Full-automatic wire bonder welding head

A wire bonding machine and wire bonding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor stability of small force output and difficult control and adjustment, and achieve stable and reliable pressure control. Improve elastic performance and stability, good repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below in conjunction with accompanying drawing:

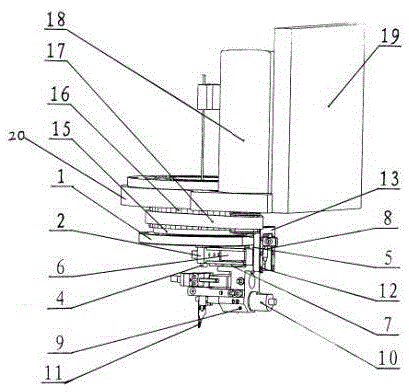

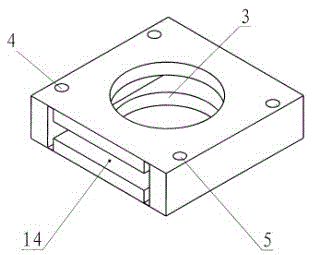

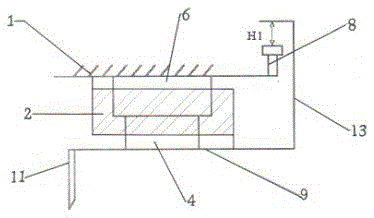

[0013] A fully automatic wire bonding machine welding head, comprising a motor fixing frame 19, a voice coil motor, an industrial control machine and a wire bonding ultrasonic transducer, a motor 18 and a bearing 20 are respectively arranged on the motor fixing frame 19, and a motor 18 and a bearing 20 are arranged on the bearing 20 is provided with rotating shaft 15, is provided with pulley 16 on rotating shaft 15, is provided with transmission belt 17 between pulley 16 and the output shaft of motor 18, is connected with fixed ring 1 at the lower end of rotating shaft 15, in The right end of the wire-bonded ultrasonic transducer is provided with a piezoelectric ceramic 10, the left end of the wire-bonded ultrasonic transducer is connected with a chopper 11, and the elastically deformable rectangular block 2 is provided with a voice coil motor in the vertical direction. The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com