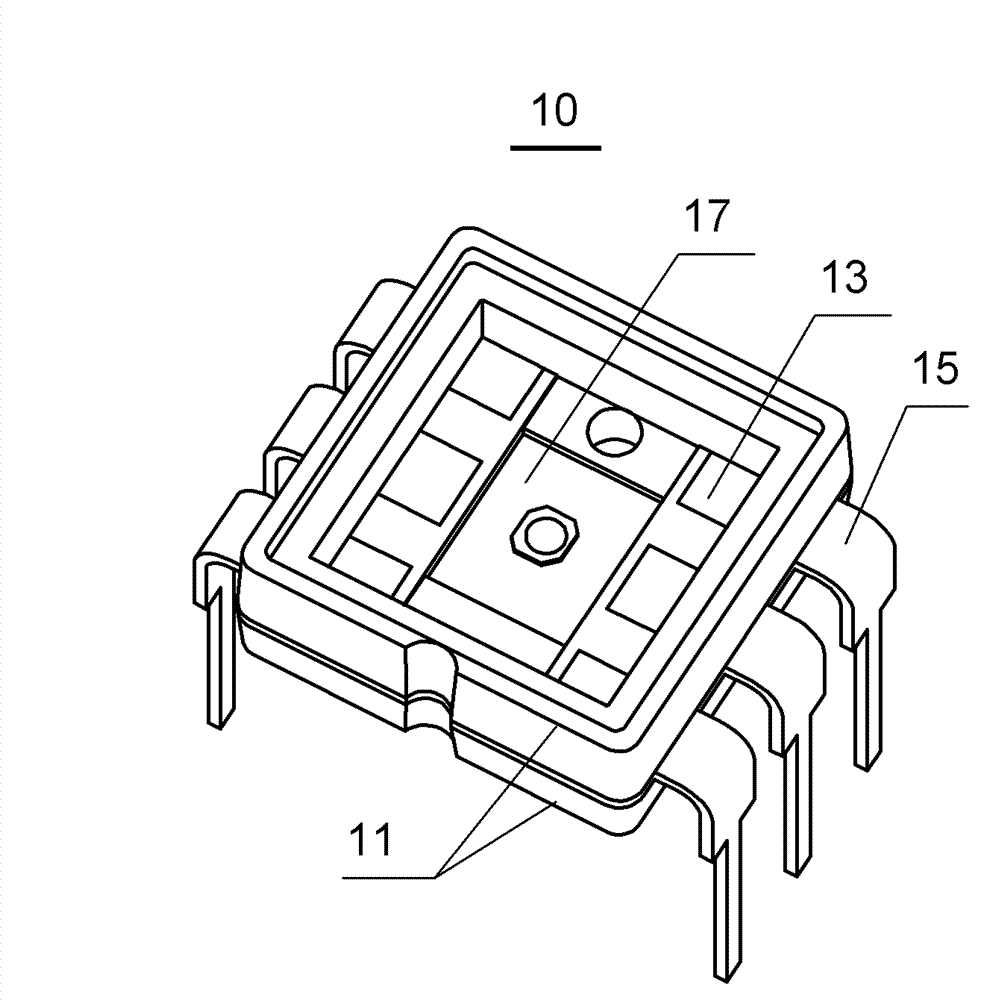

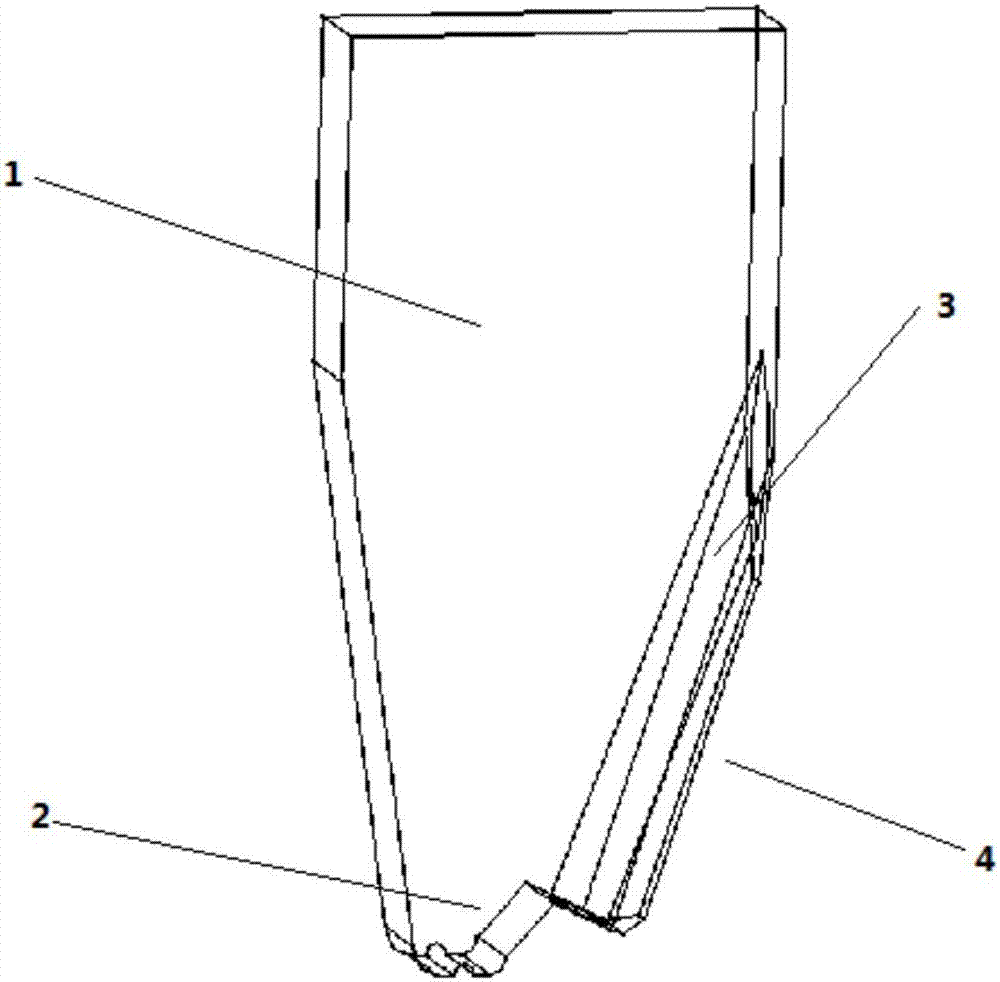

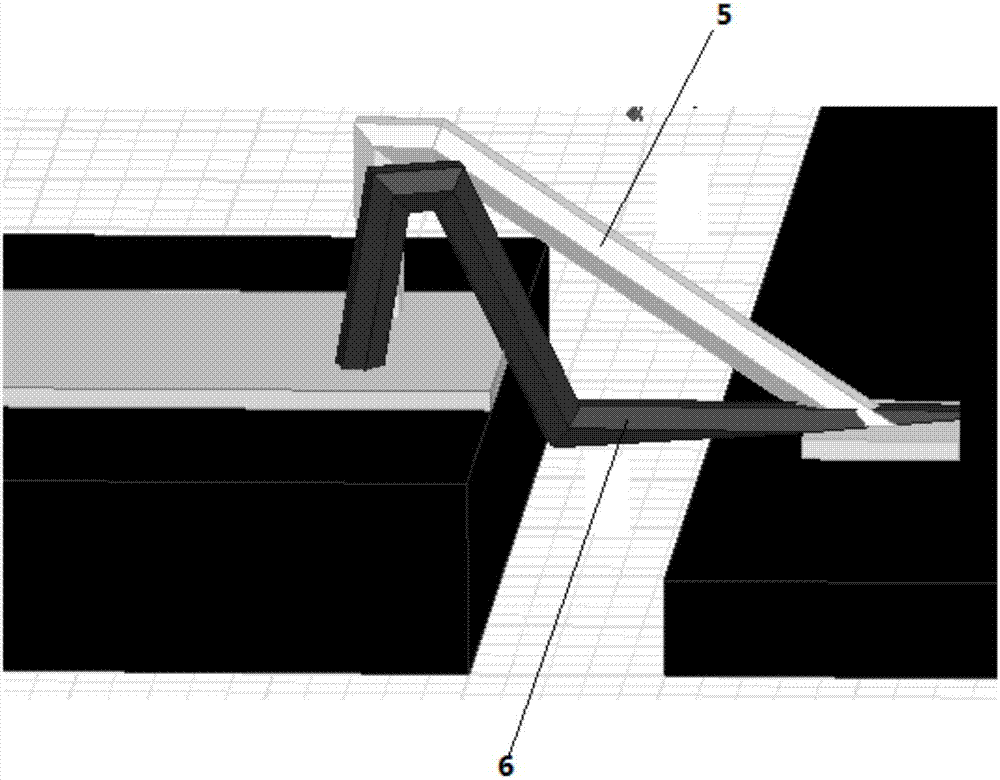

Full-automatic wire bonder welding head

InactiveCN105598613AIncrease elasticityImprove stabilityWelding/cutting auxillary devicesSolid-state devicesUltrasonic sensorFixed frame

The invention discloses a full-automatic wire bonder welding head which solves the problems that in wire wedge bonding, the micro-force output stability is poor and control regulation is difficult. The full-automatic wire bonder welding head comprises a motor fixing frame (19), a voice coil motor, an industrial control computer and a wire-bonding ultrasonic transducer; piezoelectric ceramic (10) is arranged at the right end of the wire-bonding ultrasonic transducer, the left end of the wire-bonding ultrasonic transducer is connected with a riving knife (11), a voice coil motor stator (6) is fixedly connected to the lower end face of a micro-force actuating mechanism installing plate (1) in an inverted and hung mode, an elastic deformation rectangle block (2) is connected between the micro-force actuating mechanism installing plate and a transducer installing sleeve (9), the top end face of a voice coil motor rotor (7) is connected with the top end face of the transducer installing sleeve in an abutted mode, and the piezoelectric ceramic, the voice coil motor and a position sensor (8) are all electrically connected with the industrial control computer together. In the whole pressure stroke, the full-automatic wire bonder welding head is stable and reliable in pressure control and good in repeatability.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 2 RES INST

