Lead bonding method for lead frame plastically packaged in advance

A technology of wire bonding and plastic-encapsulated leads, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the pollution of the bonding area, reduce the bonding strength between the gold wire end 193 and the inner pin 13, reduce the Solve problems such as wire bonding reliability, achieve good reliability, avoid pollution problems, and improve bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

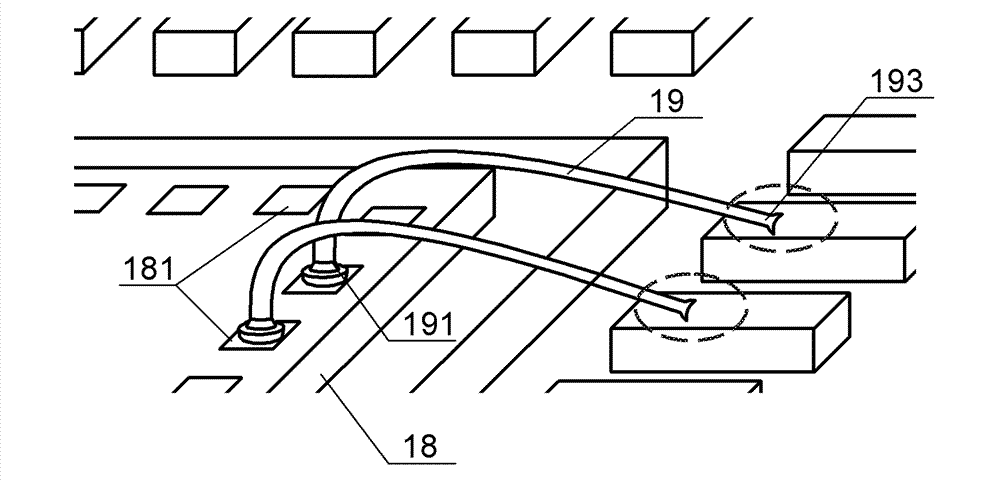

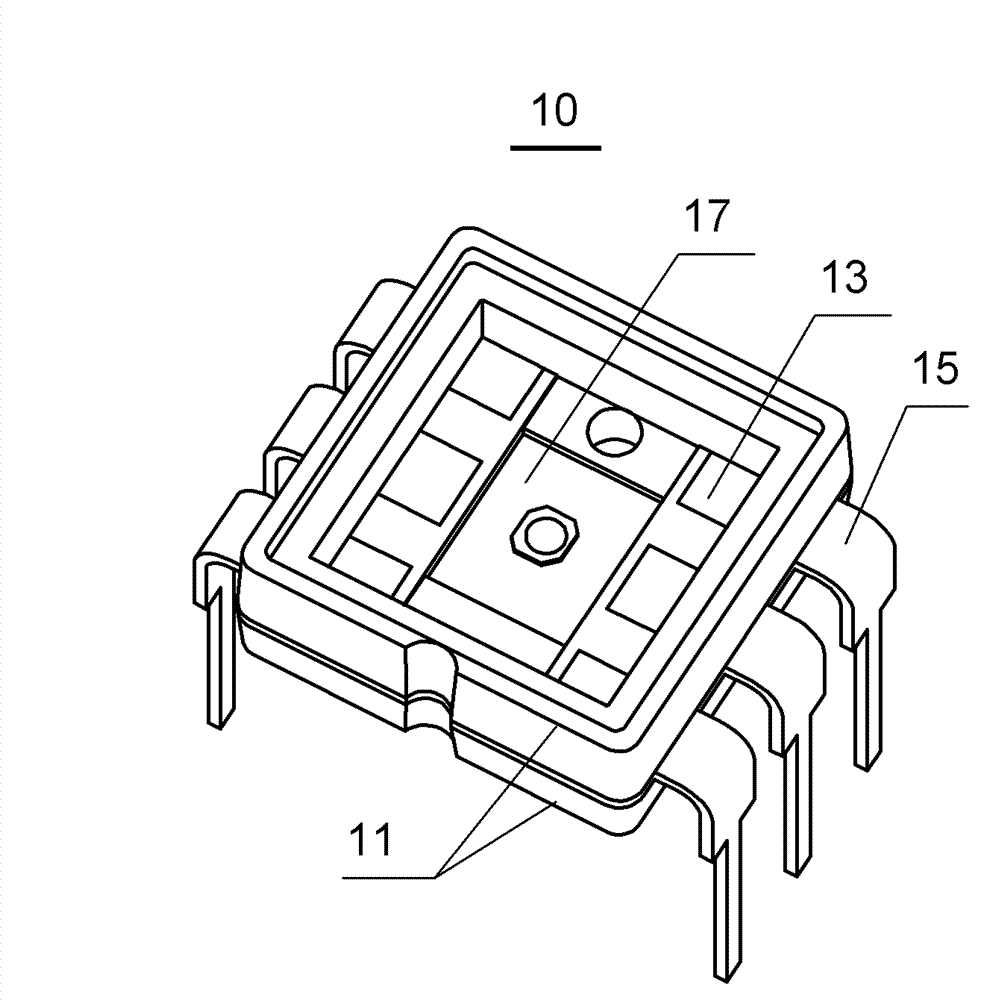

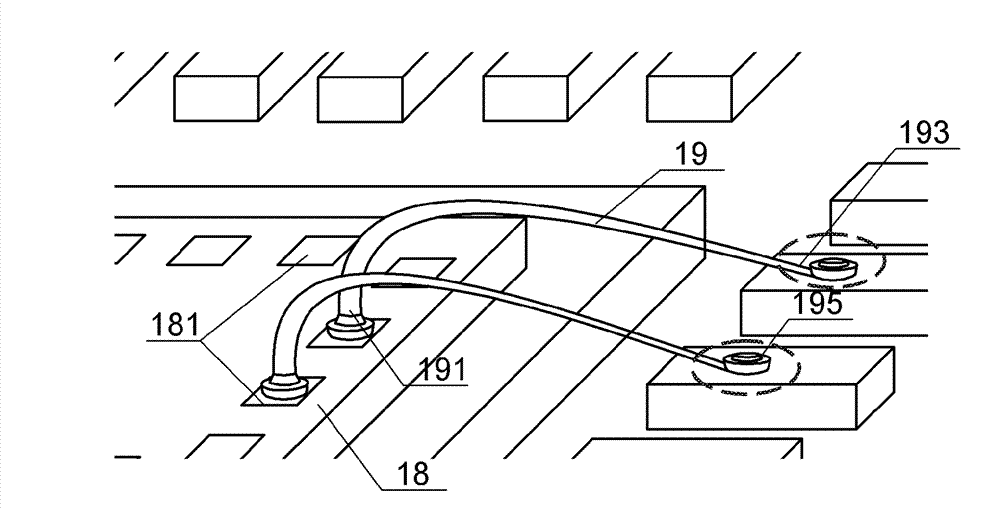

[0022] Presented below are some of the many possible embodiments of the invention, intended to provide a basic understanding of the invention. It is not intended to identify key or critical elements of the invention or to delineate the scope of protection. It is easy to understand that, according to the technical solution of the present invention, those skilled in the art may propose other alternative implementation manners without changing the essence and spirit of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or restriction on the technical solution of the present invention.

[0023] In the present invention, "the first pad" is the connection point between the lead wire and the pad of the chip, and the "second pad" is the connection point between the lead wire and the lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com