Bonding wire for semiconductor

A bonding wire and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of higher specific heat than gold, inability to form spherical parts, and high melting point of palladium, etc., to achieve good Excellent wedging property and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

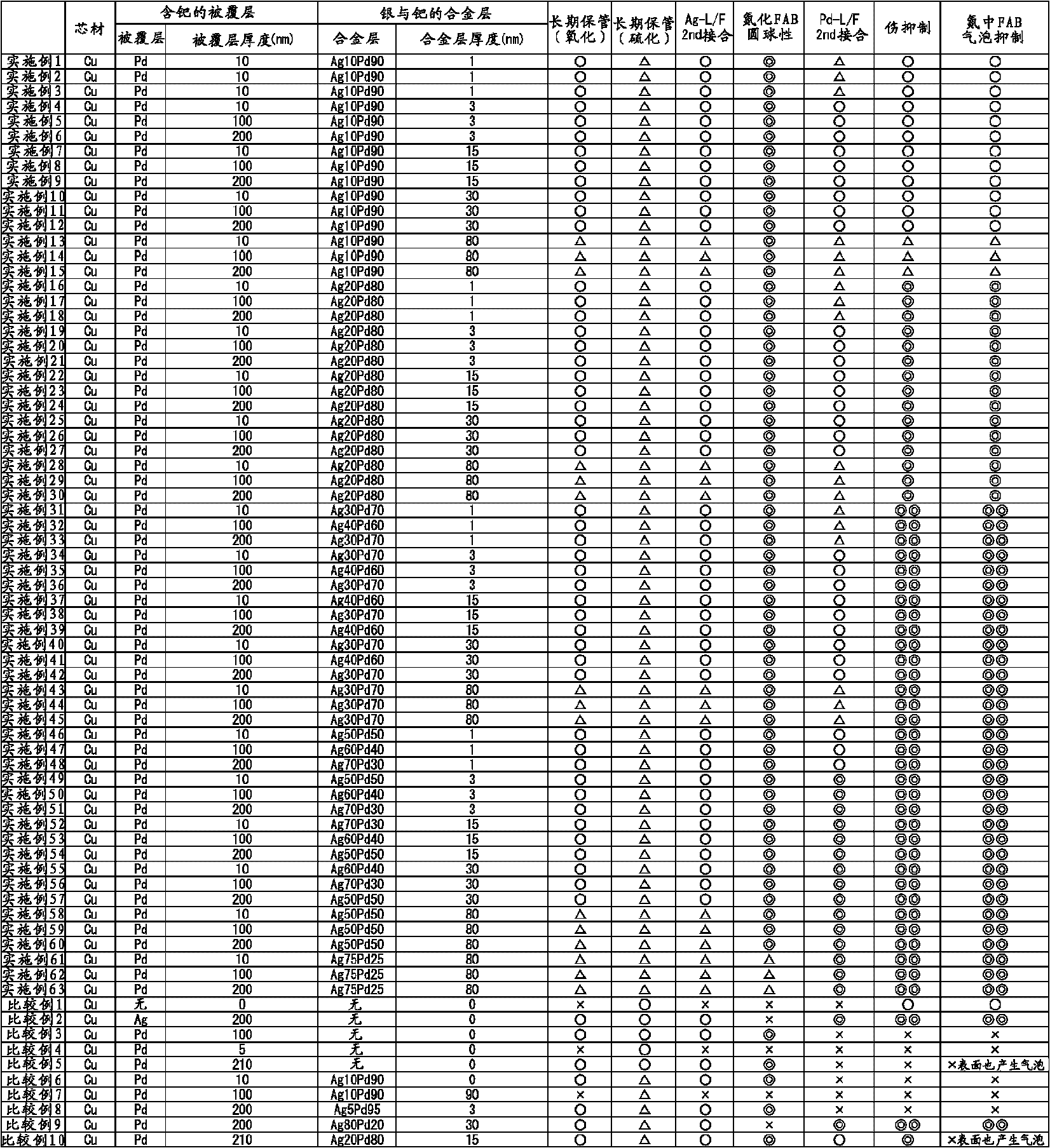

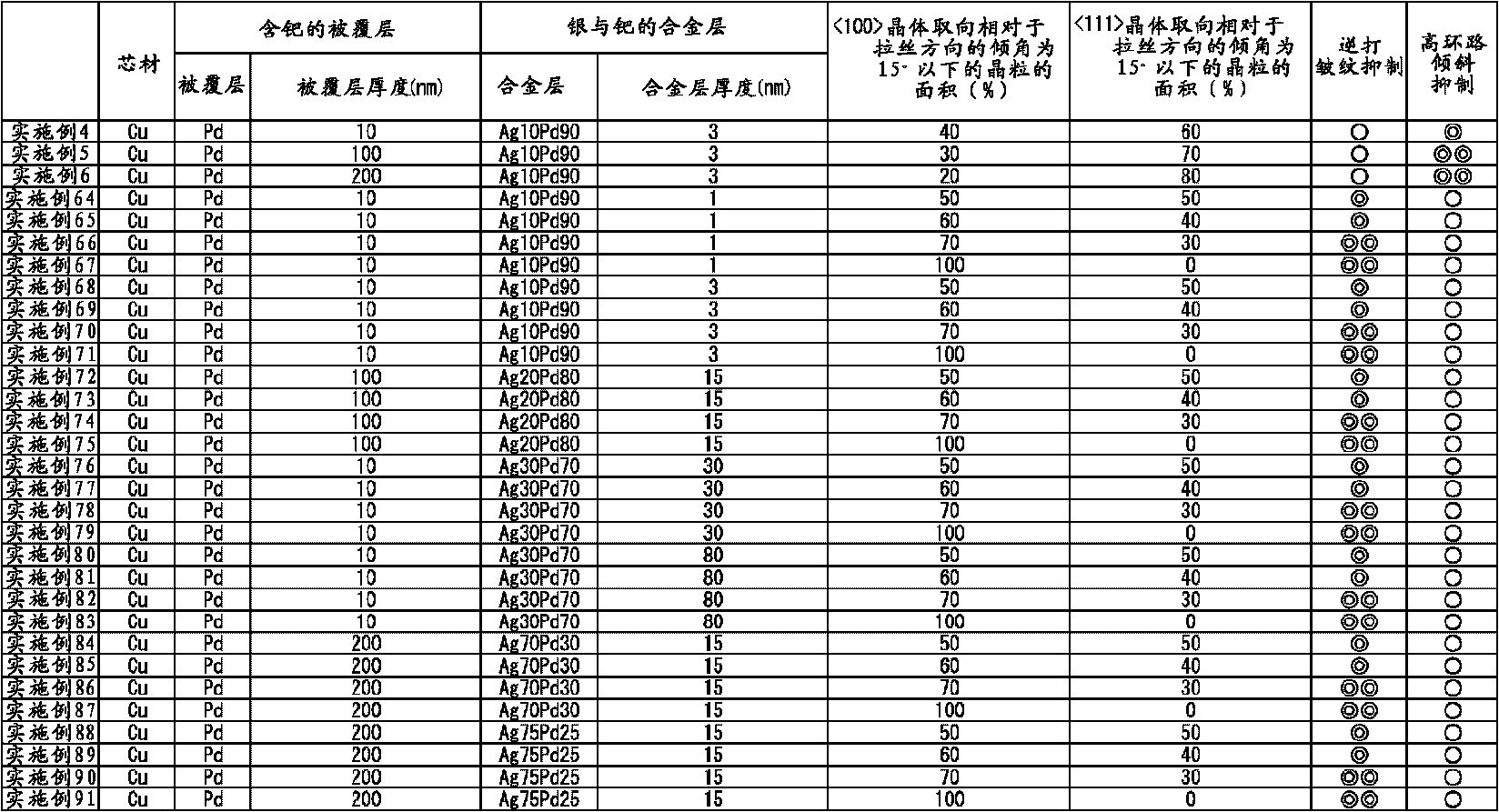

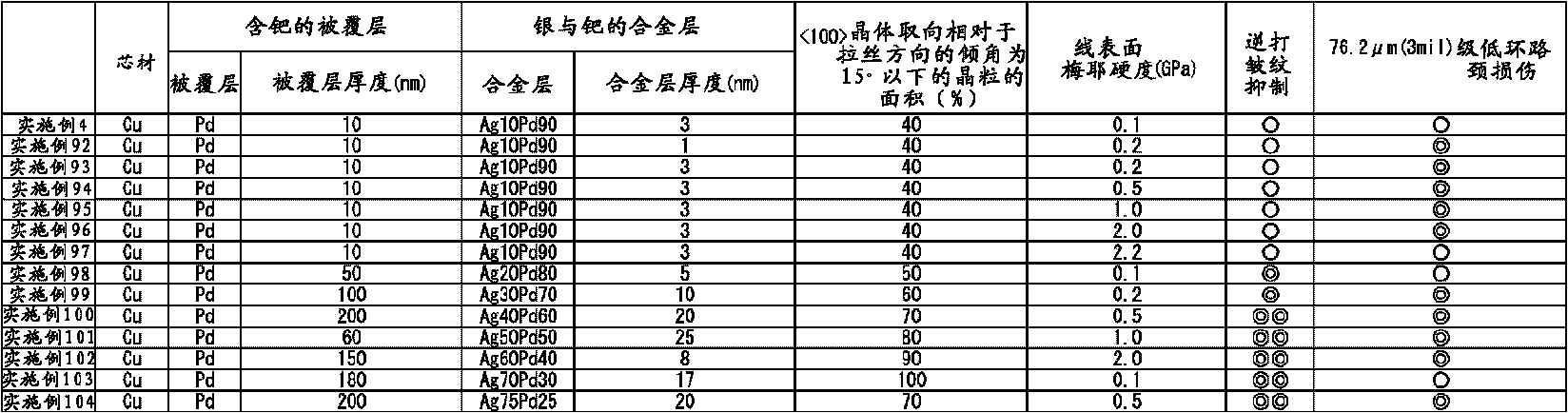

[0094] Hereinafter, Examples will be described.

[0095] First, a production example and evaluation of a bonding wire having an alloy layer containing silver and palladium on the surface of the coating layer will be described.

[0096] As the raw materials of the bonding wire, copper used for the core wire, B, P, Se, Ca, and Al as additive elements in the core wire, palladium used for the coating layer, and silver used for the skin layer, each with a purity of 99.99 was prepared. mass % or more of the billet. After weighing the above-mentioned copper or copper and additive element raw materials as starting materials, they are heated and melted under high vacuum to obtain copper or copper alloy ingots having a diameter of about 10 mm. Then, forging, rolling, and wire drawing were performed to produce a wire having a predetermined diameter. Then, a coating layer containing palladium is formed on the surface of each wire by electroplating. Here, the thickness of the above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com