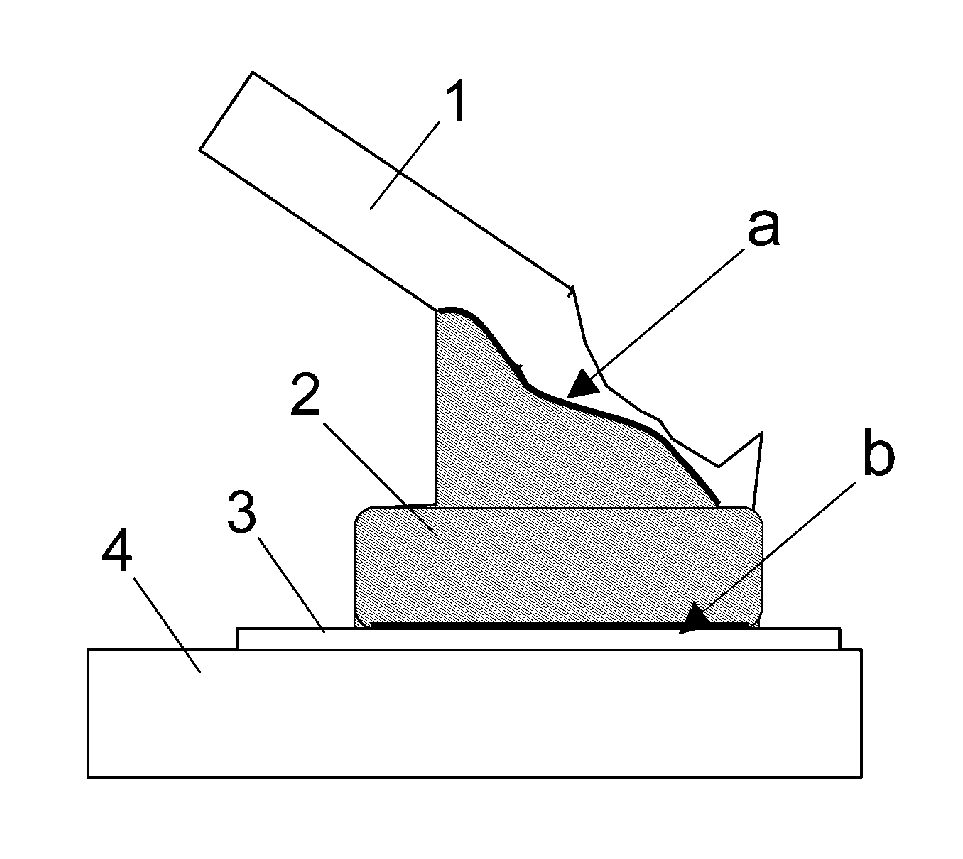

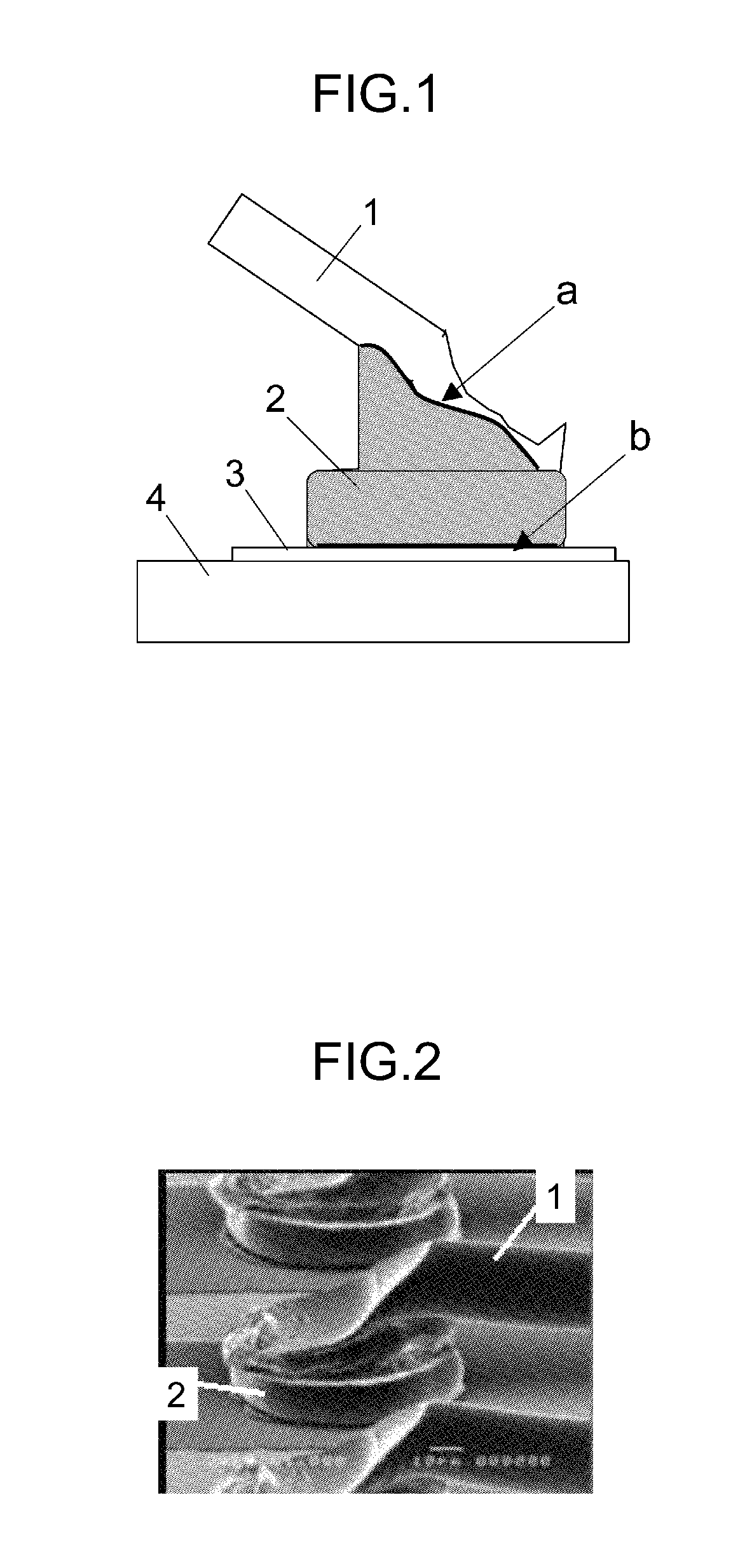

Bonding structure of bonding wire

ActiveUS20110104510A1High bonding strengthImprove continuous operabilitySolid-state devicesWelding/cutting media/materialsEngineeringCopper

The invention is aimed at providing a bonding structure of a copper-based bonding wire, realizing low material cost, high productivity in a continuous bonding in reverse bonding for wedge bonding on bumps, as well as excellent reliability in high-temperature heating, thermal cycle test, reflow test, HAST test or the like. The bonding structure is for connecting the bonding wire onto a ball bump formed on an electrode of a semiconductor device, the bonding wire and the ball bump respectively containing copper as a major component thereof. The bonding structure comprises a concentrated layer A provided at an interface of a bonding part of the ball bump and the bonding wire, wherein the concentration of a metal R other than copper in the concentrated layer A is not less than ten times the average concentration of the metal R in the ball bump; and a concentrated layer B provided at an interface of a bonding part of the ball bump and the electrode, wherein the concentration of the metal R in the concentrated layer B is not less than ten times the average concentration of the metal R in the ball bump.

Owner:NIPPON MICROMETAL CO LTD

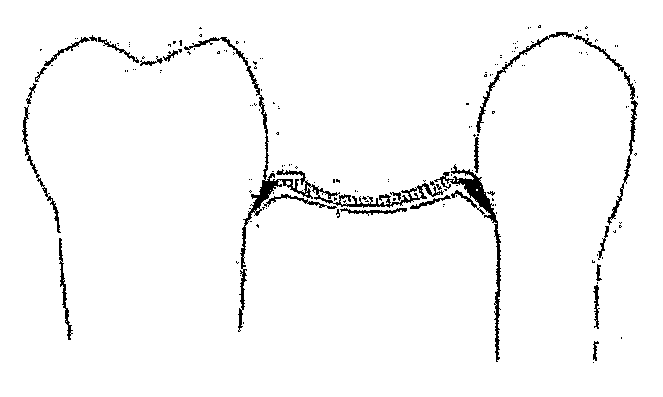

Ceramic Reinforcement Bars For Direct Dental Bridge

InactiveUS20080096166A1Reduce the amount requiredEasy to buildImpression capsFastening prosthesisFiberDental filling materials

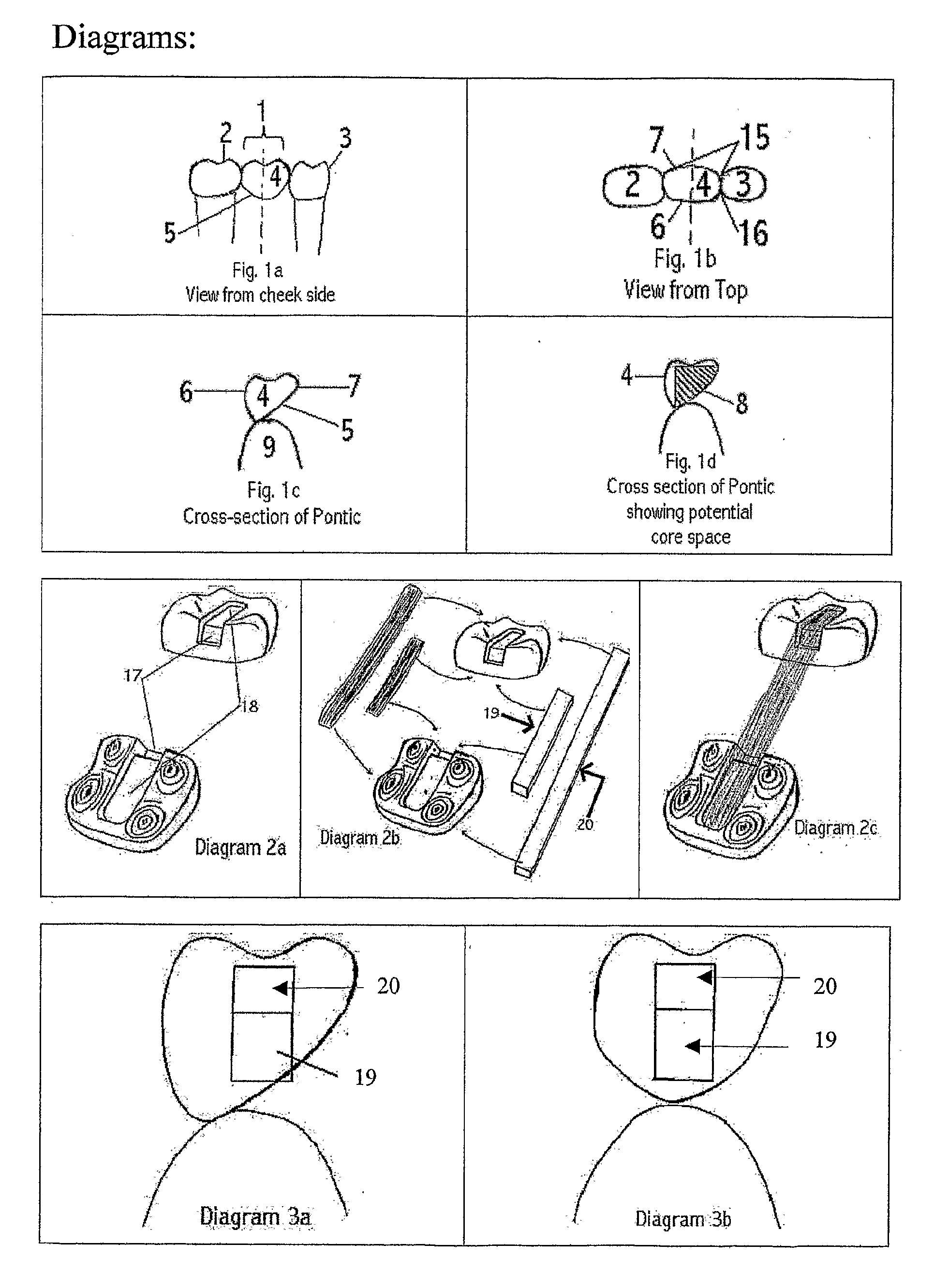

A direct dental bridge, built in the mouth of a patient, comprising Zirconium oxide or Aluminium oxide reinforcement bars (19, 20) onto which the pontic of the bridge is assembled. The ceramic bars of the present direct dental bridge bond better to dental filling materials and dental bonding resins than metal bars, and are easier to use than fiber ribbons and resin bars. Also disclosed is a method of building a direct dental bridge further comprising the use of a dental material gingival wedge bonded on an abutment tooth, demale molds for surface veneers, malleable gingival veneers and occlusal / buccal surface veneers.

