Gold alloy bonding wire for semiconductor device and process for producing the same

A connection wire and semiconductor technology, applied in the field of producing the connection wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0166] The connecting wires (1) to (14), (20) and (22) and their production methods (22) to (24) of the present invention will be described below by way of examples.

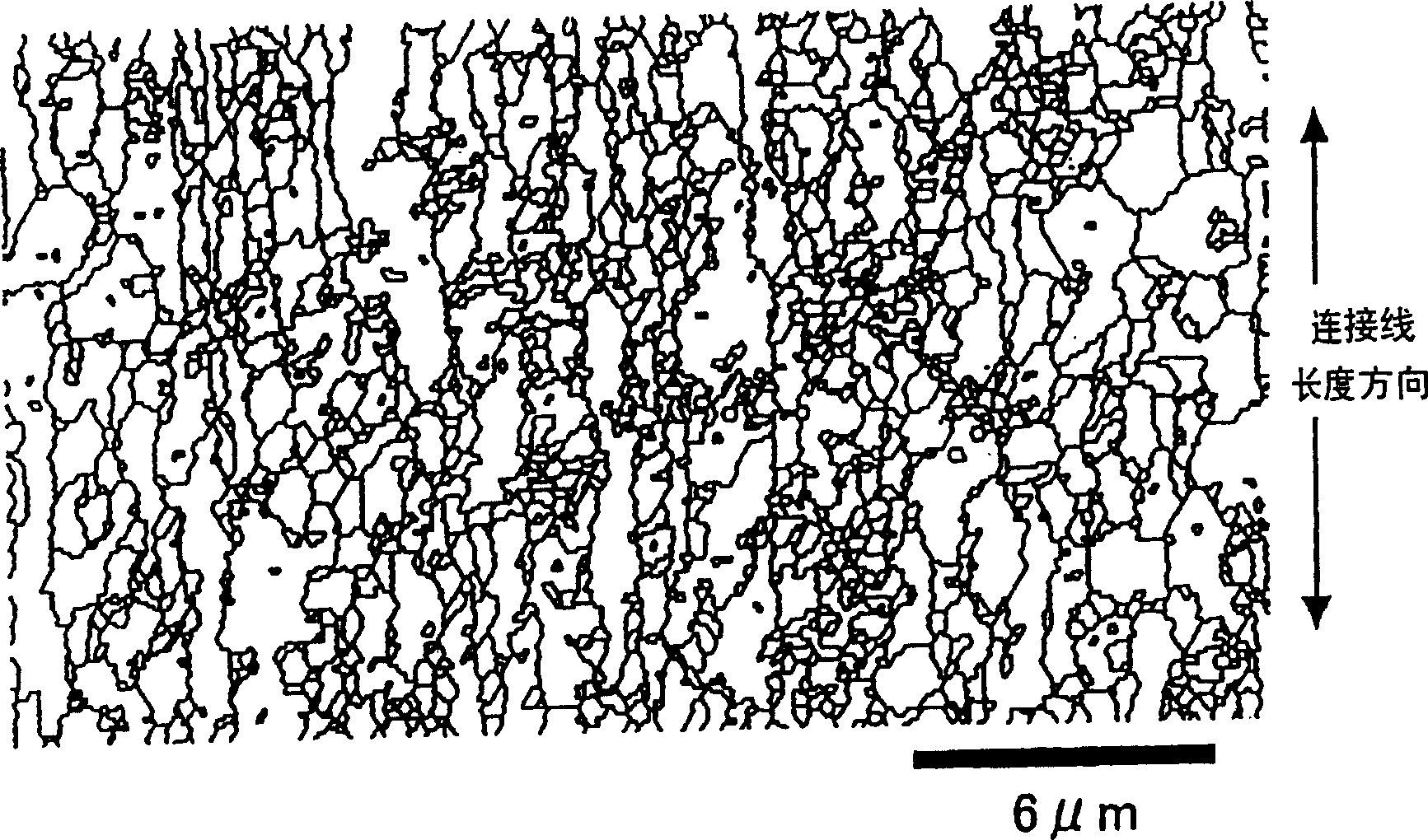

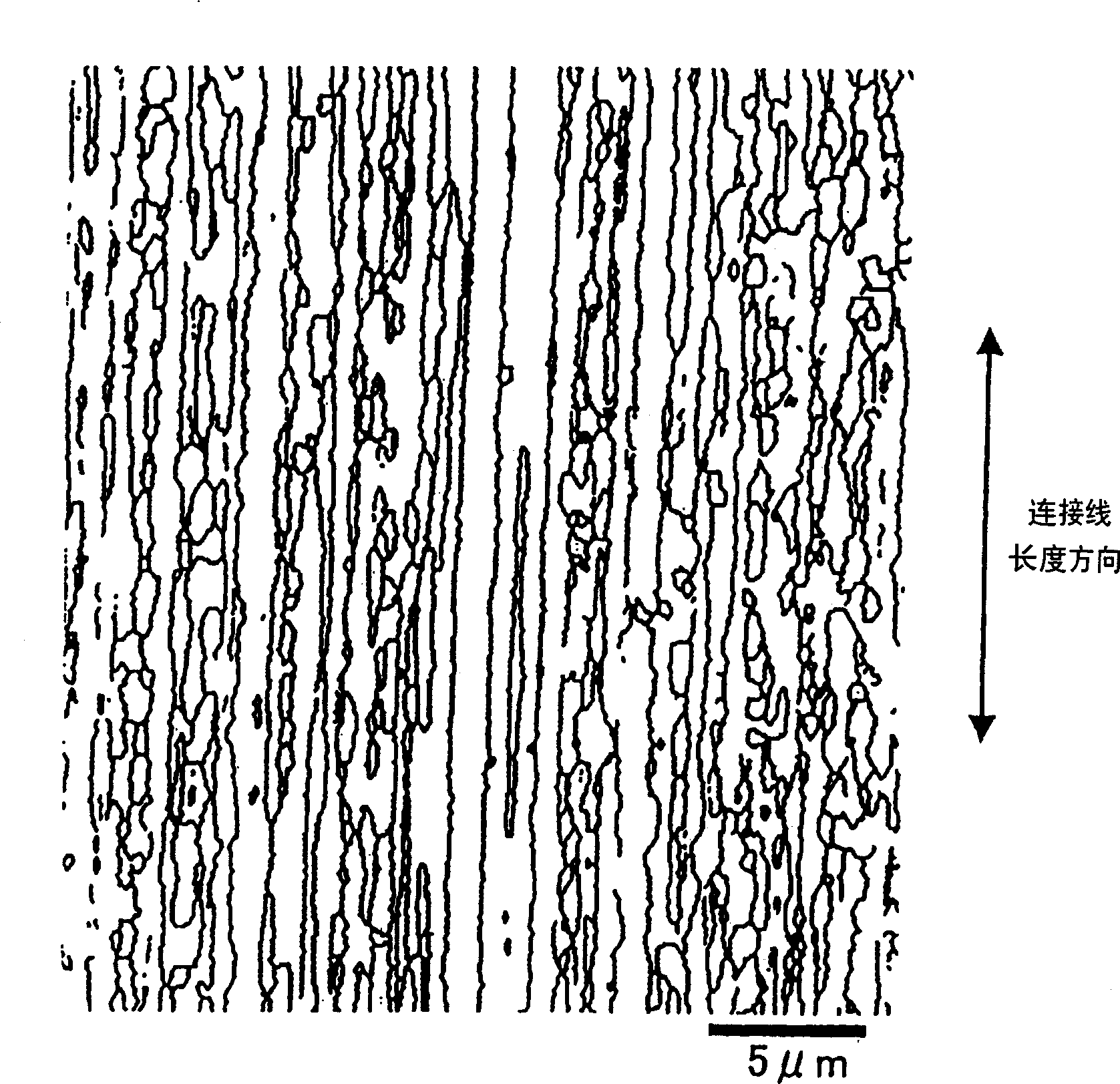

[0167] By using electrolytic gold with a gold purity of not less than about 99.995% by mass and adding necessary elements, melting and casting gold alloys having the chemical compositions shown in Tables 1 to 5 in a melting furnace, rolling the resulting ingot, heating The connecting wire of the present invention is produced by preheating in a furnace, drawing using a drawing die, and continuously scanning and heating the connecting wire through a post-heat treatment. The diameter of the final connecting wire is selected to be basically no greater than 20 microns.

[0168] The production steps will now be specifically described. First, an ingot with a diameter of 6 to 30 mm is prepared. In the rolling step, the cast ingot is rolled using thin rolls at a rate of 30 to 200 m / min until the connecting wire has a d...

Embodiment II

[0212] The connecting wires (15) to (21) of the present invention and their production methods (25) to (27) are described below by way of examples.

[0213] By using electrolytic gold with a gold purity of not less than about 99.995% by mass, melting and casting in a melting furnace containing one or more metals selected from the group consisting of Be, Ca, La, In, and Gd at a total concentration ranging from 0.0005 to 0.02% by mass , Nd, Ce, Dy, Tb, and Y elements; or a gold alloy containing one or more elements selected from Ag, Sn, Pb, Pt, and Cu at a total concentration in the range of 0.003 to 0.1% by mass , and then the obtained ingot is rolled, preheated in a heating furnace, stretched using a drawing die, and the connecting wire is continuously scanned and heated through post-heat treatment, thereby producing the connecting wire. Choose a final connecting wire diameter of 20 µm.

[0214] Tables 8 and 9 list the crystal orientation area ratios of the connecting wires a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com