Owner:MORRIS CHRISTOPHER

Low range bonding tool

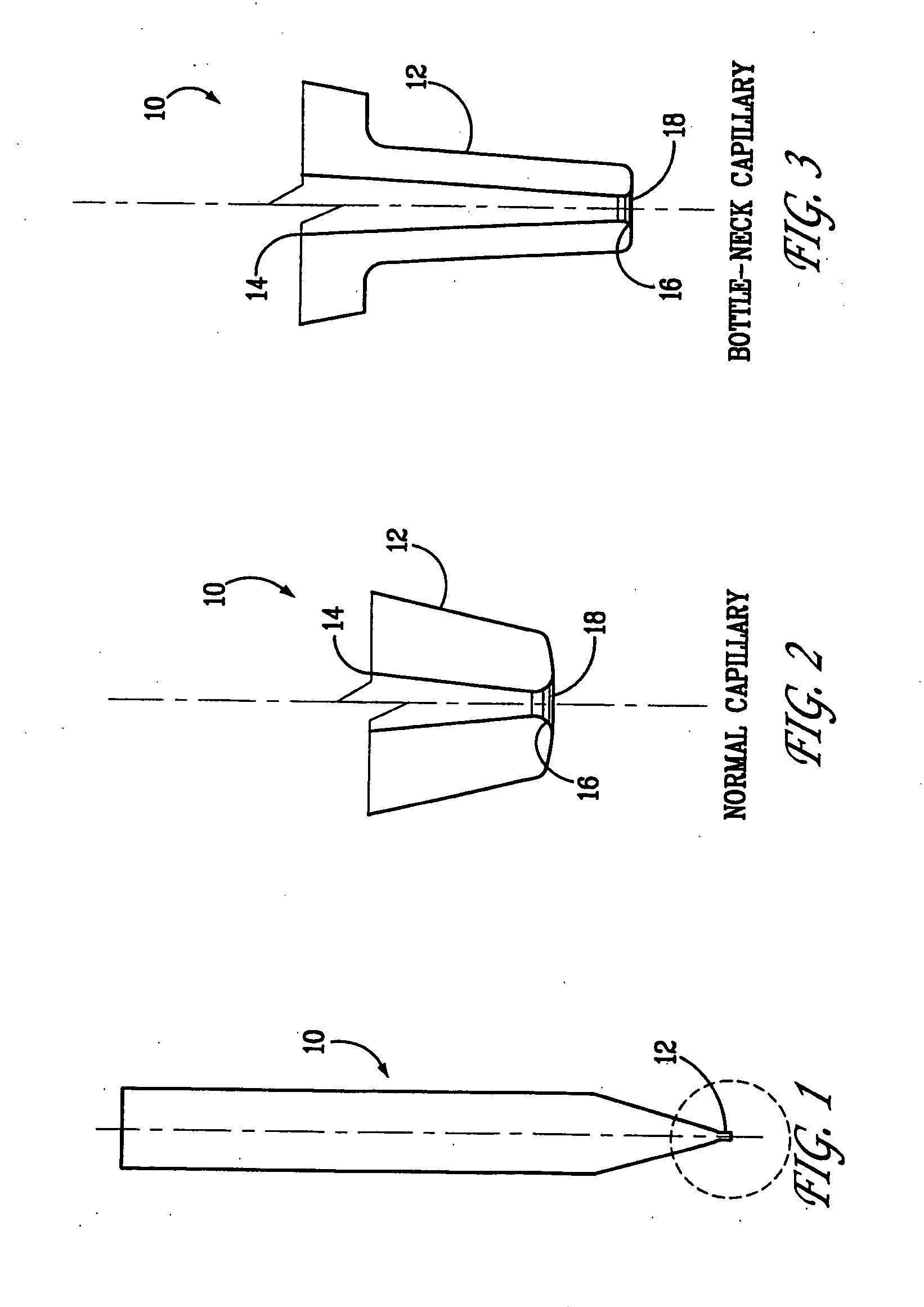

InactiveUS20060261132A1Avoid damageRange of resistanceCooking-vessel materialsSolid-state devicesElectrical resistance and conductanceElectrical connection

Bonding tool tips and wedge tools for bonding electrical connections are disclosed herein. The tool tips have 102 to 105 ohms of resistance and the wedge bonding tools have a range of 1012 to 1019 ohms of resistance. A resistive material coating the tool tip and wedge tool has a resistance low enough to discharge a voltage in a device being bonded and high enough to avoid current flow large enough to damage the device being bonded.

Owner:REIBER STEVEN F

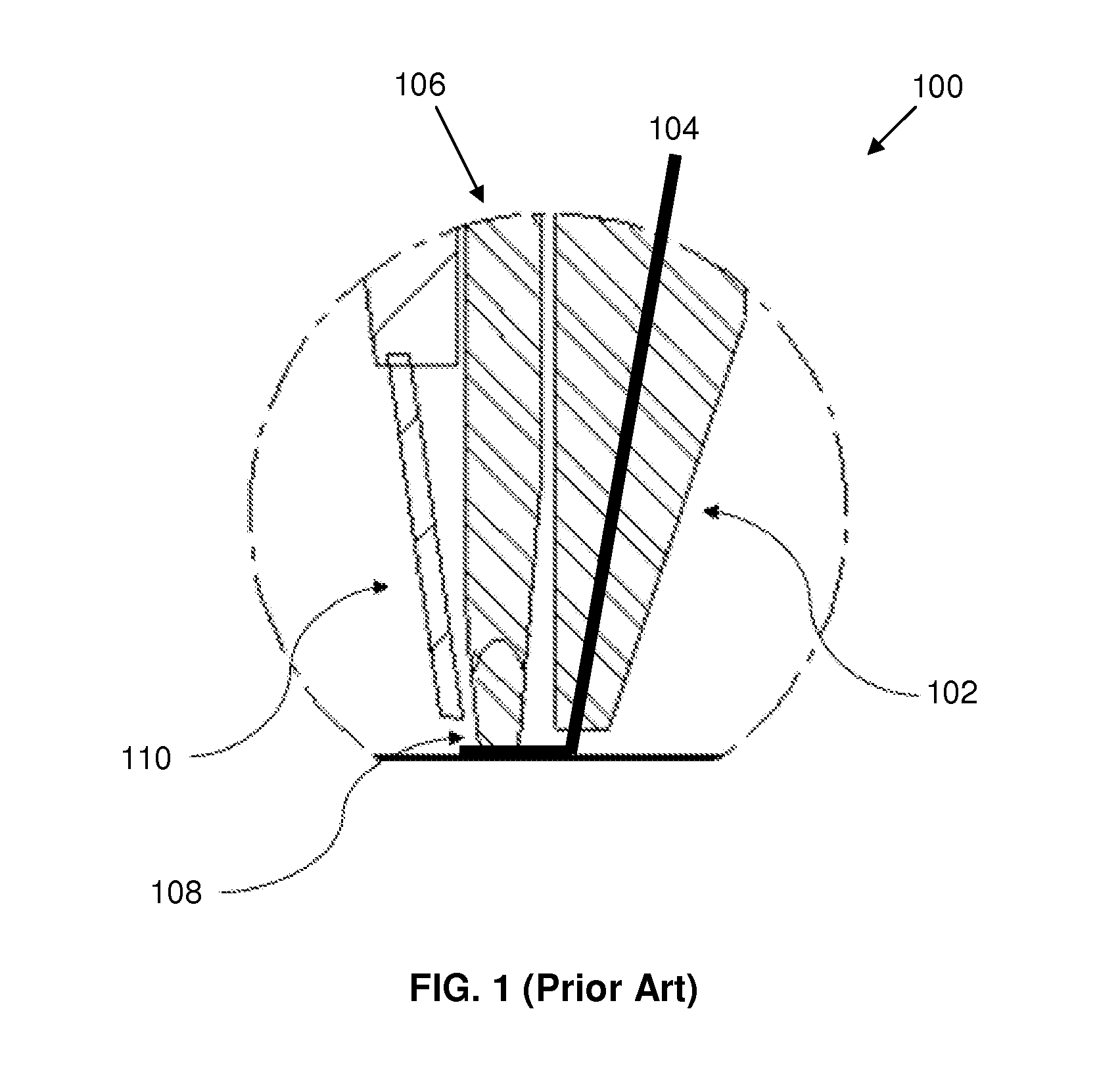

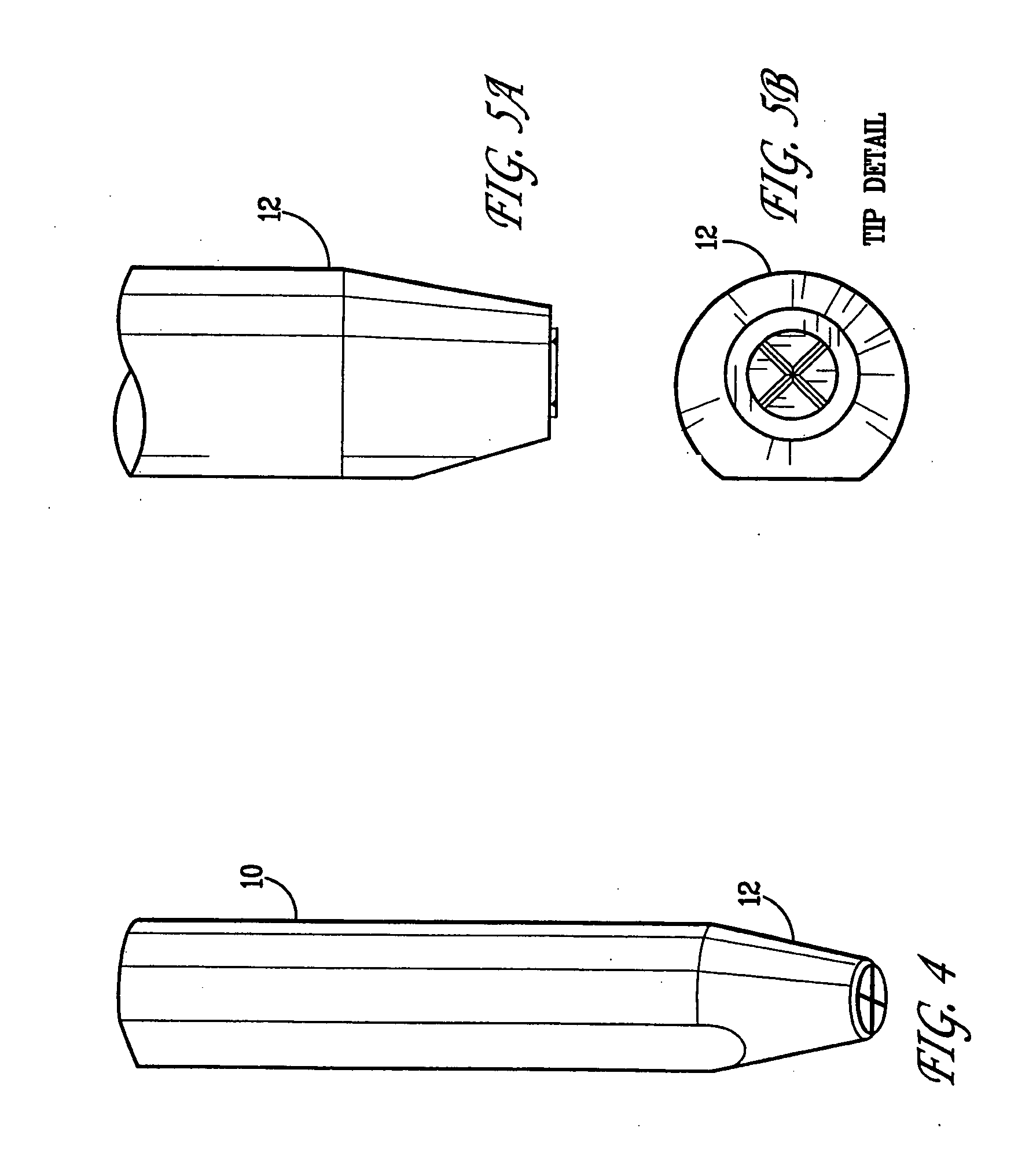

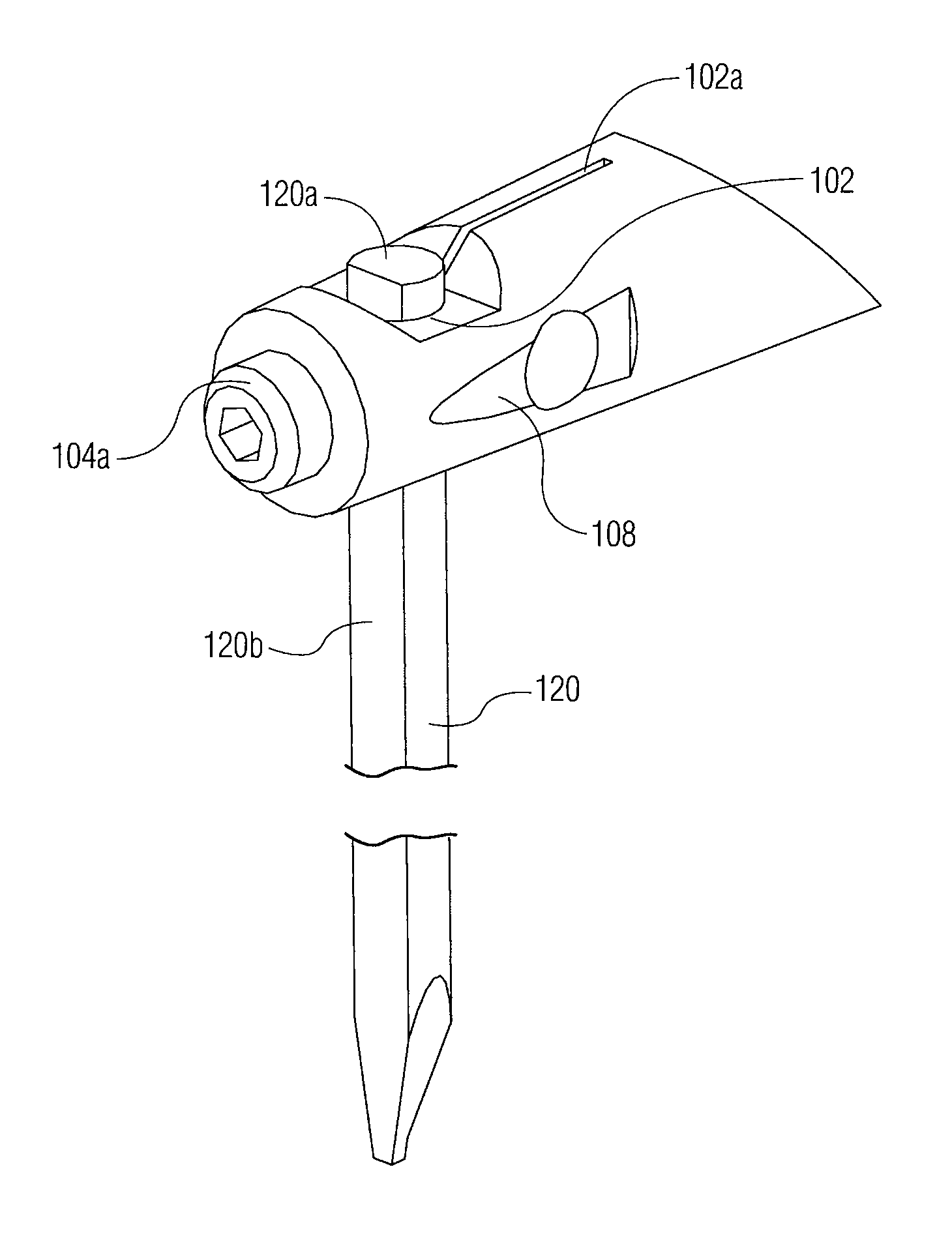

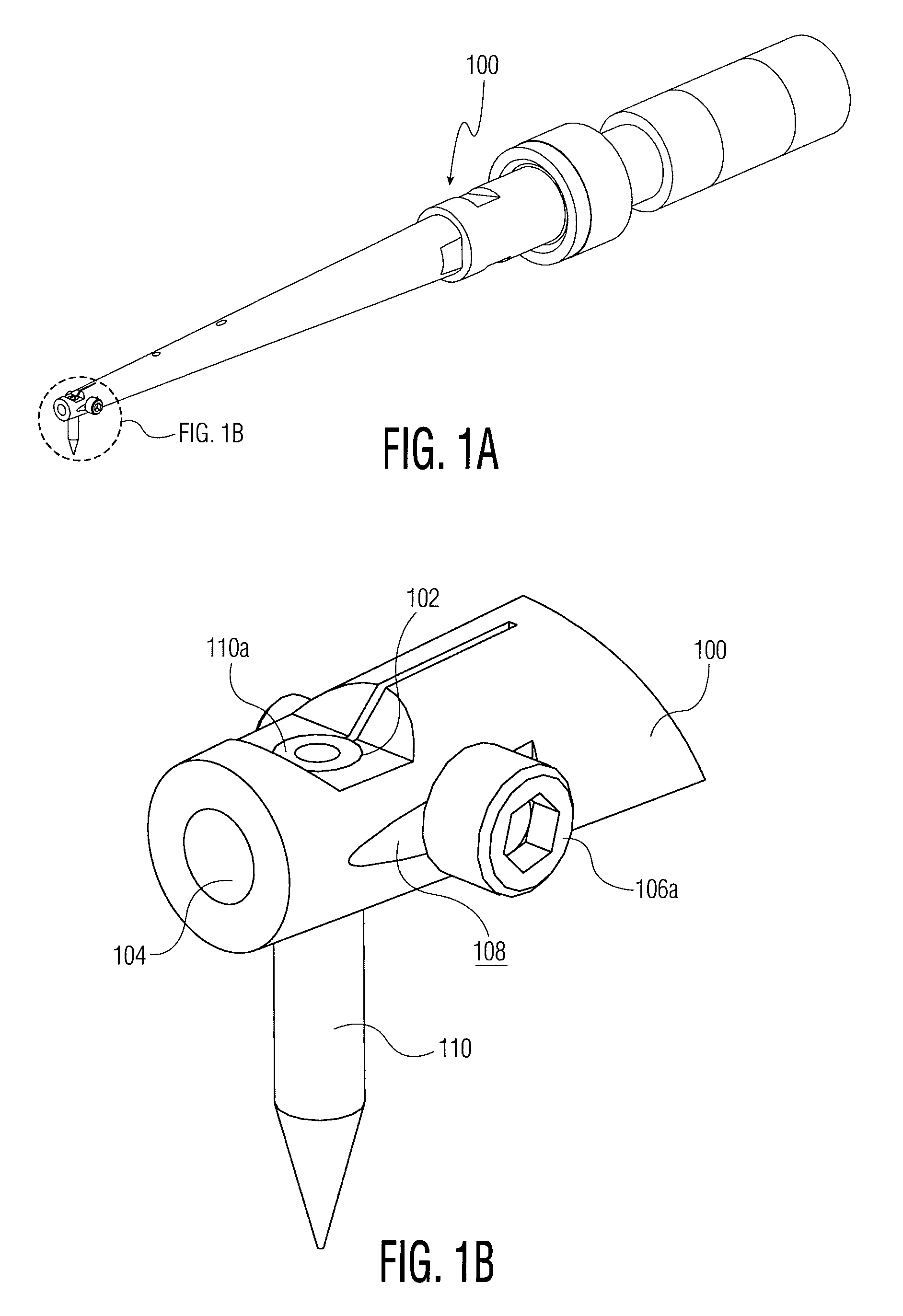

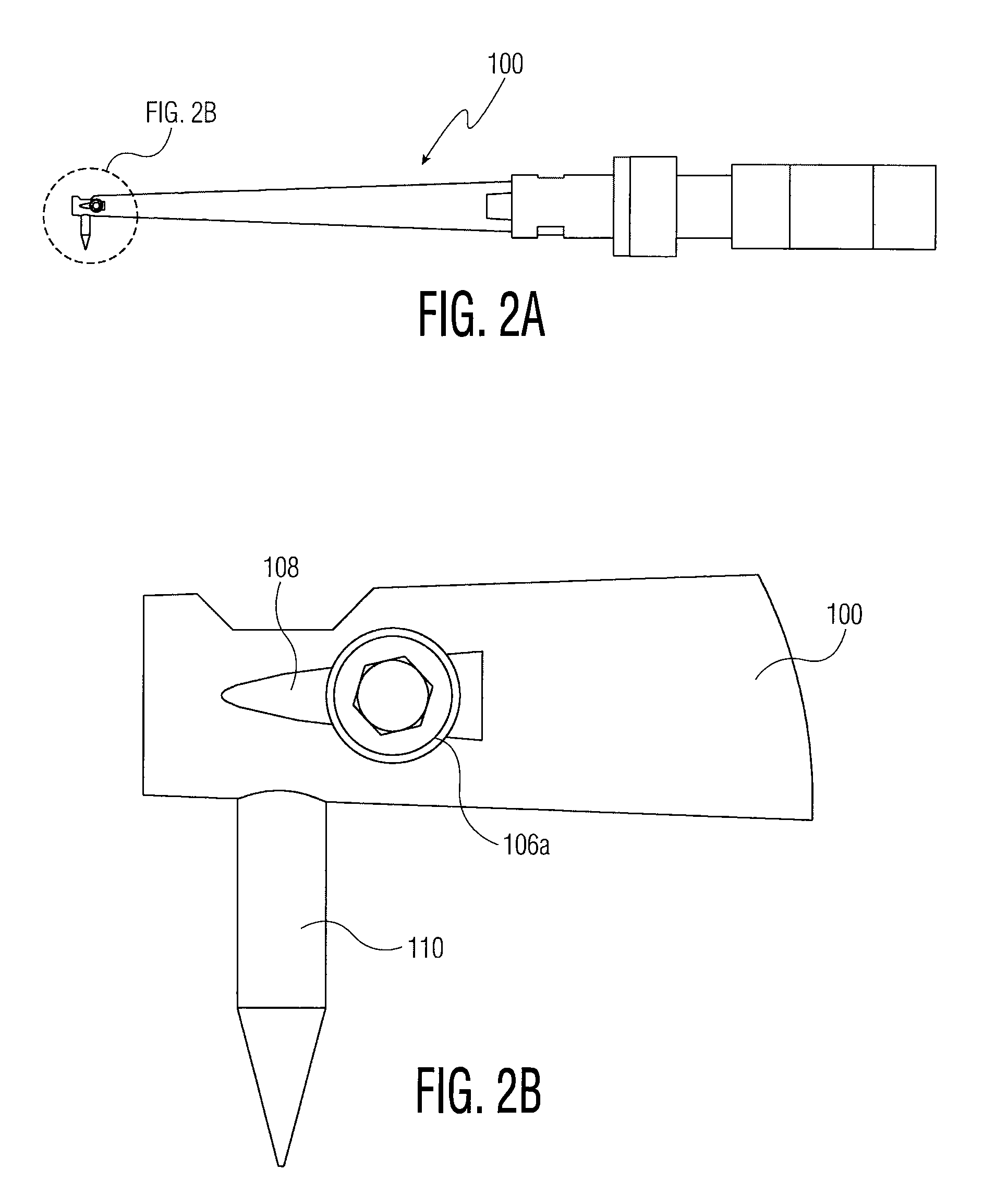

Combination wedge bonding and ball bonding transducer

A transducer configured for use with a manual wire bonding machine includes a body portion including an end portion, the end portion defining a bonding tool aperture configured to receive at least a portion of a bonding tool. The transducer also includes a first tightening mechanism for securing a ball bonding tool in the bonding tool aperture, and a second tightening mechanism for securing a wedge bonding tool in the bonding tool aperture. The first tightening mechanism is distinct from the second tightening mechanism.

Owner:KULICKE & SOFFA IND INC

Wire bonding apparatus and bonding method

ActiveUS9337166B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

Provided is a wire bonding apparatus capable of performing high-speed wedge wire bonding, the apparatus including: a bonding tool having a through hole and a pressing surface for pressing a wire; a clamper for holding the wire; and a control unit. The control unit includes: wire tail extension unit that moves the bonding tool, after wedge bonding of the wire to a first lead, upward and along a second straight line connecting a second pad and a second lead, and causes the wire to extend from the through hole in a direction along the second straight line from the second pad to the second lead; and tail cut unit that, after causing the wire tail to extend, cuts the wire tail by moving the bonding tool in the direction along the second straight line connecting the second pad and the second lead while the clamper is closed.

Owner:SHINKAWA CO LTD

Lead bonding method for lead frame plastically packaged in advance

ActiveCN102820236AHigh bonding strengthSolve pollutionSolid-state devicesSemiconductor/solid-state device manufacturingLead bondingEngineering

The invention provides a lead bonding method for a lead frame plastically packaged in advance, and belongs to the technical field of packaging of chips. The lead bonding method is characterized in that by the lead bonding method, bonded balls are planted on second bonded spots in a pressure manner after the second bonded spots are formed in a wedge bonding manner. Inner lead feet bonded by the lead bonding method are high in bonding strength and good in reliability, and the lead bonding method is particularly applicable to lead bonding for lead frames plastically packaged in advance.

Owner:WUXI CHINA RESOURCE MICRO ASSEMBLY TECH

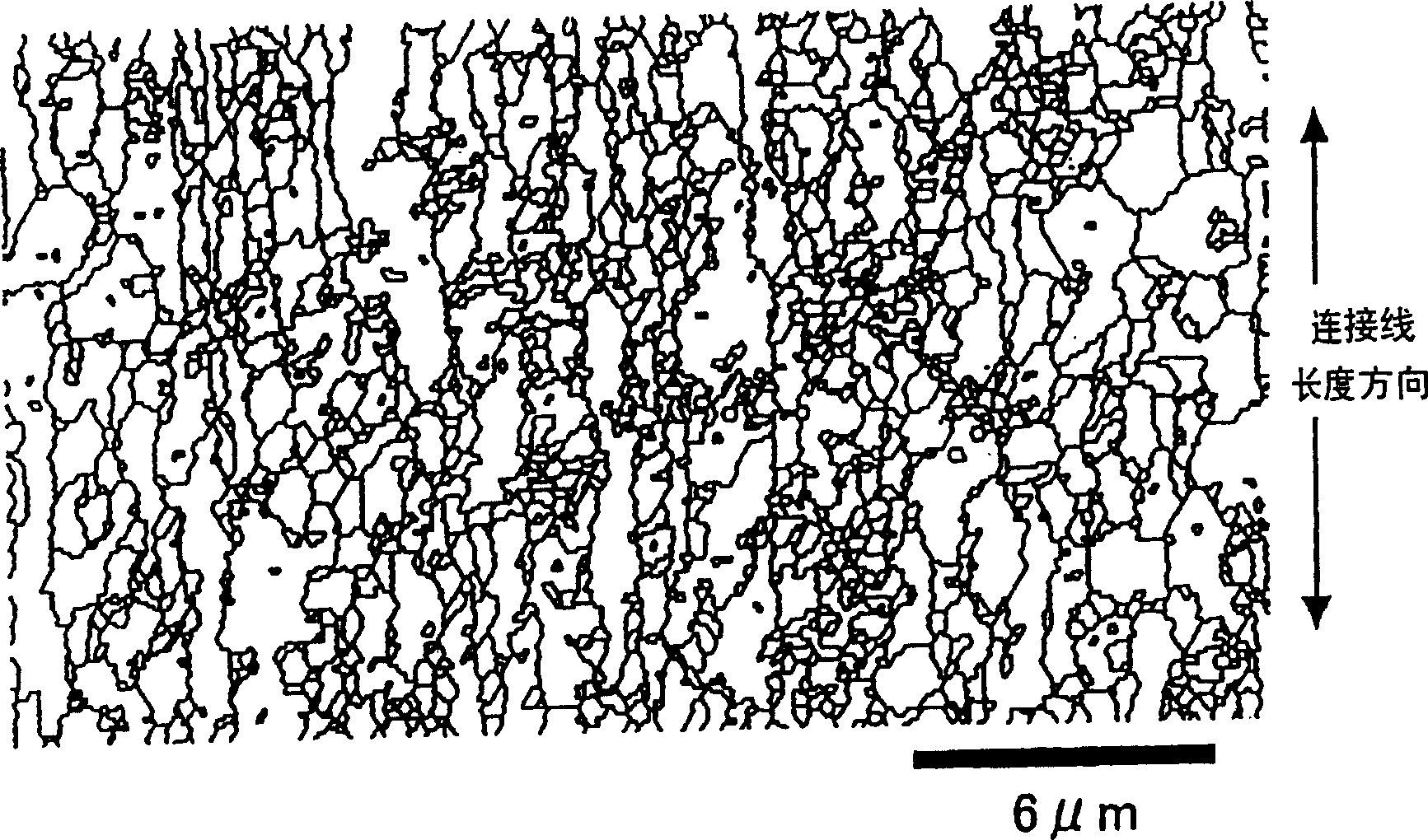

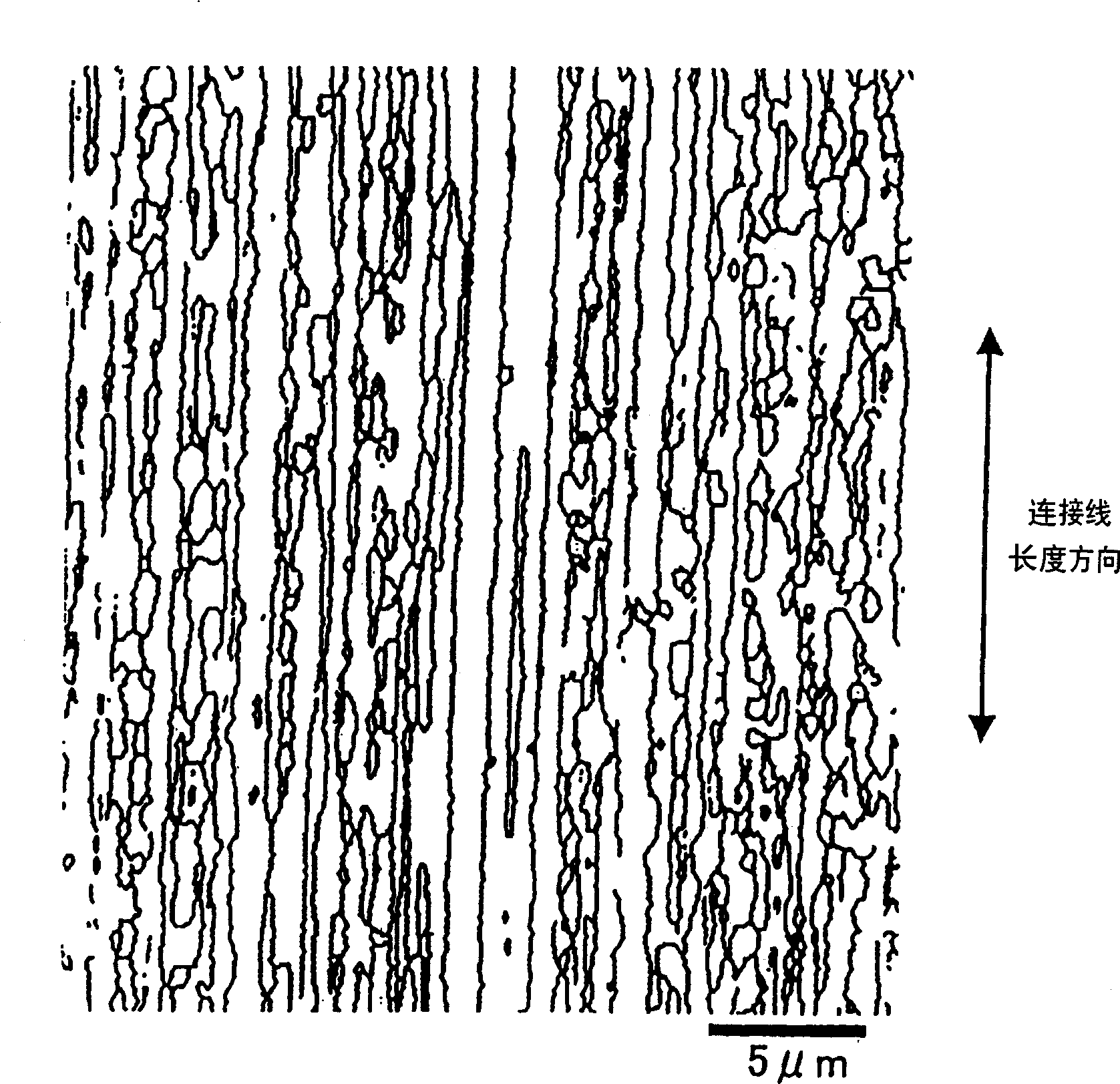

Gold alloy bonding wire for semiconductor device and process for producing the same

ActiveCN1692485ASolid-state devicesSemiconductor/solid-state device manufacturingProduction rateCrystal orientation

A gold alloy bonding wire for semiconductor device that attains collective improvement with respect to high strength / high elasticity for realizing narrow pitch bonding, stability of loop configuration, suppression of wire flowing, leaning property, bonding or fatigue characteristics at wedge bonded portions, etc. and excels in the suitability for industrial mass production; and a process for producing the same. With respect to the gold alloy bonding wire, in the crystal grain structure of longitudinal section of boding wire, the ratio of area of crystal grains exhibiting [111] orientation to area of crystal grains exhibiting [100] orientation among the crystal orientations in the longitudinal direction of wire is 1.2 or greater.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

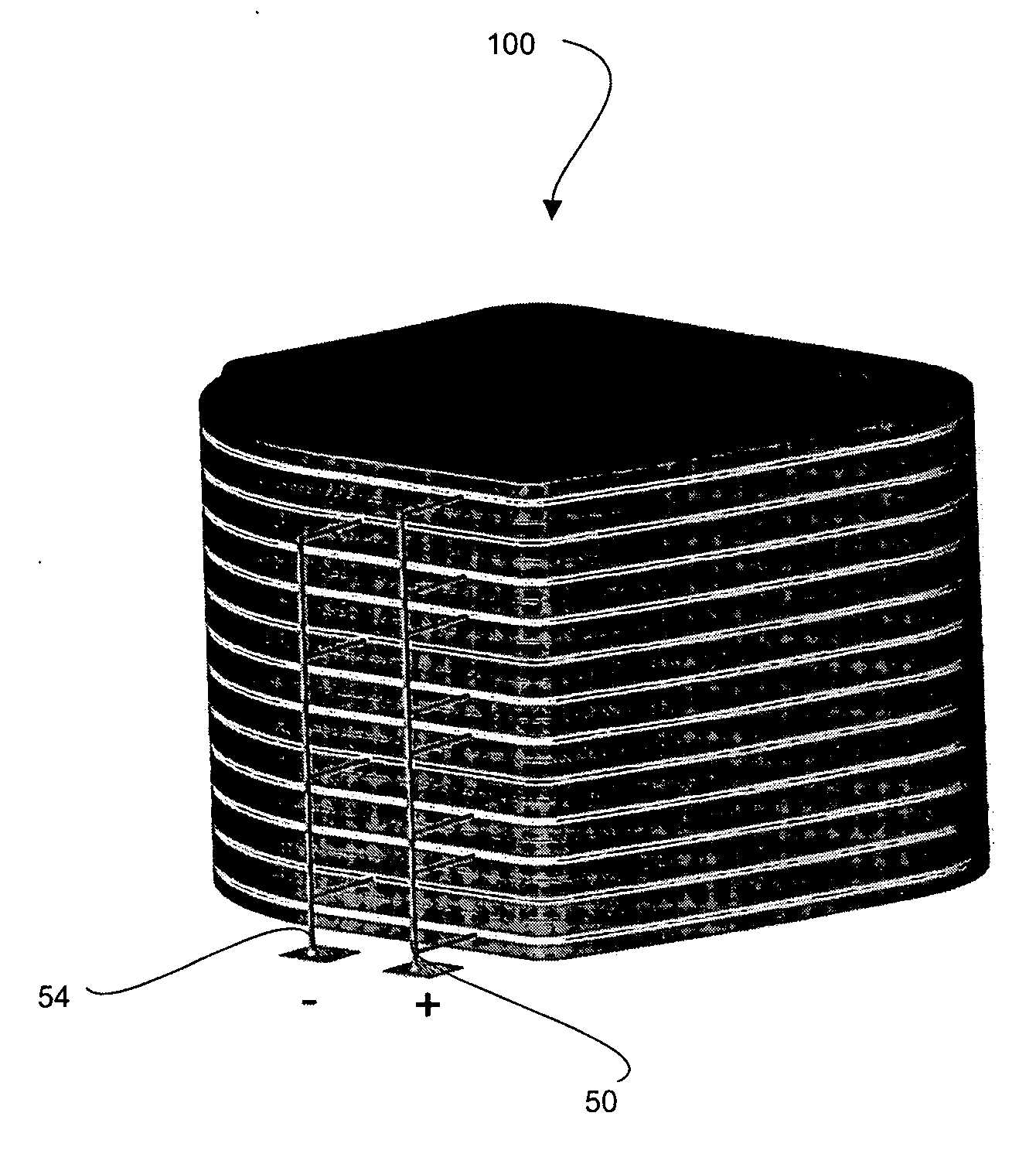

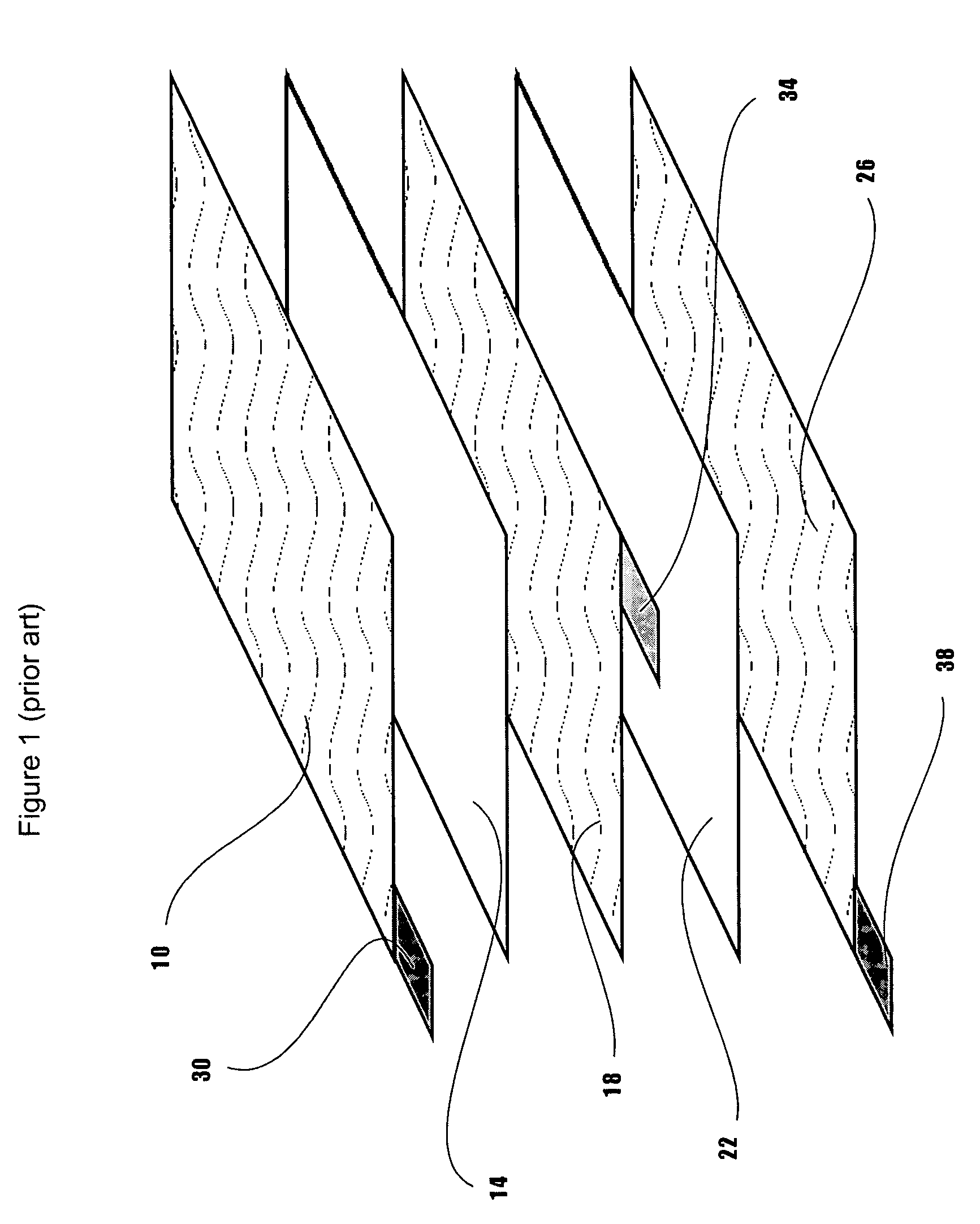

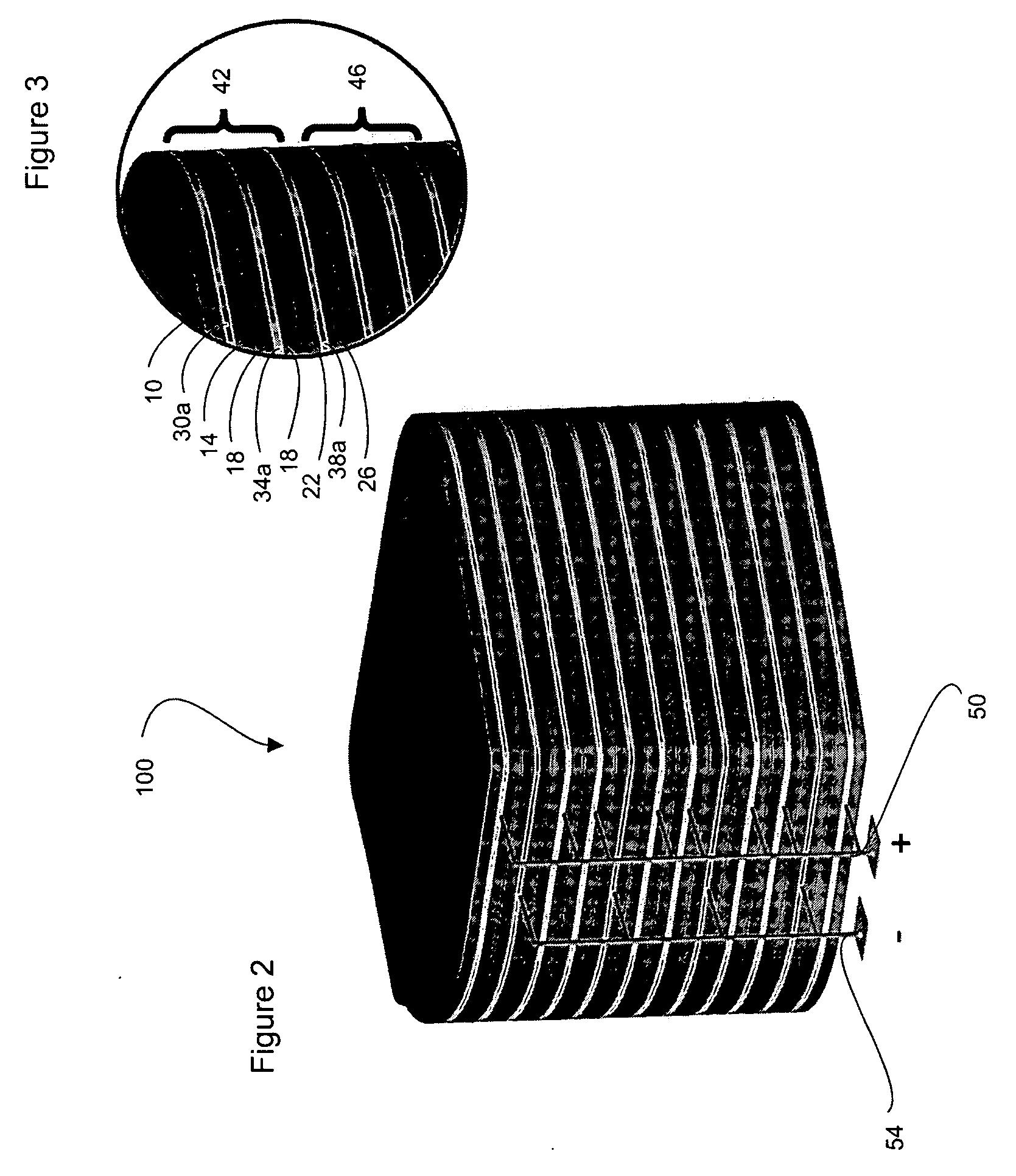

Conformal lithium polymer battery

InactiveUS20070079500A1Efficient constructionMinimized tensionFinal product manufacturePrimary cellsThermoplasticEpoxy

This invention is a method of fabricating a conformal lithium polymer battery comprising the steps of: selecting a slab of lithium polymer battery material of a desired height, containing a desired number of cells; freezing the slab; vertically cutting the slab to a desired shape; attaching a lead to each anode conductor; and attaching a lead to a each cathode conductor. The slab may contain one or many cells. The leads may be made of multistranded, metallic wire, metallic ribbon, low melting point alloy, self-healing metal, and litz wire. Attachment is accomplished so as to minimize tension on the leads. The cut slab may need to be deburred after cutting and before attaching leads. Preferably, burr formation is prevented by recessing the edge of the anodic or cathodic half cells. Lead attachment my be accomplished by: wire bonding; wedge bonding; adhesive bonding with conductive epoxy, anistotropic conductive adhesive or conductive thermoplastic; stapling; adhering the lead to the electrode by electropolymerization; welding; and growing a lead in place by electroless plating, electro-plating or a combination of electroless plating and electroplating. The distal ends of the leads may be connected together so that the cells are connected together in series, in parallel or some in series and the remainder in parallel. After the leads have been attached to the cut slab and connected together, the assembly will preferably be wrapped with standard packaging for lithium polymer batteries.

Owner:MB RES & DEV LLC A CA LTD LIABILITY

Wire bonding method for preventing polymer cracking

ActiveUS20070212869A1Simple methodSemiconductor/solid-state device detailsSolid-state devicesLead bondingBall bonding

This invention provides a wire bonding method, comprising providing an integrated circuit (IC) die having thereon a passivation layer and a plurality of first bonding pads exposed by respective openings in the passivation layer; forming a polymer layer on the passivation layer; forming an adhesive / barrier layer on the polymer layer; forming a metal pad layer on the adhesive / barrier layer; bonding a wire onto the metal pad layer to form a ball bond thereon; and after forming the ball bond on the metal pad layer, running the wire so as to contact the wire with a second bonding pad and forming a wedge bond thereto.

Owner:QUALCOMM INC

Bonding wire for semiconductor device

ActiveUS9887172B2Improve adhesionHigh bonding reliabilitySemiconductor/solid-state device detailsSolid-state devicesHigh humidityDevice material

Owner:NIPPON MICROMETAL CO LTD +1

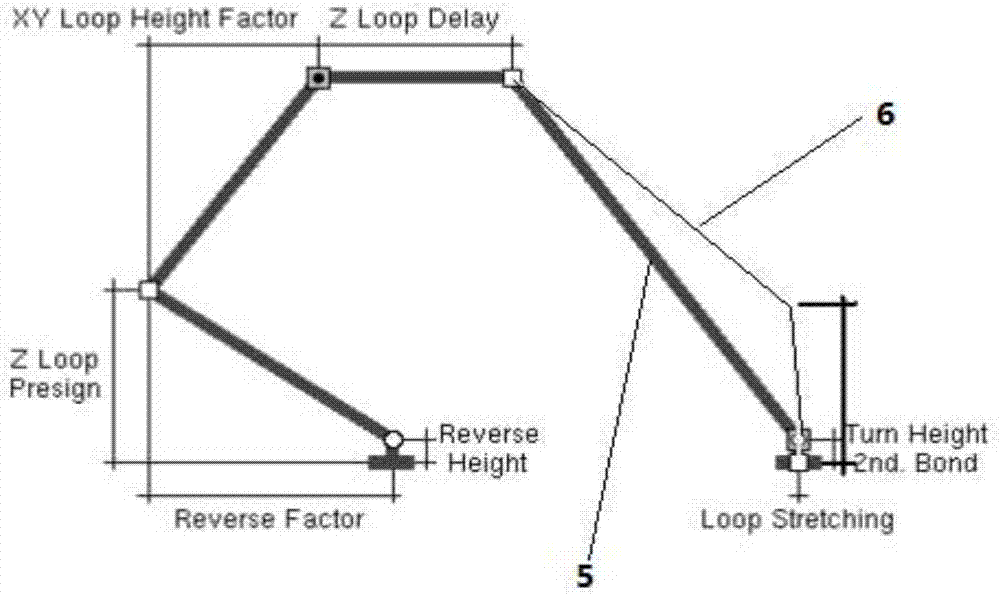

Automatic wedge bonding method on micro bonding pad in overlaying or side-by-side manner

ActiveCN107170691AIncrease coverageSmall sizeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The invention provides an automatic wedge bonding method on a micro bonding pad in an overlaying or side-by-side manner, and belongs to the technical field of microelectronics. According to the automatic wedge bonding method, a first bonding point of a first lead is bonded on a bonding pad of a first base material, and a second bonding point of the first lead is bonded on a micro bonding pad of a second base material; an improved automatic wedge bonding chopper is adopted, and the first bonding point of the second lead is bonded on the bonding pad of the first base material, and the second bonding point of the second lead is bonded above the second bonding point of the first lead in an overlaying manner or bonded in a position close to the second bonding point of the first lead in a side-by-side manner; and the above operation is executed repeatedly until the overlaying or side-by-side bonding of the last lead is completed. The invention provides the method for bonding at least two leads on the micro bonding pad in the overlaying or side-by-side manner by an automatic wedge bonding machine, so that the coverage rate of the bonded leads can be improved; and by combining the bonding pads with the same functions on a semiconductor chip, the number of input and output bonding pads can be reduced, thereby further reducing the dimension of the semiconductor chip.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

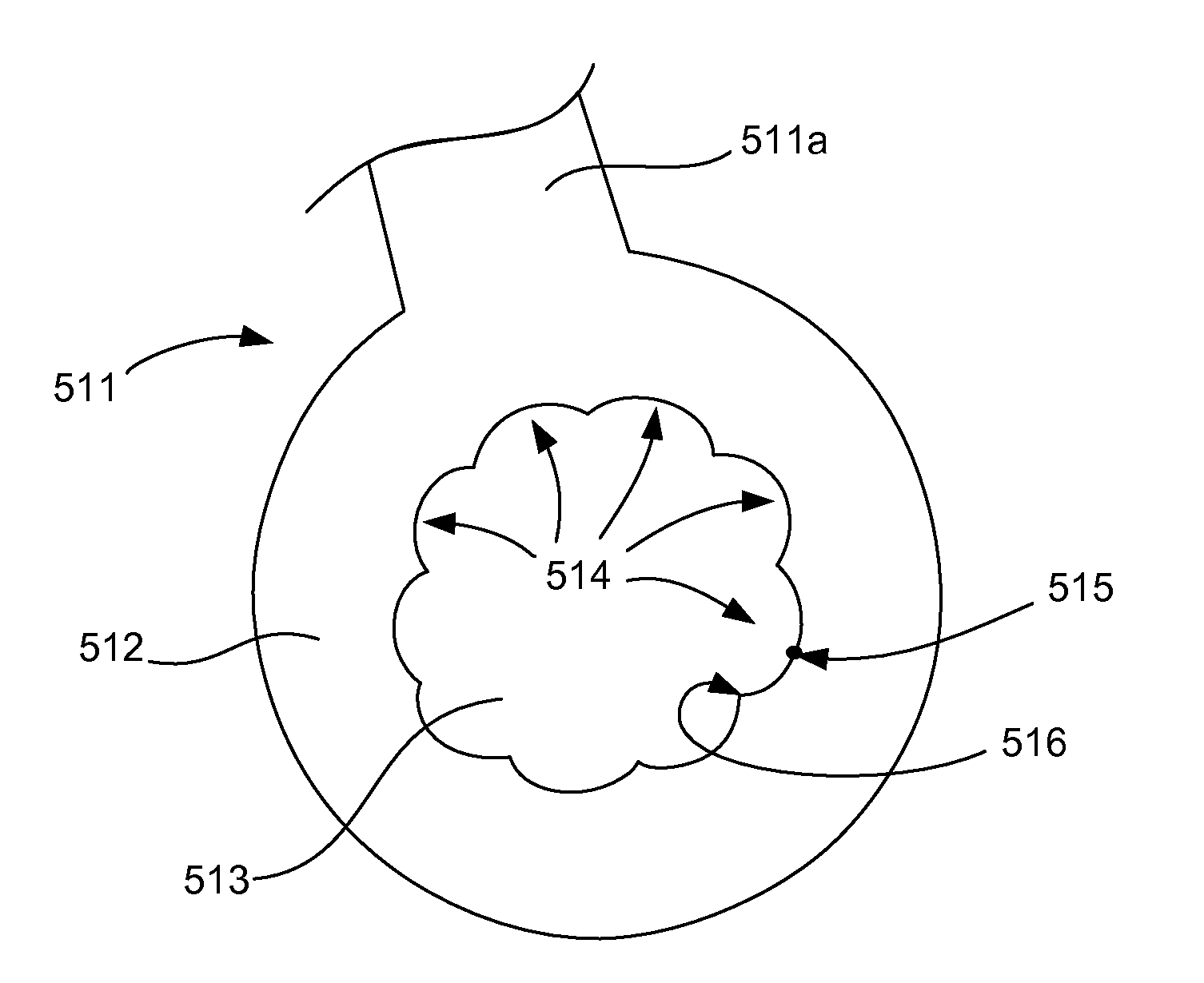

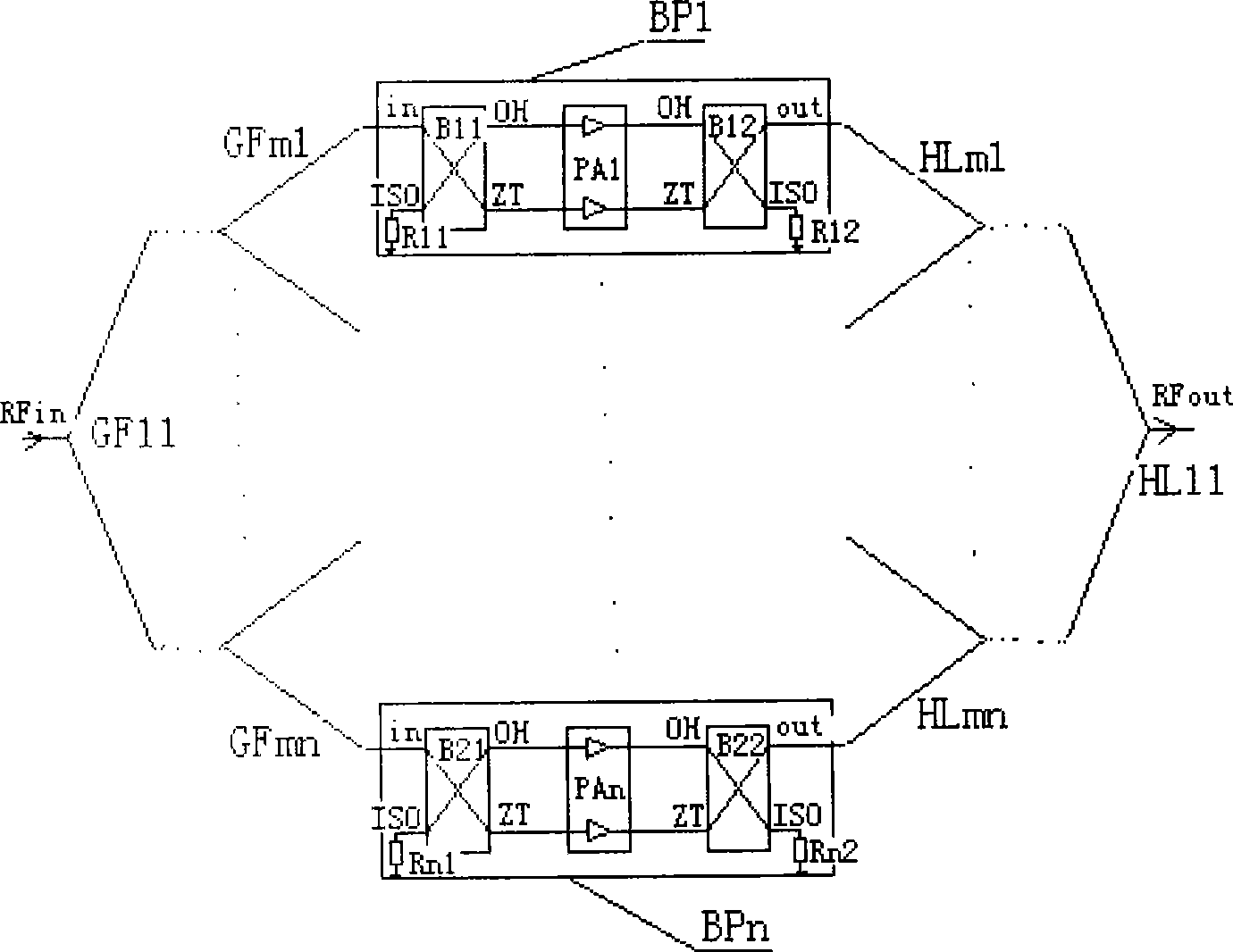

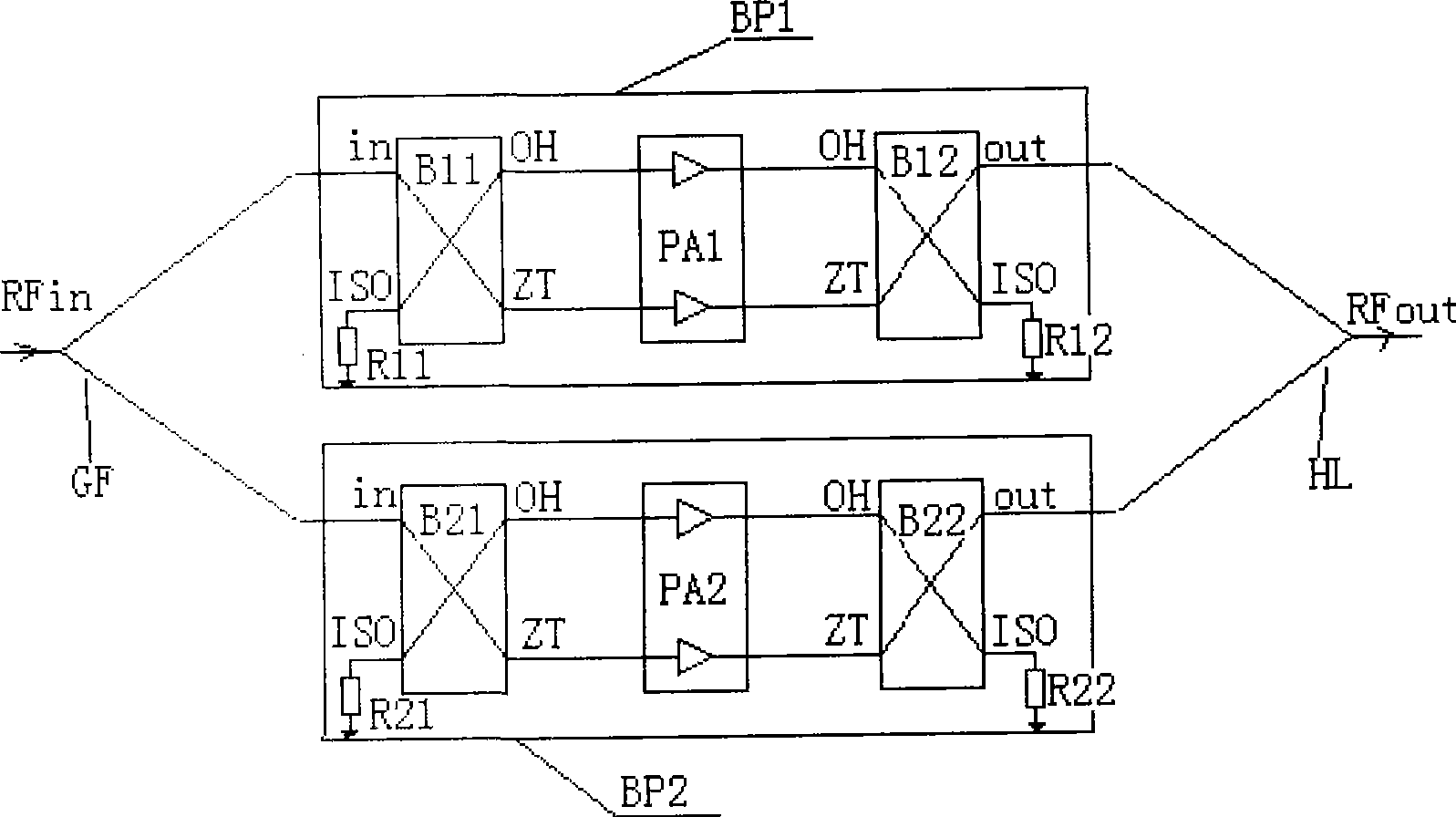

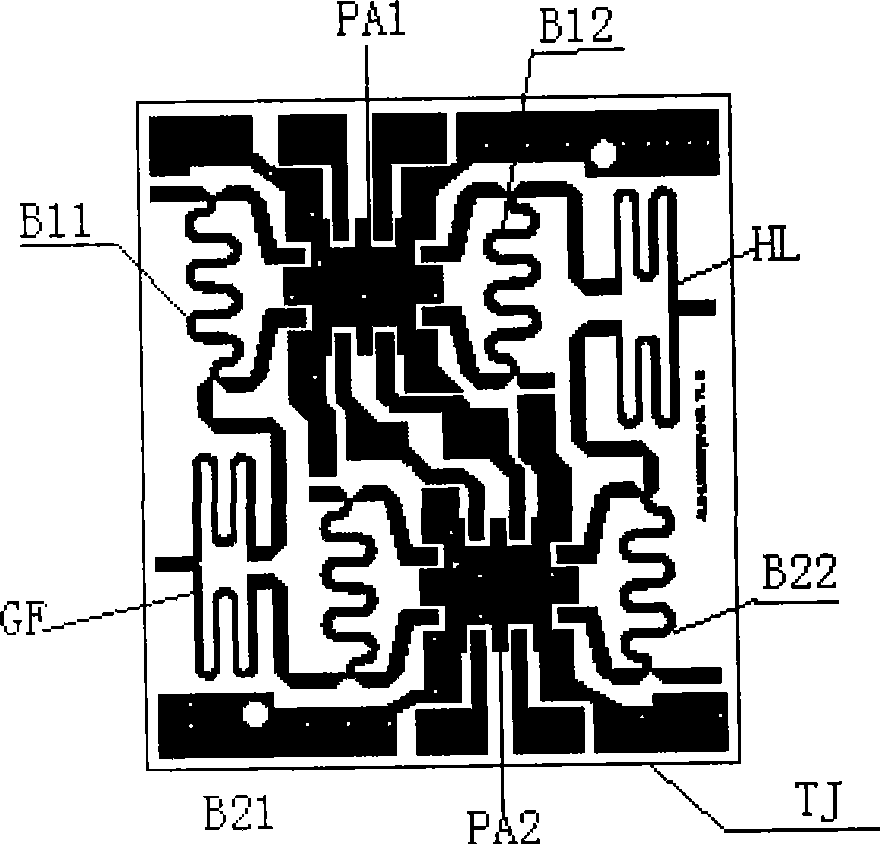

Microwave low waveband ultra-minitype power synthesizer

InactiveCN101436699AImprove consistencyHighly integratedWaveguide type devicesPower combinerBalanced amplifier

The invention discloses a micro-wave low-band ultra-micro power combiner, which is characterized in that a circuit composition comprises power dividers with a tree structure, more than or equal to 2 of multi-channel balanced amplifiers, and combiners with a tree structure, wherein each balanced amplifier consists of an IC amplifying device and two 3dB quadrature bridges, the power dividers, the combiners, the 3dB quadrature bridges in the balanced amplifiers, and peripheral circuits of the IC amplifying devices in the balanced amplifiers are produced on a ceramic substrate, and the IC amplifying devices are fixed on the ceramic substrate through wedge bonding. Circuits of a radiofrequency power combiner are produced on the ceramic substrate, the IC amplifying devices are fixed on the ceramic substrate through wedge bonding, the circuits have good consistency and the power combiner has the advantages of high gain, high integration level, high efficiency, small volume and so on, and the power combiner, is suitable for mass production, greatly reduces production cost, and is suitable to be applied to base station transmitters and small whole machines in the field of microwave communication.

Owner:SHENZHEN GRENTECH CO LTD +1

Stacked wire bonded semiconductor package with low profile bond line

ActiveUS20090321951A1Reduce the overall heightAvoid shortingSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor package

A low profile semiconductor package is disclosed including at least first and second stacked semiconductor die mounted to a substrate. The first and / or second semiconductor die may be fabricated with a plurality of redistribution pads formed over and electrically coupled to a plurality of bond pads. After the semiconductor die are formed and diced from the wafer, the die may be mounted to the substrate using a low profile reverse wire bond according to the present invention. In particular, a wedge bond may be formed between the wire and the redistribution pad without having to use a second wire bond ball on the die bond pad as in conventional reverse ball bonding processes.

Owner:SANDISK TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com